ESP Safety SGOES User manual

SGOES Infrared Hydrocarbon Gas Detector

Operating Manual

820-0006

SGOES Infrared Hydrocarbon Gas Detector

Operating Manual

820-0006

ESP Safety, Inc.

555 North First Street

San Jose, CA 95112 USA

408-886-9746

Revision History: 820-0006

Date

Revision

Description

Approved

03/20/14

4.5

Reformat

03/24/14

5

Update for clarity

10/08/18

6

Terminal Labels

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page ii

Revised 3/20/2014

Table of Contents

1.0 Introduction ...................................................................................................................................................................... 4

Product Overview ..................................................................................................................................................................... 4

ESP Safety Inc Contact Information .......................................................................................................................................... 4

Principles of Operation ............................................................................................................................................................. 5

SGOES Components.................................................................................................................................................................. 6

SGOES Dimensional Drawing .................................................................................................................................................... 6

2.0 Specifications & Technical Data ......................................................................................................................................... 7

Ordering Guide ......................................................................................................................................................................... 8

Certifications and Compliance .................................................................................................................................................. 9

Protective Weather Cover ...................................................................................................................................................... 10

Internal Optics Heater............................................................................................................................................................. 10

3.0 Safety Considerations.......................................................................................................................................................10

Guidelines ............................................................................................................................................................................... 10

Explosion Protection Means ................................................................................................................................................... 10

4.0 Installation .......................................................................................................................................................................11

Component Parts & Delivery Set ............................................................................................................................................ 11

Visual Examination.................................................................................................................................................................. 11

Guidelines for Locating the SGOES ......................................................................................................................................... 11

Mounting ................................................................................................................................................................................ 12

Earth Grounding...................................................................................................................................................................... 13

General Wiring Requirements ................................................................................................................................................ 14

SGOES Wiring Terminal Labels................................................................................................................................................ 14

Power Up and Stand Alone Operation of SGOES .................................................................................................................... 16

5.0 Calibration Procedures .....................................................................................................................................................17

SGOES Calibration Using ESP Commander.............................................................................................................................. 17

SGOES Calibration Using a HART Communicator.................................................................................................................... 19

SGOES Calibration Using Magnetic Wand............................................................................................................................... 20

6.0 Troubleshooting ...............................................................................................................................................................22

Troubleshooting Table ............................................................................................................................................................ 22

7.0 Maintenance ....................................................................................................................................................................23

Periodic Maintenance............................................................................................................................................................. 23

Maintenance Activities ........................................................................................................................................................... 23

8.0 Warranties .......................................................................................................................................................................24

9.0 Repair and Return.............................................................................................................................................................25

Field Repair ............................................................................................................................................................................. 25

Return Material Authorization (RMA) Number....................................................................................................................... 25

10.0 Parts Ordering Information.............................................................................................................................................26

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page iii

Revised 3/20/2014

Appendix 1: Calculating Values...............................................................................................................................................27

Appendix 2: Gas Measurement Range....................................................................................................................................28

Appendix 3: Gas Flash Point Temperatures.............................................................................................................................29

Appendix 4: SGOES Terminal Block & Wiring for 3-wire and 4-wire Systems...........................................................................30

Appendix 5: Maximum Cable Lengths for Analog Connection (using 24VDC Supply) ...............................................................31

Appendix 6: HART Menu Tree.................................................................................................................................................32

Appendix 7: SGOES to Vector FCU ..........................................................................................................................................33

Appendix 8: SGOES to UPES....................................................................................................................................................34

Appendix 9: SGOES to Analog Input Module...........................................................................................................................35

It is important that this entire manual be thoroughly read and

understood prior to installing or operating the SGOES. Any

deviation from this manual may impair system performance and

compromise safety.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 4

1.0 Introduction

Product Overview

The SGOES is a combustible gas detector that measures the concentration of

hydrocarbon gases present in the monitored environment. The SGOES is configured to

report alarms when the gas concentrations in the environment reach two independently

programmable levels, expressed as a percentage of the lower explosive limit (LEL) in air.

As determined by application requirements, the SGOES is factory calibrated with one of

eight hydrocarbon-based gases (typically methane or propane). Conversion factors are

used to correct for gases other than the factory calibration gas.

Moreover, SGOES is not sensitive to inadvertent detection of gases, such as nitrogen,

oxygen, carbonic acid, ammonia, and hydrogen sulfide. This makes the SGOES an

excellent choice for environments where non-hydrocarbon gases are present and precise

monitoring of combustible hydrocarbons like methane and propane is required.

Key Features

•Fast response time (T90 ≤ 5sec @ 100% LEL methane)

•Broadest operating temperature of detectors in its class (-60⁰C to 125⁰C / -

76⁰F to 257⁰F w optional Extended Temperature package)

•No significant zero drift

•High-performance weather protective cover eliminates water ingress of the

gas detection chamber, a common cause of false alarms with most IR detectors

•Simple, non-intrusive zero and span calibration

•Can be used in conjunction with ESPs SSS-903 or VECTOR Field Control Units to

provide local display of gas readings, alarm levels and device status.

ESP Safety, Inc. Contact

Information

Contact ESP Safety for application assistance or order placement.

ESP Safety, Inc.

555 North First Street

San Jose, CA 95112

USA

Telephone: 408-886-9746

FAX: 408-886-9757

website: www.espsafetyinc.com

Our Mission

ESP Safety, Inc.’s mission is to provide complete turn-key protection solutions beginning

with the design stage, through system installation and commissioning, and on-going field

service in hazardous environments. Our line of industry-leading products, services, and

systems benefits society, saves lives, and preserves capital resources.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 5

Principles of Operation

Operation is based on selective signal disruption by hydrocarbon molecules. An infrared

light source is reflected to a set of optical detectors that simultaneously monitors the

infrared power at multiple wavelengths of the infrared spectrum. If no gas is present, the

photodetectors will receive all of the power radiated by the IR source. When gas

molecules enter the collection chamber the gas selectively absorbs infrared energy at

wavelengths specific to the gas. As a result the detector monitoring the wavelength

specific to the gas records a drop in infrared signal, and the signal from the detector

monitoring a wavelength unaffected by the gas does not change. The ratio of the

photodetector signals, when properly calibrated, provides a quantitative measurement

of the target gas concentration.

Figure 1-1: Hydrocarbon Gas Detection

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 6

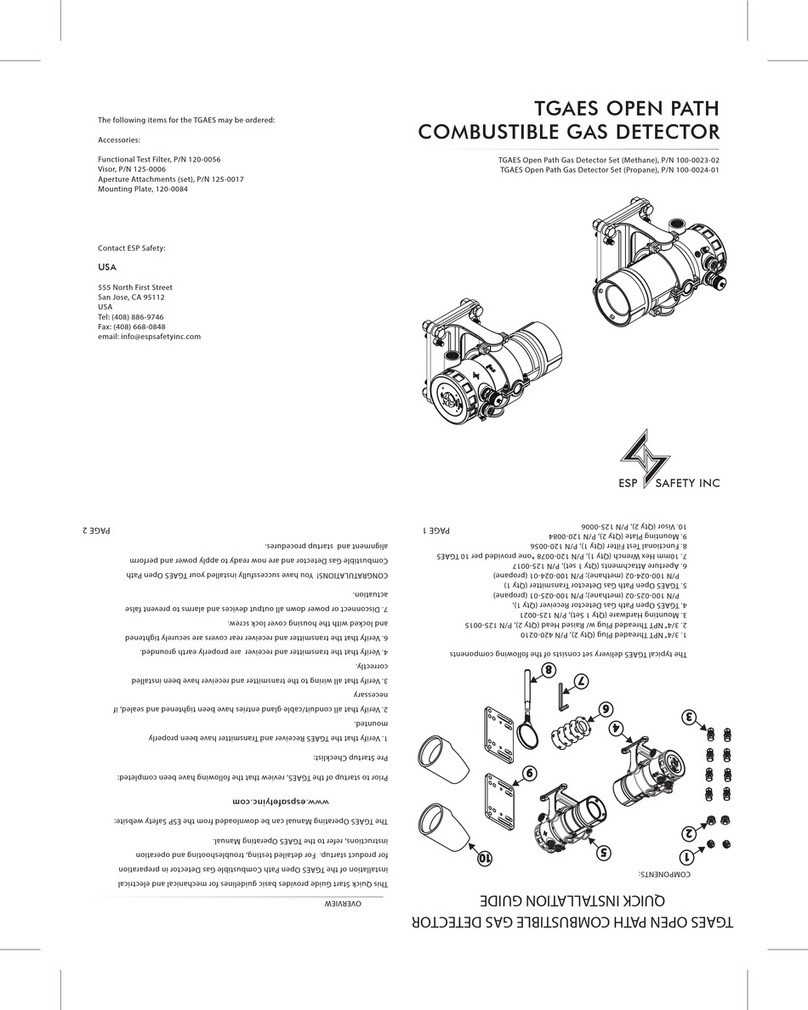

SGOES Components

A. Explosion proof housing

B. Conduit entry for Field Wiring (3/4” NPT), x2

C. Tri-color LED Status Indicator

D. HART communication port (3/4” NPT), x1

E. Gas detection chamber

F. Integral mounting lugs

G. Magnetic Calibration Point

Figure 1-2: SGOES Components

A

B

C

F

D

G

E

Figure 1-3: SGOES Dimensions

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 7

2.0 Specifications and Technical Data

Mechanical Characteristics

Material

Stainless Steel (Type 316)

Conduit Connection

¾” NPT

2 connections for Field Wiring

1 connection for HART/USB

Dimensions

8.01” x 5.30” x 5.12”(203.5mm x 134.50mm x 130mm)

Weight (no sensors)

14.33lb (6.5 kg)

Optics Protection

Weatherproof Cover

Electrical Characteristics

Input Voltage

+24VDC Nominal (+18 to 32VDC)

Power Consumption

7.9W Maximum

Output From SGOES

+4-20mA industry standard analog with embedded HART

Digital RS-485 MODBUS RTU

HART interface with easy access dedicated connector

3 “Dry Contact” relays. Fault relay (NC/Form-B), alarm level 1 (NO/Form-A), alarm level 2

(NO/Form-A).

All Relays Contact Rating 1Amp@125VAC/30VDC

Alarm Relays

2 User Programmed Alarm Relays (factory default setting: NO)

1 Fault Condition Programmed Relay (factory default setting: NC)

Operational Characteristics

Gases detected

Methane, Propane, Butane, Pentane, Hexane,

Isobutane, Cyclopentane, Ethanol.

(The target gas is factory configured according to customer request.)

Gas Detection Range

0-100% LEL

Accuracy

± 2% of the full-scale gas concentration

Response Time

(for 100% LEL methane)

50% full scale < 1.9 seconds

90% full scale < 5.0 seconds

Humidity Range

Up to 95% RH, non-condensing

(Withstands up to 100% RH for short periods)

Warm-up time

10 minutes

Operating Temperature

-40oF to + 167oF (-40oC to +75oC), Extended Range -76oF to + 257oF (-60oC to +125oC)

Ingress Protection

IP66

RFI/EMI Protection

EN50081-1 / Class B E> 50270

*Operates with no interference from a 5 watt walkie-talkie keyed (transmitting) at 1 meter

Status Indication

Tri-color status LED indicates operational mode, fault, and gas presence.

Displayed information when

used w/ Field Control Unit

(SSS-903 or Vector)

Continuous sensor data

Gas Type

Measuring Units

Three Fixed Alarm Thresholds

Graphic display of trending data for Peak Readings and Time-Weighted Average (TWA) of

gas concentration 3-30 minutes

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 8

Ordering Guide

For simplicity of ordering, the SGOES is factory configured for detection specific gases. For gases not included in the

table below, please contact ESP Safety.

Scale Range

SGOES Model to

Order

Detected

Hydrocarbon

%LEL

%vol IEC6007920-

2000/BSEN617791:200

0

%vol ISO 10156

100-0001-M11-C1

Methane

0 to 100

0 to 4.4

0 to 5.0

100-0001-M11-C2

Propane

0 to 100

0 to 1.7

0 to 2.1

100-0001-05

Butane

0 to 50

0 to 0.7

0 to 0.9

100-0001-07

Isobutane

0 to 50

0 to 0.65

0 to 0.9

100-0001-09

Pentane

0 to 50

0 to 0.7

0 to 0.75

100-0001-11

Cyclopentane

0 to 50

0 to 0.7

0 to 0.75

100-0001-13

Hexane

0 to 50

0 to 0.5

0 to 0.55

100-0001-15

Propylene/Propene

0 to 50

0 to 0.1

0 to 1.5

100-0001-17

Methanol Vapor

0 to 50

0 to 2.75

0 to 3.65

100-0001-19

Ethanol Vapor

0 to 25

0 to 50

0 to 0.78

0 to 1.55

0 to 1.08

0 to 2.15

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 9

Certifications and Compliance

Explosion-proof for Class 1, Div.1, Group B, C, D (T4) Hazardous (classified) locations per FM 3615,

6310

Dust ignition-proof for Class II, Div.1, Group E, F, G Hazardous (classified) locations per FM 3615,

6310

Non-incendiary for Class 1, Div.2, Group A, B, C, D (T4), Class 2, Div.2, Group E, F, G (T4) Hazardous

(classified) locations per FM 3611

Performance verified up to 100% LEL methane-in-air atmosphere per FM 6320

Explosion-proof for Class 1, Div.1, Group B, C, D (T4) Hazardous (classified) locations per CSA C

22.2 # 30 and Ex d IIC T4 per CSA E 60079-0-1

Dust ignition-proof for Class II, Div.1, Group E, F, G Hazardous (classified) locations per CSA C 22.2

# 25

Non-incendiary for Class 1, Div.2, Group A, B, C, D (T4), Class 2, Div.2, Group E, F, G (T4) Hazardous

(classified) locations per CSA C 22.2 # 213

Performance verified up to 100% LEL methane-in-air atmosphere per CSA C 22.2 # 152

CE 0539 II 2 G

Ex d[ia] IIC T4 (Tamb 75°C)

IP 66

Ex d [ia] IIC T4

(Tamb 75°C)

IP 66

1 Ex d [ia] IIC T4 X T= -60°C....75°C

IP 66

EN Standards

EN 60079-0: 2006

EN 60079-1: 2007

EN 61779-1: 2000

EN 60529: 1991+A1: 2000

EN 50270: 2006.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 10

Protective Weather

Cover

The protective weather cover is UV resistant, static-dissipating black plastic. It is

designed with internal baffles and hydrophobic filters to eliminate water ingress into the

detection chamber without limiting the flow of gases and vapors.

A separate calibration cup is supplied for use during zero and span calibration of the

SGOES.

Internal Optics Heater

The SGOES is designed with a heating system that eliminates moisture, condensation

and frost from the detector lens.

3.0 Safety Considerations

Guidelines

Before installing and operating the SGOES, be sure to read this entire

manual. Failure to follow these guidelines could result in impaired

product performance and safety hazards.

For maximum safety:

•SGOES wiring should comply with all governing electrical codes, standards and

regulations.

•Never operate the SGOES if the casing is damaged.

•Do not open the SGOES case when the unit is energized.

•Perform regular testing and maintenance as outlined in the Maintenance section.

•Ensure that alarm notification and control systems associated with the SGOES and its

detectors are switched off before any testing or maintenance to avoid unwanted

operation of alarms and control equipment.

Also see the individual sections in this manual for relevant specific safety guidelines.

Explosion Protection

Means

The SGOES is designed to be explosion-proof. Any user modifications to the device will

invalidate the explosion proof / flame proof certifications. All labeling must be intact and

visible. All Surfaces that are subject to disassembly or removal during installation or

maintenance must be installed as detailed in Appendix I and comply with the relevant NEC,

IEC and/or ATEX standards when replaced.

Hazardous location safety is ensured by:

•Cabling entering into and out of the SGOES must utilize connections certified for the

hazardous location where the SGOES unit is installed. The cable gland should be able to

withstand the pressure of an explosion and prevent the spread of combustion into the

hazardous area. The connection points are marked in the drawings with word “Explosion”

and indicate permissible values. Limit the ambient temperature to no higher than 85 °C.

•Use only with combustible gases with auto-ignition temperatures of 135 °C or higher.

•All the bolts securing the parts and enclosure must be sufficiently tightened and prevented

from loosening by using spring washers or lock nuts.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 11

4.0 Installation

Component Parts and

Delivery Set

The SGOES parts and delivery set consists of the following:

•One SGOES infrared combustible gas detector

•One Protective Weather Cover

•One SGOES Operating Manual

•Accessory Kit (bolts, nuts, washers, etc.).

•Calibration Magnet (magnetic wand), P/N 611-0005

Compare the contents of the set to the packing list to be sure all items were received. If any

items are missing, contact ESP Safety Inc.

Visual Examination

Before installing the SGOES, examine the unit to ensure that:

•The nameplates and warning labels are in place.

•The external surfaces and joined surfaces of the SGOES casing are free of dents or

damage.

•Make sure all removable parts are joined to the casing as tightly as possible.

Guidelines for

locating the SGOES

There are no standard rules for selection and placement of sensors since the optimum

sensor choice location is unique for each application. Before installing the SGOES, check

the conditions at the installation site to make a placement determination.

The following guidelines can assist in determining the best possible placement of the

SGOES:

•Locate the SGOES detectors near potential gas leak sources and away from

excessive heat, light, wind, dust, water, vibration, shock, and radio frequency

interference (RFI).

•Ensure the installation location has sufficient space to accommodate the

SGOES housing and all necessary cabling.

•Mount the SGOES detector pointing horizontally

Preparing For Installation

•Before installation, evaluate the gas leak locations and other conditions such as

wind or air currents at the test site and configure the unit for that particular need.

Also, be sure to consult local installation codes.

Selection of gas sensor location is critical to the overall performance of the SGOES. Five

factors play an important role in the selection of sensor locations:

•Density of the gas to be detected

•Most probable leak sources within the industrial process

•Ventilation and prevailing wind conditions

•Personnel exposure

•Maintenance access

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 12

Density of Detected

Gas

If the target gas is heavier than air, the sensor should be located within 4 feet of grade.

Heavier than air gases will tend to settle in low-lying areas. For gases lighter than air, sensor

placement should be 4-8 feet above grade in open areas or in pitched areas of enclosed

spaces.

Probable Leak

Sources

Leak sources include flanges, valves, tubing and connections of the sealed type where seals

may either fail or wear. All potential leak sources and SGOES mounting locations are best

determined by facility engineers with experience in similar processes.

Ventilation &

Prevailing Winds

Normal ventilation or prevailing wind must be considered for locating SGOES detectors.

Personnel Exposure

Consideration should be given to placement of detectors in areas where personnel may

be exposed. Account for ventilation, wind direction and potential gas cloud size when

determining the number and location of gas detectors.

Maintenance Access

Consideration should be given to providing easy access for maintenance personnel.

SGOES location should also take into account the proximity to contaminants that may

foul or obscure the SGOES optics.

Tools Required for

Mounting

•2.5-MM “Flat Head” screwdriver for protective cover lock screw and wire terminal

block clamps

•5/16 wrench for Ground Connector

•Allen wrench set

Ferrule crimper (up to 12ga)

Mounting

The SGOES must be mounted such that it is oriented at a horizontal plane.

FIGURE 4-1: REMOTE CONFIGURATION

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 13

Earth Grounding

The enclosure of the SGOES Field Control Unit must be earth grounded

for electrical safety and to limit the effects of radio frequency

interference. An earth/ground point is provided on the outside of the

VECTOR Field Control Unit Explosion Proof enclosure.

The SGOES must be earth grounded in order to operate properly. The grounding lug is located

on the SGOES housing below the HART port.

Figure 4-2: Ground Point

Ground Point

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 14

General Wiring Requirements

Caution: All cable/conduit entries must be sealed with an appropriate and

certified sealing plug and cable gland. The use of industrial grade, armored

field cable is recommended. If installing the sensor in a hazardous area using

remote configuration, armored cabling is required for the detector connection

to the SGOES.

•If installing connection cables in an explosion proof conduit, do not use the same conduit to carry

wiring for any other purpose or equipment.

•If installing the SGOES in a hazardous area, armored cabling is required for the connections to the

SGOES

•Minimum 14 AWG (2.08 mm2) shielded cable conductors are required for optimal performance.

•When using Modbus, twisted pair wiring is required for both the power and signal wires. Each

pair must be shielded to eliminate electromagnetic interference.

For reliable communications between the SGOES and the Host master, connect the Host RS-485

common or signal ground to the SGOES RS-485 common terminal. This is especially important

when connecting to an isolated RS-485 port. Failure to do so could result in communications

failures and possible damage to either the Host or SGOES RS-485 transceivers.

Terminal No Label Description

1+24V DC (DC power input)

20V System Ground

3 +24V DC (DC power input)

4 OV System Ground (common) -4-20mA

5 420 +4-20mA (current output signal)

6 485A RS-485 A (Modbus RTU output signal)

7485B RS-485 B (Modbus RTU output signal)

8FLT Fault alarm relay, pin 1(NORMALLY CLOSED when energized)

9 FLT Fault alarm relay, pin 2 (COMMON)

10 FLT Fault alarm relay, pin 3 (NORMALLY OPEN when energized)

11 A1 Alarm Relay 1, pin 1 (NORMALLY CLOSED)

12 A1 Alarm Relay 1, pin 2 (COMMON)

13 A1 Alarm Relay 1, pin 3 (NORMALLY OPEN)

14 A2 Alarm Relay 2, pin 1 (NORMALLY CLOSED)

15 A2 Alarm Relay 2, pin 2 (COMMON)

16 A2 Alarm Relay 2, pin 3 (NORMALLY OPEN)

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 15

Step 4- Wire Preparation

Figure 4-6: Wire Prep

Use a stripping tool for the selected wire gauge to remove ¼-inch (6mm) of the insulating jacket for

each conductor to be inserted in the terminal blocks of the Connector PCBA.

Caution: All cable/conduit entries must be sealed with an appropriate and certified sealing plug

and cable gland. The use of industrial grade, armored field cable is recommended. If installing

the SGOES in a hazardous area, armored cabling is required.

Step 1- Remove Conduit Plug

Using the supplied M16 hex wrench,

loosen and remove one of the

threaded conduit plugs

Step 2- Remove the rear cover

Step 3- Attach conduit gland (user

supplied) to 3/4” threaded opening on

detector body. Adapt as necessary to

user’s conduit size, using standard industry

practices.

¼” (6mm)

Shielded 14 or 16 AWG Stranded wire

(Recommended) based on cable length

6mm Insulated Crimp On Ferrule

ESP safety recommends a ferrule that is

crimped onto the wire for better

connectivity and ease of insertion into

the terminal block.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 16

Power up and Stand Alone Operation of SGOES

Installation Review Prior to

Startup

Once the mounting, cabling, and alarm relay installation has been completed, the

SGOES is ready to begin the power-on sequence.

Before applying power to the system for the first time, review the steps below:

•Verify that the SGOES has been properly mounted.

•Verify that all conduit / cable gland entries have been tightened and

sealed if necessary.

•Verify that all wiring has been installed correctly.

•Verify that the enclosure has been connected to an earth/ground.

•If using a SGOES in conjunction with a Field Control Unit such as the SSS-

903 or VECTOR, verify that the connections between the SGOES and the

Field Control Unit is secure and functional.

•Verify that the SGOES cover is securely installed and locked with the

housing cover lock screw.

•Disconnect or power down all output devices and alarms to prevent false

actuation.

Once you are ready to begin startup, verify that the power supply is connected

properly and verify the power supply voltage with the SGOES is disconnected at the

source. The SGOES is powered by 24 VDC (18 to 32 VDC voltage range).

After completing the above, the VECTOR is ready to be powered on.

Startup Procedure

Apply power to the system. Upon

first power-up, the tri-color status

LED will flash green indicating a

self-test is being performed.

After 40-60 seconds, the self-test

initialization sequence will be

completed, indicated by a solid

green status light.

At this time, the unit will be in the

normal operational state.

Allow the SGOES to warm up for 10

minutes prior to functional testing

of the unit.

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 17

5.0 Calibration Procedures

The SGOES may be calibrated by one of three methods:

•magnetic wand

•A Windows-based PC using ESP Commander software and the Modbus RTU interface

•HART Communicator

The analog output loops may be calibrated by using a HART communicator

The term SPAN GAS in these calibration procedures refers to a Full Scale gas mixture.

The term MID-SPAN GAS in these calibration procedures refers to a gas mixture of intermediate concentration

between zero and full scale.

SGOES Calibration using ESP

Commander

The example shown below is for an SGOES configured for propane.

On the Devices list of the main ESP Commander form, double click on the sensor to be calibrated (in this case, the SGOES).

This will open the form for the selected sensor.

Note the calibrate panel in the upper left quadrant of the form.

Figure 5-1: Main ESP Commander Form

Figure 5-2: SGOES Form

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 18

Step 1

Press the (7) Select/DeSelect button to start the

calibration sequence. The button will change color to

show that the calibration mode is active.

Step 2

Attach a zero gas to the sensor. When the gas

concentration stabilizes, press the (3) Set Zero button

to set the sensor zero point.

Step 3

Select the (6) Number of Span Gases to be used for

calibration using the radio buttons.

Step 4

Enter the Span Gas concentration in the units shown in

the (2) Span Conc. box.

Step 5

Apply span gas to the sensor. When the gas

concentration stabilizes, press the (4) Set Span button

to set the sensor span calibration point.

Step 6

If a two span gas calibration was selected, enter the

Mid-Span Gas concentration in the units shown in the

(1) Mid-Span Conc. box.

Step 7

If a two span gas calibration was selected, apply the

mid-span gas to the sensor. When the gas

concentration stabilizes, press the (5) Set Mid-Span

button to set the sensor mid-span calibration point

Step 8

Remove the calibration gas and allow the sensor gas

concentration to return to zero. When the

concentration has returned to zero, press the (7)

Select/DeSelect button to end the calibration sequence

2) SPAN CON

1) MID-SPAN

CONC.

3) SET ZERO

4) SET SPAN

5) SET MID-

SPAN

7) SELECT/

DESELECT

6) NUMBER

OF SPAN

GASES

Figure 5-3: SGOES Calibrate Panel

SGOES Infrared Combustible Gas Detector

820-0006 Operating Manual

Page 19

SGOES Calibration using a

HART Communicator

The following table shows the display menu tree for HART calibration of the

SGOES

Table of contents

Other ESP Safety Gas Detector manuals

Popular Gas Detector manuals by other brands

Tecnocontrol

Tecnocontrol SE138PX user manual

PNI

PNI GD-01 user manual

Domino

Domino GAS HOME Installation and operation manual

Elsner

Elsner Intra-Sewi TWIN L-Pr Installation and startup

Riken Keiki

Riken Keiki GD-84D-EX Series operating manual

Seitron

Seitron RYM02M Series User Manual and Safety Instructions