7

HL3 Series

MODEL /MODELE NO. INPUT BTU/H FOR USE WITH

NATURAL GAS

RADIATEUR A INFRAROUGE A FAIBLE INTENSITE

VOLTS A.C.

STARTING AMPS.

RUNNING AMPS.

120~60Hz

4.8

1.1

MANIFOLD PRESSURE

MIN. INLET PRESSURE

ORIFICE SIZE

3.5” WC

5.0” WC

#3 D.M.S

HEATER TYPE

VERSION

MIN. MOUNTING ANGLE:

COMBUSTION CHAMBER:

4” BC TITANIUM

FOR INDOOR USE

BRANT RADIANT HEATERS LIMITED

34 SCOTT AVE., PARIS, ONTARIO

TEL: 1-519-442-7823 WWW.BRANTRADIANT.COM

ANSI Z83.20b - 2011 CSA 2.32b - 2011 Low - Intensity Infrared Htr.

ANS Z83.20b - 2011 CSA - 2011 Low - Intensity Infrared Htr.

SERIAL NO.

0870 XXXX XXXX 0001

RE-VERBER-RAY LOW INTENSITY INFRARED HEATER

FOR INDOOR INSTALLATION ONLY. NOT FOR USE IN RESIDENTIAL DWELLING.

INSTALLATION À L’EXTÉRIEUR SEULEMENT. NE PAS INSTALLER DANS UN LOGEMENT.

MAX. MOUNTING ANGLE:

0 DEGREES

45 DEGREES

FOR STAINLESS STEEL UPGRADES THE

COMBUSTION TUBE IS UPGRADED TO 409

STAINLESS STEEL.

C1

10/11

HL3-40-125N 125,000/95,000

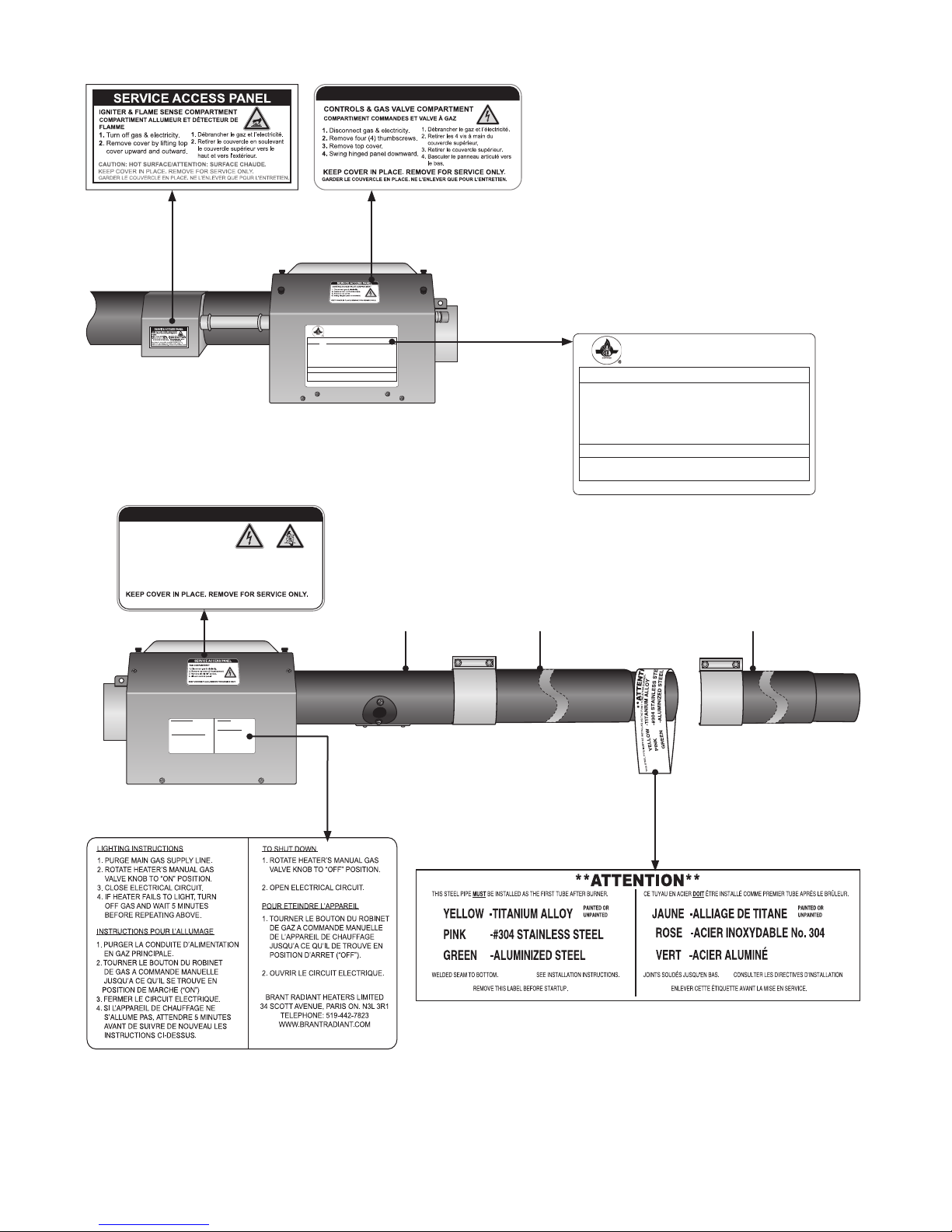

LIGHTING INSTRUCTIONS

1. PURGE MAIN GAS SUPPLY LINE.

2. ROTATE HEATER’S MANUAL GAS

VALVE KNOB TO “ON” POSITION.

3. CLOSE ELECTRICAL CIRCUIT.

4. IF HEATER FAILS TO LIGHT, TURN

OFF GAS AND WAIT 5 MINUTES

BEFORE REPEATING ABOVE.

INSTRUCTIONS POUR L’ALLUMAGE

1. PURGER LA CONDUITE D’ALIMENTATION

EN GAZ PRINCIPALE.

2. TOURNER LE BOUTON DU ROBINET

DE GAS A COMMANDE MANUELLE

JUSQU’A CE QU’IL SE TROUVE EN

POSITION DE MARCHE (“ON”)

3. FERMER LE CIRCUIT ELECTRIQUE.

4. SI L’APPAREIL DE CHAUFFAGE NE

S’ALLUME PAS, ATTENDRE 5 MINUTES

AVANT DE SUIVRE DE NOUVEAU LES

INSTRUCTIONS CI-DESSUS.

TO SHUT DOWN

1. ROTATE HEATER’S MANUAL GAS

VALVE KNOB TO “OFF” POSITION.

2. OPEN ELECTRICAL CIRCUIT.

POUR ETEINDRE L’APPAREIL

1. TOURNER LE BOUTON DU ROBINET

DE GA A COMMANDE MANUELLE

DE L’APPAREIL DE CHAUFFAGE

USU’A CE U’IL DE TROUVE EN

POSITION D’ARRET “OFF”.

2. OUVRIR LE CIRCUIT ELECTRIUE.

BRANT RADIANT HEATERS LIMITED

34 SCOTT AVENUE, PARIS ON. N3L 3R1

TELEPHONE 5144223

WWW.BRANTRADIANT.COM

Rating

Plate

Controls Compartment

Fan Compartment

Combustion Chamber

MODEL /MODELE NO. INPUT BTU/H FOR USE WITH

NATURAL GAS

RADIATEUR A INFRAROUGE A FAIBLE INTENSITE

VOLTS A.C.

STARTING AMPS.

RUNNING AMPS.

120~60Hz

4.8

1.1

MANIFOLD PRESSURE

MIN. INLET PRESSURE

ORIFICE SIZE

3.5” WC

5.0” WC

#3 D.M.S

HEATER TYPE

VERSION

MIN. MOUNTING ANGLE:

COMBUSTION CHAMBER:

4” BC ALUMINUM

FOR INDOOR USE

BRANT RADIANT HEATERS LIMITED

34 SCOTT AVE., PARIS, ONTARIO

TEL: 1-519-442-7823 WWW.BRANTRADIANT.COM

ANSI Z83.20b - 2011 CSA 2.32b - 2011 Low - Intensity Infrared Htr.

ANS Z83.20b - 2011 CSA - 2011 Low - Intensity Infrared Htr.

SERIAL NO.

0870 XXXX XXXX 0001

RE-VERBER-RAY LOW INTENSITY INFRARED HEATER

FOR INDOOR INSTALLATION ONLY. NOT FOR USE IN RESIDENTIAL DWELLING.

INSTALLATION À L’EXTÉRIEUR SEULEMENT. NE PAS INSTALLER DANS UN LOGEMENT.

MAX. MOUNTING ANGLE:

0 DEGREES

45 DEGREES

FOR STAINLESS STEEL UPGRADES THE

COMBUSTION TUBE IS UPGRADED TO 409

STAINLESS STEEL.

C1

10/11

HL3-40-125N 125,000/95,000

HL3

SERVICE ACCESS PANEL

SERVICE ACCESS PANEL

COMPARTIMENT VENTILATEUR

FAN COMPARTMENT

1. Disconnect gas & electricity.

2. Remove top cover

(2 thumbsscrews).

3. Remove six (6) 1/4” screws.

4. Lift and remove panel.

1. Débrancher le gaz et l’electricité.

2. Retirer les 2 vis à main du couvercle

supérieur.

3. Retirer les 6 vis 1/4 po.

4. Soulever et retirer le panneau.

GARDER LE COUVERCLE EN PLACE. NE L’ENLEVER QUE POUR L’ENTRETIEN.

Radiant Tube(s)

2.0 Safety • Safety Labels and Locations

16” Burner Tube

SAMPLE

Lighting /Shut Down Instructions Label

Yellow Titanium Alloy Tag

(150,000 BTU/H models and greater)

F/N: LLTB026

F/N: LLTB025R

F/N: LLTB024L