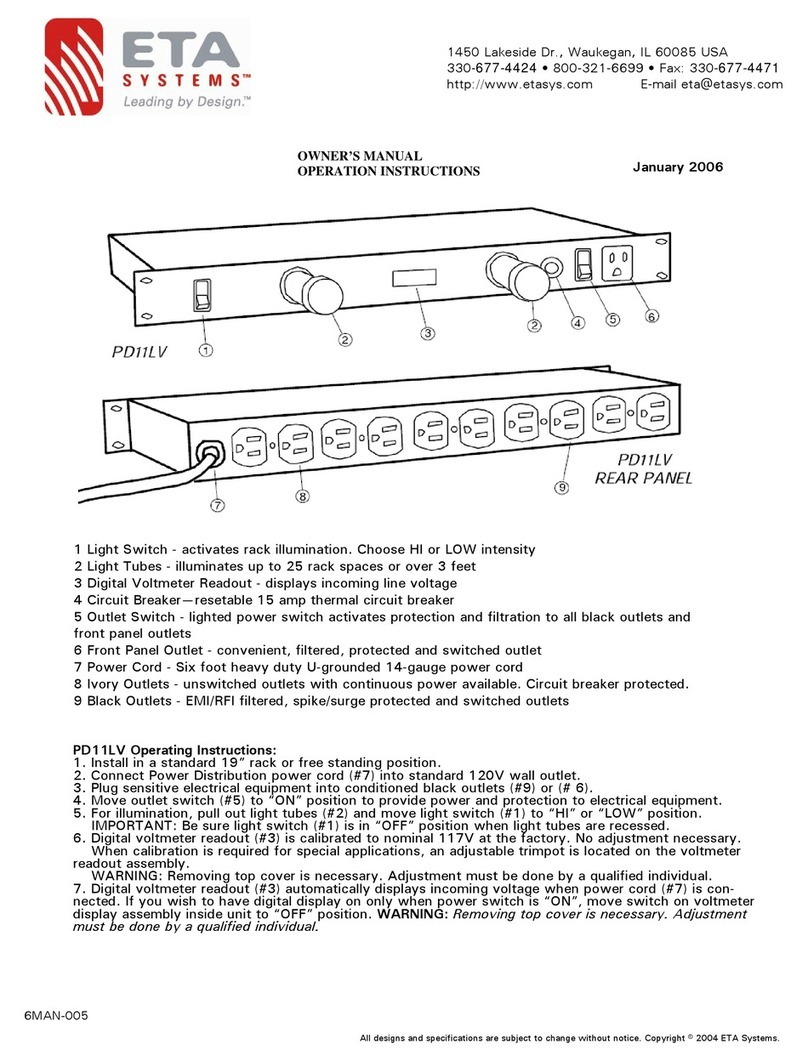

Operating Instructions

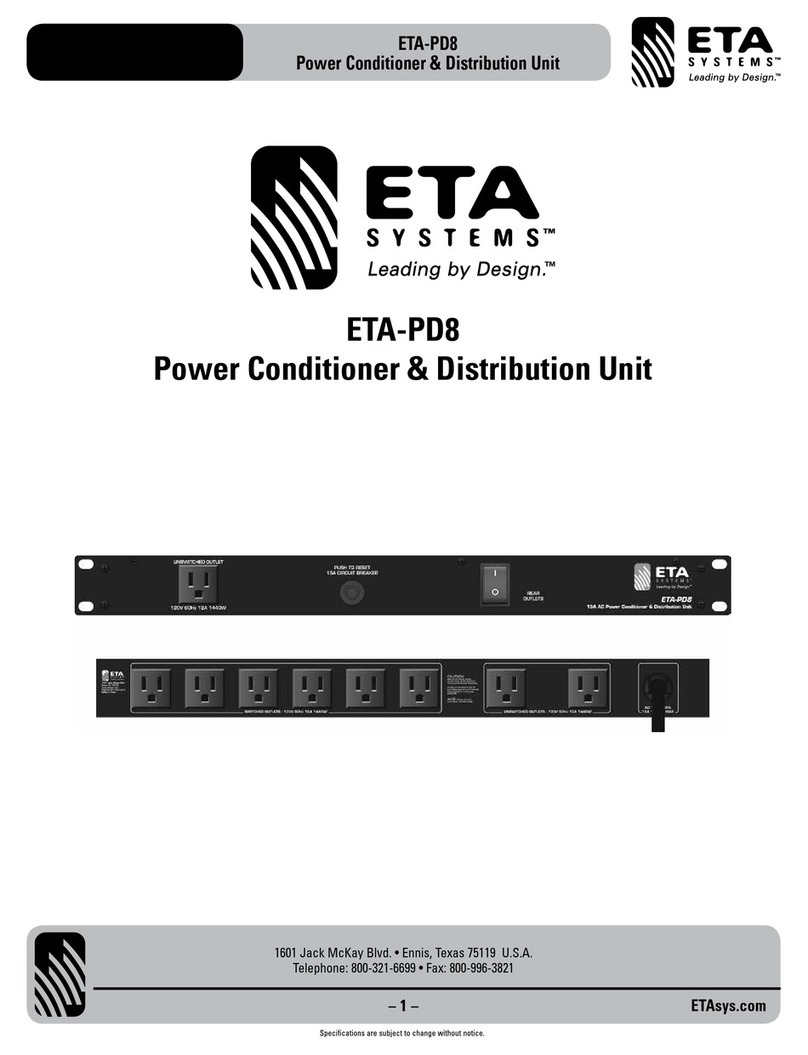

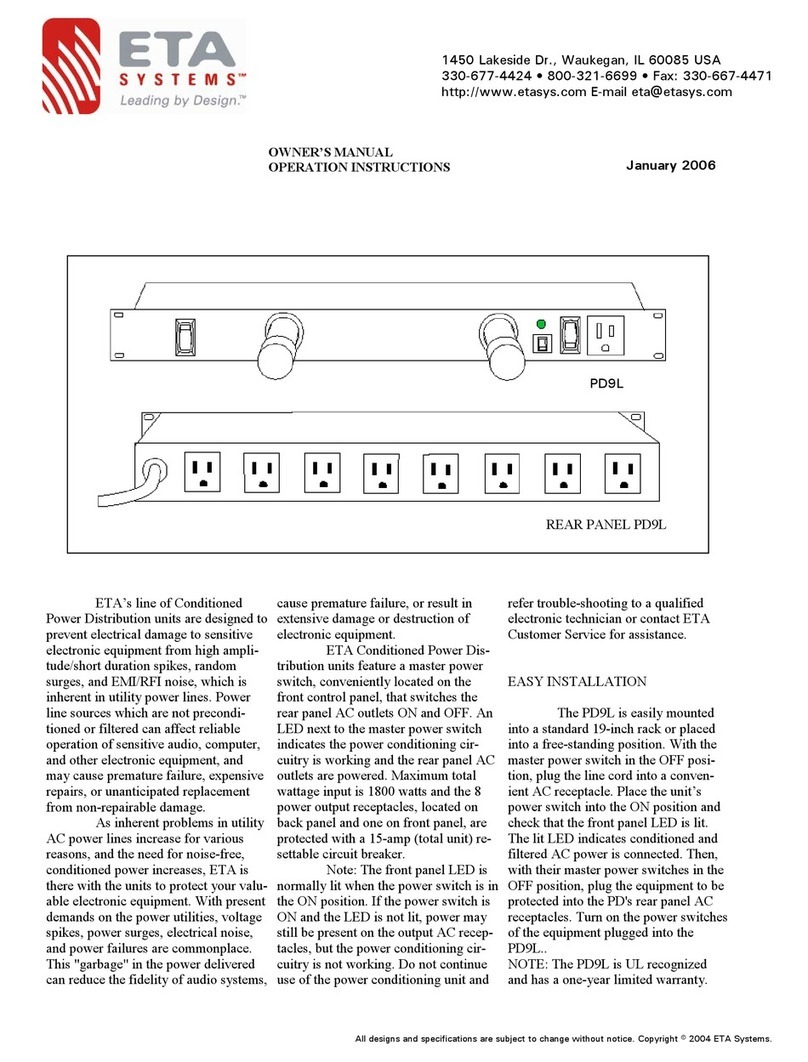

1. Install in a standard 19" rack or free-standing position.

2. Connect Power Distribution power cord into a 20 amp,

120 volt wall outlet (15 amp for Model PD11SS).

3. Plug sensitive electrical equipment into conditioned

outlets. All models have an additional protected outlet on

the front panel.

4. Move power outlet switch to "ON" position to provide

power to electrical equipment.

5. For illumination, pull out light tubes (PD11LP/LVP/LVSP)

and move light switch to "HI" or "LOW" position.

IMPORTANT! Be sure light switch is in "OFF"

position when light tubes are recessed.

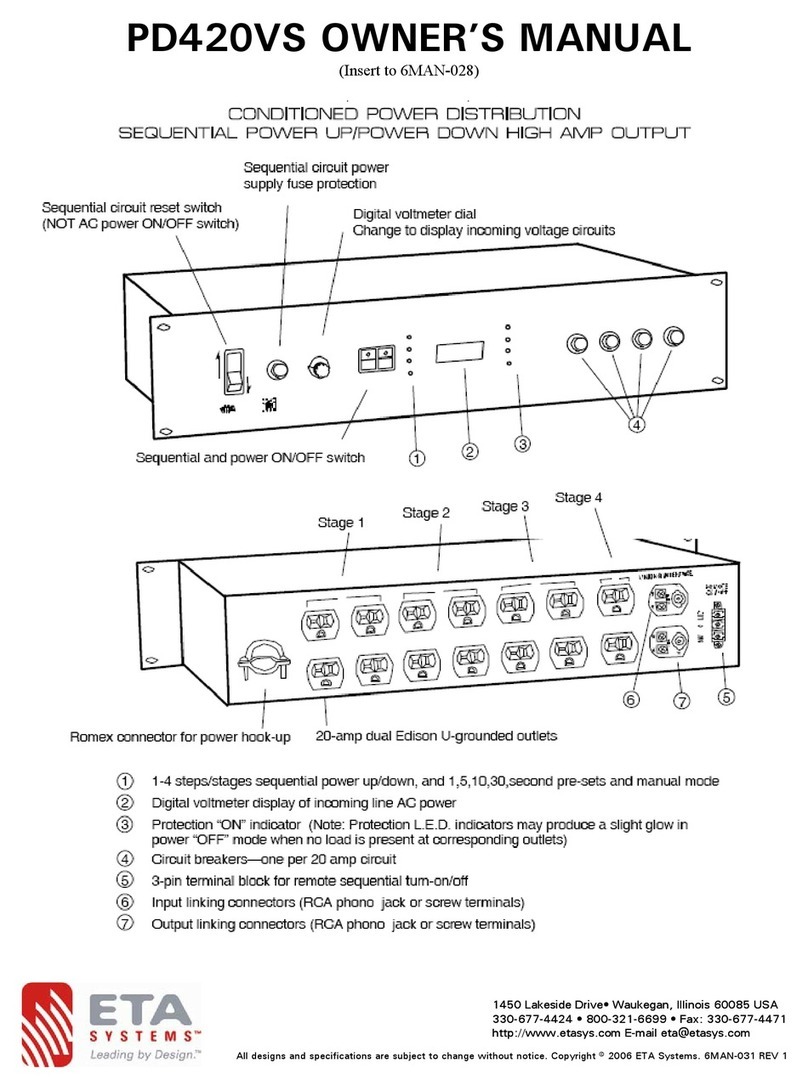

6. Digital voltmeter readout (PD11VP/LVP/LVSP) is

calibrated to nominal 117V at the factory. No adjustment

necessary.

7. Digital voltmeter readout automatically displays

incoming voltage when power cord is connected.

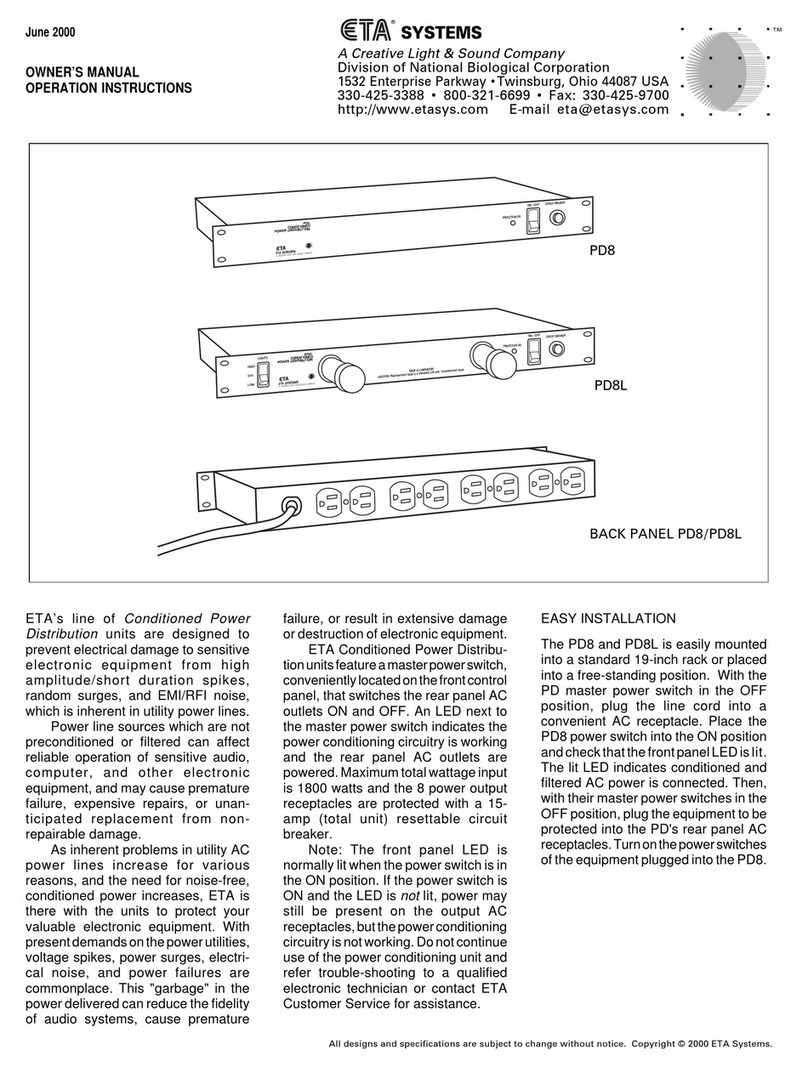

Power Problems

Standard AC outlets often supply raw and unprocessed

power that not only can diminish the clarity of audio signals

and cause premature failure of parts, it can completely de-

stroy your valuable equipment.

Power problems such as spikes, line surges and noise

interference transmit through all standard electrical lines and

affect power quality: therefore, affecting you.

Solutions

Conditioned Power Distribution can eliminate such prob-

lems from affecting you. As it filters the line voltage from your

AC outlets, eliminating noise and interference, such as radio

frequency interference (RFI) and electromagnetic interfer-

ence (EMI), it will reduce the residual noise in the system,

which will enhance audio clarity.

Installation Requirements

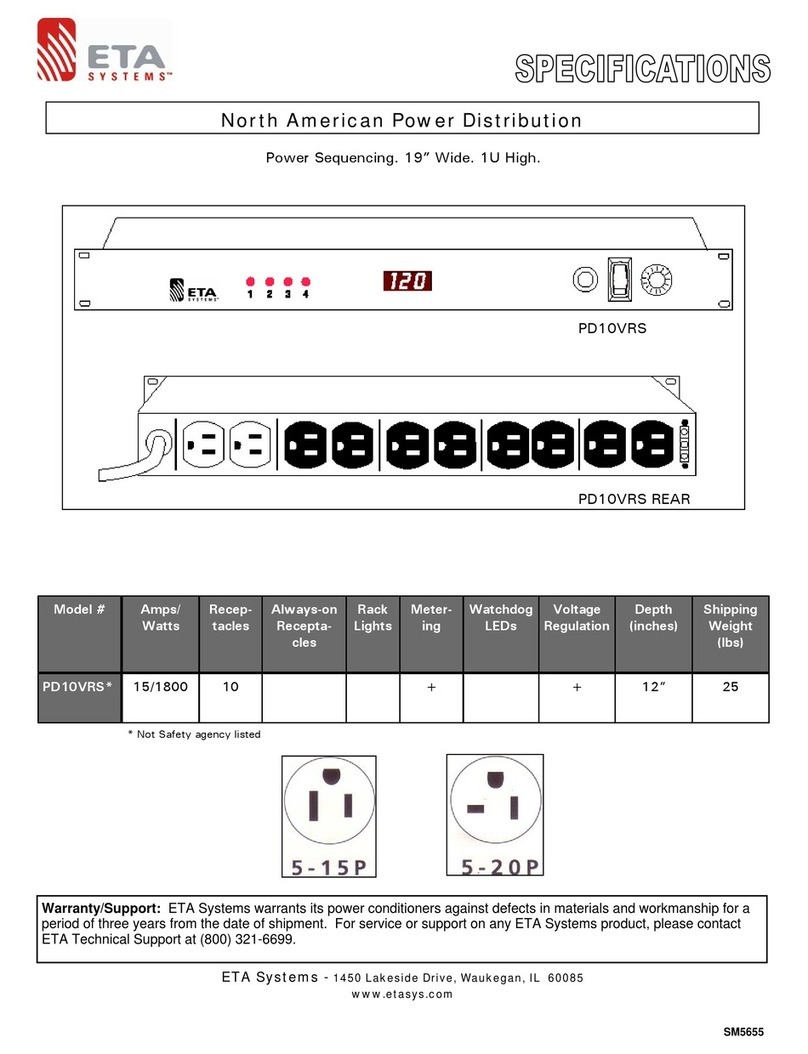

PD11P, PD11VP, PD11LP, PD11SP, PD11LVP, PD11LVSP

Plug unit into power source and observe status of four

"Protection" light emitting diodes. The (green) “1st Stage”,

“2nd Stage”, and “GROUND OK” L.E.D.’s should normally

be illuminated and the (red) “FAULT” L.E.D. should be off.

When these indications are present, test the power “On/Off”

switch which will illuminate to indicate that power is being

supplied to the switched outlets on the rear of the unit.

A. The “1st Stage” and “2nd Stage” L.E.D.’s indicate that

both the input (1st) and output (2nd) stages of circuit

protection are active.

B. The “GROUND OK” L.E.D. indicates that the chassis

is connected to the ground wire of the supply outlet.

C. Fault conditions are represented by the following

indications:

1st 2nd

Ground Fault

Stage Stage OK

(X) (X) (X) ( ) Supply circuit outlet wiring OK

( ) ( ) ( ) ( ) Open hot

( ) ( ) (X) (X) Open Neutral

or

Hot & Ground Reversed

(X) (X) ( ) ( ) Open Ground

(X) (X) ( ) (X) Hot & Neutral Reversed

NOTE: (X) = “ON” ( ) = “OFF”

NOTE: On the PD11SS Model a green L.E.D. located on the

front panel is illuminated (indicating “Protection On” status)

when unit is plugged into a power source ensuring input and

output stages of circuit protection are active.

Audio Conditioned Power Distribution is also designed to

protectelectronicequipmentfrompotentiallydamaginghigh-

voltage spikes and surges.

Sequencing Audio Conditioned Power Distribution is de-

signed to initiate a turn-on cycle, energizing one circuit

immediately with remaining circuits energizing in a delayed

fashion.Thisallowscircuitstostabilizewhenpoweringupand

downeliminatingthaton-rushofpowerandpotentialdamage

to equipment at output receptacle.

6

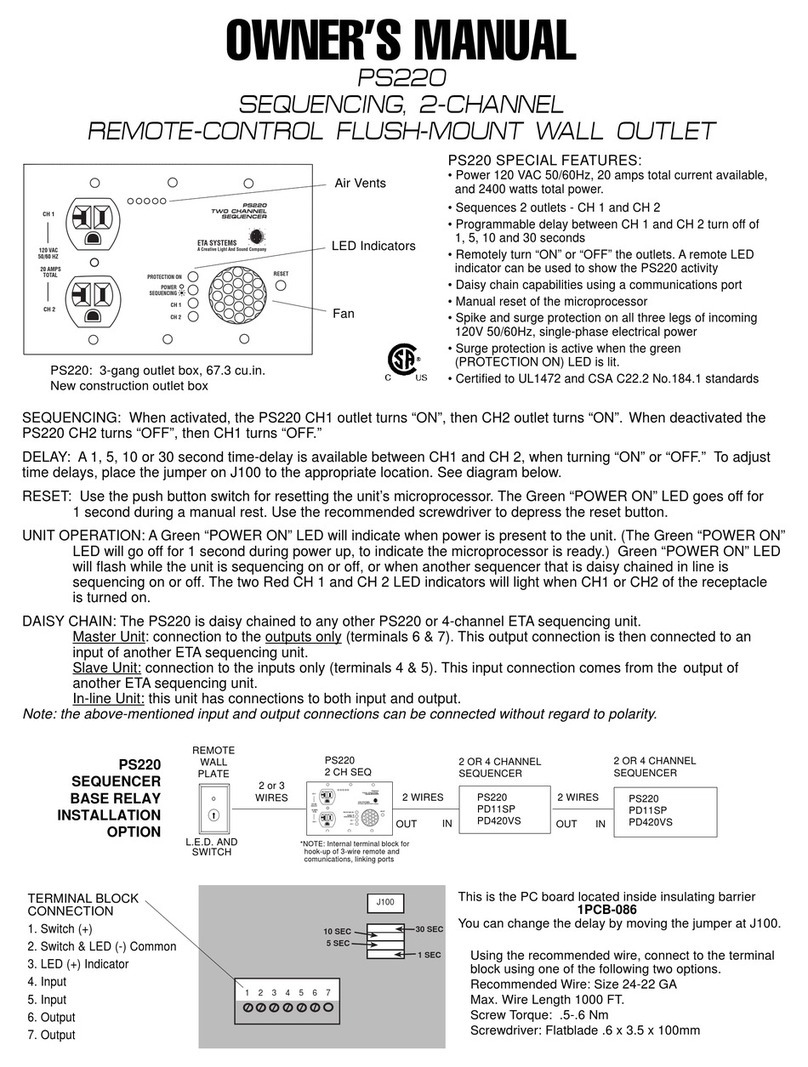

Programming Time Delays

The PD11SP, PD11SS and PD11LVSP come from the

factorysettoa1-seconddelayforeachofthefouroutlets

to turn on. The following instruction will enable you to

change the amount of time between each outlet turn on.

•

The main power switch must be on

•

The sequenced outlets must not be active

• The switches to change the delay time are to left

of the unit and they have green L.E.D.s in the

switch.

• The switches are labeled POWER DOWN/UP

and OFF/ON PRESETS

• The POWER DOWN/OFF is the left switch

• The POWER UP/DOWN is the switch to the right

Programming Preset Time Delays

Step 1:

Depress and hold the DOWN/OFF switch

Step 2:

Depress and hold the UP/ON switch

Step 3:

Red L.E.D. to the right of the switches will

start to flash

Step 4:

When flashing red L.E.D. goes out, release

both switches

Step 5:

Both green L.E.D.s on the switches will start

to flash rapidly

Step 6:

You are in program mode at this time

Step 7:

The red L.E.D.s to the right indicate what the

time delay is set for:

L.E.D. 1 = 1 second delay

L.E.D. 2 = 5 second delay

L.E.D. 3 = 10 second delay

L.E.D. 4 = 30 second delay

Step 8:

Depress the UP/ON switch to the right to

increase the time delay

Step 9:

Depress the OFF/DOWN switch to the left to

decrease the time delay

Step 10:

Depress both OFF and ON switches to finish

the delay programming

Programming Manual Time Delays

Step 1:

Follow above instruction to activate L.E.D. 4

Step 2:

Depress the UP/ON switch one more time to

activate manual programming time delay

mode

Step 3:

All 4 red L.E.D.s to the right will be lit to

indicate manual mode

Step 4:

The UP/ON switch green L.E.D. will be lit

Step 5:

Depress the UP/ON switch to start manual

delay programming—can program from 5

sec. to 240 sec. delay

Step 6:

Depress the OFF/DOWN to stop the manual

delay timing

Step 7:

Depress both the OFF and ON switches to

finish programming mode