Esse Engineering WarmHeart User manual

Non-Confidential Business Information

(Non-CBI)

Certification Test Report

Esse Engineering Ltd.

Models: WarmHeart, BakeHeart

Wood-Fired Freestanding Room Heater, Non-Catalytic

Prepared for: Esse Engineering Ltd.

3131 Baptiste Rd. Mill Bay

B.C. Cananda, VOR 2P3

Prepared by: OMNI-Test Laboratories, Inc.

13327 NE Airport Way

Portland, OR 97230

(503) 643-3788

Test Period: December 15, 2020 – December 16, 2020

Report Issued: April 27, 2021

Report Number: 0224WS009E

All data and information contained in this report are confidential and proprietary to Esse

Engineering Ltd. Its significance is subject to the adequacy and representative character of

the samples and to the comprehensiveness of the tests, examinations, or surveys made. The

contents of this report cannot be copied or quoted, except in full, without specific, written

authorization from Esse Engineering Ltd. and OMNI-Test Laboratories, Inc. No use of the

OMNI-Test Laboratories, Inc. name, logo, or registered mark (O-TL) is permitted, except as

expressly authorized by OMNI-Test Laboratories, Inc. in writing.

-Document Edition # 000 (4/27/21) -

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

AUTHORIZED SIGNATORIES

This report has been reviewed and approved by the following authorized signatories:

Evaluator:

__________________________

Bruce Davis, Testing Manager

OMNI-Test Laboratories, Inc.

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

TABLE OF CONTENTS

PREFACE...............................................................................................................(3 pages)

1. SAMPLING PROCEDURES AND TEST RESULTS........................................................4

Introduction..........................................................................................................................5

Individual Run summaries ...................................................................................................6

Summary Tables

Table 1 - Particulate Emissions Results...............................................................................7

Table 2 - Particulate Emissions Results (First Hour)...........................................................7

Table 3 – B415.1 Efficiency and CO Emissions .................................................................7

Table 4 - Test Facility Conditions .......................................................................................8

Table 5 – Kindling and Start-up Fuel Description Summary ..............................................8

Table 6 - Fuel Measurements and Cordwood Descriptions - Test.......................................9

Table 7 - Dilution Tunnel Gas Measurements and Sampling Data .....................................9

Table 8 - Test Configurations ............................................................................................10

2. PHOTOGRAPHS/APPLIANCE DESCRIPTION/DRAWINGS......................................11

Fuel Photographs ...............................................................................................................13

Appliance Description .......................................................................................................18

3. TEST DATA BY RUN......................................................................................................19

Run 1..................................................................................................................................26

Run 2..................................................................................................................................44

Run 3..................................................................................................................................54

Run 4..................................................................................................................................62

4. QUALITY ASSURANCE/QUALITY CONTROL ..........................................................72

Sample Analysis.................................................................................................................74

Calibrations – ASTM E2515, ASTM E3053.....................................................................84

Example Calculations ......................................................................................................100

5. LABELING & OWNER’S MANUAL............................................................................112

Appendix A Alt-125 E3053 Letter

Appendix B Revision History Table

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

Section 1

Sampling Procedures and Test Results

4 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

INTRODUCTION

Esse Engineering Ltd. retained OMNI to perform U.S. Environmental Protection Agency (EPA)

certification testing on the WarmHeart Freestanding woodstove. The WarmHeart Freestanding

wood stove is a Non-Catalytic-type room heater. The firebox is constructed of mild steel. Usable

firebox volume was measured to be 1.09 cubic feet and the stove is vented through 6” flue collar

located on the stove top. Stove model BakeHeart shares the same firebox and emissions control

system, the oven under the firebox is the only difference. It was determined no additional testing

was required to include this design variant.

Testing was performed at Nelke Consulting. The altitude of the laboratory is 500 feet above sea

level. The unit was received in good condition and logged in on 12/15/20, then assigned and

labeled with OMNI ID #2400A. OMNI representative Bruce Davis conducted the certification

testing and completed all testing by December 16, 2020.

This report is organized in accordance with the EPA-recommended outline and is summarized in

the Table of Contents immediately preceding this section. The results in this report are limited to

the item submitted.

SAMPLING PROCEDURE

The WarmHeart wood stove was tested in accordance with the U.S. EPA 40 CFR Part 60,

Subpart AAA – Standards of Performance for New Residential Wood Heaters using ASTM

E2515 and EPA Alt-125, ASTM E3053. Particulate emissions were measured using sampling

trains consisting of two Teflon coated 47mm filters (front and back). See Appendix A for details

on EPA Alt-125.

The model WarmHeart was tested for thermal efficiency and carbon monoxide (CO) emissions

in accordance with CSA B415.1-10 using Maple cordwood. A spread sheet provided by CSA

was used to calculate efficiency values.

An ambient filter (Background) was not operated during this series, there were no operations in

the area that would have generated additional particulate into the ambient air. Running an

ambient filter can only reduce emissions by backing out any particulate not generated by fuel in

the appliance, it can never increase emissions. Tests conducted without an ambient filter are

worse case.

SUMMARY OF RESULTS

The weighted average emissions of the three test runs included in the results indicate a

particulate emission rate of 2.15 grams per hour. The WarmHeart results are within the emission

limit of 2.5 g/h for affected facilities tested with cordwood, manufactured on or after May

15, 2020.

The proportionality results for all 3 test runs were acceptable. Quality check results for each test

run are presented in Section 2 of this report.

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

INDIVIDUAL RUN SUMMARIES

Run 1 - Test procedures followed to produce a high burn rate with a primary air setting of

fully open. Observed burn rate was calculated from a hot to hot cycle at 3.37

kg/hr. Emissions results were calculated using particulate sampling from kindling,

start-up fuel, and test fuel load combined (cold to hot). Burn rate, and efficiency

were calculated using data from the test fuel load only (hot to hot). Gravimetric

analysis of probe assemblies did not produce negative weights, train precision

meets specified limits. No sampling anomalies occurred, this test run was

determined to be valid and appropriate for inclusion in the weighted average.

Run 2 - Test procedures were followed to produce a low burn rate with a primary air

setting of full closed. Observed burn rate was calculated at 0.73 kg/hr. Emissions

and efficiency results were calculated using a hot to hot burn cycle, a coal bed

generated by the high burn procedure was used. Gravimetric analysis of probe

assemblies did not produce negative weights, train precision meets specified

limits. No sampling anomalies occurred, this test run was determined to be valid

and appropriate for inclusion in the weighted average.

Run 3 - Test procedures followed to produce a high burn rate with a primary air setting of

fully open. Observed burn rate was calculated at 2.77 kg/hr. Burn rate was

calculated using data from the kindling, start-up, and fuel load (cold to hot). No

sampling occurred, this test run was not included in the weighted average.

Run 4 - Test procedures were followed to produce a medium high burn rate with a

primary air setting of 6” from the left stove leg to the right edge of the air control.

Observed burn rate was calculated at 0.70 kg/hr. Burn rate was 0.03 kg/h slower

than the low burn operated at an air setting of full closed due to the way the logs

fell during the combustion process, coal bed adjustment with intent to increase

combustion occurred at 4 hours 50 minutes into the test due to 0 weight loss in 10

minutes. Emissions and efficiency results were calculated using a hot to hot burn

cycle, a coal bed generated by a high burn conducted in test three was used.

Gravimetric analysis of probe assemblies did not produce negative weights, train

precision meets specified limits. No sampling anomalies occurred, this test run

was determined to be valid and appropriate for inclusion in the weighted average.

6 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

Table 1 – Particulate Emissions

Run

Burn Rate

Calculated from a

Hot to Hot burn

cycle

(kg/h dry)

ASTM E2515

Emissions

(g/h)

ASTM E3053

Weighting Factor

(%)

ASTM E3053 Weighted

Emissions

(g/h)

1 3.37 14.44 20 0.888

2 0.73 1.85 40 0.740

4 0.70 1.30 40 0.520

The sum of weighted particulate emission of 3 test runs: 0.888 + 0.740 + 0.520 =

2.15 grams per hour.

1. Based on a cold start including kindling and start-up fuel.

Table 2 – Particulate Emissions (First Hour)

Run

ASTM E2515

Emissions – First Hour

(g/h)

1 3.21

2 5.80

4 3.89

Table 3 – B415.1 Efficiency and CO Emissions

Run

Heat

Output

(BTU/h)

HHV

Efficiency

(%)

LHV

Efficiency

(%)

CO Emissions

(g/MJ Output)

CO Emissions

(g/kg Dry Fuel)

CO Emissions

(g/min)

1 48,685 74.4 79.5 5.58 79.50 1.526

2 10,486 75.9 81.2 7.41 112.36 1.365

4 10,001 75.4 80.7 5.51 82.98 0.968

Weighted average HHV efficiency of three test runs: 14.88 + 30.36 + 30.16 = 75.4%.

Average CO Emissions of three tests: (1.526 + 1.365 + 0.968) / 3 = 1.286 g/min

7 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

Table 4 – Test Facility Conditions

Run

Room Temperature

(°F)

Barometric Pressure

(Hg)

Air Velocity

(ft/min)

Before After Before After Before After

1 64 66 29.42 29.45 <50 <50

2 68 66 29.45 29.52 <50 <50

3 67 68 29.22 29.20 <50 <50

4 68 66 29.19 28.96 <50 <50

Table 5 – Kindling and Start-up Fuel Description Summary

Maple Cordwood

Run

Kindling

Weight

Wet Basis

(lbs)

Start-up

Fuel Weight

Wet Basis

(lbs)

Residual

Start-up

fuel weight

(lbs)

1 2.00 3.00 1.3

3 2.10 3.20 1.3

8 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

Table 6 – Fuel Measurement and Cordwood Description Summary – TEST

All tests conducted using Maple Cordwood

Run

Test Fuel

Wet Basis

(lbs)

Firebox

Volume

(ft3)

Fuel Loading

Density Wet

Basis

(lbs/f

t

3)

Test Fuel

Dry Basis

(lbs)

Test Fuel

Consumed

During Test

Dry Basis (lbs)

Nominal

Piece

Length

(in)

Table 7 – Dilution Tunnel Gas Measurements and Sampling Data Summary

Run

Length of Test

(min)

Average Dilution Tunnel Gas Measurements

Velocity

(ft/sec)

Flow Rate

(dscf/min)

Temperature

(°F)

1 99 19.61 213.3 91

2 385 20.17 225.6 77

4 395 19.91 219.5 77

9 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Table 8 – Test Configurations

Run Startup Procedures Combustion Air

1

Fuel Loading: Kindling and start-up fuel loaded together; a torch was used

for 60 seconds to establish a top-down fire. At 37 minutes placed fuel load

into the firebox. Loading required less than 1 minute to complete.

Door: For kindling and start-up fuel, loading door was closed by 150

seconds. Test fuel load: fuel loading door was closed 2 minutes and 30

seconds after loading.

Primary Air: Air control fully open for the entire test.

Secondary: No user control for secondary air.

Fan: N/A

Bypass: N/A

Fully open for

entire test.

2

Fuel Loading: Test fuel loaded onto coal bed generated by test number 1 by

45 seconds.

Door: Closed by 3 minutes.

Primary Air: Fully open, then set to full closed by 12 minutes.

Secondary: No user control for secondary air.

Fan: N/A

Bypass: N/A

Fully open for first

12 minutes, then

set to full closed.

3

Fuel Loading: Kindling and start-up fuel loaded together; a torch was used

for 60 seconds to establish a top-down fire. At 40 minutes placed fuel load

into the firebox. Loading required less than 1 minute to complete.

Door: For kindling and start-up fuel, loading door was closed by 150

seconds. Test fuel load: fuel loading door was closed 2 minutes and 30

seconds after loading.

Primary Air: Air control fully open for the entire test.

Secondary: No user control for secondary air.

Fan: N/A

Bypass: N/A

Fully open for

entire test.

4

Fuel Loading: Test fuel loaded onto coal bed generated by test number 3 by

40 seconds.

Door: Closed by 2 minutes 30 seconds.

Primary Air: Fully open, then set to 6” from left leg by 15:30 minutes.

Secondary: No user control for secondary air.

Fan: N/A.

Bypass: N/A

Fully open for first

15.5 minutes, then

set to 6” from left

leg.

10 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Section 2

Photographs/Appliance Description/Drawings

11 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Esse Engineering Ltd.

WarmHeart

Test Dates: August 4, 2020 – August 5, 2020

12 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Esse Engineering Ltd.

WarmHeart

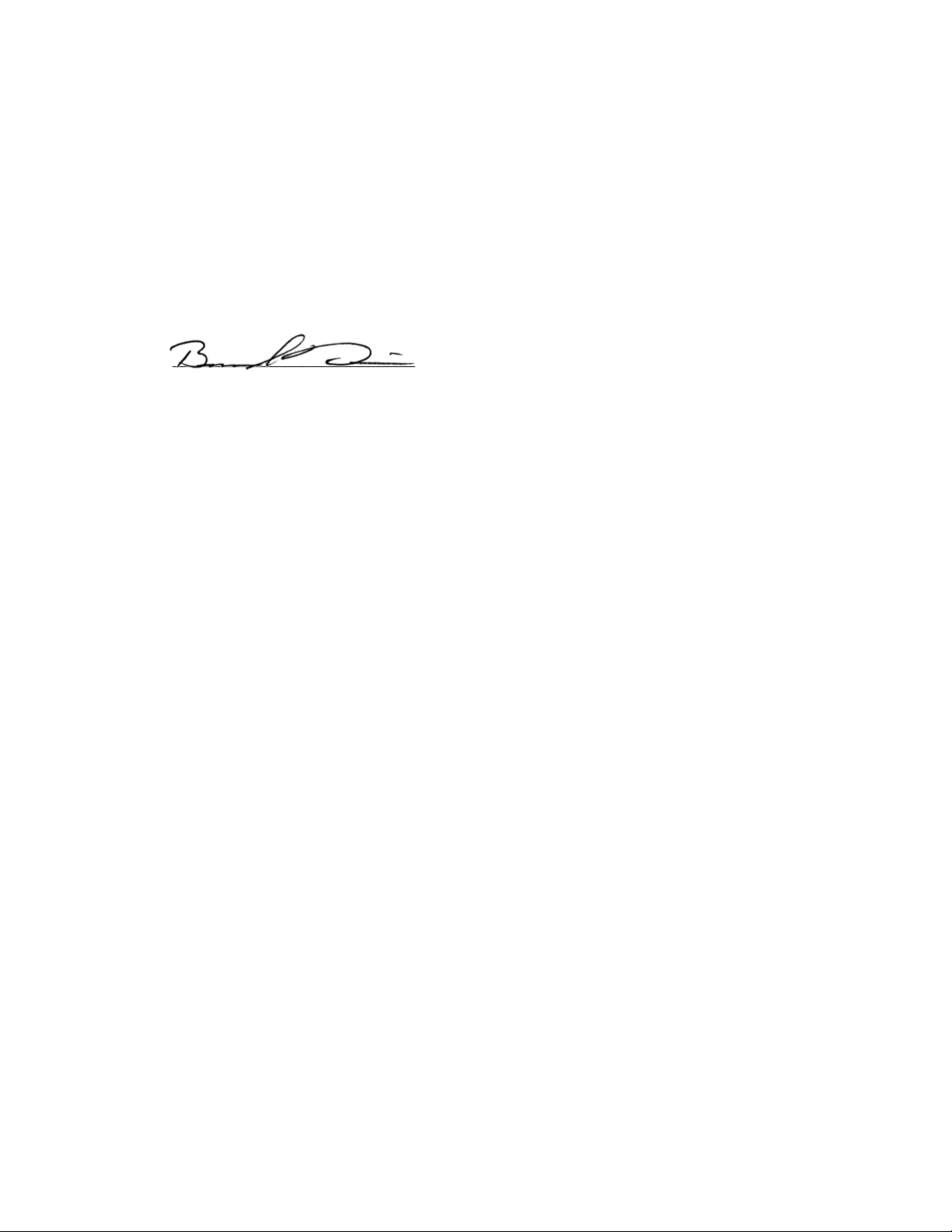

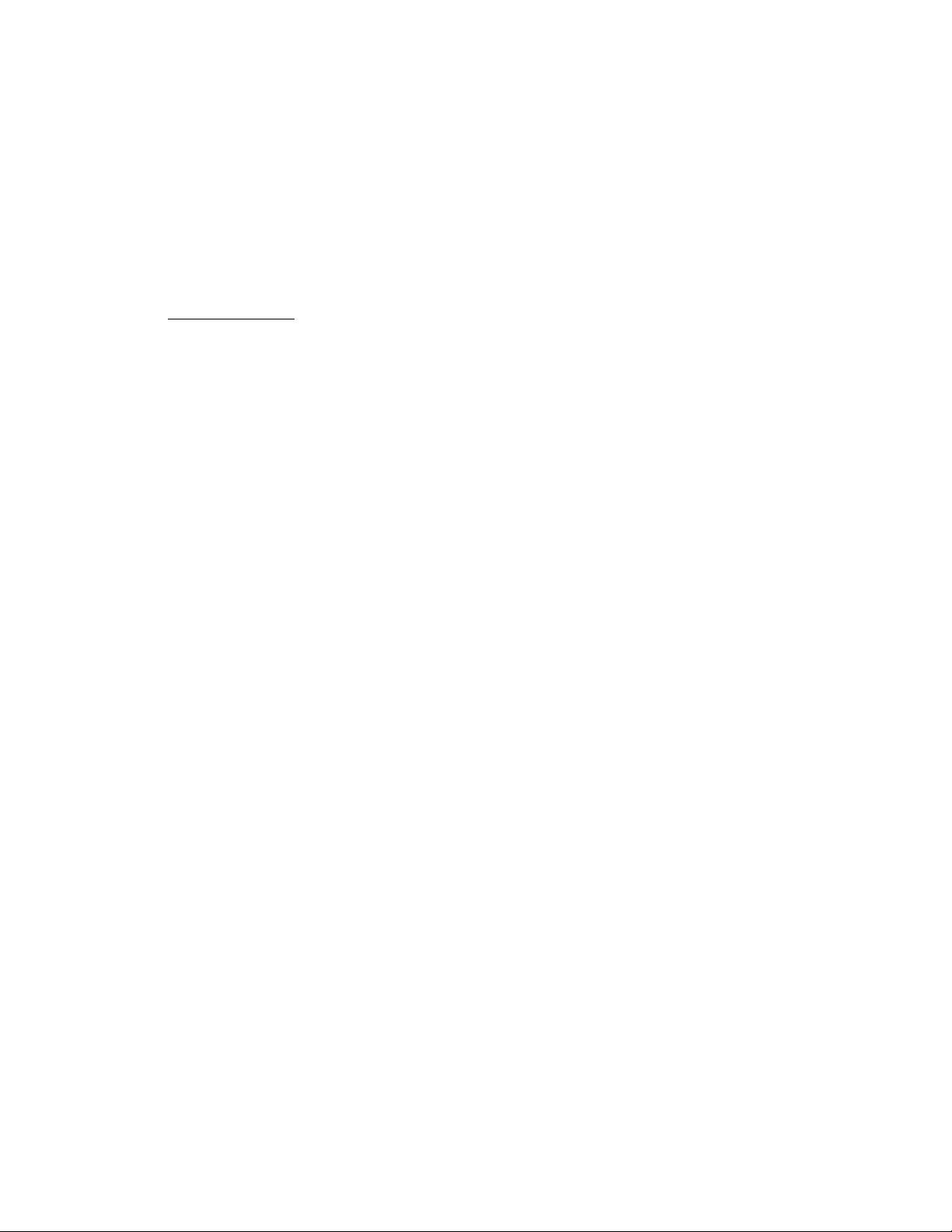

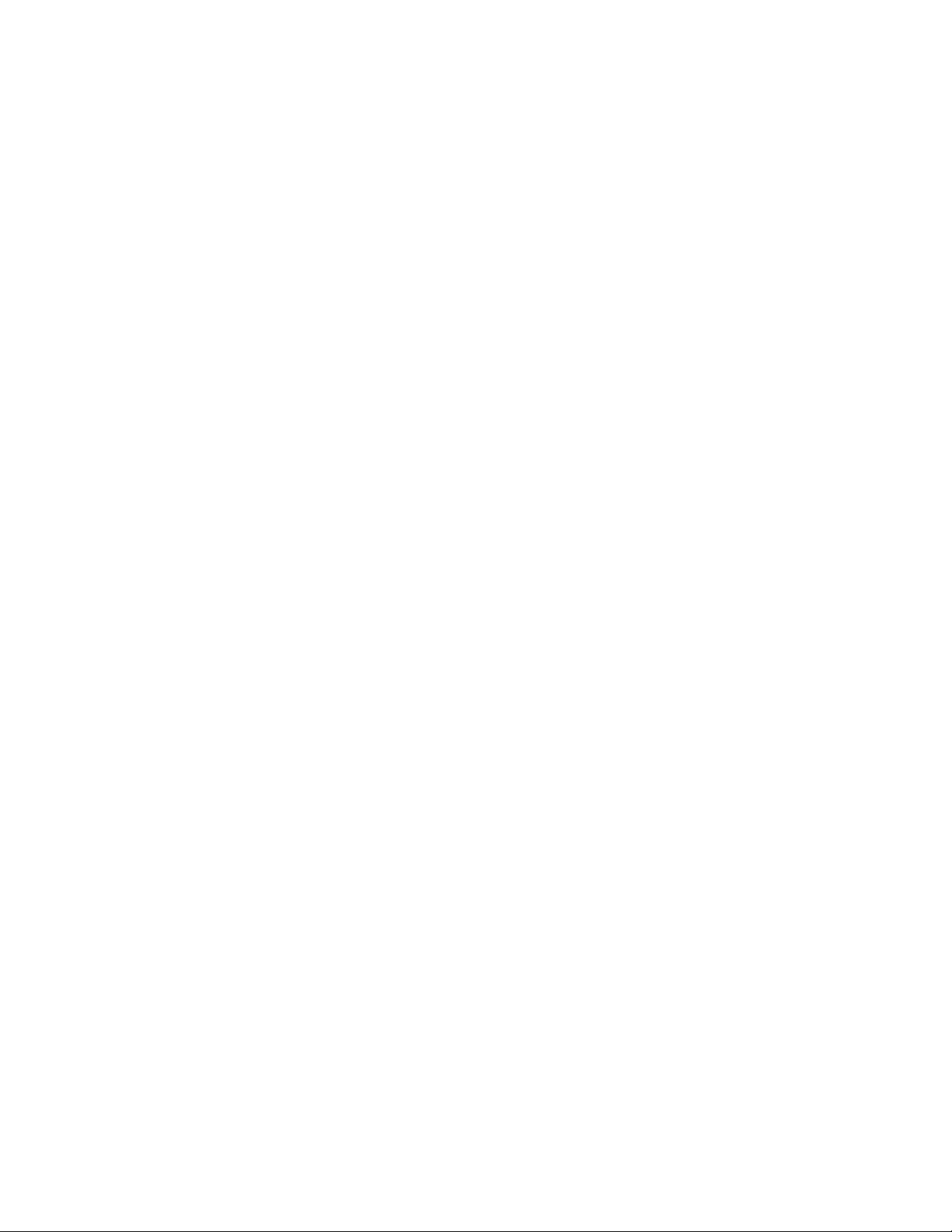

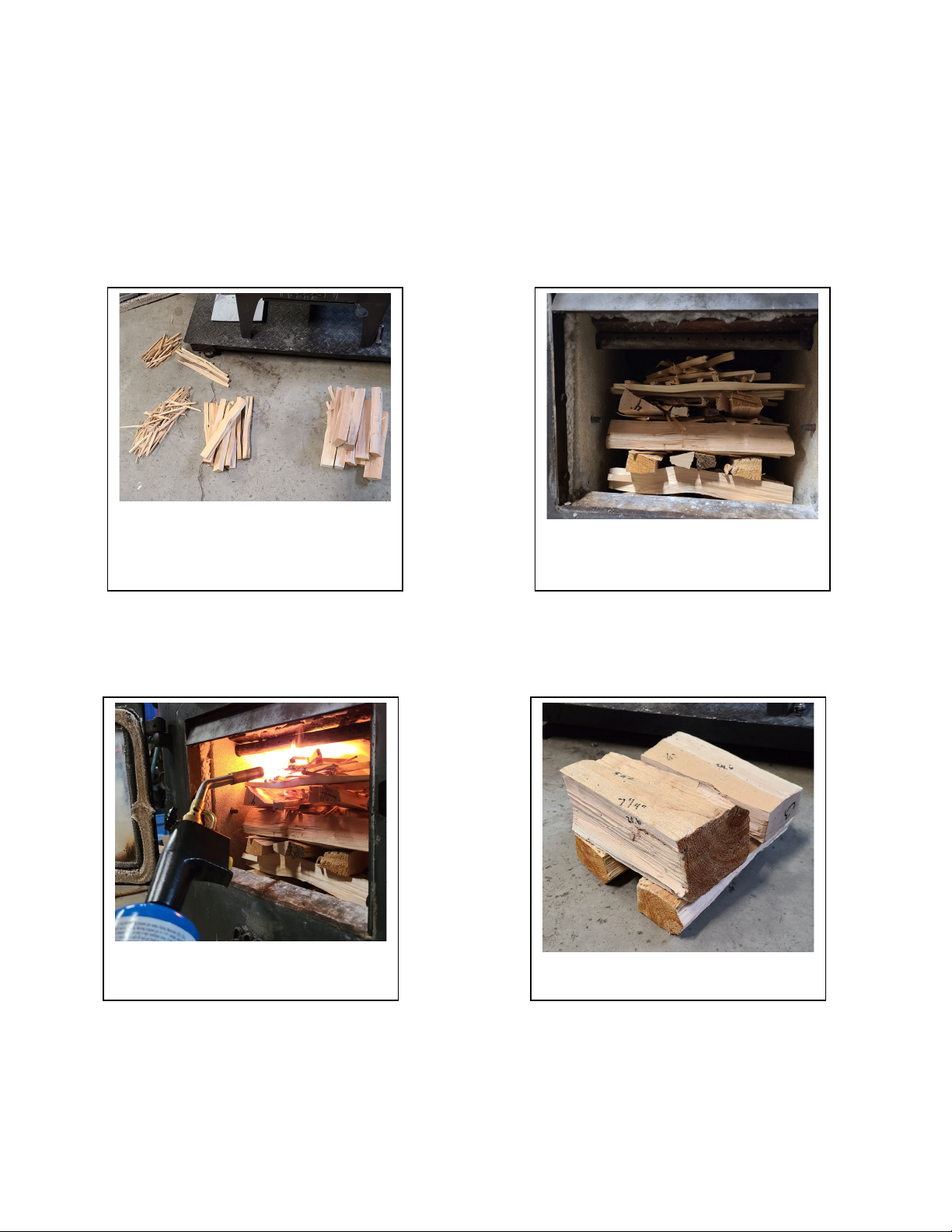

Run 1 – Kindling and start-up fuel Run 1 Kindling and start-up fuel

Run 1 – Ignition of kindling Run 1 Fuel load

13 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Esse Engineering Ltd.

WarmHeart

Run 1 Test Fuel Load In Stove Run 1 Remaining Coal Bed

Run 2 Test Fuel Load Run 2 – Test Fuel Loaded into Stove

14 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Run 3 – Kindling and start-up fuel Run 3 Ignition of kindling

Run 3 – Test Fuel Load Run 3 – Test Fuel Loaded into Stove

15 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Run 3 - Remaining Coal After Test Run 4 – Test Fuel Load

Run 4 – Test Fuel Loaded into Stove Run 4 – Air control setting

16 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Run 4 – Coal bed prior to stir Run 4 – Coal bed after stir

Run 4 - Remaining Coal After Test

17 of 161

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

WOOD HEATER DESCRIPTION

Appliance Manufacturer: Esse Engineering Ltd.

Wood Stove Model: WarmHeart, BakeHeart

Type: Freestanding Non-Catalytic Wood Fired Room Heater

WOOD HEATER INFORMATION

Materials of Construction: The unit is constructed primarily of cast iron and mild steel.

The firebox is lined with fire compressed vermiculite panels that measures 12.0” x 13.9”

at the rear. The feed door has a 12.8 x 9.4 glass panel and 13mm diameter glass fiber seal.

Air Introduction System: Air is introduced into three different areas of the fire chamber

and is controlled by one sliding control rod. Secondary air is introduced into the rear of

the fire box through the bottom, it is then channeled up into the secondary air tubes

located under the baffle. Air wash air is introduced through an opening in the bottom of

the fire box. It is then channeled up to a manifold across the top of the door, air is

directed down across the glass and into the fire chamber. A lower primary air orifice is

mounted on the firebox floor near the loading door. Air is routed through the bottom of

the firebox and into the lower orifice manifold, it is then directed horizontally into the

coal bed near the front of the combustion chamber.

Combustion Control Mechanisms: Combustion air control mechanism is a sliding rod

with flat plates attached that cover and uncover air inlets when the rod is moved from left

to right.

Combustor: N/A

Internal Baffles: A fire brick baffle is mounted above the secondary air tubes, a ½” thick

ceramic wool blanket rests on top for additional firebox insulation.

Other Features: The BakeHeart model has an oven mounted below the firebox, oven is

heated by heat transfer through the firebox bottom, flue gas passageway is not directed

around the oven. Additional testing was not required to include this model design.

Flue Outlet: The 6” diameter flue outlet is located at the rear of the top of the appliance.

WOOD HEATER OPERATING INSTRUCTIONS

Specific Written Instructions: See Section 4 of this report. All markings and

instruction materials were reviewed for content prior to printing.

Esse Engineering Ltd.

Model: WarmHeart, BakeHeart

Project Number: 0224WS009E

OMNI-Test Laboratories, Inc.

Section 3

Test Data by Run

19 of 161

OMNI-Test Laboratories, Inc.

Conditioning Data - ASTM E3053/ ASTM E2515

Manufacturer:

Model:

Tracking No.:

Project No.:

Test Date:

Technician:

Operation Category:

Elapsed Time

(hr) Scale(lb) Flue (F) Elapsed Time

(hr) Scale(lb) Flue(F)

00.0 221.6 26 2.8 354.0

15.2 301.0 27 1.5 226.0

21.7 203.0 28 0.8 196.0

31.2 159.0 29 0.3 180.0

40.7 147.0 30 0.3 302.4

50.2 147.0 31 4.8 350.0

67.2 392.0 32 1.8 243.0

72.0 297.0 33 1.3 200.0

81.2 227.0 34 0.9 183.0

90.7 194.0 35 0.5 170.0

10 0.2 177.0 36 0.2 160.0

11 7.5 429.0 37 5.5 405.0

12 2.1 327.0 38 1.8 251.0

13 0.9 253.0 39 1.1 206.0

14 0.4 220.0 40 0.5 186.0

15 0.1 201.0 41 0.0 173.0

16 5.5 452.0 42 5.8 399.0

17 1.4 276.0 43 1.9 271.0

18 0.7 232.0 44 1.5 209.0

19 0.3 201.0 45 1.1 189.0

20 9.8 386.0 46 0.6 178.0

21 2.5 373.0 47 0.3 164.0

22 1.2 236.0 48 0.1 153.0

23 0.8 212.0 49 5.9 378.0

24 0.3 194.0 50 2.0 238.0

25 9.1 366.0

Technician Signature:___________________________

Medium

Esse

WarmHeart

2400A

0224WS0009E

Sept, Oct. 2020

Ben Nelke

Control No. P-SSAR-0003 High Burn Run 1 Emissions (003)-EsseWarmheart

Fuel moisture between 19 - 25% db, operated at a medium burn rate.

20 of 161

This manual suits for next models

1

Table of contents