Eskridge 50L User manual

MODEL 50L PLANETARY GEAR

DRIVE SERVICE MANUAL

THIS SERVICE MANUAL IS EFFECTIVE:

S

/N: 38489# TO CURRENT

DATE: 12-16-98 TO CURRENT

VERSION:SM50LD2-AB

!WARNING: While working on this equipment, use safe lifting procedures,

wear adequate clothing and wear hearing, eye and respiratory protection.

NOTE: Individual customer specifications (mounting

case, output shaft, brake assembly, etc.) may vary from

exploded drawing and standard part numbers shown.

If applicable, refer to customer drawing for details.

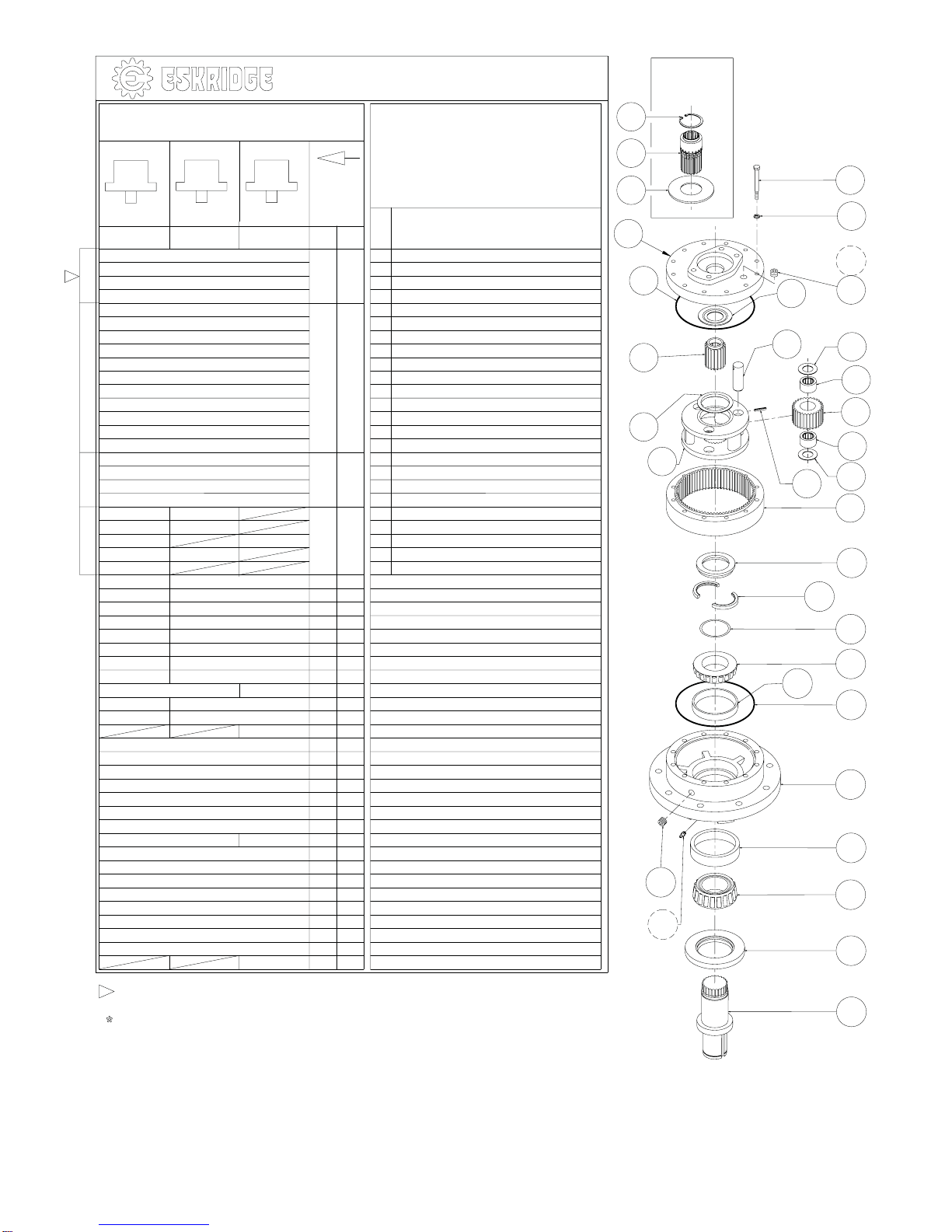

Model 50 service manual, SM50LD2-AB Page 2

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

MATCHING

HALVES

2

NOTES:

BEARING PRELOAD DETERMINES QUANTITY OF SHIMS.

30A

30B

(OPTIONAL)

35C

35B

35A

20C

20D

16B

1

20B

20A

16A

2

S2 - SHAFT REQUIRES STUDS (QTY 5) PART NO. 01-164-0040.

FOR GREASE ZERK OPTION, ADD 'Z' SUFFIX TO BASE P/N

(OPTIONAL)

30C

25A

25B

30A

14B

4

5C

5B

5D

5E

5D

5E

14A

5A

5F

12

16B

E.C.N. # 2791

X50LD1-AF 01/15/08

WITH CODE 4

INPUT SPLINE

ONLY

4

35D

14C

ITEMQTY.

85-004-1051

-

DESCRIPTION

RING GEAR

CARRIER

PLANET GEAR

SHIM(S)

SUN GEAR

PLANET SHAFT

CARRIER THRUST WASHER

PLANET THRUST WASHER

BEARING CONE (OUTER)

BEARING CONE (INNER)

BEARING CUP (OUTER)

BEARING CUP (INNER)

PLANET BEARING

INPUT THRUST WASHER

HEX CAPSCREW

ROLL PIN

LOCKWASHER

PIPE PLUG-MAGNETIC

O-RING

SEAL-SHAFT

1

1

3

*

-

3

1

6

1

1

1

1

1

1

6

1

12

3

12

2

2

1

12

3

5A

5B

35A

6

5C

14A

5E

20A

20C

20B

20D

35C

35B

5D

14B

25A

5F

25B

30A

16B

16A

30B

50-004-1033

01-102-0140

01-102-0150

01-103-0130

01-103-0140

01-150-1540

01-166-0340

01-207-0070

01-402-0560

01-405-0530

3/16 X 7/8

7/16 MED

3/8 NPT-SOC HD

11

50-004-3003

50-004-3013

50-004-3193

50-004-1173

50-004-1183

50-004-1233

50-004-1333

12

14

85-004-1382 85-004-1392

85-004-1272 85-004-1262

85-004-1292

85-004-1562 85-004-1572

85-004-1592

COVERS SHAFTS

C

O

D

E

01-215-0010

01-216-0070

(1)

(1)

5:1

5.05 RATIO

PART NUMBER PART NUMBER

BASES

INPUT GEARS

SINGLE PLANETARY

AIR VENT 3/8 NPT (OPTIONAL)

GREASE FITTING (OPTIONAL) STR. 1/8 NPT

MODEL 50L

2

71-004-0121

50-004-1011

85-004-1181

01-105-0010

50-004-1091

01-153-0210

114C

135D

THRUST WASHER

RETAINING RING

4:1

4.08

50-004-1023

85-004-1041

71-004-0121

50-004-1011

85-004-1181

01-105-0010

50-004-1091

01-150-1550

01-153-0210

50-004-1112

5:1

5.05

PART NUMBER

WITHOUT CODE 4

INPUT SPLINE

WITH CODE 4

INPUT SPLINE

81-004-2883

01-160-0350

LOCK RING

50-004-1462

50-004-1452 SPLIT RING (MATCHING HALVES)

50-004-4012L

50-004-4022L

50-004-4032L

50-004-4052L

50-004-4212L

50-004-4082L

50-004-4092L

50-004-4312L

50-004-4292L

50-004-1521

7/16-20 GR8

50-004-4502L

EFFECTIVE

FROM: S/N 16130 07-01-93

TO: (CURRENT)

50-004-1062 50-004-1052 1

CARRIER ASSEMBLY

5

50-005-2041 50-005-2031 1

INPUT GEAR 13T 16/32 DP SPLINE

INPUT GEAR SAE 1"-6B SPLINE

INPUT GEAR14T 12/24 DP SPLINE

INPUT GEAR 15T 16/32 DP SPLINE

INPUT GEAR 1" DIA X .25 KEY

COVER-SAE 'A'

2"DIA SHAFT-3/8" KEYWAY

COVER-SAE 'B' 2-BOLT

23T 12/24 D.P. SPLINE

COVER-SAE 'C' 4-BOLT

COVER-SAE 'C' 2-BOLT

2"DIA X .50" KEY (INTERNAL)

2"DIA SHAFT-1/2" KEYWAY

2"HEX SHAFT-13/16 DIA.HOLE

2"DIA AUGER-.562"HOLE

SHAFT-CUSTOM

A

FLANGLESS (NO ZERK)

7" SPINDLE 50L (5) X 1/2-13

2-1/8"DIA SHAFT-1/2" KEYWAY

7" SPINDLE 50L (5) X .610 DIA THRU HOLES

2-5/8"HEX SHAFT-13/16 DIA.HOLE

CUSTOM

ROUND FLANGE (NO ZERK)

RECTANGULAR FLANGE (NO ZERK)E

F

C

D1

D2

D3

D4

F2

H2

H3

R2

S1

S2

C1

A

B

C

K

2

3

4

5

6

30C

30D

01-207-0030 (1) PIPE PLUG (C & K COVER ONLY) 1/8 NPT

3

SEAL KIT (1 SEAL, 2 O-RINGS)

16

85-016-0601 -

-

X50LD1-AF,

Page 1 of 1

Effective date 7-16-93

Effective serial # 16130

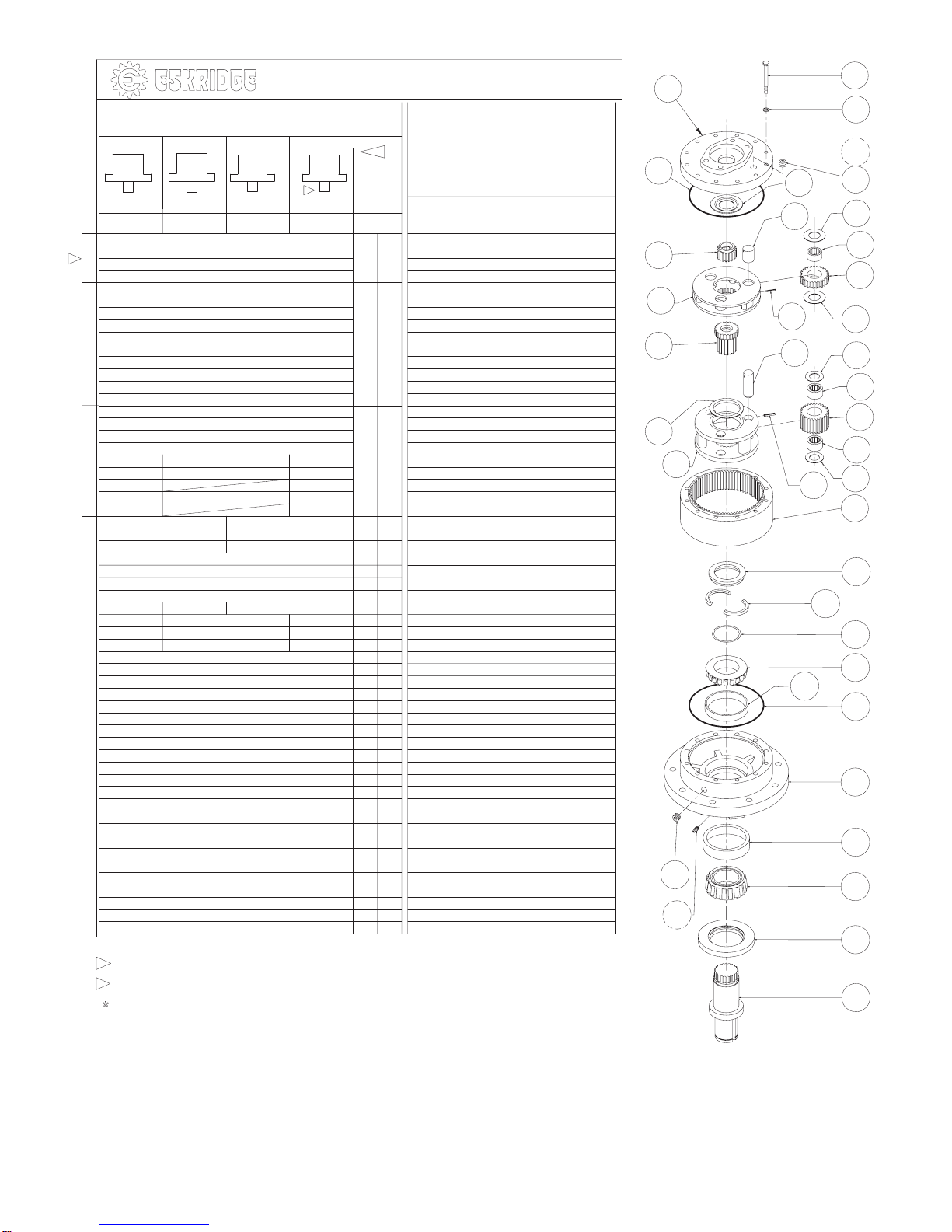

Model 50 service manual, SM50LD2-AB Page 1

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

MATCHING

HALVES

2

NOTES:

BEARING PRELOAD DETERMINES QUANTITY OF SHIMS.

30A

30B

(OPTIONAL)

35C

35B

35A

20C

20D

16B

1

20B

20A

16A

2

S2 - SHAFT REQUIRES STUDS (QTY 5) PART NO. 01-164-0040.

FOR GREASE ZERK OPTION, ADD 'Z' SUFFIX TO BASE P/N

(OPTIONAL)

30C

25A

25B

30A

14B

4

5C

5B

5D

5E

5D

5E

14A

5A

5F

12

16B

E.C.N. # 2791

X50LD2-AE 01/15/08

ITEMQTY.

50-004-1082

85-004-1051

85-004-1031

DESCRIPTION

RING GEAR

CARRIER

PLANET GEAR

PLANET GEAR

SHIM(S)

SUN GEAR

PLANET SHAFT

PLANET SHAFT

CARRIER THRUST WASHER

PLANET THRUST WASHER

PLANET THRUST WASHER

BEARING CONE (OUTER)

BEARING CONE (INNER)

BEARING CUP (OUTER)

BEARING CUP (INNER)

PLANET BEARING

PLANET BEARING

INPUT THRUST WASHER

HEX CAPSCREW

ROLL PIN

ROLL PIN

LOCKWASHER

PIPE PLUG-MAGNETIC

O-RING

SEAL-SHAFT

1

1

3

*

-

3

1

6

1

1

1

1

1

1

1

12

3

12

2

2

1

12

3

5A

7B

5B

35A

6

7C

5C

14A

7E

5E

20A

20C

20B

20D

35C

35B

7D

5D

14B

25A

7F

5F

25B

30A

16B

16A

30B

30C

50-004-1023

81-004-1561

01-102-0140

01-102-0150

01-103-0130

01-103-0140

01-150-1550

01-153-0080

01-166-0340

01-207-0070

01-402-0560

01-405-0530

3/16 X 7/8

1/8 X 1

7/16 MED

3/8 NPT-SOC HD

01-105-0410

1 1

50-004-3003

50-004-3013

50-004-3193

50-004-1173

50-004-1183

50-004-1233

50-004-1333

12

14

85-004-1102 85-004-1062

85-004-1122 85-004-1112

85-004-1533

85-004-1542 85-004-1422

85-004-1582

COVERS SHAFTS

C

O

D

E

INPUT GEAR 13T 16/32 DP SPLINE

INPUT GEAR SAE 1"-6B SPLINE

INPUT GEAR 14T 12/24 DP SPLINE

INPUT GEAR 15T 16/32 DP SPLINE

INPUT GEAR 1" DIA X .25 KEY

COVER-SAE 'A'

2"DIA SHAFT-3/8" KEYWAY

COVER-SAE 'B' 2-BOLT

23T 12/24 D.P. SPLINE

COVER-SAE 'C' 4-BOLT

COVER-SAE 'C' 2-BOLT

2"DIA X .50" KEY (INTERNAL)

2"DIA SHAFT-1/2" KEYWAY

2"HEX SHAFT-13/16 DIA.HOLE

SHAFT-CUSTOM

01-215-0010

01-216-0070

(1)

(1)

RATIO

PART NUMBER PART NUMBER

BASES

INPUT GEARS

AIR VENT 3/8 NPT (OPTIONAL)

GREASE FITTING (OPTIONAL) STR. 1/8 NPT

MODEL 50L

A

FLANGLESS (NO ZERK)

2

81-004-0071

50-004-1072

85-004-1041

85-004-1021

71-004-0121

50-004-1011

85-004-1181

01-105-0010

50-004-1091

01-153-0210

PART NUMBER

LOCK RING

50-004-1462

50-004-1452 SPLIT RING (MATCHING HALVES)

7" SPINDLE 50L (5) X 1/2-13

50-004-4012L

50-004-4022L

50-004-4032L

50-004-4052L

50-004-4212L

50-004-4082L

50-004-4312L

50-004-4292L

50-004-1521

7/16-20 GR8

2-1/8"DIA SHAFT-1/2" KEYWAY

7" SPINDLE 50L (5) X .610 DIA THRU HOLES

2-5/8"HEX SHAFT-13/16 DIA.HOLE

50-004-4502L

CARRIER7A

50-004-1062

1

CARRIER ASSEMBLY5

CARRIER ASSEMBLY7

50-005-2041

1

25.53:1

5.05

5.05

20.62:1

4.08

5.05

INVERTED

1

16.65:1

4.08

4.08

20.62:1

5.05

4.08

PART NUMBER

50-004-1082

85-004-1031

50-004-1052

50-005-2031

50-005-2011 50-005-2021 50-005-2011

85-004-1072

85-004-1412 85-004-1092

INVERTED RATIO SUNGEAR IS NOT COUNTERBORED FOR CODE 4 INPUT. MOTOR COMPATIBILITY MUST BE VERIFIED.

1

6

7B

7D

7E

7E

7C

7A

7F

EFFECTIVE

FROM: S/N 38000 11-01-98

TO: (CURRENT)

DOUBLE PLANETARY

CUSTOM

ROUND FLANGE (NO ZERK)

RECTANGULAR FLANGE (NO ZERK)

E

F

C

D1

D2

D3

D4

F2

H2

H3

S1

S2

C1

A

B

C

K

2

3

4

5

6

30D01-207-0030 (1) PIPE PLUG (C & K COVER ONLY) 1/8 NPT

3

3

6

6

3

1

1

3

3

-

-

85-004-1533

-

85-004-1582

SEAL KIT (1 SEAL, 2 O-RINGS)

-1685-016-0601

X50LD2-AE,

Page 1 of 1

Effective date 12-16-98

Effective serial # 38489

Model 50 service manual, SM50LD2-AB Page 2

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

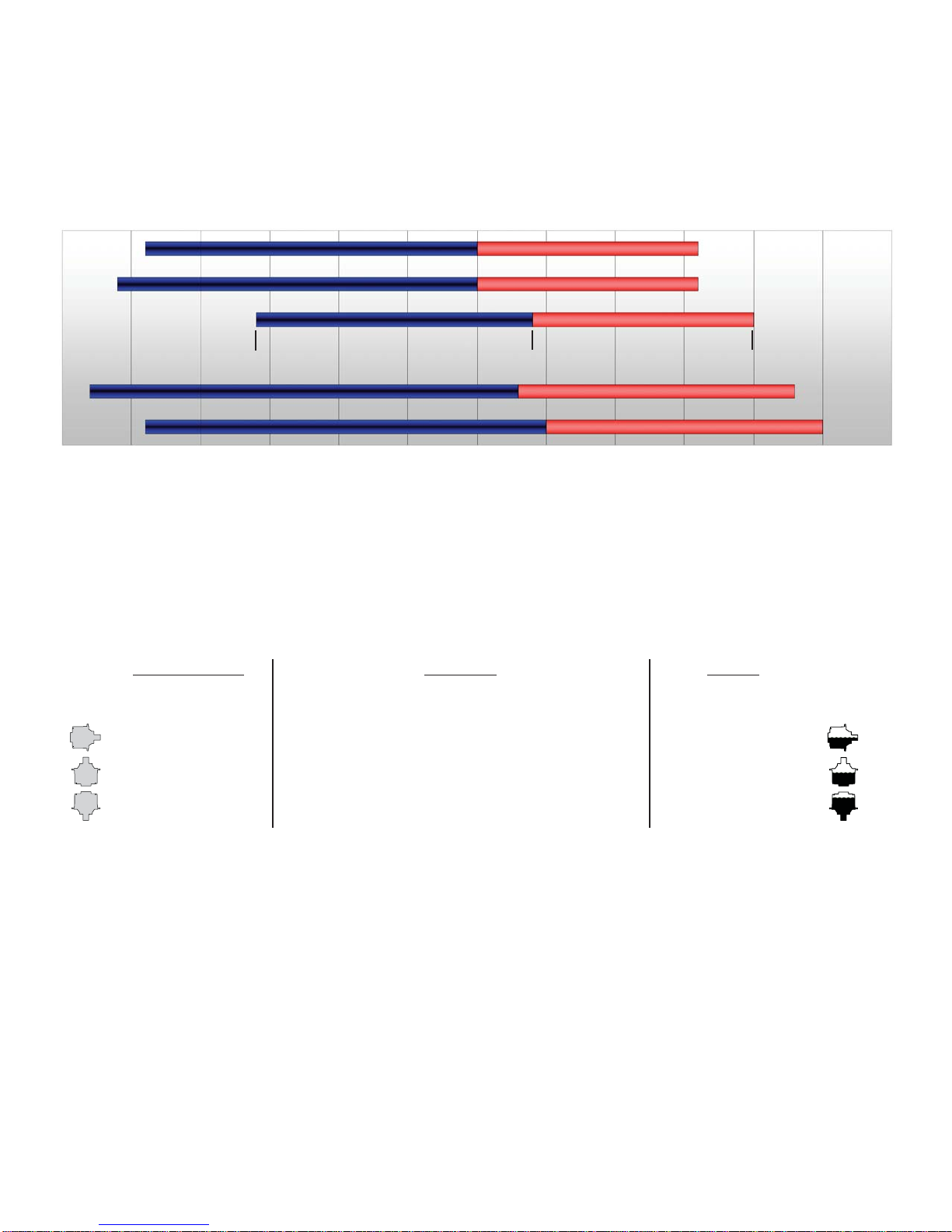

LUBRICATION & MAINTENANCE

Operating Position

Single stage

Oil Capacity

Double stage Triple stage

Oil Level

Horizontal Shaft 1.4 pt / 0.7 l 1.6 pt / 0.8 l 1.8 pt / 0.9 l To horizontal centerline of

gear drive

Vertical Shaft (Pinion Up) 1.7pt / 0.8 l 2.2 pt /1.0 l 2.7 pt /1.3 l To side port on gear drive

base

Vertical Shaft (Pinion Down) 2.2pt / 1.0 l 2.7 pt /1.3 l 3.2 pt /1.6 l To midway on upper/

primary gear set

Using the chart below, determine an appropriate lubricant viscosity. Use only EP (extreme pressure) or API GL-5 designated lubricants.

Change the lubricant after the first 50 hours of operation and at 500 hour intervals thereafter. The gear drive should be partially disas-

sembled to inspect gears and bearings at 1000 hour intervals.

80W90 conventional

75W90 conventional

85W140 conventional

75W90 synthetic

80W140 synthetic

Note: Ambient temperature is the air temperature measured in the immediate vicintiy of the gearbox. A Gearbox exposed to the direct rays of

the sun or other radiant heat sources will operate at higher temperatures and therefore must be given special consideration. The max operating

temp must not be exceeded under any circumstances, regardless of ambient temperature.

If your unit was specified “shaft up” or with a “-Z” option, a grease zerk was provided in the base housing. For shaft-up operation, the

output bearing will not run in oil and must be grease lubricated. Use a lithium based or general purpose bearing grease sparingly every

50 operating hours or at regular maintenance intervals. Over-greasing the output bearing should be avoided as it tends to fill the housing

with grease and thicken the oil

Recommended ambient and operating temperatures for conventional and synthetic gear lubricants

-50 -25 0 25 50 75 100 125 150 175 200 225 250 F

-45 -32 -18 -4 10 24 38 52 66 79 93 107 121 C

Min Ambient/operating temp Max Operating temp

Max Ambient temp

ESKRIDGE MODEL 50 OIL CAPACITIES

ESKRIDGE PART NUMBER INTERPRETATION

Note:All non-custom Eskridge Geardrives are issued a descriptive part number which includes information regard-

ing the Model, means of shaft retention, base style, shaft style, input mounting, input shaft size, overall ratio and

various available options. For a detailed breakdown of this information, please refer to Eskridge product specifica-

tion sheets found at: http://www.eskridgeinc.com/geardrives/gearprodspecs.html

Model 50 service manual, SM50LD2-AB Page 3

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

Unit Teardown

1) Scribe a diagonal line across the outside of the unit from the

cover (3) to the base (1) before disassembly to aid in the proper

positioning of pieces during reassembly.

2) Remove drain plugs (30A) and drain oil from unit. The oil will

drain out more quickly and completely if warm.

3) Remove the 12 7/16-20 capscrews (25A) and lockwashers

(25B) securing the cover.

4) Remove the cover (3), thrust washer (14B), and input gear (4).

Inspect o-ring (16B); discard if damaged or deformed.

5) Lift the planet carrier assembly out of the unit .

6) Remove ring gear(s) (12) and subsequent carrier assemblies

and thrustwasher (14A). Inspect gear to gear and gear to base

O-ring(s) (16B); as before, discard if damaged or deformed.

7) The unit is now disassembled into groups of parts. the area(s)

requiring repair should be identified by thorough inspection of

the individual components after they have been cleaned and

dried.

Carrier Assembly Teardown

Rotate planet gears (7B pri/5B sec) to check for abnormal

noise or roughness in bearings (7D pri/5D sec). If further in-

spection or replacement is required, proceed as follows.

1) Drive roll pins (7F pri/5F sec) completely into the planet shafts

(7C pri/5C sec).

2) Slide planet shafts (7C pri/5C sec) out of carrier (7A pri/5A

sec).

3) Remove planet gears (7B pri/5B sec), washers (7E pri/5E

sec) and bearings (7D pri/5D sec) from carrier (7A/5A).

4) Inspect the planet gear (7B pri/5B sec), bearing bore and plan-

et shaft (7C pri/5C sec) and bearings (7D pri/5D sec). Check

for spalling, bruising or other damage and replace components

as necessary.

5) Remove roll pins (7F pri/5F sec) from planet shafts (7C pri/5C

sec) using a 1/8” (pri) or 3/16” (sec) pin punch.

Carrier Reassembly

1) Planet shafts (7C pri/5C sec) should be installed with cham-

fered end of 1/8”(pri), or 3/16”(sec) roll pin hole towards outside

diameter of carrier (7A pri/5A sec); this will ease alignment of

holes while inserting roll pins (7F pri/5F sec).

2) Drive roll pin (7F pri/5F sec) into the carrier hole and into plan-

et shaft to retain parts. Repeat for remaining planet gears.

Base Subassembly Teardown

1) Remove the shaft retainer lock ring (35C) using a heel bar or

puller; if using a heel bar, be sure not to pry against the cage

of the inner output shaft bearing (20C). Remove the split ring

segments (35B) and shims (35A).

Caution: Since the shaft is no longer positively retained,

care should be taken to avoid personal injury. Care should

also be taken not to damage it while pressing through

base.

Note: Removing the shaft from the base assembly damages

the shaft seal. The seal will need to be replaced.

2) Place base (1) external side down, supported at the case

perimeter. Press output shaft out bottom of base by apply-

ing a load to internal end of shaft until it passes through

inner shaft bearing cone (20C).

3) A gear puller may be used to remove the outer bearing

cone (20A) from the shaft (2). If reusing old bearing cone,

donotpullonordamagerollercage.If shaft bearings show

evidence of wear or damage they should be replaced at

this time. Remove the shaft seal (16A) for inspection or

replacement.

Note: When installing new shaft bearings. press the bearing

cone onto output shaft by pressing on inner race only. DO

NOT press on roller cage, as it will damage the bearing.

4) Lubricate inner lip of new shaft seal (16A) and slide it onto

the shaft (2) until it fits snugly over the shaft seal diameter

with the open side toward the interior of the gear drive.

5) Inspect inner and outer bearing cups (20D & 20B). If cups

are damaged, drive them out using a brass drift and utiliz-

ing the bearing knock-out notches in the base (1)

Base Reassembly

1) Clean all foreign material from any magnetic oil plugs lo-

cated on base (1).

2) Place base exterior side up on work table.

3) Apply a layer of lithium or general purpose bearing grease

to the roller contact surface of outer bearing cup (20B).

4) Press outer bearing cone (20A) onto the shaft until it seats

against the shoulder.

5) Place the shaft (2) with the bearing cone (20A) into the

base.

6) Flip shaft/base assembly, and apply lithium or general pur-

pose bearing grease to roller contact surface of the inner

cup (20D), then press inner bearing cone (20C) onto shaft

until it seats against inner bearing cup (20D).

7) Prior to installation of the shaft seal (16A), the pre-

load may result in a rolling torque which varies be-

tween 50 to 80 in-lb. The bearing preload should be

tailored to your application; a low-speed application may

require a high pre-load, while high-speed applications

usually benefit from low pre-load. Adding shims (35A) will

increase the pre-load on the bearing set. Determine your

pre-load requirement and install shims to obtain this pre-

load.

8) Install the Load-N-Lock™ segments (35B) over the shims

Model 50 service manual, SM50LD2-AB Page 4

Eskridge, Inc. Olathe, Ks. 913-782-1238 www.eskridgeinc.com

(35A) and into the groove in the shaft (2). Then, install the lock

ring (35C) over the segments (35B).

All subassembly service or repairs should be complete at this

time. Continue to Unit Reassembly to complete unit buildup..

Unit Reassembly

1) Install the secondary carrier assembly (5) onto the output shaft

(2); align the splines of the carrier (5A) with the output shaft (2)

splines and slide the carrier onto the shaft.

2) Lubricate o-rings (16B) and install into the corresponding base

(1) and cover (3) pilot(s).

Caution: Hold ring gear(s) by outside diameter or use lifting de-

vice to avoid injury.

3) Aligngearteethoftheringgear(12)withthegearteethoftheplan-

etgears(5B)andplaceonbase(1),thenalignmountingholesof

ring gear (12) with holes in base (1). Use the scribed line made

during disassembly for reference.

4) Install the carrier thrust washer (14A) and sun gear (6) into the

secondary carrier (5A).

5) Install the primary carrier assembly (7).

6) Install the input gear (4).

7) Install the input thrust washer (14B) Refer to exploded view for

details.

8) Noting the scribed line made during disassembly, (with lubri-

cated o-ring in place) align and install the cover (3).

9) Install and torque the 12 7/16-20 hex-head cap-screws (25A)

with lockwashers (25B). The torque for the cap-screws: 80 ft-lb

dry, 60 ft-lb if lubricated.

10) Using a splined shaft to drive the input gear (4) ensure that the

unit spins freely.

11) Fill the unit to the proper level, as specified, with recommended

gear oil (refer to chart, page 2) after unit is sealed with brake

and/or motor.

The gearbox is now ready to use.

Table of contents

Other Eskridge DC Drive manuals

Popular DC Drive manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 user manual

Nidec

Nidec DFS Series Power Installation Guide

StepperOnline

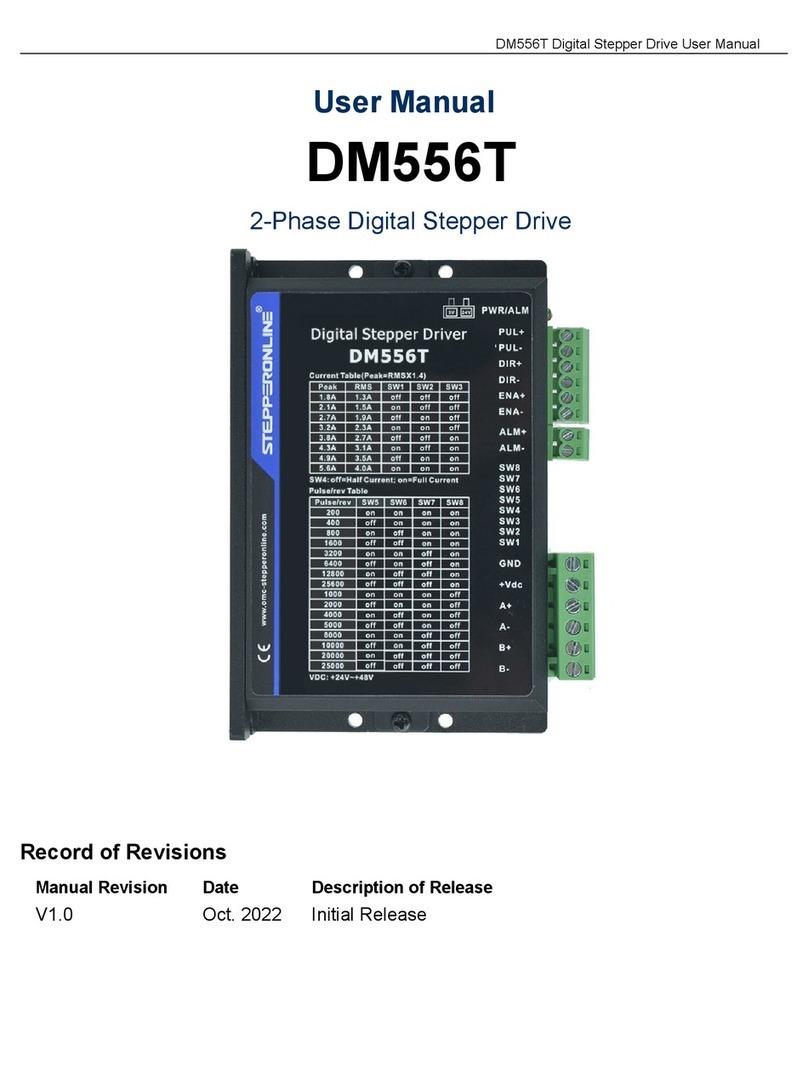

StepperOnline DM556T user manual

Smartrise

Smartrise HPV900 Startup manual

GFA

GFA ELEKTROMAT SE 9.15 WS-25,40 installation instructions

Knauer

Knauer Azura V 2.1S user manual