ETH-messtechnik DRVL User manual

tel. +49 (0)79 72 93 10-0

hagstrasse 10 . D-74417 gschwend

Operator manual

English

messtechnik

DRVL

Option „F“

with base/foot

messtechnik gmbh

2

©ETH messtechnik gmbh

This operator manual is not a quality agree-

ment or durability guarantee as set out in

Section 443 of the German Civil Code.

Specification changes, typing and printing

errors reserved.

messtechnik gmbh

3

Inhalt

Important instructions: ...................................................................................................4

1. Preliminaries ...............................................................................................................5

2. Applicability and instructions for use ..........................................................................5

3. Description and functionality of the device ...............................................................6

3.1 Torsional shaft .....................................................................................................6

3.2 Enclosure .............................................................................................................6

3.3 Principle of operation .........................................................................................6

3.4 Disturbances and their compensation.................................................................7

4. Conditions on location ................................................................................................ 8

4.1 Ambient temperature..........................................................................................8

4.2 Moisture and dust................................................................................................8

4.3 Chemical effects...................................................................................................8

4.4 Deposits ..............................................................................................................8

5. Mechanical installation................................................................................................9

5.1 Precautions to be taken when assembling the transducer..................................9

5.2 General assembly guidelines ...............................................................................9

5.3 Additional parts and suggested values for the installation .....................................10

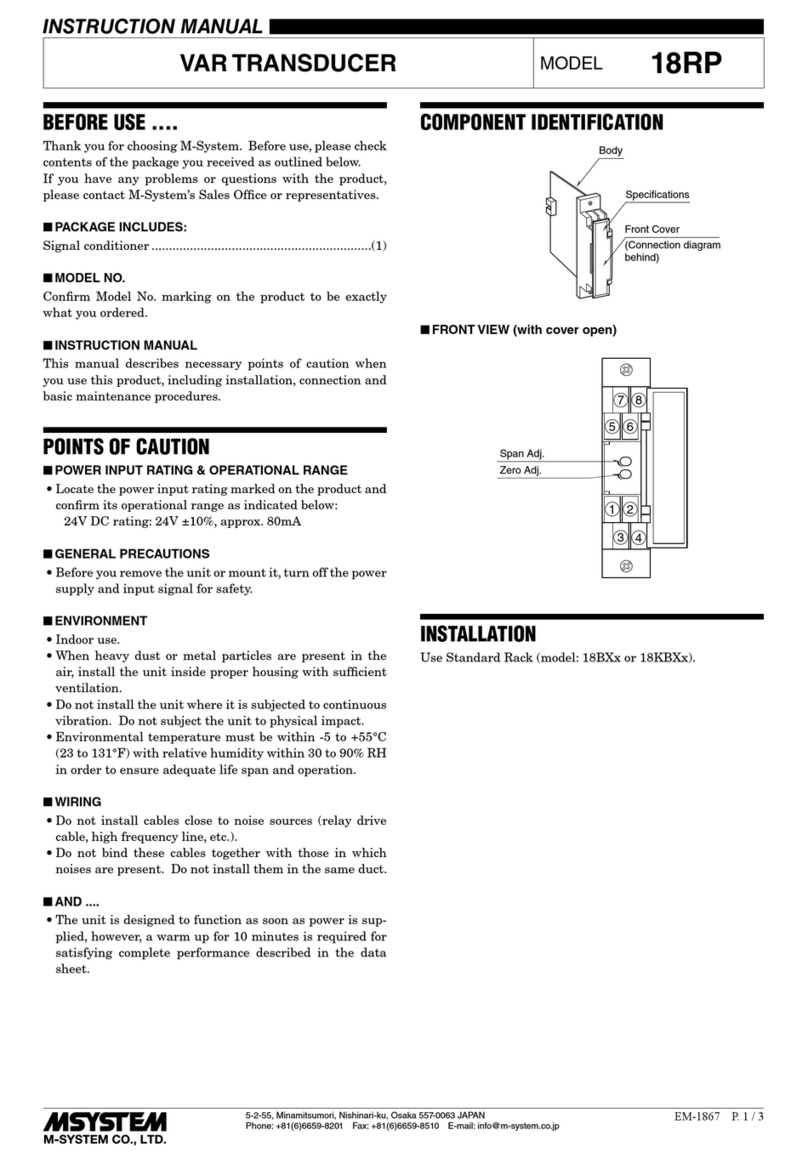

6. The measurement-chain setup..................................................................................11

7. Electrical connection .................................................................................................12

7.1 Wiring instructions.............................................................................................13

7.2 Connectors.........................................................................................................13

7.3 Pin assignment for the connectors ....................................................................14

7.4 Control activation ..............................................................................................14

7.5 Extension cables ................................................................................................14

7.6 The power supply ..............................................................................................14

8. Pin assignment .........................................................................................................15

8.1 DRVL standard cable ..........................................................................................15

8.2 DRVL robot cable ...............................................................................................16

9. Measurement outputs ..............................................................................................17

10. Recalibration............................................................................................................17

11. Disposal ...................................................................................................................17

12. Datasheet DRVL.......................................................................................................18

12.1 Electrical Specifications....................................................................................18

12.2 Mechanical Dimensions DRVL-F.......................................................................19

12.3 Technical Specifications DRVL ..........................................................................20

messtechnik gmbh

4

Important instructions:

The model DRVL torque transducer can be deployed as a component in a test

bench, for example.

The installation position of the drive and transducer sides should be taken into

account in applications where mass is critical.

Please note that in order to achieve greater sensitivity the transducer

has not been designed with the safety factors 2 to 20 that are common in me-

chanical engineering.

Please pay special attention to the specified overload factors.

Where there is a risk of personal injury or damage to equipment due to mechani-

cal failure leading to breakage, the user of the device must put in place adequate

safety measures (e.g., covers and guards, and overload protections). All applicab-

le accident prevention regulations must be followed.

The torque transducer is not approved for use in hazardous areas.

Opening or disassembling the transducer during the warranty period

will void the warranty.

messtechnik gmbh

5

1. Preliminaries

The torque transducers are made of different shaft materials to suit the loads.

Torque transducers measure torque in the unit Nm.

Please refer to the relevant data sheet for the current technical specifications.

www.eth-messtechnik.de

2. Applicability and instructions for use

The torque transducers measure clockwise and counterclockwise loads. In case

of clockwise load, the output signal is positive.

The full-scale value is printed on the device label.

The torque transducers can measure both static and dynamic torques. The low

masses and high torsional stiffness are particularly beneficial in this context.

Please refer to the data sheet for the specified signal rise for the transducer.

The torque transducers need no maintenance as they are fitted with contactless

outputs. Their electrical outputs can be transmitted to remote test benches,

where they can be displayed, recorded, processed and used for control opera-

tions.

The torque transducers are precision devices and should be handled carefully

when transported and when being installed to prevent them being damaged by

shocks or if they fall to the ground. Torque peaks above the rated overload can

severely damage the torsional shaft. These peaks must be intercepted and absor-

bed if they cannot be avoided.

The limits for the permissible mechanical, thermal and electrical stresses are

detailed in the data sheet. They must be strictly observed. Please consider these

limits when designing, installing and operating the measurement setup.

messtechnik gmbh

6

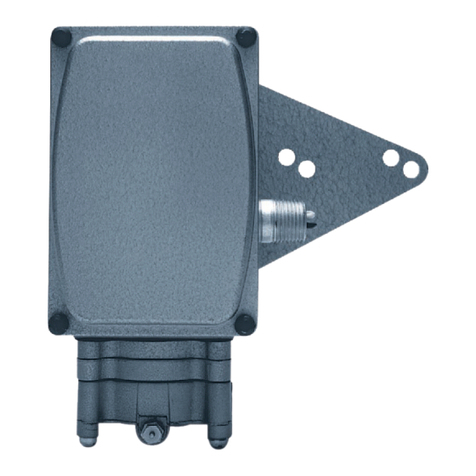

3. Description and functionality of the device

3.1 Torsional shaft

The torsional shaft is constructed with special aluminum or hardened carbon

steel to suit the full-scale value.

Strain gauges attached to the torsional shaft sense the shaft torsion, which is

proportional to the torque and is within its elastic range. The strain gauges are

arranged as a Wheatstone bridge circuit. The force is transmitted via cylindrical

shaft extensions with smooth shaft extensions or a featherkey as per DIN 6885.

A pulse disk for speed or rotation angle measurement can be fitted to the torsio-

nal shaft if needed. Please refer to the data sheet for more details.

3.2 Enclosure

The enclosure for the torque transducer is made of high-strength aluminum; the

enclosure surface is hard-anodized to protect it. The torsional shaft is supported

in the enclosure with two deep-grooved ball bearings. The transducer can either

be base mounted or flange mounted. An electronics module for conditioning

and analyzing the signal for torque, speed or angle of rotation is installed in the

enclosure.

3.3 Principle of operation

The torsional shaft, and thus the strain gauges, are elastically deformed by the

torsional force. The ohmic resistances of the strain gauges change proportional

to their change in length. The electronics module is connected in series and it

transfers the measurements by means of optical frequency modulation to the

enclosure.

The signal is then converted by the external electronics unit to an analog voltage

that is proportional to the change in frequency. Those signals and frequency

output are available as an electrically isolated signal for further processing.

The pulse disk on the torsional shaft is sampled with an encoder in the enclosure.

Two waveforms are available for analysis: (1) a square wave with 60 pulses/turn

for the speed option, and (2) two square waves offset by 90° with 360 pulses/

turn for the angle of rotation option.The direction of rotation can be detected

with the angle of rotation option. Channel A leads channel B by 90° for clockwise

rotation.

messtechnik gmbh

7

3.4 Disturbances and their compensation

Flexural, axial and radial forces are disturbances and, hence, should be avoided.

We recommend the use of clamping hub couplings. They must be selected to

suit the operating conditions.

Shielded cables should be used for the electrical connections. The electroma-

gnetic compatibility (EMC)of the torque transducers are tested for compliance

with EN 55011:2011.

The immunity of the torque transducers to noise is tested to the following stan-

dards:

• 61000-4-2:2009

• 61000-4-3:2009

• 61000-4-4:2009

• 61000-4-5:2009

• 61000-4-6:2009

• 61000-4-8:2009

messtechnik gmbh

8

4. Conditions on location

4.1 Ambient temperature

For best results, the device must be operated within the nominal temperature

range. The best operating conditions are constant and, if necessary, slowly

changing temperatures. The specified temperature errors apply if the tempera-

ture does not change faster than 5K/h. One-sided thermal radiation or cooling

should be avoided and appropriate technical preventive measures taken, if

necessary.

4.2 Moisture and dust

The torque transducers comply with protection type rating IP40 as per DIN

40050.

Note: There should be no moisture inside the transducer connector

4.3 Chemical effects

The torque transducers are not protected against chemical effects. They must

not be used in caustic or corrosive environments.

4.4 Deposits

Dirt, dust or other foreign substances should not accumulate so that they can

enter the bearing or the connectors.

messtechnik gmbh

9

5. Mechanical installation

5.1 Precautions to be taken when assembling the transducer

• Handle the transducer carefully.

• IMPORTANT!

While assembling the couplings, don’t overload the transducer, even

temporarily. It is highly suggested to connect the transducer electri

cally first and monitor the torque signal in order to prevent exceeding

the torque range!

• Axial and radial misalignments must be avoided.

• Make sure the enclosure is correctly connected electrically to

the grounded parts.

5.2 General assembly guidelines

The drive and transducer sides should not be swapped, otherwise measurements

(readings) will be invalidated during accelerations, for example.

When reading the device label, the drive side is on the right and the transducer

side on the left of the transducer. There is a small cavity in the cover on the mea-

surement side.

Flexural, axial and radial forces are disturbances that cause incorrect measure-

ments

Be careful with the thermal expansion of the assembly.

Measuring side mark

Direction of rotation for positive indication

messtechnik gmbh

10

5.3 Additional parts and suggested values for the installation

Model DRVL-F DRVL-I-F DRVL-Ib-F DRVL-II-F DRVL-III-F DRVL-IV-F DRVL-V-F DRVL-VI-F

Addional parts:

1. Hexagon socket

head cap screw

(DIN912-8.8-Zn)

M5x25 M5x25 M6x30 M6x30 M8x35 M10x45 M12x55 M16x80

2. Fan washer

(DIN6798 A-Zn) 5,3 5,3 6,4 6,4 8,4 10,5 13 17

3. Plain washer

(DIN433-4.8-Zn) 5,3 5,3 6,4 6,4 8,4 10,5 13 17

4. Straight pin

(DIN6325) 4m6x8 4m6x8 5m6x10 5m6x10 6m6x12 8m6x16 10m6x20 12m6x24

5. Parallel key

(DIN6885 A) 6x6x50 6x6x50 8x7x60 8x7x60 10x8x60 10x8x60 10x8x80 10x8x100

Suggested

values for the

installaon:

Maximum fastening torque of the screws at the base onto steel (Nm)

5,0 5,0 8,6 8,6 21,0 40,8 71,4 190,0

Maximum fastening torque of the screws at the base onto aluminum (Nm)

5,8 5,8 9,9 9,9 24,1 40,8 82,3 164,5

Maximum fastening torque of the screws onto the ange (Nm)

0,6 1,0 1,0 1,0 2,6 8,6 -- --

Minimum installaon depth of the straight pins into the sensor (mm)

4 4 5 5 6 8 10 12

messtechnik gmbh

11

6. The measurement-chain setup

A measurement chain is required for the transducer to take measurements.

The measurement chain consists of:

• a torque transducer

• a connection cable

• a power supply and display unit

A power supply is required to supply the transducer with the necessary opera-

ting voltage. The transducer is fitted with a measurement amplifier (hence, no

other amplifier is needed). The measurement data can be transmitted to a lap-

top, for example, or displayed and analyzed with power supply and display units.

messtechnik gmbh

12

7. Electrical connection

The electrical connection of a torque transducer with a 12-pin connector

messtechnik gmbh

13

7.1 Wiring instructions

Electrical and magnetic fields often disturb the measurement circuit. These dis-

turbances typically emanate from power lines running parallel to the test cables,

but they can also come from nearby contactors or electric motors. Interference

or noise voltages can be injected into the circuit as well electrically, especially if

the measurement chain is grounded at many points. This can give rise to potenti-

al differences.

Please note the following instructions.

• Use only shielded, and low-capacitance cables.

• Connect the supply voltage correctly

• Do not lay the device cable parallel to heavy-duty or control lines.

• Avoid leakage fields from transformers, motors and contactors.

• Do not ground the transducer, analyzer and indicating unit

at multiple points.

Connect all devices in the measurement chain to the same

protective conductor.

7.2 Connectors

The transducers are fitted with a 12-pin integrated connector Binder model 680.

messtechnik gmbh

14

7.3 Pin assignment for the connectors

The pin assignments for the connectors are detailed on the following pages.

The transducer outputs the measurements as an electrically isolated signal. The

ground potentials should not be directly bridged at the transducer, as this could

lead to incorrect measurements, depending on the length of the cable to the

power supply and display unit. Instead, they can be bridged at the power supply

and display unit, if necessary.

7.4 Control activation

The “control activation” is used to test the transducer. This emits its maximum

signal of e.g. 10 V and 15 kHz (with right-hand load). The control level is 4.5 V up

to the supply voltage; the reference ground point is the supply ground.

Attention: Note the tare!

7.5 Extension cables

Extension cables must be shielded and have low capacitance. We recommend

you use our cable, as it meets these requirements. Pay particular attention to the

connectors and ensure good insulation when using cable extensions. The cable

cross-section should be sufficiently large to ensure adequate power reaches the

transducer. There is no need to recalibrate the transducer when extending the

cable.

7.6 The power supply

The torque transducer is fitted with a universal voltage input for the voltage ran-

ge 10 V - 28.8 V. If the voltage goes above 28.8 V, the internal suppressor circuit

is activated and the power supply is shorted.

messtechnik gmbh

15

8. Pin assignment

8.1 DRVL standard cable

AK12.4 for active sensors

12-pin connector

(Top view of transducer connector)

External EMC circuit

A 100 nF / 50 V ceramic capacitor can be soldered between pins C - D at the

analyzer to suppress conductor-borne disturbances.

PIN D (torque ground) and PIN E (power supply ground) are electrically isolated

internally, short at the power source if required (not at the transducer).

Pin Colour Occupancy DRVL

A Green Frequency output

B Red / Blue Angle exit track B = 90 °

C Yellow Moment exit

D White Moment mass

EGrey Supply + angle / speed ground

F Pink Supply + 9… 28V

G Grey / Pink Speed / angle output track A = 0 °

H Purple Memory chip

J Black Message ready for operation

KRed Control entrance

L Brown Inverted frequency output

M Blue Voltage reference angle signal

messtechnik gmbh

16

8.2 DRVL robot cable

AK12.5 for active sensors

12-pin connector

(Top view of transducer connector)

External EMC circuit

A 100 nF / 50 V ceramic capacitor can be soldered between pins C - D at the

analyzer to suppress conductor-borne disturbances.

PIN D (torque ground) and PIN E (power supply ground) are electrically isolated

internally, short at the power source if required (not at the transducer).

Pin Colour Occupancy DRVL

A Black Frequency output

BRed Angle exit track B = 90 °

C Brown Moment exit

D White Moment mass

E Yellow Supply + angle / speed ground

F Purple Supply + 9… 28V

G Green Speed / angle output track A = 0 °

H Pink Memory chip

JGrey Message ready for operation

K Grey/Pink Control entrance

L Blue/Red Inverted frequency output

M Blue Voltage reference angle signal

messtechnik gmbh

17

9. Measurement outputs

The transducer outputs a 0 – 10 V DC voltage that is proportional to the tor-

que. The output voltage is positive for clockwise torque, and negative for

counterclockwise torque. The transducer outputs a 10 kHz ± 5 kHz differential

frequency signal (RS422), as well.

The torque sensor has a permitted zero point deviation of ± 50 mV / ± 50 Hz. A

taring option must be provided for precise measurements.

Each of the speed and angle-of-rotation outputs has an active driver in the

system. The speed, angle and ready outputs deliver a TTL signal in the absence of

an external voltage reference.

The device also outputs a ready signal (Pin J): logic HIGH means the device is

ready, LOW means there is a fault in the device.

If a higher voltage output is needed, for PLC inputs, for example, a voltage

reference can be set through pin M. The voltage reference tolerates a 5 V - 24 V

voltage range.

10. Recalibration

We recommend, regardless of use, a recalibration (deadline see certificate) in

the house of ETH.

11. Disposal

The transducer along with the measuring cable can be returned free of charge to

us for disposal. As soon as you have packaged the transducer, send us an e-mail

at sales@eth-messtechnik.de. We will then instruct our parcel service to pick it

up.

We are sorry, but we cannot accept any goods sent to us unannounced and

freight-collect.

messtechnik gmbh

18

Supply voltage: 10 - 28,8 V DC

Power consumption: at Ub 12 V approx. 180 mA (switching converter 2.2 W)

Rise time 10-90 %: 2 ms (optional 400 μs)

Limit frequency -3 dB: 200 Hz (optional 1 kHz)

Voltage output: Output frequency:

Voltage output: 0 ± 10 V 10 kHz ± 5 kHz (RS422)

Resolution: 16 bit ≙0,38 mV 16 bit ≙0,19 mHz

Max. output range: ± 11 V ± 6,3 KHz

Internal resistance: 100 Ω _

Ripple: < 100 mVss _

Nonlinearity/max. measurement error (of full scale)

DRVL: 0,15 % (optional 0,1 % )

DRVL-

I

to DRVL-

VI

: 0,1 % (optional 0,05%)

0,15 % (optional 0,1 % )

0,1 % (optional 0,05 % )

Hysteresis 0,1 % 0,1 %

Deviation at zero point: ≤ 50 mV ≤ 50 Hz

Operating temperature: 0 - 60 °C

Compensated temperature range: 5 - 45 °C

Temperature error

Zero point:

Sensitivity:

0,02 % / K

0,01 % / K

Mechanical overload: 100 %

Internal protection: IP 40 (DIN 40050)

Connection: 12pin-connector

Interference emission

Basic standard

EN55011 Limit class B

Frequency range

150 kHz - 6 GHz

Immunity to interference

Basic standard

EN61000-4-2:2009 Electrostatic discharge (ESD)

EN61000-4-2:2009 Electrostatic discharge (ESD)

EN61000-4-3:2009 Electromagnetic fields

EN61000-4-4:2009 Bursts

EN61000-4-5:2005 Surge voltages

EN61000-4-6:2009 Conductor-borne RF disturbances

EN61000-4-8:2005 Power frequency magnetic fields

A: Deviation of outputs during the test < 0.3 % of full scale

B: Deviation of outputs during the test > 0.3 % of full scale

Speed Option (n) Angle Option (w)

max rev.: ≤ 37.000 1/min* ≤ 20.000 1/min*

Output: TTL or over voltage on pin 5 V - 24 V

Impedance: 22 Ω 22 Ω

Imax: 20 mA 20 mA

Pulses/rev.: 60 2 x 360

Resolution: -- 1°

Phase shift: -- Channel A 90° at right spin of propulsion side

* The values are valid for ETH test cables ≤ 10 m, the maximum permissible speed of the sensor must be observed.

Testing accuracy coupling Result

4 kV

4 kV

10 V/m

2 kV

1 kV

10 V/m

30 A/m

direct

indirect

indirect

indirect

direct

indirect

indirect

A

A

A

A

B

A

A

12. Datasheet DRVL

12.1 Electrical Specifications

messtechnik gmbh

19

12.2 Mechanical Dimensions DRVL-F

Typ DRVL DRVL-IDRVL-IbDRVL-II DRVL-III DRVL-IV DRVL-VDRVL-VI

Mess-

bereiche:

(± 0 - ... Nm)

0,02

0,05

0,10

0,05

0,1

0,2

0,5

1

2 1

2

5

10

5

10

20

30

50

50

100

150

200

300

500

1000

1300

1500

2000

3000

4000

5000

10.000

15.000

20.000

Abmessungen: (andere Messbereiche auf Anfrage; Allgemeintoleranzen nach DIN 2768-m)

L (mm) 82 89 95 110 145 170 270 320 355

B (mm) 56 60 78 78 98 158 208 298

B1 (mm) 32 28 36 42 56 88 105 168

B2 (mm) 24 (→ LK) (→ LK) (→ LK) (→ LK) (→ LK) -- --

H (mm) 78 85 85 82 90 172 228,5 316

H1 (mm) 45 45 45 45 45 112 160 215

H2 (mm) 12 12 15 15 15 20 30 40

Ø D1 g6 (mm) 3 8 8 10 15 26 45 70 110

Ø D2 g6 (mm) 3 5 6 10 15 26 45 70 110

Ø D3-0,1 (mm)

15 27 32 38 54 80 -- --

Ø LK ± 0,1 (mm)

(→ B2/H3) 32 38 45 65 98 -- --

L1 63 62 68 79 72 84 95 121

L2 7,5 11 14 18 30 45 85 110 115

L3 7,5 10 14 18 30 45 85 110 115

L4 67 66 72 83 78 90 -- --

N1H8 (mm) 6 6 8 8 10 10 10 10

N2 (mm) 2,8 2,8 3,3 3,3 3,3 3,3 3,3 3,3

N3 (mm) 50 50 60 60 60 60 80 100

S1 5,5 5,5 6,6 6,6 911 13 17

S2 50 50 50 65 55 65 70 90

S3 44 44 58 58 76 124 156 233

Ø Z E8

4

4 5 5 6

810

12

M

M2,5 x 5M3 x 6 M3 x 6 M3 x 6 M4 x 8 M6 x 12 -- --

P (DIN 6885)

optional -- -- 2x

A3x3x14

2x

A5x5x25

2x

A8x7x40

4x

A14x9x80

4x

A20x12x100

--

Gewicht ca. (g)

400 400 600 900 1600 6600 15.000 43.000

n max (

min-1

)

20.000 37.000 26.000 19.000 13.500 7900 6300 4000

messtechnik gmbh

20

Model Torque range

(Nm)

Spring constant C

(Nm/rad)

Mass moment of

inertia J (g x cm²)

Rated axial load

(N) *

Rated radial load

(N) *

DRVL

0,02 16 7 35 30

0,05 16 7 35 30

0,1 16 7 35 30

DRVL-I

0,05 20 10 105 2

0,1 35 10 140 3

0,2 35 10 140 3

0,5 45 10 160 4

1 90 10 210 7

2 135 10 210 13

DRVL-Ib

1 255 30 630 10

2 255 30 630 10

5 715 30 725 25

10 1320 30 725 50

DRVL-II

5 960 100 1200 15

10 2115 100 1300 30

20 3955 100 1300 60

30 5340 105 1300 100

50 6700 105 1300 155

DRVL-III

50 17 x 103775 1800 125

100 30 x 103785 1800 215

150 45 x 103800 1800 340

200 54 x 103810 1800 450

300 67 x 103840 1800 650

DRVL-IV

500 260 x 1039935 4150 650

1000 387 x 10310.140 4150 1275

1300 429 x 10310.285 4150 1650

1500 449 x 10310.380 4150 1700

DRVL-V

2000 1,45 x 10663 x 1034800 1950

3000 1,85 x 10664 x 1034800 2930

4000 2,10 x 10664 x 1034800 3880

5000 2,30 x 10665 x 1034800 4000

DRVL-VI

10.000 8,20 x 106440 x 10311.800 8895

15.000 10,45 x 106448 x 10311.800 9830

20.000 11,80 x 106546 x 10311.800 9830

12.3 Technical Specifications DRVL

Ordering code system

Available Accessories

Supply and display unit: GMV2

ValueMasterBase

Cables

Couplings

A Standard

n Speed op�on

w Angle op�on

- - --

0

Standard accuray

1

Op�on higher accuray

K Op�on keyway

Model/size

Torque range (Nm)

DRVL

F Op�on base

--

071 Op�on limit frequency 1kHz

* The values for axial and radial load apply to the non-fixed case

Other manuals for DRVL

1

This manual suits for next models

8

Table of contents

Other ETH-messtechnik Transducer manuals

Popular Transducer manuals by other brands

Balluff

Balluff BTL6-V5 V-M PF-S115 Series user guide

S&P

S&P TDP-D quick start guide

MKS

MKS 905 MicroPirani Design guide

S+S Regeltechnik

S+S Regeltechnik PREMASGARD 711x Series Operating Instructions, Mounting & Installation

Endress+Hauser

Endress+Hauser Cerabar PMP23 operating instructions

Petroline-A

Petroline-A TP-140D Operation manual