ETI Snow Owl User manual

INSTALLATION GUIDE & OPERATION MANUAL | PART NO. 25484 REV B

FEATURES

Reduced energy consumption with automatic snow

melting.

Slim design minimizes visual impact.

Mounts on ¾”PVC or ½” PVC with optional reducing

bushing or ½” NPT with included fittings.

Operates on safe low voltage power.

Simple 3 wire connections, 2 power, one signal.

Drop in replacement for ETI’s CIT-1 aerial sensor

Convenient power-on self-test to verify proper sensor

operation

Housing made with ASA UV-resistant plastic that was

formulated by the auto industry for exterior plastic trim

Made in the USA

•

•

•

•

•

•

•

•

•

2

SAFETY

Make all electrical connections in compliance

with the National Electrical Code (NFPA 70)

and the local electrical code.

ABNORMAL ODOR OR SMOKE

In the event of smoke, a burning odor or

abnormal odor, immediately interrupt power

to the unit by unplugging the unit or by turning

off the circuit breaker protecting the unit

ELECTRICAL SHOCK / FIRE HAZARD

As a low voltage control the SNOW OWL has a

maximum current load of 2 amps resistive for

24 VAC and presents little hazard of electrical

shock or fire. The SNOW OWL is intended

to control higher voltage / current heating

circuits which can present such hazards so

care must be taken when using the sensor for

these applications. This product is intended for

residential or light commercial applications.

Any installation involving electric heaters must

be grounded to earth to protect against shock

and fire hazard. Use a suitably sized ground

fault detection and interruption system to

reduce shock and fire hazard and to protect

SPECIFICATIONS

Dimensions

Input Power

Ouput

Hold On Time

Operating Temperature

Temperature Set Point

Storage Temperature

Height: 3.75” Diameter: 1.75”

24 V AC 50/60 Hz or 24V DC or 24V full wave rectified AC/ Pulsed DC 0.2A max

Relay Contacts: 2 Amps max, 30 V

Zero hold on time

-40ºC to +85ºC (-40ºF to +185ºF)

38ºF

-40ºC to +85ºC (-40ºF to +185ºF)

equipment. Wiring to heating elements must

be installed in accordance with the National

Electrical Code (NEC) requirements and all

other local and applicable electrical codes

and any third party standards. Follow the

installation instructions contained in this

manual and those provided by the heater

manufacturer.

Use a GFEP (Ground Fault Equipment

Protection) circuit breaker on each branch

circuit connected to the ice melting system.

Clearly label each circuit breaker with its

function. This is vitally important when there is

more than a single point of disconnect. Size

the circuit breaker in accordance with the size

of the maximum expected load.

Make certain that the heater shield is properly

grounded. Failure to do so may result in

electrical shock, damage to equipment or fire.

The Snow Owl performs an internal self test

when the power is first turned on. During the

first 10 seconds of power up the sensor will

turn on its output for a short time and engage

any contactor that is connected to it. For this

reason care should be taken to ensure that

heater power is either connected properly or

that it is turned off/ disconnected before

powering up the sensor.

Following installation and prior to beginning

system operation refer to and perform the

post-installation tests described in this

manual.

THEORY OF OPERATION

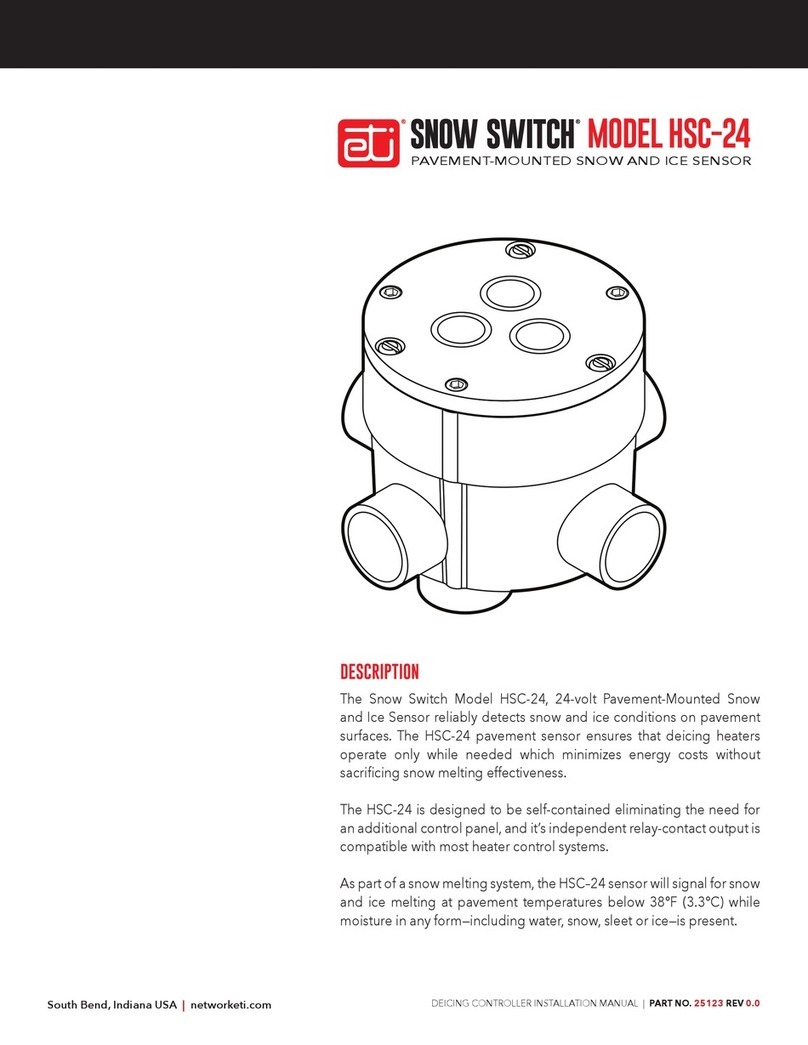

The SNOW OWL sensor monitors atmospheric

conditions to determine when a snow/ freezing

rain event occurs and responds by providing

a grounded output to the control circuit or

contactor which in turn will enable the heating

system.

It does this by using the snowflake shaped

moisture sensor on the top cap to melt the

snow/ ice that lands on it and then detects the

resulting water using a low voltage current.

The detection of water alone will not provide

an output but is used in combination with a

temperature reading below 380F. An Internal

processor looks for this combination or

moisture and temperature and triggers the

output only when both conditions are present.

This allows the SNOW OWL to trigger a heat

cycle only when it is needed. Once the SNOW

OWL has triggered it will remain on until

one or both of the stimuli is removed, and it

determines that the stimuli remains missing

for the next 4 minutes.

3INSTALLATION GUIDE & OPERATION MANUAL | PART NO. 25484 REV B

Make all electrical connections in compliance

with the National Electrical Code (NFPA 70)

and the local electrical code.

ABNORMAL ODOR OR SMOKE

In the event of smoke, a burning odor or

abnormal odor, immediately interrupt power

to the unit by unplugging the unit or by turning

off the circuit breaker protecting the unit

ELECTRICAL SHOCK / FIRE HAZARD

As a low voltage control the SNOW OWL has a

maximum current load of 2 amps resistive for

24 VAC and presents little hazard of electrical

shock or fire. The SNOW OWL is intended

to control higher voltage / current heating

circuits which can present such hazards so

care must be taken when using the sensor for

these applications. This product is intended for

residential or light commercial applications.

Any installation involving electric heaters must

be grounded to earth to protect against shock

and fire hazard. Use a suitably sized ground

fault detection and interruption system to

reduce shock and fire hazard and to protect

equipment. Wiring to heating elements must

be installed in accordance with the National

Electrical Code (NEC) requirements and all

other local and applicable electrical codes

and any third party standards. Follow the

installation instructions contained in this

manual and those provided by the heater

manufacturer.

Use a GFEP (Ground Fault Equipment

Protection) circuit breaker on each branch

circuit connected to the ice melting system.

Clearly label each circuit breaker with its

function. This is vitally important when there is

more than a single point of disconnect. Size

the circuit breaker in accordance with the size

of the maximum expected load.

Make certain that the heater shield is properly

grounded. Failure to do so may result in

electrical shock, damage to equipment or fire.

The Snow Owl performs an internal self test

when the power is first turned on. During the

first 10 seconds of power up the sensor will

turn on its output for a short time and engage

any contactor that is connected to it. For this

reason care should be taken to ensure that

heater power is either connected properly or

that it is turned off/ disconnected before

powering up the sensor.

Following installation and prior to beginning

system operation refer to and perform the

post-installation tests described in this

manual.

THEORY OF OPERATION

The SNOW OWL sensor monitors atmospheric

conditions to determine when a snow/ freezing

rain event occurs and responds by providing

a grounded output to the control circuit or

contactor which in turn will enable the heating

system.

It does this by using the snowflake shaped

moisture sensor on the top cap to melt the

snow/ ice that lands on it and then detects the

resulting water using a low voltage current.

The detection of water alone will not provide

an output but is used in combination with a

temperature reading below 380F. An Internal

processor looks for this combination or

moisture and temperature and triggers the

output only when both conditions are present.

This allows the SNOW OWL to trigger a heat

cycle only when it is needed. Once the SNOW

OWL has triggered it will remain on until

one or both of the stimuli is removed, and it

determines that the stimuli remains missing

for the next 4 minutes.

INSTALLATION INSTRUCTIONS

With user supplied hardware, mount the

SNOW OWL securely in an upright position

(sensor snowflake at top) in a clear and open

area typical of the area to be melted, either

above the roof line or removed from the

building in an area exposed to falling snow.

Avoid overhead trees, shrubs, wires, eaves,

etc., and falling or blowing debris.

Avoid vehicle and foot traffic. Avoid creating

a tripping or safety hazard.

Avoid exposure to artificial heat sources and

excessive shock and vibration.

Position the sensor at a height to reduce,

eliminate or discourage damage caused by

animals or vandals.

Install in accordance with the requirements of

all applicable electrical and building codes

and regulations. Ensure that all conduit and

cable terminations are watertight.

NEC Article 426.28 requires equipment

ground fault protection (GFEP) for ice and

snow melting equipment. This functionality is

not provided as part of this sensor and must

be provided as part of the overall system.

The SNOW OWL can be mounted at a distance

up to 500 feet away from the controller or

contactor using 22-gauge wires and up to

1000 feet using 18 gauge wires.

Once the SNOW OWL has been mounted in

the desired location it can be connected to the

controller or contactor.

•

•

•

•

4INSTALLATION GUIDE & OPERATION MANUAL | PART NO. 25484 REV B

With user supplied hardware, mount the

SNOW OWL securely in an upright position

(sensor snowflake at top) in a clear and open

area typical of the area to be melted, either

above the roof line or removed from the

building in an area exposed to falling snow.

Avoid overhead trees, shrubs, wires, eaves,

etc., and falling or blowing debris.

Avoid vehicle and foot traffic. Avoid creating

a tripping or safety hazard.

Avoid exposure to artificial heat sources and

excessive shock and vibration.

Position the sensor at a height to reduce,

eliminate or discourage damage caused by

animals or vandals.

Install in accordance with the requirements of

all applicable electrical and building codes

and regulations. Ensure that all conduit and

cable terminations are watertight.

NEC Article 426.28 requires equipment

ground fault protection (GFEP) for ice and

snow melting equipment. This functionality is

not provided as part of this sensor and must

be provided as part of the overall system.

The SNOW OWL can be mounted at a distance

up to 500 feet away from the controller or

contactor using 22-gauge wires and up to

1000 feet using 18 gauge wires.

Once the SNOW OWL has been mounted in

the desired location it can be connected to the

controller or contactor.

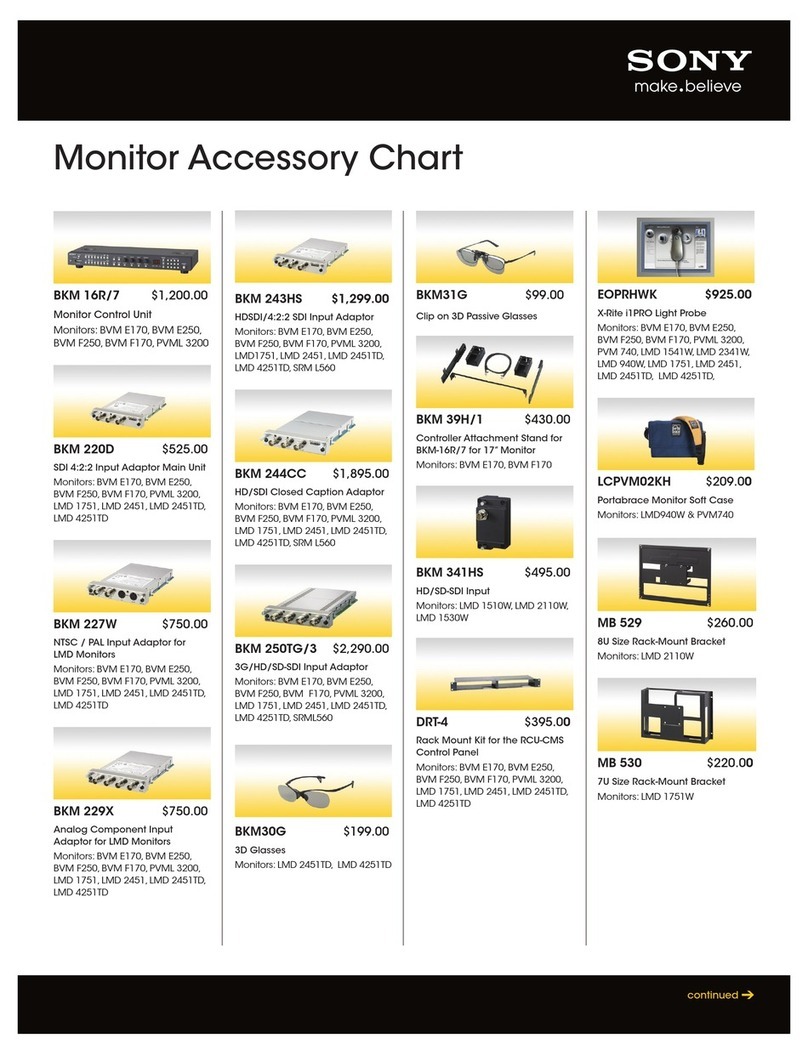

INSTALLATION DIAGRAMS

The following diagrams show the SNOW OWL

and CIT -1 drop in installations

POWER ON SELF TEST

PRE-INSTALLATION TEST

The SNOW OWL performs an internal self test

when the power is first turned on. During the

first 10 seconds of power up the sensor will

turn on its output and engage any contactor

that is connected to it for a short time. For this

reason care should be taken to ensure that

heater power is either connected properly

or that it is turned off/ disconnected before

powering up the sensor. If the sensor gives

a continuous ON-OFF-ON-OFF output then

this is an indication of a bad sensor. As a pre

installation test the POST can be run simply by

powering the unit and observing the output.

TESTING AFTER INSTALLATION

After installation the sensor can be tested

by cooling the sensor base with either ice

(do not immerse the sensor in ice water, it is

not water proof.) or freeze mist. Locate the

internal temperature sensor by first locating

the indexing tab (in the red circle in picture

below) and apply the mist to the base of the

sensor on the opposite side of the indexing

tab.

Once the unit is cooled continue by placing a

drop of water on the moisture grid. If testing in

the winter and the temperature is below 3.30C

(380F) then simply placing a drop of water or a

small amount of snow on the moisture grid will

start a heating cycle. To stop the cycles simply

turn off the power for 5 to 10 seconds and then

turn it back on.

LIMITED WARRANTY

ETI, offers a limited warranty on the SNOW

OWL covering material and workmanship.

The warranty starts from date of manufacture

and extends for one (1) year. However, if you

fill out the enclosed warranty card and return

it to ETI, then the warranty will be extended to

two (2) years from date of purchase.

For complete warranty information please visit

our web site at: www.networketi.com

GF-PRO, PD-PRO, APS-3C, APS-4C, EUR-5A & CIT-1 are trademarks

of Environmental Technology Inc. SNOW OWL is a trademark of ETI.

INSTALLATION GUIDE & OPERATION MANUAL | PART NO. 25484 REV B

5

Table of contents

Other ETI Accessories manuals