Eskridge 600 User manual

MODEL 600 DOUBLE PLANETARY

SPINDLE DRIVE SERVICE MANUAL

THIS SERVICE MANUAL IS EFFECTIVE:

S/N:25000 TO CURRENT

DATE:02/01/1996 TO CURRENT

VERSION:SM600LS2-AG

!WARNING: While working on this equipment, use safe lifting procedures,

wear adequate clothing and wear hearing, eye and respiratory protection.

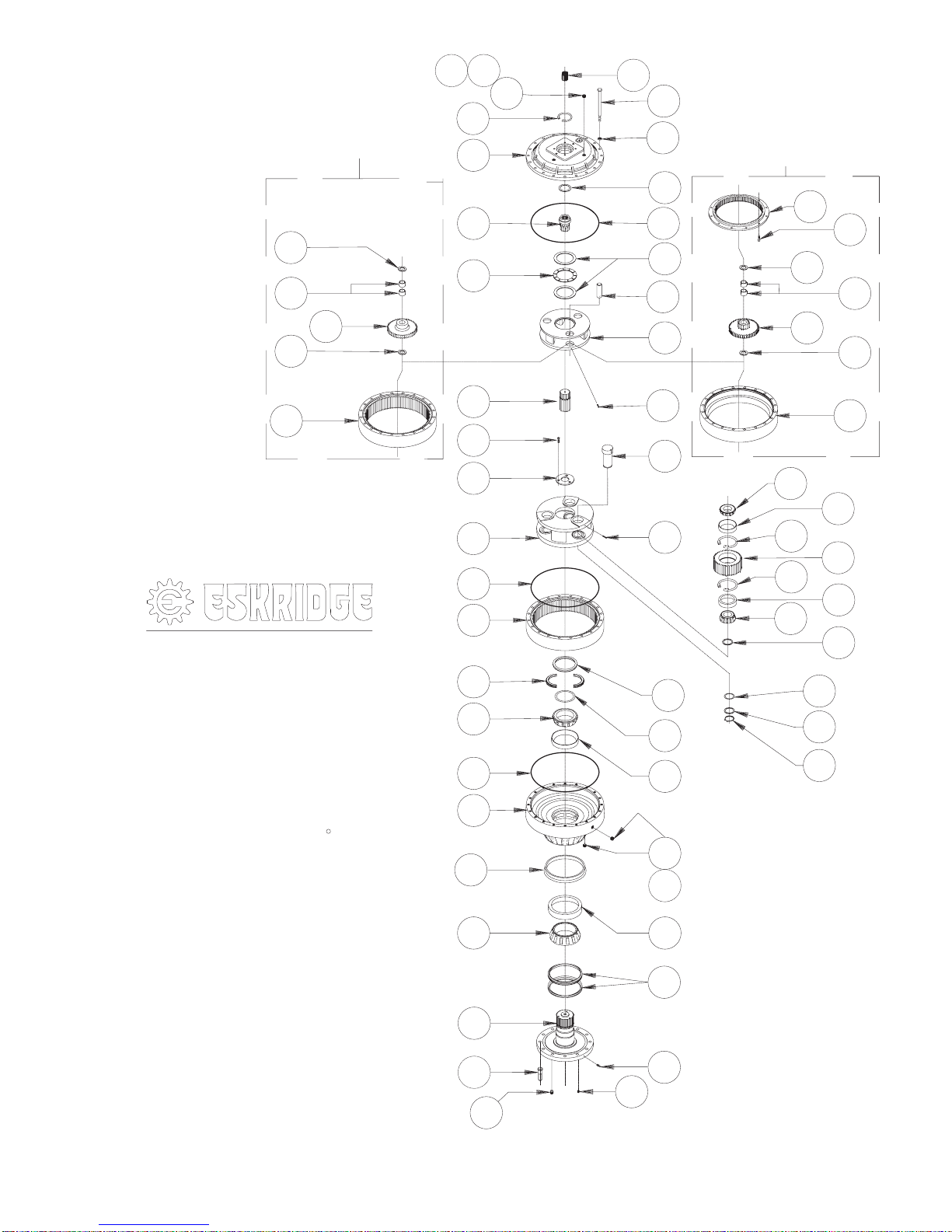

NOTE: Individual customer specifications (mounting

case, output shaft, brake assembly, etc.) may vary from

exploded drawing and standard part numbers shown.

If applicable, refer to customer drawing for details.

Model 600 Spindle Drive service manual, SM600LS2-AG Page 1

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

8

22

12

29

22

SIMPLE

PRIMARY

42

1

33 26

25

15

35

7

33

21

27

28

37

11

37

28

27

39

5

10

18

22

13

29

22

45

2

43

32

17

33

31

30

6

38

14

36

21

20

COMPOUND

PRIMARY

39

46

19

42

9

47

16

48

3

23 24

49

50

51

52

57

54

55

53

56

ECN 2681

R

EQUIPPED WITH PATENTED "LOAD-N-LOCK" SHAFT

RETENTION SYSTEM (U.S. PATENT NO.5746517).

MODEL 600L

SPINDLE

OUTPUT

NOTES:

-J- BEARING PRELOAD DETERMINES

QUANTITY OF SHIMS.

SEAL KIT (P/N 60-016-2101) INCLUDES

3 EA. ITEM (33) O-RINGS,

1 EA. ITEM (49) SEAL, AND

1 EA. ITEM (50) SEAL BOOT.

58

X600LS2-AD DATE 06-13-07

EFFECTIVE S/N 75300 - UP

EFFECTIVE DATE 06/19/07

*UNITS MANUFACTURED PRIOR TO S/N 75300 UTILIZE

(OBSOLETE) P/N 60-004-1301 FOR ITEM 22. USE OF P/N

60-004-1881 WILL MAKE OLDER UNITS IDENTICAL TO

CURRENT UNIT (SHOWN ON THIS DRAWING)

X600LS2-AD,

Page 1 of 2

Effective date 07/01/2007

Effective serial # 74362

Model 600 Spindle Drive service manual, SM600LS2-AG Page 2

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

X600LS2-AD

Page 2 of 2

Effective date 07/01/2007

Effective serial # 74362

1

1

1

3

-

-J-

1

3

-J-

6

6

1

1

3

1

6

6

6

1

6

ITEM QTY. DESCRIPTION

SHIM(S) - SHAFT

SUN GEAR

PLANET SHAFT-SECONDARY

PLANET SHAFT-PRIMARY

SHIM(S) - SECONDARY PLANET

WASHER - SECONDARY PLANET

WASHER - PRIMARY PLANET

ROLL PIN - PRI. 1/4 X 1 3/8

PART NUMBER

3

3

1

3

5

6

11

12

14

15

16

18

19

20

21

22

25

26

27

28

33

35

36

37

39

43

60-004-1311

60-004-1102

60-004-1262

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0230

01-103-0230

01-160-0490

60-004-1472

01-102-0210

01-402-0660

01-153-0150

60-004-1482

01-160-0500

PART NUMBER

1

01-103-0210

01-150-1580H.H.C.S 3/4-10 X 10.5 GRD 820

01-207-0100PIPE PLUG 3/4 NPT MAGNETIC42 6

60-004-1092

60-004-1132

60-004-1082

60-004-1122

60-004-1044

PART NUMBER

3 CLUSTER GEAR13

RING GEAR - SECONDARY7 1

RING GEAR - SIMPLE PRIMARY8 - 60-004-1193

60-004-1213RING GEAR - COMPOUND PRIMARY9 1

60-004-1253RING SPACER - PRIMARY10 1

1

1

23

24

01-102-0190

01-103-0190

629 01-105-0510

130 01-112-0340

231 01-112-0350

45 S.H.C.S 1/2-13 X 1.5 GRD 812 01-150-0570

46 01-166-0350HARDWASHER - 3/420

47 60-004-1352RING - SEC CARRIER RETAINER1

48 01-150-1590FLAT HD. SOC. C.S. 3/8-24 X 1 GR83

01-406-0020

01-207-0030

01-215-0010

49 1

50 1

51 1

52 1

01-406-0010SEAL - METAL FACE

SEAL - RUBBER FACE

PIPE PLUG (1/8 NPT-HOLLOW HEX)

GREASE FITTING-STRAIGHT, 1/8 NPT

54

55

( 1 )

( 1 )

01-216-0030

01-201-0530

98-005-1141

53 1 98-004-1141

60-004-1523

60-004-1523

98-005-1141

01-216-0030

01-201-0530

01-215-0010

01-160-0490

01-153-0150

01-160-0500

01-150-1580

01-207-0100

60-004-1482

01-166-0350

60-004-1352

01-150-1590

01-406-0020

01-207-0030

01-406-0010

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0230

01-103-0230

01-102-0210

01-103-0210

01-102-0190

01-103-0190

01-105-0510

01-112-0340

01-112-0350

60-004-1262

01-402-0660

60-004-1311

60-004-1472

60-004-1193

60-004-1014

24.66:1 38.56:1 89.38:1

RATIOS

60-004-4122L60-004-4122L60-004-4122L

60-004-3034

60-004-3044

60-004-3034

60-004-3044

60-004-3034

60-004-3044

60-004-1064

PLANET GEAR - SECONDARY

PLANET GEAR - PRIMARY

CARRIER - SECONDARY

CARRIER - PRIMARY

60-004-1054

60-004-1014

60-004-1193

60-004-1193

60-004-1044

60-004-1024

60-004-1193

60-004-1472

60-004-1311

60-004-1262

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0190

01-103-0190

01-102-0230

01-103-0230

01-102-0210

01-103-0210

01-105-0510

01-112-0340

01-112-0350

01-402-0660

01-150-1580

01-207-0100

01-153-0150

01-160-0500

01-160-0490

60-004-1482

01-166-0350

60-004-1352

01-150-1590

01-406-0010

01-406-0020

01-207-0030

01-215-0010

01-216-0030

01-201-0530

MODEL 600L

PART NUMBER

60-004-1213

60-004-1253

70.39:1

60-004-4122L

60-004-3034

60-004-3044

60-004-1044

60-004-1024

60-004-1193

60-004-1092

01-150-0570

98-004-1141

01-216-0030

01-201-0530

60-004-1472

60-004-1311

60-004-1262

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0190

01-103-0190

01-102-0230

01-103-0230

01-102-0210

01-103-0210

01-105-0510

01-112-0340

01-112-0350

01-402-0660

01-150-1580

01-207-0100

01-153-0150

01-160-0500

01-160-0490

60-004-1482

01-166-0350

60-004-1352

01-150-1590

01-406-0010

01-406-0020

01-207-0030

01-215-0010

60.29:1

PART NUMBER

60-004-3034

60-004-3044

60-004-1311

60-004-1102

60-004-1472

60-004-4122L

60-004-1054

60-004-1024

60-004-1193

60-004-1193

60-004-1262

60-004-1321

60-004-1291

60-004-1881

01-102-0230

01-103-0230

01-160-0490

01-102-0210

01-402-0660

01-153-0150

60-004-1482

01-160-0500

01-103-0210

01-150-1580

01-207-0100

01-102-0190

01-103-0190

01-105-0510

01-112-0340

01-112-0350

60-004-1272

60-004-1352

01-150-1590

01-406-0020

01-207-0030

01-215-0010

01-406-0010

01-216-0030

01-201-0530

98-005-1141

60-004-1523

01-166-0350

12

139.76:1110.08:1

PART NUMBER

60-004-4122L

60-004-3034

60-004-3044

PART NUMBER

60-004-4122L

60-004-3034

60-004-3044

60-004-1213

60-004-1253

01-150-0570

98-004-1141

01-216-0030

01-201-0530

60-004-1054

60-004-1024

60-004-1193

60-004-1472

60-004-1311

60-004-1262

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0190

01-103-0190

01-102-0230

01-103-0230

01-102-0210

01-103-0210

01-105-0510

01-112-0340

01-112-0350

01-402-0660

01-150-1580

01-207-0100

01-153-0150

01-160-0500

01-160-0490

60-004-1482

01-166-0350

60-004-1352

01-150-1590

01-406-0010

01-406-0020

01-207-0030

01-215-0010

60-004-1213

60-004-1253

60-004-1054

60-004-1024

60-004-1193

60-004-1112

01-150-0570

98-004-1141

01-216-0030

01-201-0530

60-004-1472

60-004-1311

60-004-1262

60-004-1272

60-004-1321

60-004-1291

60-004-1881

01-102-0190

01-103-0190

01-102-0230

01-103-0230

01-102-0210

01-103-0210

01-105-0510

01-112-0340

01-112-0350

01-402-0660

01-150-1580

01-207-0100

01-153-0150

01-160-0500

01-160-0490

60-004-1482

01-166-0350

60-004-1352

01-150-1590

01-406-0010

01-406-0020

01-207-0030

01-215-0010

COVER - SAE `C' (2 AND 4 BOLT)

COVER - SAE `D' (4 BOLT)

60-004-4052L 60-004-4052L 60-004-4052L 60-004-4052L 60-004-4052L 60-004-4052L 60-004-4052L

(OPTIONAL)

(OPTIONAL)

(OPTIONAL)

60-004-1074

60-004-1064

60-004-1074

60-004-1064

60-004-1074

60-004-1064

60-004-1074

60-004-1064

60-004-1074

60-004-1064

60-004-1074

60-004-1064

60-004-1074

60-004-1112 60-004-1112

60-004-1132 60-004-1152

138 01-160-0510

01-160-0510 01-160-0510

60-004-1402

17 1 CODE 8 - (16T; 8/16 SPLINE)

CODE 9 - (13T; 8/16 SPLINE) 60-004-1122

60-004-1402

60-004-1142

60-004-1492

60-004-1142

60-004-1492

60-004-1172

60-004-1452 60-004-1492

60-004-1142

60-004-1452

60-004-1172

32 1 01-112-0060 01-112-0060 01-112-0060

01-160-0510 01-160-0510 01-160-0510 01-160-0510

60-004-1523 60-004-1523 60-004-1523 60-004-1523

01-112-0060 01-112-0060 01-112-0060 01-112-0060

60-004-108260-004-1082 60-004-1102 60-004-1102

60-004-1162 60-004-116260-004-1182 60-004-1182

60-004-1092 60-004-1112

LOCK RING - SHAFT BEARING

SPLIT RING

BEARING CONE - SHAFT OUTER

BEARING CUP - SHAFT OUTER

BEARING CONE - SHAFT INNER

BEARING CUP - SHAFT INNER

CONE - SEC.PLANET

CUP - SEC.PLANET

BRG-PRIMARY PLANET

BRG-PRI. CARR. THRUST

RACE-PRI. CARR. THRUST

O-RING - RING GEAR

RACE- INPUT THRUST

RETAINING RING -SEC. PIN

RETAINING RING-SEC. PLNT.

RETAINING RING - INPUT

BASE

SPINDLE

SHAFT

COVERSPLINE

ADAPT .

56

57 (12 )

( - )

CODE F - FLANGELESS

CODE A - FLANGED

CODE F - FLANGELESS W/ZERK GREASE FITTING

CODE A - FLANGED W/ZERK GREASE FITTING 60-004-3044Z 60-004-3044Z 60-004-3044Z

60-004-3034Z 60-004-3034Z 60-004-3034Z 60-004-3034Z

60-004-3044Z 60-004-3044Z

60-004-3034Z

60-004-3044Z

60-004-3034Z

60-004-3044Z

60-004-3034Z

CODE S2 - 17" DIA.; 12X 1.225 DIA. THRU HOLES

CODE S1 - 17" DIA ; 12X 1 1/8 - 12 UNF-2B

CODE 4;: 14T, 12/24 D.P.

CODE 7: 17T, 12/24 D.P.

ADAPTER ; 3/4" NPT-M, 1/8" NPT - F

(OPTIONAL)

CODE S - SPINDLE STUDS

01-215-0040 01-215-0040 01-215-0040 01-215-0040 01-215-0040 01-215-0040 01-215-0040

COVER - SAE `E' (4 BOLT)

CODE C1 - SPINDLE - CUSTOM

01-164-0050 01-164-0050 01-164-0050 01-164-0050 01-164-0050 01-164-0050 01-164-0050

SPINDLE DRIVE

SIMPLE PRIMARY

COMPOUND PRIMARY

600C_ - CUSTOM MTG - PER CUSTOMER SPECS.

CODE V - AIR VENT; 1/8 NPT

CODE Z - GREASE FIT.-STR., 1/4 NPT

(OPTIONAL)

(OPTIONAL)

60-004-1564 60-004-1564 60-004-1564 60-004-156460-004-1564 60-004-156460-004-1564

-

-

-

-

-

-

---

----

----

INPUT

GEAR .

---

01-207-002058 1 PIPE PLUG (1/4 NPT) 01-207-0020 01-207-0020 01-207-0020

01-207-0020 01-207-0020 01-207-0020

Model 600 Spindle Drive service manual, SM600LS2-AG Page 3

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

LUBRICATION & MAINTENANCE

Operating Position

Single stage

Oil Capacity

Double stage Triple stage

Oil Level

Horizontal Shaft - 17 qts / 16 Liters 19 qts / 18 Liters To horizontal centerline of

gear drive

Vertical Shaft (Pinion Up) - 26 qts / 24 Liters 28 qts / 26 Liters To side port on gear drive

base

Vertical Shaft (Pinion Down) 29 qts / 27 Liters 32 qts / 30 Liters To midway on upper/

primary gear set

Using the chart below, determine an appropriate lubricant viscosity. Use only EP (extreme pressure) or API GL-5 designated lubricants.

Change the lubricant after the first 50 hours of operation and at 500 hour intervals thereafter. The gear drive should be partially disas-

sembled to inspect gears and bearings at 1000 hour intervals.

80W90 conventional

75W90 conventional

85W140 conventional

75W90 synthetic

80W140 synthetic

Note: Ambient temperature is the air temperature measured in the immediate vicinity of the gearbox. A Gearbox exposed to the direct rays of

the sun or other radiant heat sources will operate at higher temperatures and therefore must be given special consideration. The max operating

temp must not be exceeded under any circumstances, regardless of ambient temperature.

Recommended ambient and operating temperatures for conventional and synthetic gear lubricants

-50 -25 0 25 50 75 100 125 150 175 200 225 250 F

-45 -32 -18 -4 10 24 38 52 66 79 93 107 121 C

Min Ambient/operating temp Max Operating temp

Max Ambient temp

ESKRIDGE MODEL 600 OIL CAPACITIES

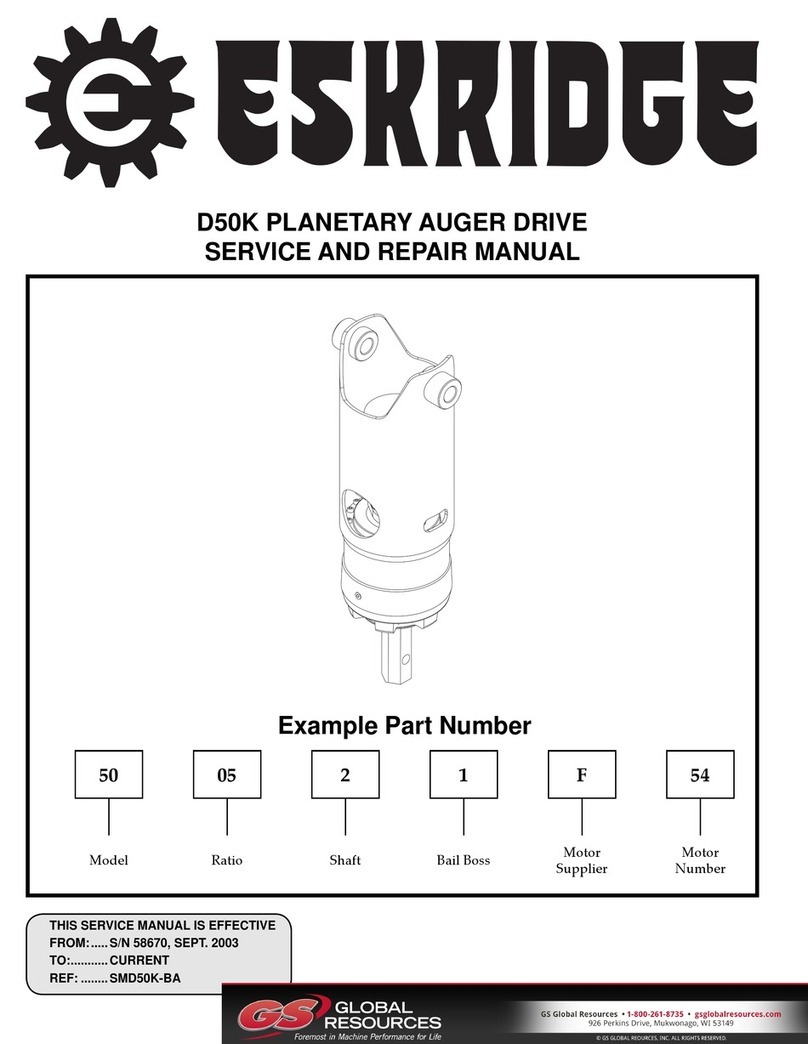

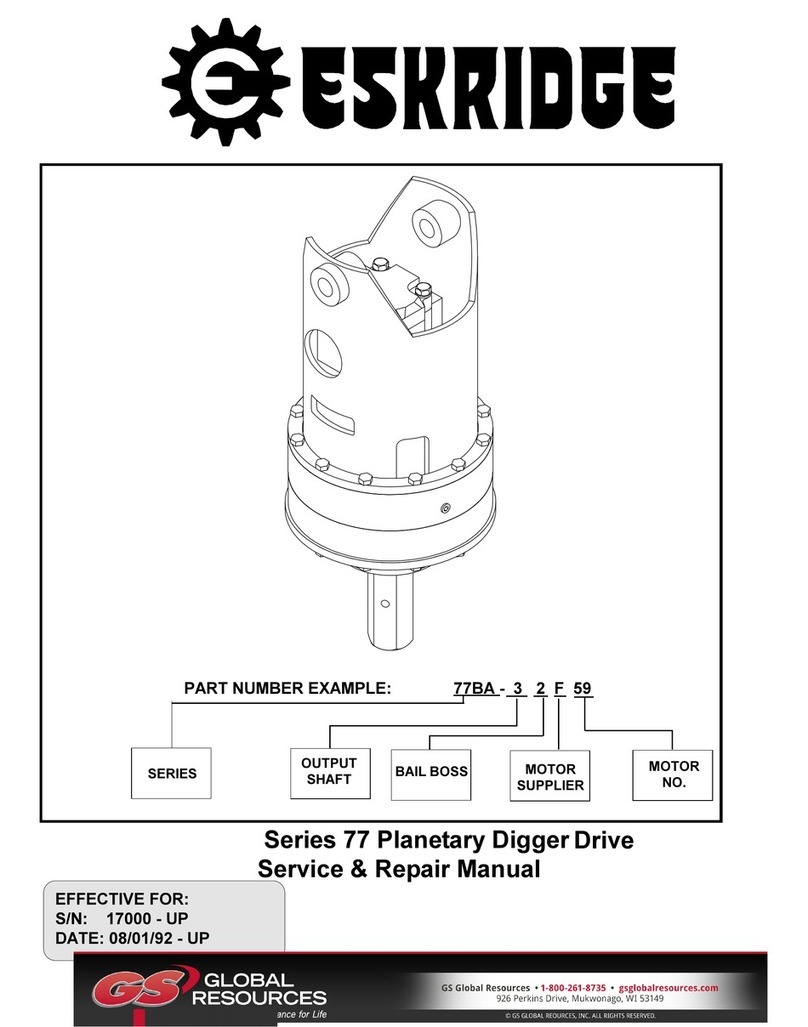

ESKRIDGE PART NUMBER INTERPRETATION

Note: All standard Eskridge Geardrives are issued a descriptive part number which includes information regarding

the Model, means of shaft retention, base style, shaft style, input mounting, input shaft size, overall ratio and vari-

ous available options. For a detailed breakdown of this information, please refer to Eskridge product specification

sheets found at: http://www.eskridgeinc.com/geardrives/gearprodspecs.html

Model 600 Spindle Drive service manual, SM600LS2-AG Page 4

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

Unit Teardown

1) Scribe a diagonal line across the outside of the unit from the

cover (2) to the base (1) before disassembly to aid in the proper

positioning of pieces during reassembly.

2) Remove drain plugs (42) and drain oil from unit. The oil will

drain out more quickly and completely if warm.

3) Remove the 20 3/4-10 capscrews (43) and

lockwashers (46) retaining the cover (2).

4) Remove the cover (2), thrust washer(s)/bearing(s) (30,31,32),

and input gear (17). Inspect o-ring (33); discard if damaged or

deformed.

5) Lift the planet carrier assembly out of the unit .

6) Remove ring gear(s)/spacer (8/10pri, 7sec) and subsequent

carrier assemblies. Inspect gear to gear and gear to base O-

ring(s) (33); as before, discard if damaged or deformed.

7) The unit is now disassembled into groups of parts.

The area(s) requiring service should be identified by thorough

inspection of the individual components after they have been

cleaned and dried.

Carrier Assembly Teardown

Rotate planet gears (12/13 pri;11 sec) to check for abnormal

noise or roughness in bearings. If further inspection or re-

placement is required, proceed as follows.

1) Primary: Drive roll pins (39) completely into the planet shafts

(19). Secondary: Remove planet shaft retaining rings (36),

spacers (21) and preload shims (20)

2) Slide planet shafts (19 pri/18 sec) out of carrier.

3) Remove planet gears (12/13 pri; 11 sec), washers (22 pri/21

sec) and bearings (29 pri;27/28 sec) from carrier (6).

4) Inspect the planet gear (12/13 pri; 11 sec), bearing bore and

planet shaft (19 pri/18 sec) and bearings (29 pri; 27/28 sec).

Check for spalling, bruising or other damage and replace com-

ponents as necessary.

5) Primary only: Remove roll pins (39) from planet shafts (19) us-

ing a 1/4 inch pin punch.

Carrier Reassembly

1) Primary: Planet shafts (19) should be installed with cham-

fered end of 1/4 inch roll pin hole towards outside diameter of

carrier (6); this will ease alignment of holes while inserting roll

pins (39). Secondary: Planet shafts must be installed aligning

the slot in the large end of the shaft with the roll pin protruding

into the shaft bore.

2) Primary: Drive roll pin (39) into the carrier hole and into planet

shaft to retain parts. Secondary: Install the first planet washer

(21) to the small end of the planet shaft, the appropriate num-

ber of preload shims (20) and then the second planet washer

(21) and retaining ring (36) Repeat for remaining planet gears.

Base Subassembly Teardown

1) Remove the output shaft lock ring (14) using a heel bar or pull-

er; if using a heel bar, be sure not to pry against the cage of the

inner spindle bearing (25). Remove the split ring segments (35)

and shims (15).

Caution: Since the shaft is no longer positively retained,

care should be taken to avoid injury. Care should also be

taken not to damage it while pressing through base.

2) Place base (1) exterior side down, on a plate or table.

Press output shaft out bottom of base by applying a load

to internal end of spindle (3) until it passes through inner

spindle bearing cone (25).

3) A gear puller may be used to remove the outer bearing

cone (23) from the spindle (3). If reusing old bearing cone,

do not pull on or damage roller cage.

Note: Press bearing cone onto output spindle by pressing

on inner race only. DO NOT press on roller cage, as it may

damage the bearing assembly.

4) Inspect inner and outer bearing cups (26 & 24). If cups are

damaged they must be replaced, drive them out using a

brass drift and utilizing the bearing knock-out notches in

the base (1)

Base Reassembly

1) Clean all foreign material from magnetic oil plugs located

In base (1).

2) Place base exterior side up on work table.

3) Apply a layer of lithium or general purpose bearing grease

to the roller contact surface of outer bearing cup (24).

4) Press outer bearing cone (23) onto the spindle (3) until it

seats against the shoulder.

5) Wipe the face of each half of the metal face seal (49) using

a lint-free wipe. No particles of any kind are permissible on

the sealing surfaces. (Even a hair is sufficient to hold the

seal surfaces apart and cause a leak.) Apply a thin film

of oil on the entire seal face of one or both seals using a

clean finger or lint-free applicator. Oil must not contact any

surfaces other than the sealing faces. (See Pages 6-8 for

seal inspection and service procedures.)

6) Place the spindle (3) with the outer bearing cone into the

base.

7) Flip shaft/base assembly, and apply lithium or

general purpose bearing grease to roller con-

tact surface of the inner cup (26), then press

inner bearing cone (25) onto shaft until it seats against

inner bearing cup.

8) Proper spindle bearing preload will result in

a rolling torque which varies between 200

to 300 in-lb. The bearing preload should be

tailored to your application; a low-speed application may

require a high pre-load, while high-speed applications

usually benefit from low pre-load. Adding shims (15) will

increase the pre-load on the bearing set. Determine your

pre-load requirement and install shims to obtain this pre-

load.

9) Install the Load-N-Lock™ halves (35) over the shims and

into the corresponding spindle groove. Then, install the

lock ring (14) over the Load-n-Lock halves (35B).

All subassembly service or repairs should be com-

plete at this time. Continue to Unit Assembly to com-

Model 600 Spindle Drive service manual, SM600LS2-AG Page 5

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

plete buildup of unit.

Unit Reassembly

1) Install the secondary carrier assembly onto the output shaft;

aligning the splines of the carrier (5) with the output spindle

(3) splines and centering the three threaded holes in the ouput

spindle between the planet gears. Once aligned slide the car-

rier onto the spindle.

2) Install carrier retaining plate (47) & secure using provided 3/8-

24 Flathead capscrews (48). If using thread locking compound

to assist in screw retention, apply only a small amount to inter-

nal threads. Use of excess thread lock may cause screws to be

irremovable once compound has cured.

3) Lubricate o-ring (33) and install on the ring gear (7) pilot.

Caution: Hold ring gear by outside diameter or use lifting device

to prevent injury.

4) Align the gear teeth of secondary ring gear (7) with

the gear teeth of the planet gears (11) and place

ring gear on base aligning mounting holes of ring

gear with holes in base. Use the scribed line made

during disassembly for reference. With carrier in place, install

secondary sun gear.

Simple Planetary Primary, for compound primary skip to step 5C

5S) Install primary ring gear (with lubricated o-

ring in place), align mounting holes of ring gear

with holes in base using the scribed line made

during disassembly for reference. Install the primary carrier as-

sembly aligning gear teeth of ring gear with those of the planet

gears and place on base. Install the input gear (17).

Compound primary (76:1 ratio and up):

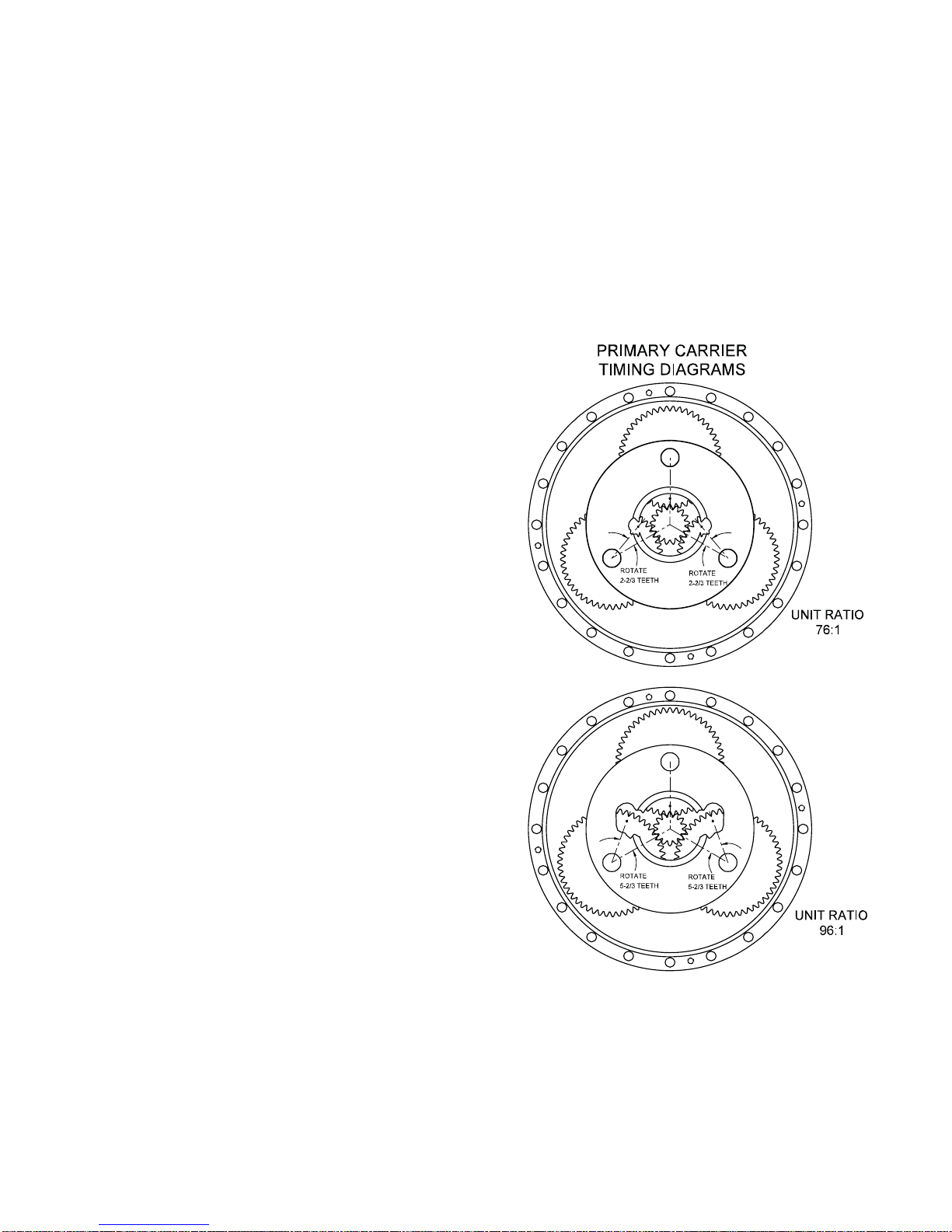

5C) a) The planet gears will now need to be timed. Refer to the

diagram appropriate for your unit’s gear ratio (at right). The

planet gears each have a timing mark, usually a round punch

mark stamped into the surface which is shown as a circle on

the diagram.

b) As seen from above, start with the top planet gear with

it’s timing mark pointing straight down. Next, rotate the

lower left planet gear counterclockwise as indicated in the

timing diagram. Then rotate the lower right planet gear

clockwise as indicated.

c) Set the input gear (17) and the input thrust race (32) into

the center of the primary planet carrier assembly.

d) If compound primary ring gear (9) was not removed dur-

ing disassembly, then skip to step 7. Otherwise, bolt to the

inside of the cover (2) with twelve bolts (45). Use a remov-

able thread locking compound on the threads of the bolts

(45). Tighten to 110 ft.-lbs. dry or 80 ft.-lbs. lubricated.

e) Install primary ring spacer (10) w/ O-ring (33) in place.

6) Install the input to cover thrust washer (32) and carrier to cover

thrust washers (31, 2ea; 30, 1ea) Refer to exploded view for

details.

7) Noting the scribed line made during disassembly, (with lubri-

cated o-ring in place) align and install the cover (2).

8) Install and torque the 20 3/4-10 hex-head cap-

screws (43) with lockwashers (46). The torque for the

cap-screws: 380 ft-lb dry, 280 ft-lb if the fasteners are lu-

bricated.

9) Using a splined shaft to drive the input gear (17) ensure

that the unit spins freely.

10) Fill the unit to the proper level, as specified, with recom-

mended gear oil (refer to chart, page 3) after unit is sealed

with brake and/or motor.

The gearbox is now ready to use.The gear drive is now

ready to use.

Model 600 Spindle Drive service manual, SM600LS2-AG Page 6

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

Seal Assembly for

Duo-Cone Seals

Installation Instructions courtesy Caterpillar, Inc.

Seal Assembly Contents:

(2) Metal Seal Rings

(2) Rubber Toric Rings

Terminology:

1 - Seal Ring 6 - Seal Ring Face

2 - Rubber Toric 7 - Seal Ring Ramp

3 - Housing Retainer Lip 8 - Seal Ring Retaining Lip

4 - Housing Ramp 9 - Installation Tool (Optional)

5 - Seal Ring Housing (Base/Shaft)

4

3

7

5

2

8

48

2

6

7

2

1

Model 600 Spindle Drive service manual, SM600LS2-AG Page 7

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

2

9

1

Housing Preparation

The housing components (3, 4) that contact the rubber toric rings

must be free from foreign material (oil, grease, dirt, metal chips

dust or lint particles, etc.) before installing the seal. This should be

done with a lint-free wipe and a non-petroleum based solvent.

1) Remove any foreign material from the rubber torics (2), ramps

(7) and lips (8) of both seal rings. This should also be done

with a lint-free wipe and non-petroleum based solvent.

2) Dry with a clean wipe.

3) Place the rubber toric (2) on the metal seal ring (6) at the

bottomofthesealringramp(7)andagainsttheretaininglip(8)

(see illustration on previous page). Make sure

the rubber toric is straight on the seal ring and

not twisted. Be careful not to nick or cut the

torics during this assembly, as this can cause leaks.

4) Put the installation tool (9) onto the metal seal ring (6) and

rubber toric (2). Lightly dampen the lower half of the rubber

toric with the appropriate assembly lubricant. Techniques to

dampen the toric include wiping with a lint-free towel, lubricat-

ing using a clean foam brush, or dipping into a container lined

with towels saturated in the assembly lubricant (as shown).

Approved Assembly Lubricants*

Isopropyl Alcohol

Houghto-Grind 60 CT

Quaker® Solvo Clean 68-RAH

*Do not use Stanosol or any other liquid that leaves an oil film

or does not evaporate quickly.

Inspection of Worn Seals

Seals wear in an axial, rather than radial, direction (as depicted

in Figure Y). The total thickness of the flange is usable wear ma-

terial on the formed seal rings and good seal performance can

generally be expected until the flange is completely worn away.

Remaining service life can be estimated by measuring the ring

flange thickness, and using the chart below. Minimum flange

thickness required for reusability is 0.05” (1.27 mm).

Formed Seal Wear Chart

Flange Thickness

in (mm) Seal Wear

Percent Worn

0.075 (1.91) 0

0.062 (1.59) 25

0.050 (1.27) 50

0.038 (0.95) 75

0.025 (0.64) 100

0.012 (0.32) 125

0.000 (0.00) 150

The measured parameter used to check the remaining seal life is

flange thickness, at the outer edge (once any wear lip is removed).

The measurement must be made carefully because the shoulder

is only 0.06” (1.52 mm) from the edge of the flange.

Estimates of expected seal life are difficult, because there

are many differences in machine applications, job conditions,

maintenance and other factors that affect seal service life.

Mishandling Of Seals

Mishandling of seals during assembly can cause immediate leaks

or premature failure. Failure can occur due to cutting or tearing of

the elastomeric load ring, breakage of the sealing ring, contamina-

tion of the sealing face with dirt or lint, etc. When assembling metal

face seals, please carefully observe assembly instructions.

F

Figure Y

Development of a Wear

Lip in This Area Makes it

Necessary to Install a

New Seal

Measure Flange

Thickness Here

Model 600 Spindle Drive service manual, SM600LS2-AG Page 8

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

Dim A

Installation Process

1) With the lower half of the rubber toric still wet, use the

installation tool (9) to position the seal ring (1) and the rub-

ber toric (2) squarely against the housing retainer lip (3)

(as shown).

2) Forsmaller diameter seals, usesuddenand even pressure

topushtherubbertoricundertheretaininglipofthehousing.

Forlargerdiameterseals,whichwillnotpressinwithsudden

andevenpressure,itisacceptabletoworkthetoricpastthe

retaining lip by starting on one side and tapping the oppo-

site side of the installation tool with a rubber mallet until it is

engaged past the retaining lip of the housing.

3) Check the assembled height (A) (see below) in

at least four places, 90º apart, using either a cali-

per, tool makers’ ruler or any other calibrated mea-

suring device. The difference in height around the

ring must not be more than 0.04” (1 mm). If small

adjustments are necessary, do not push or pull directly on

the seal ring. Use the installation tool (9) to push down

and your fingers to pull up uniformly on the rubber toric

and seal ring.

NOTE: The rubber toric can twist if it is not completely wet

during installation or if there are burrs or fins on the retain-

ing lip of the housing. Twists, misalignments and bulges of

the toric will result in seal failure. If correct installation is

not apparent, remove seal from the housing and repeat the

process.

The rubber toric must never slip on the ramps of either the

sealringorthehousing.Topreventslippage,allowadequate

evaporation time for the lubricant before proceeding with

further assembly. Once correctly in place, the rubber toric

must roll on the ramp only.

4) Wipe each seal ring face (6) using a lint-free wipe. No par-

ticles of any kind are permissible on the sealing surfaces.

(Even a hair is sufficient to hold the seal surfaces apart

and cause a leak.)

5) Apply a thin film of oil on the entire seal face (6) of one or

both seals using a clean finger or lint-free applicator. Oil

must not contact surfaces other than the sealing faces.

NOTE: Mishandling of seals during assembly can cause

immediate leaks or premature failure. Failure can occur due

to curing or tearing of the elastromeric load ring, breakage

of the sealing ring, contamination of the sealing face with

dirt or lint, etc. When assembling metal face seals, please

carefully observe assembly instructions.

Final Assembly

While completing the final assembly of the unit, make sure

that both housings are in correct alignment and are concentric.

Slowly bring the two housings together. High impact can scratch

or break the seal components.

If the rubber toric slips at any location, it will twist, causing the

seal rings to cock. Any wobbling motion of the seal is an indica-

tion of cocked seals and can cause dirt to enter by pumping mud

past the torics.

Table of contents

Other Eskridge DC Drive manuals

Popular DC Drive manuals by other brands

Aerotech

Aerotech XC4 Hardware manual

Danfoss

Danfoss VLT PTC Thermistor Card MCB 112 operating guide

KB Electronics

KB Electronics Penta Power KBRG-255 Installation and operating instructions

WEG

WEG DeviceNet CFW500 Quick setup guide

Twin Disc

Twin Disc AM080 Operator's manual

RIB

RIB KING FAST Simplified instructions