Esta OILMAC 800 User manual

OPERATING INSTRUCTIONS

The World of Extraction

OILMAC

Oil Mist Extractor

Your purchase of an ESTA machine has

been a good decision. The design of

our quality products complies with the

latest state of the art. ESTA products

have been devised to provide for clean

air at the workplaces at which they are

applied. This results in an even more

enhanced level of quality and longer

machine times and, particularly, healthier

working conditions. Should you have

any questions pertaining to suction tech-

nology issues, please feel free to contact

us at any time. Our experts will be gladly

at your disposal.

Your ESTA Absaugtechnik Team

The World of Extraction

www.esta.com

Welcome to the sphere of suction

technology

Operating Instructions

OILMAC 800

OILMAC 1600

with backup filter stage H13

OILMAC 800 (order no.: 56201)

OILMAC 1600 (order no.: 56202)

with backup filter stage combination mesh

OILMAC 800 (order no.: 56211)

OILMAC 1600 (order no.: 56212)

Do not use this device unless you have

read the operating instructions and understood them.

Original operating instructions

56201-08-08

2

OILMAC

56201-52-08

Edition notice

Original operating instructions

Document no.: 56201-08-08

Publishing date: 11/04/2017

Type of device: OILMAC oil mist separator

Article no.: 56.201 // 56.202 // 56.211 // 56.212 and versions

Publisher

ESTA Apparatebau GmbH & Co. KG Tel.: +49 (0) 73 07 80 4 -0

Gotenstr. 2-6 Fax: +49 (0) 73 07 80 4 -500

Germany www.esta.com

Copyright notice (per DIN ISO 16016:2007-12)

Transfer or reproduction of this document, or the use or communication of its content, is forbidden

without explicit consent. Violators will be liable for damages. All rights to patent, utility or design

registration are reserved.

56201-52-08

OILMAC

3

Contents

Contents .................................................................................................................................3

1. General instructions........................................................................................................5

2. Product identification......................................................................................................6

2.1 Technical data .............................................................................................................6

2.1.1 With backup filter stage H13.................................................................................6

2.1.2 With backup filter stage combination mesh...........................................................7

2.2 Intended application..............................................................................................7

2.2.1 Ambient conditions ...............................................................................................7

2.2.2 Intended use .........................................................................................................8

2.2.3 Improper use.........................................................................................................8

2.2.4 Reasonably foreseeable misuse...........................................................................8

3. Product Description ........................................................................................................9

3.1 Picture of the device..............................................................................................9

3.1.1 OILMAC 800 .........................................................................................................9

3.1.2 OILMAC 1600 .......................................................................................................9

3.2 Separation and filter elements ............................................................................10

3.2.1 Pre-filter .............................................................................................................. 10

3.2.2 Backup filter stage ..............................................................................................11

3.3 Functional description .........................................................................................12

4. Safety instructions ........................................................................................................12

4.1 Hazard categories...............................................................................................12

4.2 Symbol explanation............................................................................................. 13

4.3 General safety instructions..................................................................................13

4.4. Preventing mechanical hazards ..........................................................................14

4.5 Preventing electrical hazards ..............................................................................14

4.6 Preventing material and substance hazards .......................................................15

5. Delivery and commissioning........................................................................................16

5.1 Delivery and transport .........................................................................................16

5.2Connection..........................................................................................................17

5.2.1 Electrical connection...........................................................................................18

5.2.2 Suction line connection.......................................................................................19

5.2.3 Siphon connection ..............................................................................................20

5.3 Function check.................................................................................................... 21

5.3.1 Rotation direction monitoring ..............................................................................21

5.4 Commissioning ...................................................................................................22

5.5 Troubleshooting during commissioning...............................................................22

6. Operating instructions ..................................................................................................23

6.1 Operating the device ...........................................................................................23

7. Maintenance & troubleshooting................................................................................... 23

7.1 Maintenance instructions ....................................................................................23

7.2 Inspection and maintenance intervals .................................................................25

7.2.1 Spare and wear parts .........................................................................................26

7.3 Cleaning and replacing the separation and filter elements..................................27

7.3.1 Cleaning and replacement intervals....................................................................28

7.3.2 Pre-separator......................................................................................................28

7.3.3 Pre-filter aluminium wire mesh............................................................................ 29

4

OILMAC

56201-52-08

7.3.4 Pre-filter filter pads.............................................................................................. 30

7.3.5 Pre-filter labyrinth filter........................................................................................ 30

7.3.6 Pre-filter labyrinth filter........................................................................................ 31

7.4. Backup filter stage filter element .........................................................................32

7.4.1 Backup filter stage H13....................................................................................... 32

7.4.2 Backup filter stage combination mesh ................................................................33

7.5 Siphon connection maintenance .........................................................................34

7.6 Cleaning filter and separation elements that can be cleaned.............................. 35

7.7 Clean the device .................................................................................................35

7.8 Store the device ..................................................................................................35

7.9 Troubleshooting .................................................................................................. 36

8. Disposal .........................................................................................................................38

8.1 Disposing of the separation and filter elements ..................................................38

8.2 Dispose of the device..........................................................................................38

9. Optional equipment....................................................................................................... 39

9.1 Start-up with potential-free contact .....................................................................39

9.2 Air vents ..............................................................................................................40

9.2.1 Connecting the discharge airline to discharge air ports ......................................41

9.3 Motor protection switch .......................................................................................41

9.4 Set-up on adjacent stand ....................................................................................41

9.5 Mobile design......................................................................................................42

9.6 Saturation display................................................................................................ 43

10. Declarationen.................................................................................................................44

10.1 Declaration of incorporation for incomplete machines pursuant to EC guideline

2006/42/EC, Appendix II, Part 1 B ......................................................................44

10.1.1 OILMAC 800 (without ESTA motor circuit breaker) ............................................44

10.1.2 OILMAC 1600 (without ESTA motor circuit breaker) ..........................................46

10.2 EU/EC Declaration of conformity for machines pursuant to EU/EC guideline

2006/42/EC, Appendix II, Part 1 A ......................................................................48

10.2.1 OILMAC 800 (with ESTA motor circuit breaker) .................................................48

10.2.2 OILMAC 1600 (with ESTA motor circuit breaker) ...............................................49

Notes.....................................................................................................................................50

Notes.....................................................................................................................................51

Notes........................................................................................................................................

56201-52-08

OILMAC

5

1. General instructions

Before operation, all persons who are to use the device or perform maintenance

on it must be provided with information, instructions and training in using the device

and on the substances for which it is to be used, including the procedure for safe

disposal of the collected material. Responsibilities must be clearly established for

the following:

Installation

Commissioning

Operation

Maintenance and repairs

Read the operating instructions carefully before working with the device.

The device must be used only by persons who have been instructed in its handling

and are explicitly authorised to use it.

Always keep the operating instructions at the place where the device is being used,

so that it can be seen by personnel at all times.

6

OILMAC

56201-52-08

2. Product identification

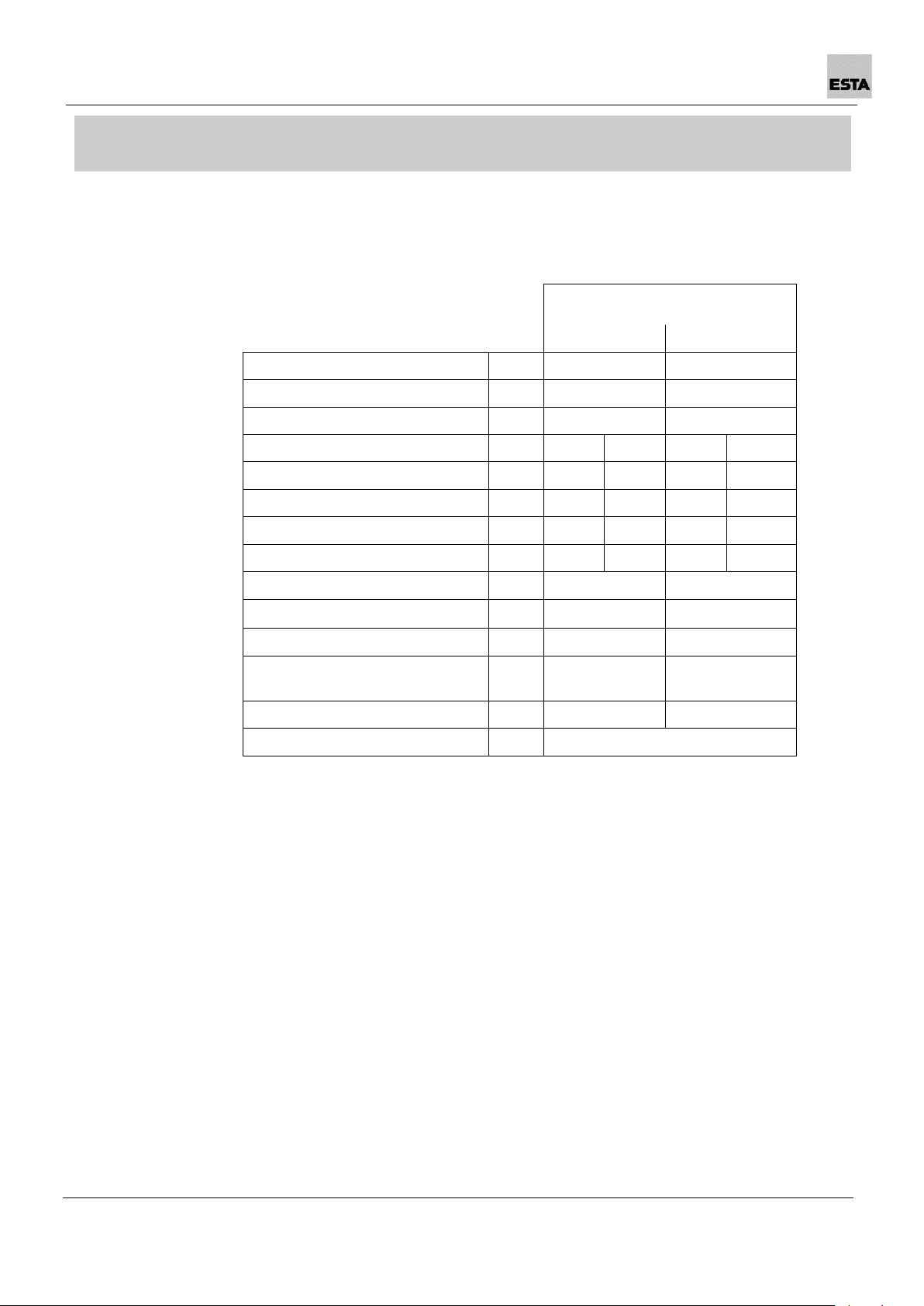

2.1 Technical data

2.1.1 With backup filter stage H13

We reserve the right to make technical

changes.

OILMAC

800

1600

Item no.

56201

56202

Max. volume flow

[m³/h]

840

1,800

Drive power

[kW]

0.55

**

1.1

**

Connection voltage

[V]

400

**

400

**

Nominal frequency

[Hz]

50

**

50

**

Nominal current

[A]

1.5

**

2.4

**

Circuit breaker

[A]

16

**

16

**

Protection class

IP 54

IP 54

Intake port ø

[mm]

200

250

Dimensions (L x W x H)

[mm]

1,140x685x475

1,270x685x805

Average sound pressure level

LpA

[dBA]

69

71

Weight

[kg]

approx. 80

approx. 130

Production year

See model plate

* Using the enveloping surface method DIN EN ISO 3744, measured at minimum volume flow; noise measurement margin

of error approx. 4 dBA

** Custom voltage on request

56201-52-08

OILMAC

7

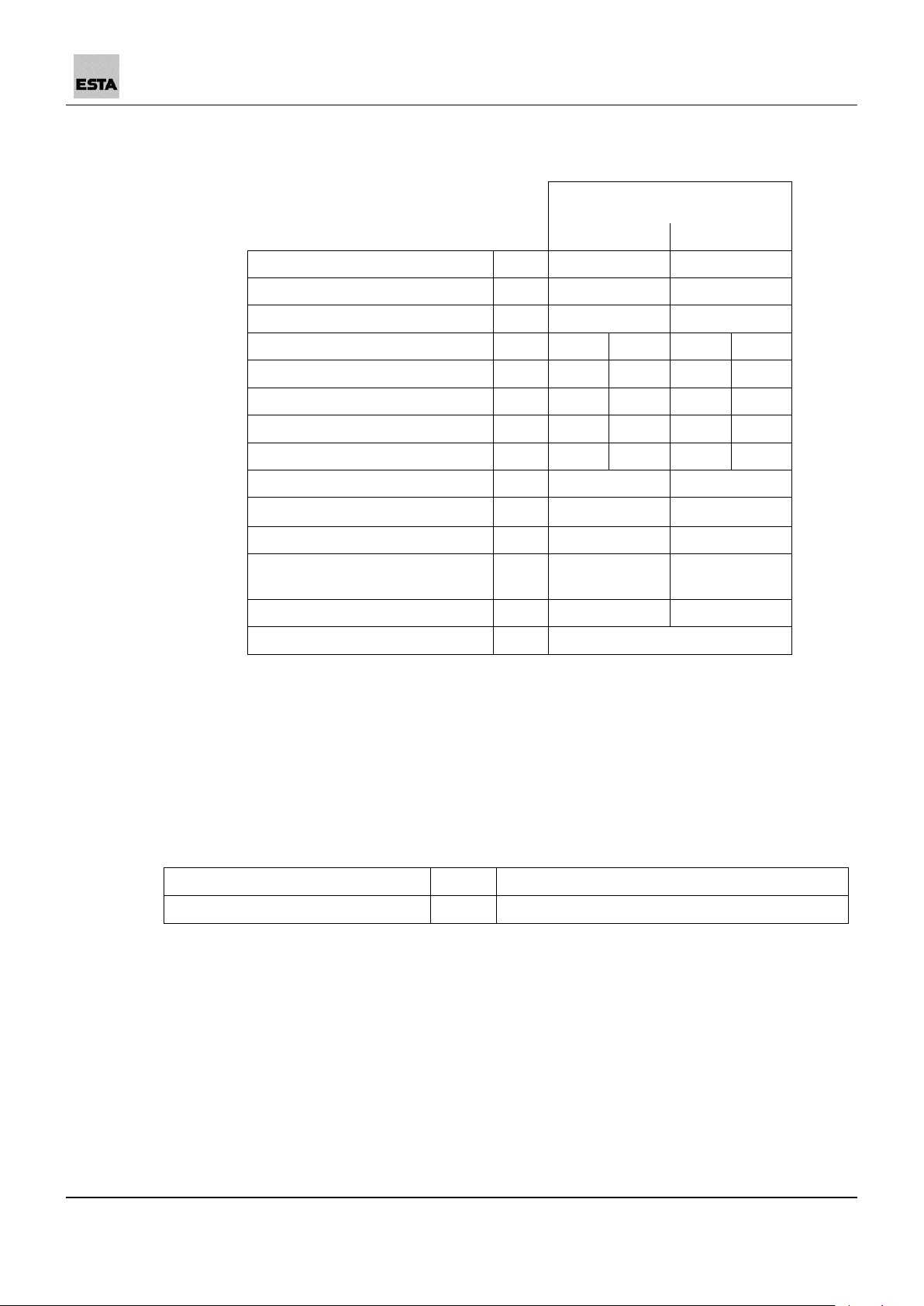

2.1.2 With backup filter stage combination mesh

We reserve the right to make technical

changes.

OILMAC

800

1600

Item no.

56211

56212

Max. volume flow

[m³/h]

840

1,800

Drive power

[kW]

0.55

**

1.1

**

Connection voltage

[V]

400

**

400

**

Nominal frequency

[Hz]

50

**

50

**

Nominal current

[A]

1.5

**

2.4

**

Circuit breaker

[A]

16

**

16

**

Protection class

IP 54

IP 54

Intake port ø

[mm]

200

250

Dimensions (L x W x H)

[mm]

1,140x685x475

1,270x685x805

Average sound pressure level

LpA

[dBA]

69

71

Weight

[kg]

approx. 80

approx. 130

Production year

See model plate

* Using the enveloping surface method DIN EN ISO 3744, measured at minimum volume flow; noise measurement margin

of error approx. 4 dBA

** Custom voltage on request

2.2 Intended application

2.2.1 Ambient conditions

Ambient temperature

[°C]

+5 +40

Rel. humidity

[%]

30 - 70

8

OILMAC

56201-52-08

2.2.2 Intended use

The device has been manufactured based on state-of-the-art technology and

according to recognized safety regulations and must be used as intended:

For commercial use, such as in industrial enterprises and workshops.

For the separation of aerosols (e.g. cooling lubricant) which arise during the

mechanical processing of metallic parts.

For installation on a processing machine.

Approved for air recirculation operation with backup filter stage H13.

Approved for air extraction operation with backup filter stage combination

mesh.

Other applications are considered unintended use. ESTA is not liable for damages

due to unintended use!

The manufacturer sets up the device according to the operator’s information.

2.2.3 Improper use

The device has been manufactured according to the state of the art and recognized

safety regulations. Unintended use may cause hazards.

Therefore:

Do not use or store outdoors.

Do not change the location of the device during suction operation.

Do not set up or operate in dust/gas-explosive areas.

Do not use in painting operations.

Do not use in food operations.

Do not suck up aggressive gases.

2.2.4 Reasonably foreseeable misuse

Do not suck up hot embers, such as cigarette butts.

Do not cause complete closure of the suction openings.

56201-52-08

OILMAC

9

3. Product Description

3.1 Picture of the device

3.1.1 OILMAC 800

3.1.2 OILMAC 1600

Intake port

Fan unit with motor

Filter unit

Inlet element

Intake port

Fan unit with

motor

Filter unit

Inlet element

10

OILMAC

56201-52-08

3.2 Separation and filter elements

3.2.1 Pre-filter

The separation and filter elements are designed so that the air is filtered

mechanically through several stages of filtration.

The pre-separator consists of the following filter elements:

1. Pre-filter metal mesh

2. Pre-filter fibre mat

3. Main separator labyrinth filter

4. Pre-filter fibreglass mat

1

1

2

3

2

4

56201-52-08

OILMAC

11

3.2.2 Backup filter stage

The separation and filter elements are designed so that the air is filtered

mechanically through several stages of filtration.

Depending on the design, the backup filter is designed as:

1. Backup filter stage H13

2. Backup filter combination mesh

12

OILMAC

56201-52-08

3.3 Functional description

The device is equipped with a three-phase motor which drives a radial fan.

Due to the negative pressure created by the fan, air containing oil and emulsion is

drawn from the processing machine through the suction hose connected to the

device's intake port. Filters located in the filter housing reliably separate dust

particles and oil and emulsion residue. The purified air is returned through outlet

openings (with backup filter stage H13) at the top of the device or a corresponding

discharge air line (the combination mesh with a backup filter stage.

The housing is designed so that separated, fluid oil and emulsion residue at the

bottom of the housing accumulate and can be drained through a siphon

connection.

Separated cooling lubricant can contain impurities which could negatively affect

machine availability in closed systems.

4. Safety instructions

4.1 Hazard categories

Safety instructions and cross-topic information are indicated in this manual by

symbols.

Based on the severity of the hazard, the hazard warnings are categorized as

follows:

DANGER

Hazard warning about an immediate danger to people.

Failure to comply can lead to severe injury or death.

WARNING

Warning about a recognisable hazard.

Failure to comply can lead to severe injury or death, and can destroy the device

or parts thereof.

CAUTION

Instruction about a hazard.

Failure to comply can lead to mild injury and to damage to the device.

56201-52-08

OILMAC

13

4.2 Symbol explanation

Further information

Reference to ESTA customer service

Reference to legal regulations

4.3 General safety instructions

During extraction, the volume flow returned from the device into the room should

be no more than 50% of the air supplied. With open room ventilation, supply air

flow should be assumed as equal to the room volume every hour. This means that

the rate of air replacement must be once per hour.

Supply air flow [m³/h] = room volume [m³] air replacement rate [1/h]

Example:

When the device is operating at the nominal airflow volume of 1,060 m³/h, the

same volume of fresh air must be supplied. This occurs with natural ventilation if

the volume of the work room is 1,060 m³ (e.g., 353 m² surface with a 3 m ceiling

height).

According to work equipment user directives 2009/104/EG and TRGS 560, safety

devices for prevention or removal of hazards must be regularly maintained and

regularly inspected by an expert for safe, flawless operation.

In all emergencies, disconnect the device from the power supply immediately.

If there is a fire, alert the fire department immediately, and contain the fire by

appropriate means. Therefore keep a suitable extinguishing agent near the device

before start-up and during operation.

14

OILMAC

56201-52-08

4.4. Preventing mechanical hazards

DANGER

Risk of injury posed by the drawing-in or catching of hair or loose items (e.g. chains,

hair, ties, etc.).

Observe the safety regulations for work on devices with rotating parts!

Before working on the device, turn it off and secure it against unintentional

reactivation.

When working on the device, tie back long hair or wear a hairnet!

When working on the device, do not wear any loose items (chains, ties, etc.).

WARNING

Crushing hazard due to loose or open covers

Keep covers closed during operation!

Before working on the device, turn it off and secure it against unintentional

reactivation.

Seal inspection openings securely after working on the device.

All movable machine parts driven by electric motors must be covered by fixed,

securely fastened protective covers that can be removed only with tools.

4.5 Preventing electrical hazards

DANGER

Electric shock from high voltages

Follow the safety rules for working with electrical devices!

Before working on the device, disconnect it from the voltage supply.

Any work on the electrical grid and on live components parts may only be

performed by an electrician.

DANGER

Residual hazard from loose or open covers

Keep covers closed during operation!

Any work on the electrical grid and on live components parts may only be

performed by an electrician.

All electrical parts must be covered by fixed, securely fastened protective covers that

can be removed only with tools. The device complies with Protection Class I

according to EN 60 335.

After use, before moving the device to another site and before cleaning,

maintenance, or replacement or removal of movable parts, switch off the device and

secure it from reactivation.

56201-52-08

OILMAC

15

4.6 Preventing material and substance hazards

CAUTION

Damage from improper handling of separated substances

Maintenance, cleaning, repair and emptying work must be done only by

expert personnel.

Observe the instructions of the cooling lubricant manufacturer about

handling these substances.

Absorb leaks with binding agents and dispose of them according to local

regulations.

Wear personal protective equipment.

- Gloves (impermeable and resistant to cooling lubricant)

- Aprons (impermeable and resistant to cooling lubricant)

- Protective clothing

- Respirator mask (particle filter class P3)

CAUTION

Damage from improper filter installation

Set up locally filtered forced-air ventilation where the device is being

maintained, inspected, cleaned or disposed of.

Operate the device only with the complete filtration system.

Always pay attention to the arrangement and installation location of the

filters.

Wear personal protective equipment.

- Gloves (impermeable and resistant to cooling lubricant)

- Aprons (impermeable and resistant to cooling lubricant)

- Protective clothing

- Respirator mask (particle filter class P3)

The people assigned to cleaning work must be instructed on the aspirated toxic

materials. Harm to bystanders and the environment must be prevented by all

means.

16

OILMAC

56201-52-08

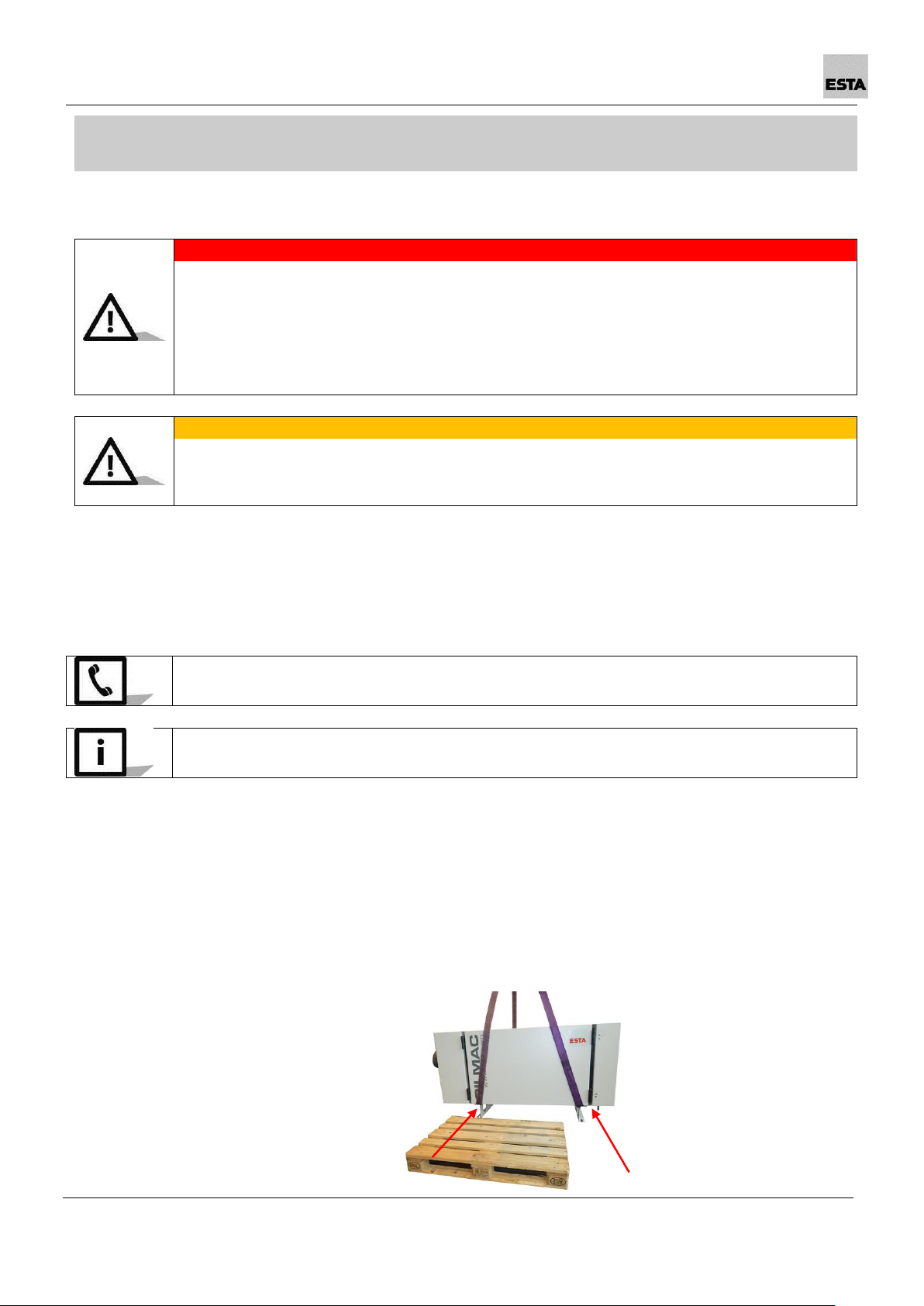

5. Delivery and commissioning

5.1 Delivery and transport

DANGER

Danger from falling device

Do not walk under heavy loads.

The lifting equipment must be designed for the weight of the device.

Only attach the lifting equipment to the marked points.

(See illustration)

Do not suspend from the motor.

WARNING

Crushing hazard if the device settles during transport

Secure the device during transport.

Wear safety shoes.

At delivery, the device is fastened to a pallet. Remove the protective cover and

floor securing devices. Inspect the delivery for completeness.

Please inspect the device for transportation damage when it arrives. Damage

determined must be reported and documented immediately.

ESTA customer service: +49 (0) 7307 804 - 0

Make sure the floor has adequate weight capacity and can be properly driven on

when transporting the device.

When transporting to the installation location, transport the device (leave pallet

secured below the device) with a forklift or lift truck.

To place it on the processing machine, use

suitable slings,

guide these under the device,

hang these on a suitable crane or the fork of the forklift. Also pay attention

here to the illustration!

56201-52-08

OILMAC

17

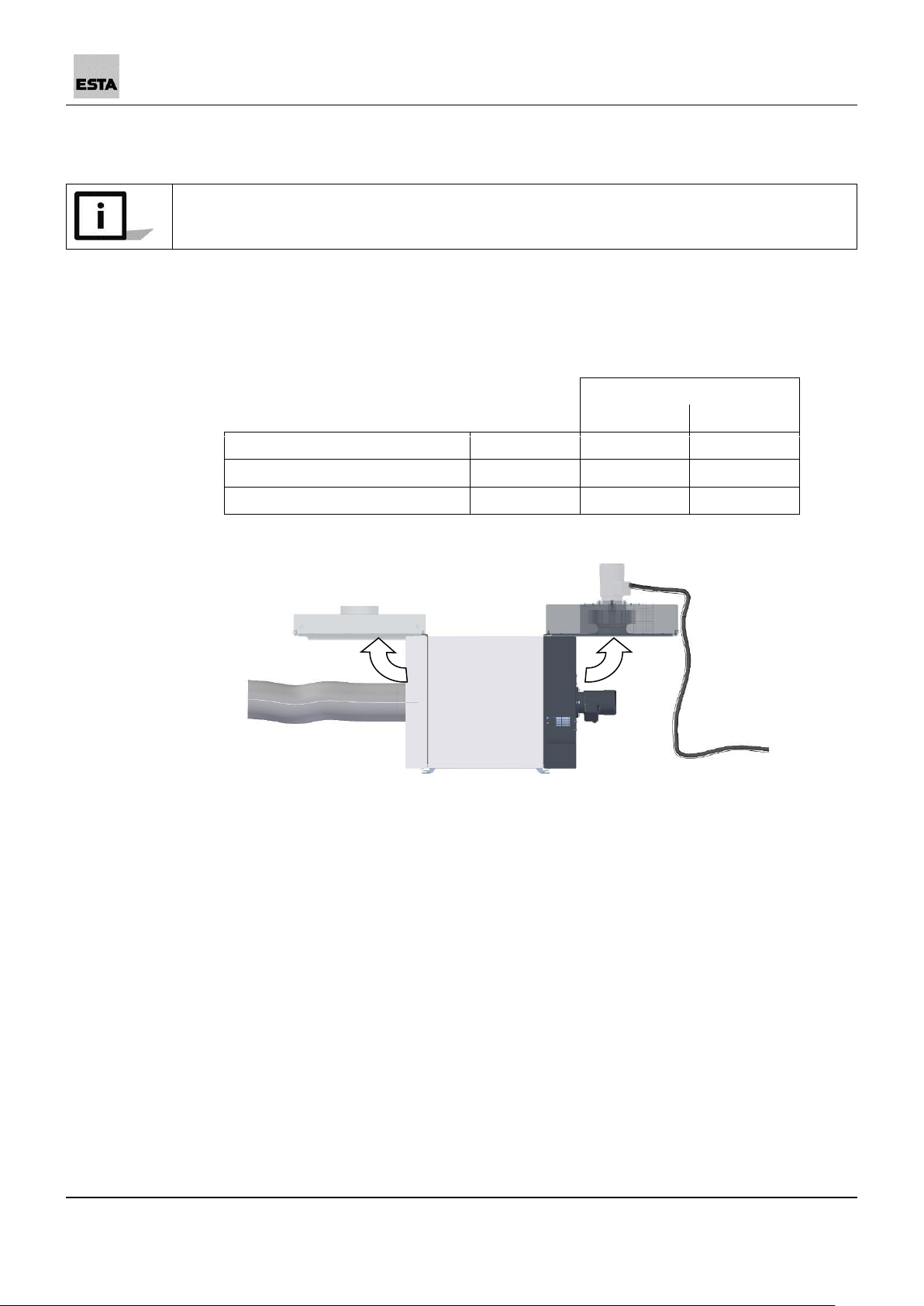

5.2 Connection

Before establishing cable connections between the device and the mains, check

whether the operating voltage specified on the rating plate matches that of the

mains.

The device must always be set up horizontally on a rigid, vibration-insulated

surface. Bolt the device tightly together with the processing machine.

In so doing, watch out for the minimum required clearances from ceilings and walls.

OILMAC

800

1600

Top of the device (air outlet)

[mm]

> 800

> 800

Fan unit

[mm]

> 800

> 800

Intake port

[mm]

> 800

> 800

18

OILMAC

56201-52-08

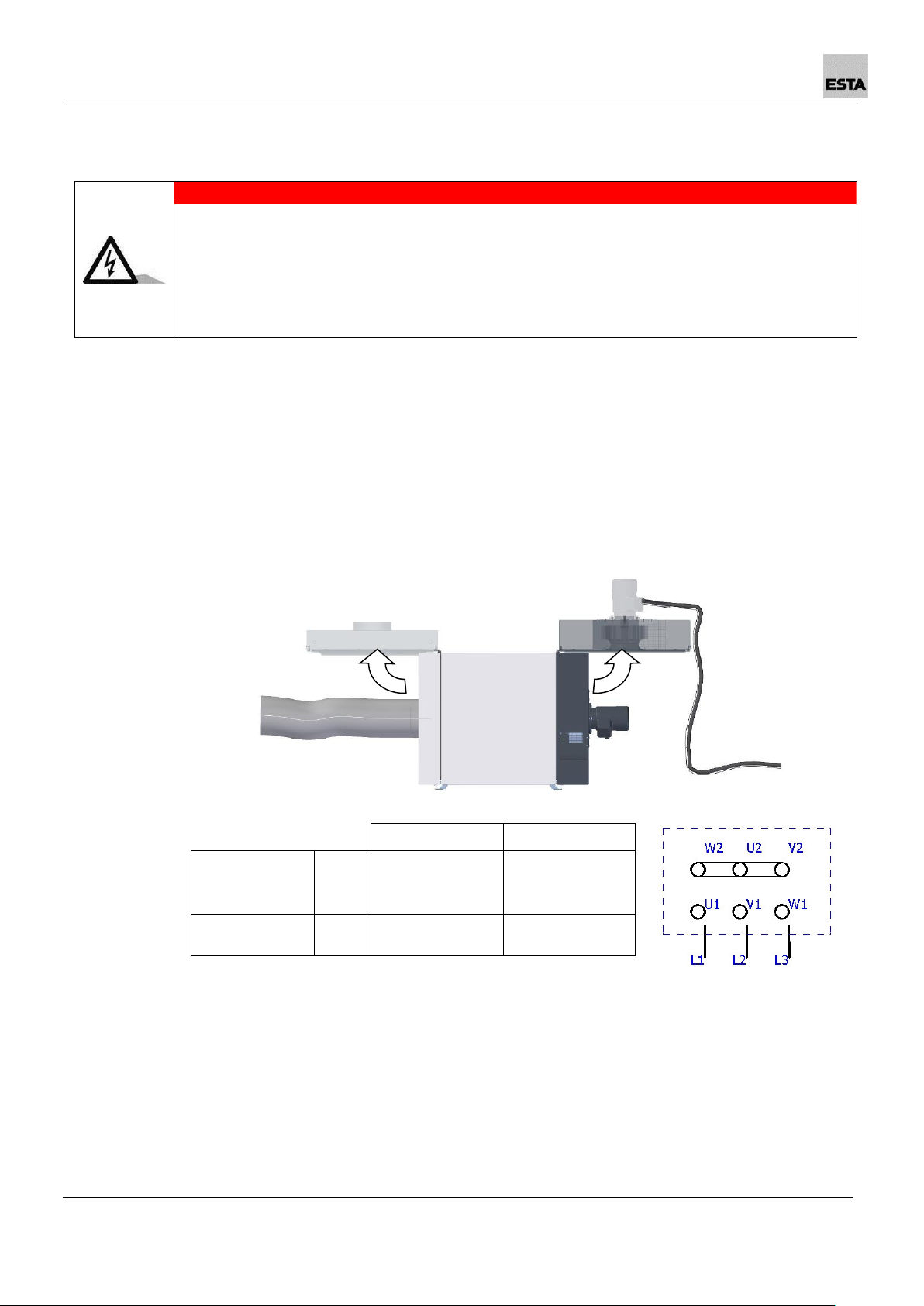

5.2.1 Electrical connection

DANGER

Electric shock from high voltages

Follow the safety rules for working with electrical devices!

Only operate the device with a suitable, lockable motor circuit breaker!

When working on the device, disconnect it from the voltage supply!

Any work on the electrical grid and on live components parts may only be

performed by an electrician.

The device power supply requires connection of a customer-side cable connection

with a slow-blow fuse and lockable motor protection switch to the device motor.

Connection to the building's power supply or a machine control cabinet is made

at the installation location.

The device is isolated from the mains during maintenance, cleaning and servicing

work via a lockable motor circuit breaker.

When choosing the cable length, remember that the ventilator unit needs to be

swung open for maintenance, cleaning and servicing work.

If the device is controlled on site via a control system, this must be designed so

that the oil mist separator starts up before the processing machine starts the

processing sequence. If the processing sequence has been completed, the oil

mist separator must continue running afterwards.

Domestic

Abroad *

Mains supply

Star

400 V; 50 Hz; 3

N~

Star

400V; 50 Hz; 3~

Fuse

[Amp.]

16 (slow-blow)

16 (slow-blow)

This manual suits for next models

3

Table of contents

Other Esta Scrubber manuals