Z203

95

9-

0D

P

AGE

4

©

2008

V

er

is

Indus

tries

USA

800.3

54.85

56

or

503

.598

.4564

/

suppor

[email protected] 06081

inStallation GUiDe

ep3 SerieS

PWM Mode

4-20mA

Voltage

Tristate

PWM

Network

Control

INPUT

Tristate Timing

Network

FS Point

Zero

RUN

SETTING

The tristate pullup is requires to ensure correct operation when using the tristate or

PWM modes.

To set the minimum pulse value, adjust the Setting and Input switches as shown:

sPecial instructions

The number displayed on the LCD screen is the minimum pulse in 100ths of a second.

If the controller receives a pulse of this duration or shorter, the output will go to 0%

of the range specified with the zero and span settings. After setting this value, wait

10 seconds before power cycling the EP. If you power cycle before 10 seconds, your

settings will be erased and the setpoint will default to the previous setting. The

full scale (100%) pulse is 126 * minimum pulse; a pulse of this duration or longer

will produce 100% output. Output is calculated as the linear ratio between the zero

and span setpoints. The minimum pulse setting has a minimum number of 1 and a

maximum number of 60. The device's internal counters measure the contact closure

time with 100Hz resolution.

Tristate Mode

The tristate pullup is required to ensure correct operation when using the tristate or

PWM modes.

Traveltime is defined as the contact closure time required to go from zero to full scale.

If traveltime is set to 10 seconds and the TRISTATE 1 input is shorted out for 5 seconds,

the output will be 50%. If the input is shorted for another 5 seconds, the output

will be 100%. If you short out TRISTATE 2 (the decreasing input) for 10 seconds, the

products output will return to 0%.

To set the travel time, adjust the Setting and Input switches as shown:

4-20mA

Voltage

Tristate

PWM

Network

Control

INPUT

Press the (+) or (-) buttons to increase or decrease the travel time. Minimum travel

time is 5 seconds; maximum is 600 seconds. After setting this value, wait 10 seconds

before power cycling the EP. If you power cycle before 10 seconds, your settings

will be erased and the setpoint will default to previous setting. The device's internal

counters measure the contact closure time with 100Hz resolution.

Note: If Tristate input is to be operated by a triac output, an AC relay is required to

provide a dry contact closure to the EP3 input.

Analog Output

The output is generated from the branch pressure. It is calculated as the ratio of the

Zero and FS Point settings, i.e. (Branch psi)/(FS-zero)= %.

For a Zero set at 0psi, FS Point at 20psi, and branch pressure at 16psi in 4-20mA:

16/(20-0)=0.80

(16mA*0.8)+4ma=16.8mA

For a Zero set at 0psi, FS Point at 20psi, and branch pressure at 16psi in voltage:

10V*0.8=8VDC

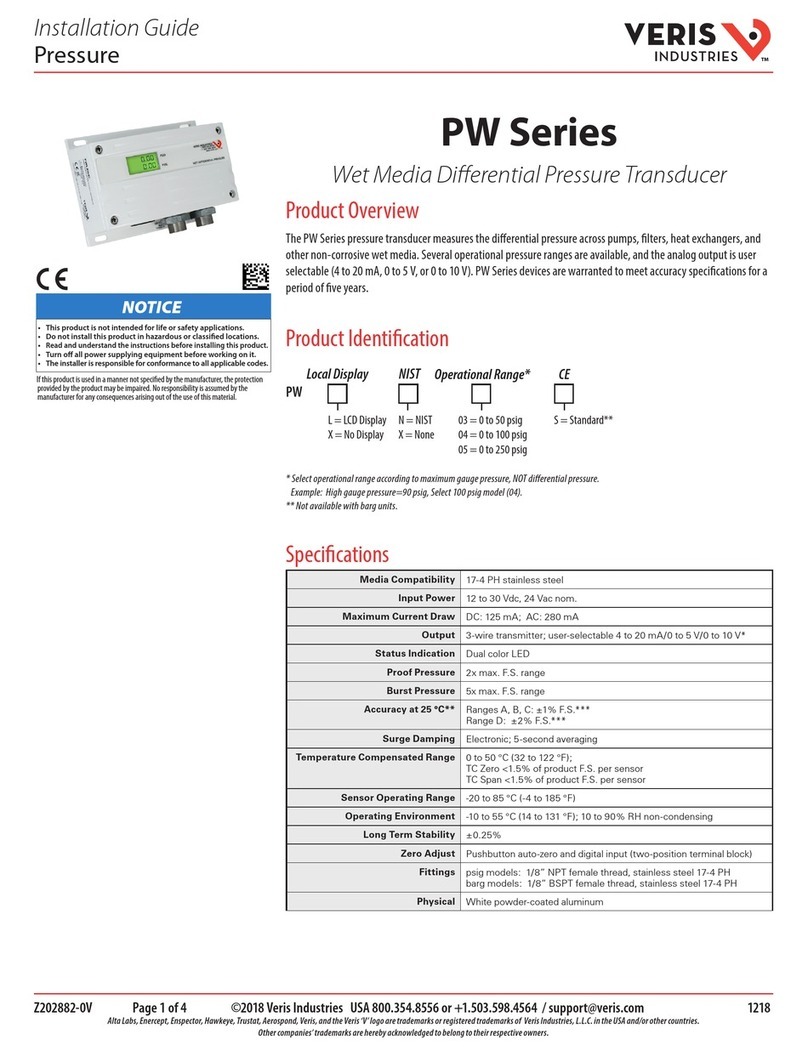

FS Point and Zero Setting

To set the Zero or FS point, move the SETTING slide switch from RUN to Zero or FS

point setting, respectively.

Slow green Normal operation

Slow green with one fast red Manual mode alarm (contacts open)

Slow green with two fast reds Pressure loss alarm active (contacts open)

Slow red SETTINGS slide switch not in RUN position

Two fast reds Slide switch not in RUN position and Alarm

(contacts open)

Three fast reds Over-voltage or over-current fault

Four fast reds Over pressure on branch side; over 25 psi.

Blink Codes

Tubing Length

Minimum tubing length is 15ft or an equivalent volume of 2.2 cubic inches. Shorter

tubing lengths can cause the unit to oscillate.

Tristate Timing

Network

FS Point

Zero

RUN

SETTING

Alarms

Alarm contacts are closed in "normal" operation (auto mode setting).

Alarm Contact: Contacts open when no power is applied or when the device

is in an alarm state.

Manual Mode Alarm: The contacts are open in manual mode setting.

Contacts will then close for normal operation. Move the P-LOSS/MAN jumper

to the manual mode setting. You do not need to power cycle the product

after moving jumpers or switches.

Pressure Loss Alarm: The contacts will open when the branch pressure falls

and stays below 20% of the desired pressure for a period of 2 minutes.

Tristate Timing

Network

FS Point

Zero

RUN

SETTING

Tristate Timing

Network

FS Point

Ze ro

RUN

SETTING

The ‘Set’ icon will appear on the LCD. Using the (+) and (-) buttons, add or decrease

the pressure setpoints.