Installation — Drives Without Shaft Fans

CAUTION: Refer to direction of rotation arrow on backstop.

Before installation make sure that the direction of rotation is

correct. To change the backstop over running direction, rotate

the backstop 180° end for end on shaft. For some

backstop/drive combinations, it will be necessary to have the

torque arm mounted on the outside of the backstop due to

interference with the anchor bracket. Follow specific instructions

found in Manual 568-810 shipped with the backstop. Check

backstop size on nameplate and make certain it is correct.

1. If installing external backstop on drive not previously

supplied with a backstop, a special - long high speed shaft

is required. Refer to drive assembly/disassembly

instructions for installation of high speed shaft.

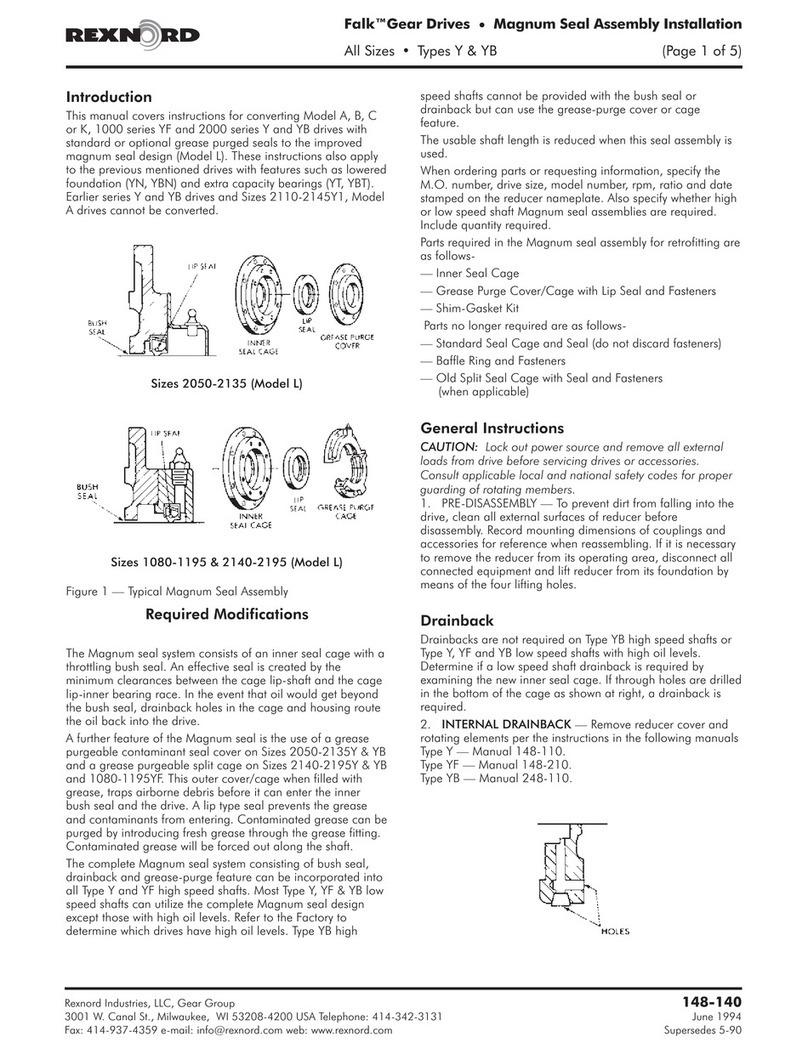

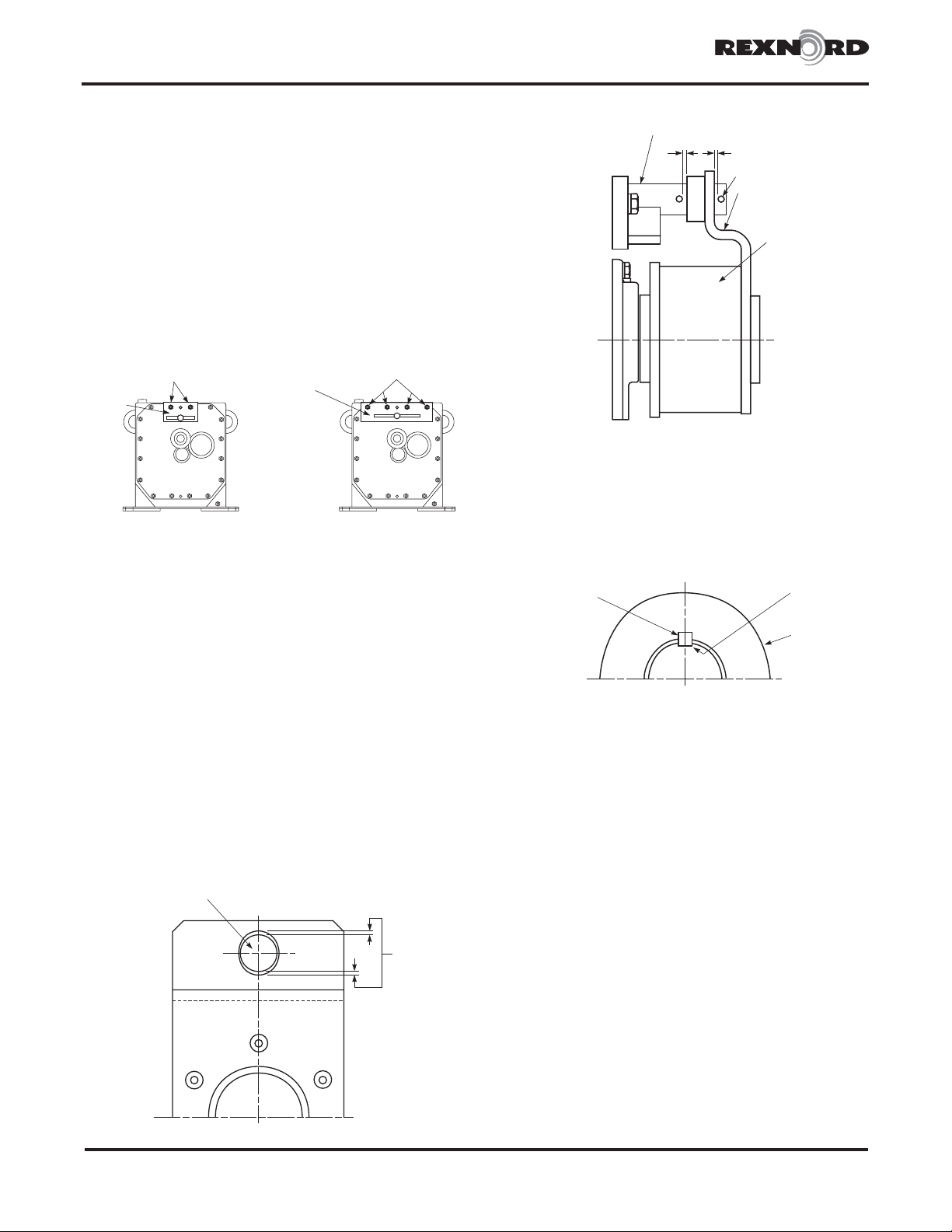

2. Install anchor bracket if necessary by removing the

appropriate high speed head fasteners to allow anchor

bracket to be centered above the high speed shaft (see

Figures1&2).Mount anchor bracket and insert the longer

fasteners and lock washers that were supplied with the

backstop kit. Tighten fasteners to values shown in Table 1.

3. Clean the backstop bore and the shaft on which the

backstop will be mounted. Make sure the short key is clean

and completely seated in the shaft.

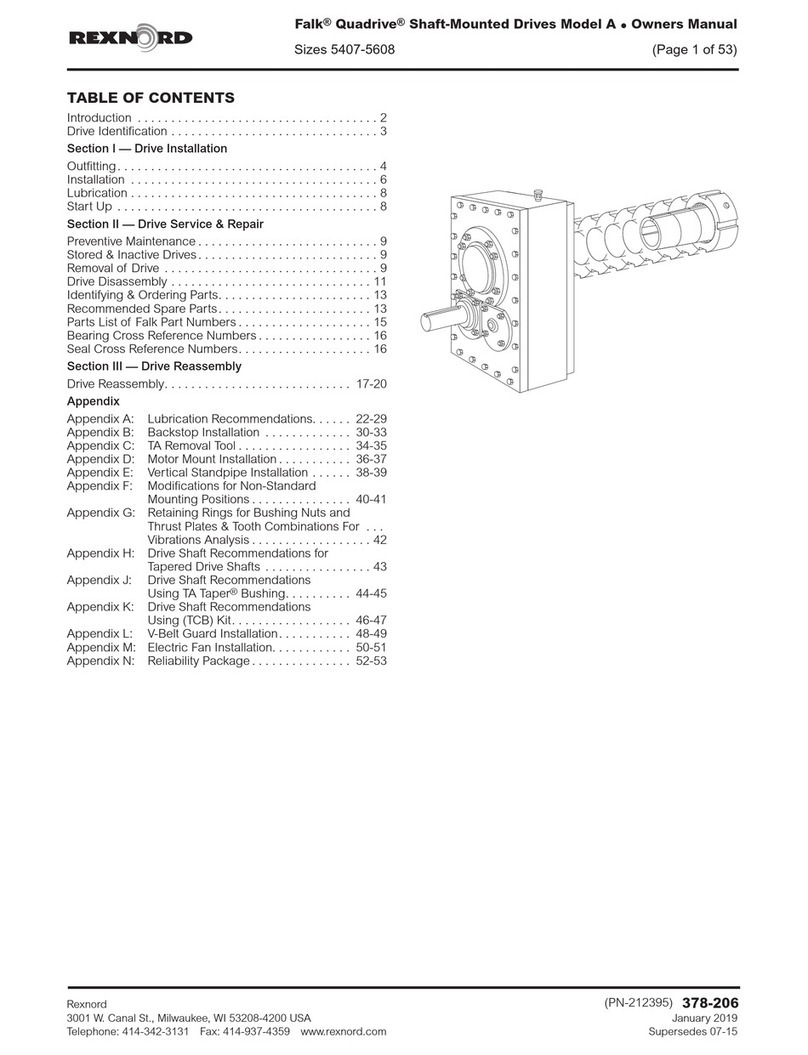

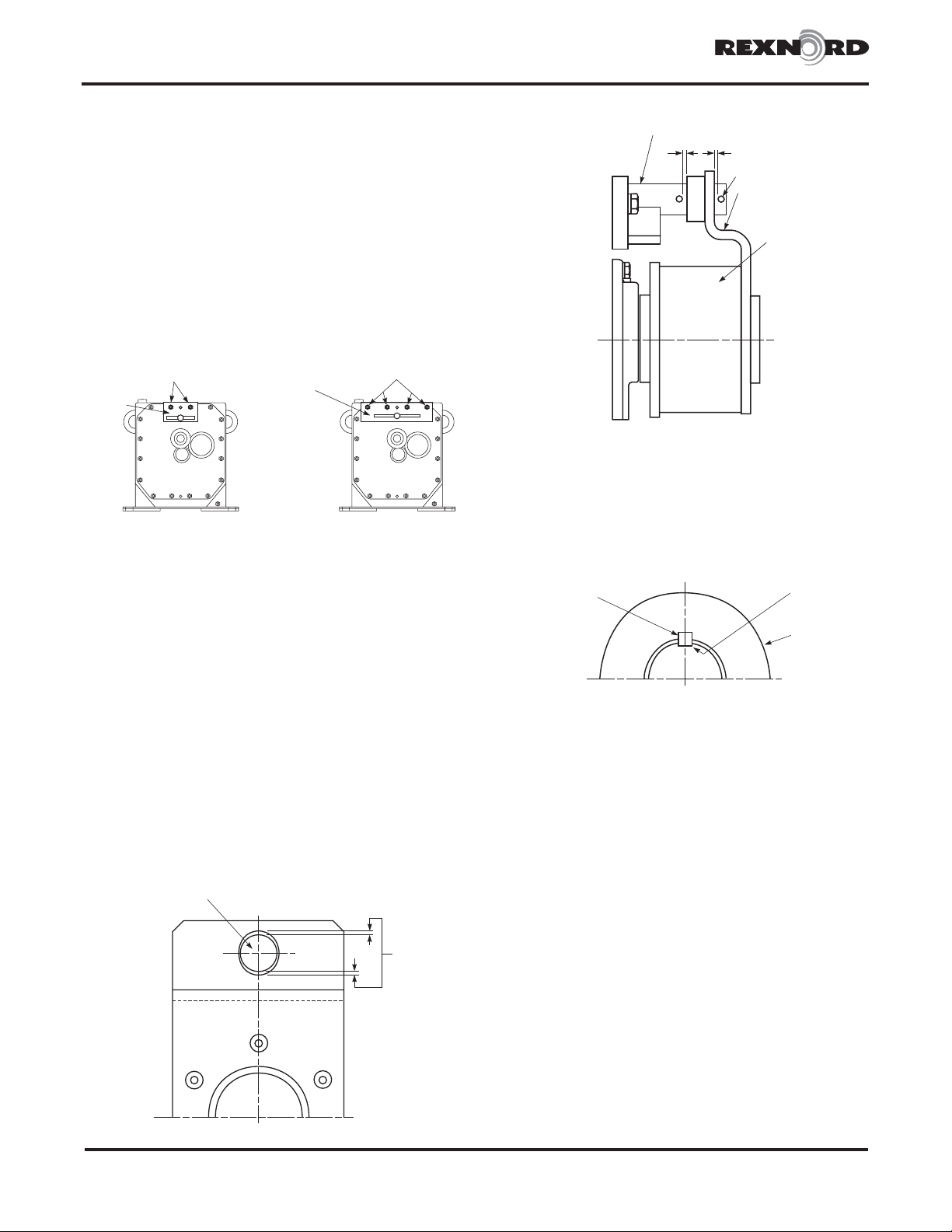

4. Align the hub keyway with the shaft key and slide backstop

onto shaft and anchor bracket torque arm pin. The

backstop must slip onto shaft. DO NOT hammer backstop

onto shaft. There should be clearance between the

backstop anchor lug and torque arm pin as shown in

Figure 3. Position the backstop axially to allow clearance

for the extreme float limits of the shaft, Figure 4.

5. Install spring pins to hold backstop onto torque arm pin.

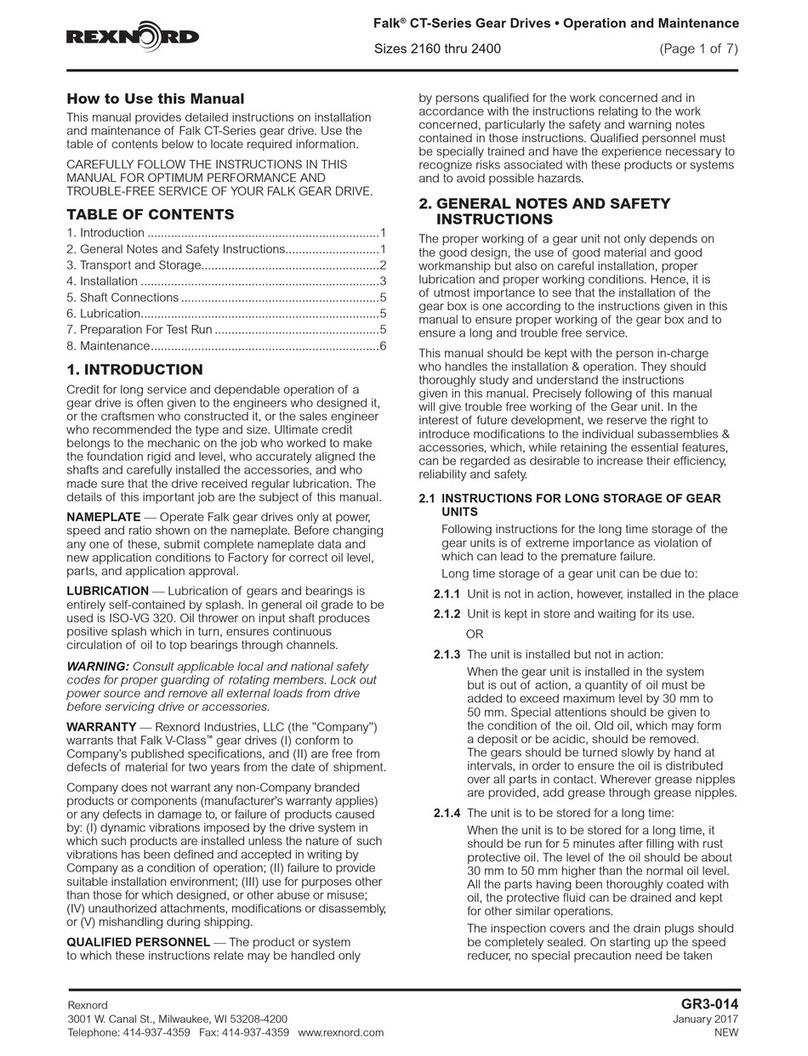

6. Check free, or overrunning, and locked rotation of

backstop. If satisfactory, stake key (inch series) to through

hardened shaft, Figure 5, or use an anaerobic thread

sealant such as Loctite 242 if shaft is carburized.

Installation — Drives with Shaft Fans

CAUTION: Refer to direction of rotation arrow on backstop.

Before installation make sure that the direction of rotation is

correct. To change the backstop over running direction, rotate

the backstop 180° end for end on shaft. For some

backstop/drive combinations, it will be necessary to have the

torque arm mounted on the outside of the backstop due to

interference with the anchor bracket. Follow specific instructions

found in Manual 568-810 shipped with the backstop. Check

backstop size on nameplate and make certain it is correct.

1. If installing external backstop on drive not previously

supplied with a backstop, a special - long high speed shaft

is required. Refer to drive assembly/disassembly

instructions for installation of high speed shaft.

2. Install anchor bracket if necessary by removing the

appropriate high speed head fasteners as shown in Figures

6 & 7. Mount anchor bracket and insert the longer

fasteners and lock washers that were supplied with the

backstop kit. Tighten fasteners to torque values shown in

Table 2.

WARNING:To meet OSHA requirements, double

reduction drives require a shaft sleeve between the fan

guard and backstop (see Figure 8).

Rexnord Industries, LLC, Gear Group318-814

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131December 2006

External Backstop Installation •Falk™ UltraMax®Gear Drives

(Page 2 of 3) Type F •Sizes 2100 thru 2130

TORQUE

ARM

PIN

CLEARANCE

FIGURE 3

4-FASTENERS

ANCHOR

BRACKET

ANCHOR

BRACKET

2-FASTENERS

CLEARANCE

ANCHOR BRACKET

SPRING PINS

TORQUE ARM

PRT

BACKSTOP

FIGURE 4

FIGURE 1

Sizes 2100- 2130

with #20 PRT Backstops

without shaft fans

FIGURE 2

Sizes 2100- 2130 with

#60 or 65 PRT Backstops

without shaft fans

STAKE

KEY

BACKSTOP

KEY

FIGURE 5