Super Saver Bunsen Jet Brooder with SPI Table of Contents

Table of Contents

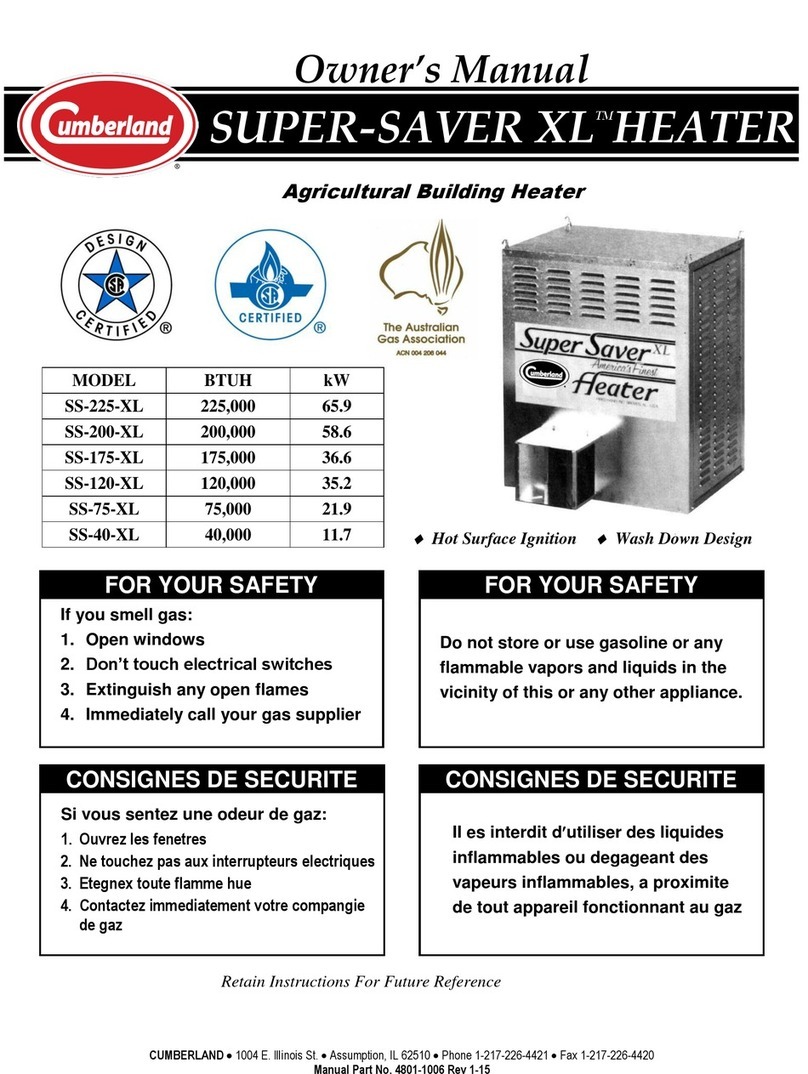

1. RATINGS AND SPECIFICATIONS......................................................................................................1

1.1. RATINGS................................................................................................................................................1

1.2. GAS PRESSURE REQUIREMENTS ............................................................................................................1

1.3. CAUTION!MINIMUM CLEARANCES......................................................................................................1

2. WARNINGS ..............................................................................................................................................2

3. LIMITED WARRANTY..........................................................................................................................3

4. PHYSICAL DESCRIPTION / DRAWING OF PRODUCT.................................................................3

5. ASSEMBLY...............................................................................................................................................4

5.1. TOOLS REQUIRED..................................................................................................................................4

5.2. SUPPORT RING ASSEMBLY ....................................................................................................................4

5.3. BURNER UNIT ASSEMBLY .....................................................................................................................5

5.4. BURNER UNIT ASSEMBLY .....................................................................................................................6

5.5. FINAL BROODER ASSEMBLY..................................................................................................................6

5.6. GAS TUBING ASSEMBLY........................................................................................................................8

6. INSTALLATION ......................................................................................................................................9

6.1. HANGING THE UNIT...............................................................................................................................9

6.1.1. Hanging SPI Aluminum Brooder with 34" or 48" Diameter Canopy ..........................................9

6.1.2. Hanging SPI Galvanized Brooder with 34" Diameter Canopy...................................................10

6.2. GAS HOOKUP.......................................................................................................................................11

6.2.1. Connection of gas hose to brooder..............................................................................................11

6.2.2. Checking Manifold Gas Pressure................................................................................................11

7. OPERATING INSTRUCTIONS ...........................................................................................................12

7.1. PLACING BROODER IN SERVICE...........................................................................................................12

7.2. TAKING BROODER OUT OF SERVICE ....................................................................................................12

7.3. THERMOSTAT SETTINGS ......................................................................................................................12

8. MAINTENANCE....................................................................................................................................12

9. TROUBLESHOOTING GUIDE............................................................................................................13