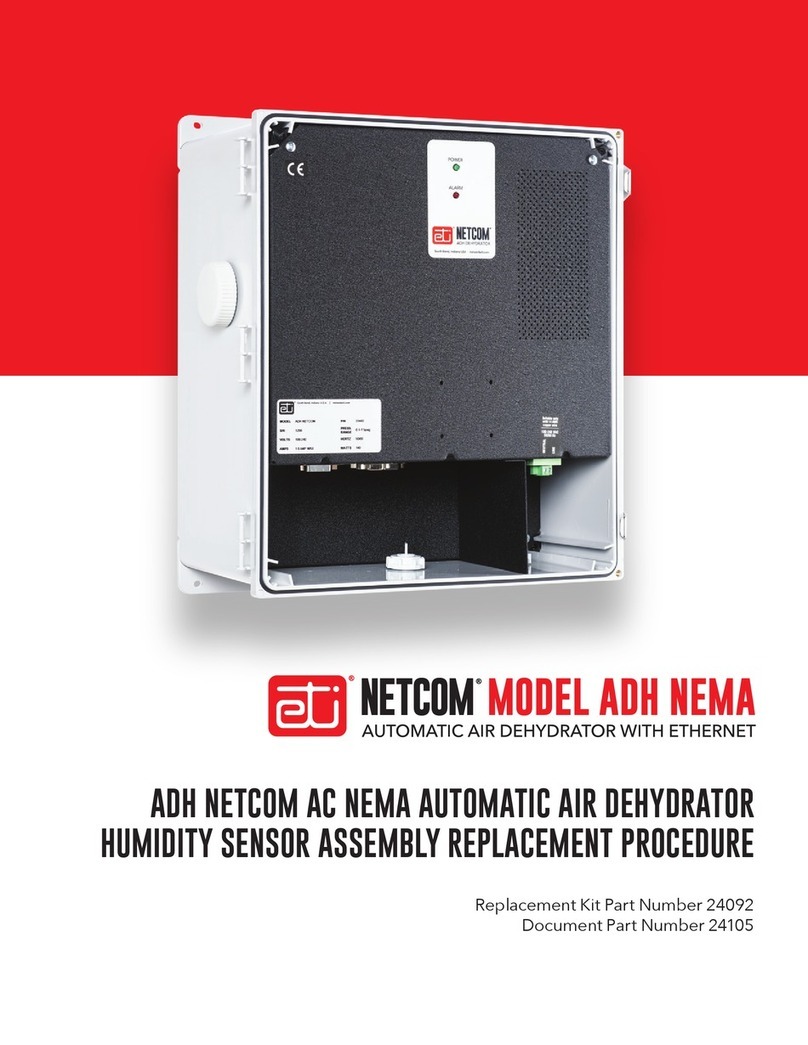

ETI NETCOM ADH Use and care manual

HUMIDITY SENSOR ASSEMBLY REPLACEMENT PROCEDURE | PART NO. 24104 REV B.0

MODEL ADH

ADH NETCOM AUTOMATIC AIR DEHYDRATOR

HUMIDITY SENSOR ASSEMBLY REPLACEMENT PROCEDURE

Replacement Kit Part Number 24092

Document Part Number 24104

HUMIDITY SENSOR ASSEMBLY

REPLACEMENT PROCEDURE

MODEL ADH

Lethal Voltages Present

Lethal voltages are present inside the ADH

NETCOM. Service should be performed by

qualified personnel only. There are no user

serviceable components inside the chassis.

Abnormal Odor or Smoke

In the event of smoke or a burning or abnormal

odor, immediately interrupt power to the ADH

NETCOM with the POWER switch at the rear of the

unit, unplug the unit, or turn off the circuit breaker

controlling the outlet. Note that only the AC model

of the ADH NETCOM has an ON / OFF switch.

Pneumatics

Each of the air pumps inside the ADH NETCOM

automatic air dehydrator is capable of generating

as much as 24 psig (1,655mbar). Other attached

dry air sources may be capable of generating even

higher pressures. Proper safety practice requires

treating all pneumatic components with care.

Always vent the system to atmospheric pressure

before servicing pneumatic components.

Rack Mounting

Before and after rack mounting the ADH

NETCOM, ensure that the rack is stable. Mounting

of the ADH NETCOM into a rack should be such

that a hazardous condition is not created due to

uneven mechanical loading. Verify that adequate

air flow and power source capacity is available to

the unit. Ensure that the ADH NETCOM maximum

operating temperature of 130°F (55°C) will not be

compromised by other components in the rack.

Ensure reliable earthing of the ADH NETCOM.

ADH NETCOM HUMIDITY SENSOR ASSEMBLY

REPLACEMENT PROCEDURE

This procedure addresses the removal and replacement of

the Humidity Sensor Assembly in either an ADH NETCOM

Automatic Air Dehydrator with AC power or with Redundant

DC power. It is recommended to read the entire procedure

prior to beginning work.

INVENTORY LIST

Identify the following items in this kit prior to beginning

work.

TOOLS REQUIRED

The following tools are needed to perform this procedure:

• Small flat blade screwdriver

• Tubing wrench or vacuum tube pliers

• Diagonal Cutters

NOTE :

On AC units, it might be useful to move the power filter

module and switch assembly out of the way for better access

to the humidity sensor during this procedure. Refer to Figure

1a. To do so, from the inside of the machine, after first noting

their placement, carefully disconnect the three electrical

leads from the filter module. Do not separate the leads from

the spade lugs. Then, from the back of the machine, unscrew

the two screws securing the power filter module to the

machine chassis then gently push the power filter module

toward the back of the dehydrator. It is not necessary to fully

remove the power filter module.

2

PART NO. DESCRIPTIONQTY.

23368

24104

Humidity Sensor Assembly

Instruction Manual (this document)

1

1

HUMIDITY SENSOR ASSEMBLY REPLACEMENT PROCEDURE | PART NO. 24104 REV B.0

3

Shut off AC unit power by placing the power switch in the

OFF (O) position. Unplug the power cord. Shut off DC unit

power by shutting off the external power supply. If possible,

move the unit to a work table.

Remove both top machine panels for easier access to the

humidity sensor assembly. Retain mounting hardware.

Using a tubing wrench or vacuum tubing pliers, carefully

disconnect from the “Y” hose assembly the length of hose

running between the “Y” assembly and the evaporator tray.

Refer back to Figure 1a for AC units and Figure 1b for DC

units.

Using a tubing wrench or vacuum tubing pliers, carefully

remove the two air hoses connected to the existing

humidity sensor. Refer to Figure 2.

To replace the Humidity Sensor Assembly (23368) in either an

ADH NETCOM Automatic Air Dehydrator with AC power or an

ADH NETCOM with Redundant DC power, perform the steps

below. Refer to Figure 1a or 1b, respectively, for AC and DC unit

illustrations.

HUMIDITY SENSOR ASSEMBLY REMOVAL AND

REPLACEMENT

1.

2.

3.

4.

Using the diagonal cutters, cut the two tie wraps securing

the humidity sensor assembly to its tie wrap mounts then

move the sensor out of the way to gain access to the

electrical connector.

Using a small tool, press in on either orange release tab

on the humidity sensor electrical connector on the PC

board then carefully remove the lead from that terminal.

Repeat for the other lead. Once both air hoses and both

electrical leads have been disconnected and the two tie

wraps cut, remove the existing humidity sensor from the

dehydrator.

5.

6.

HUMIDITY SENSOR ASSEMBLY REPLACEMENT PROCEDURE | PART NO. 24104 REV B.0

HUMIDITY SENSOR ASSEMBLY

REPLACEMENT PROCEDURE

MODEL ADH

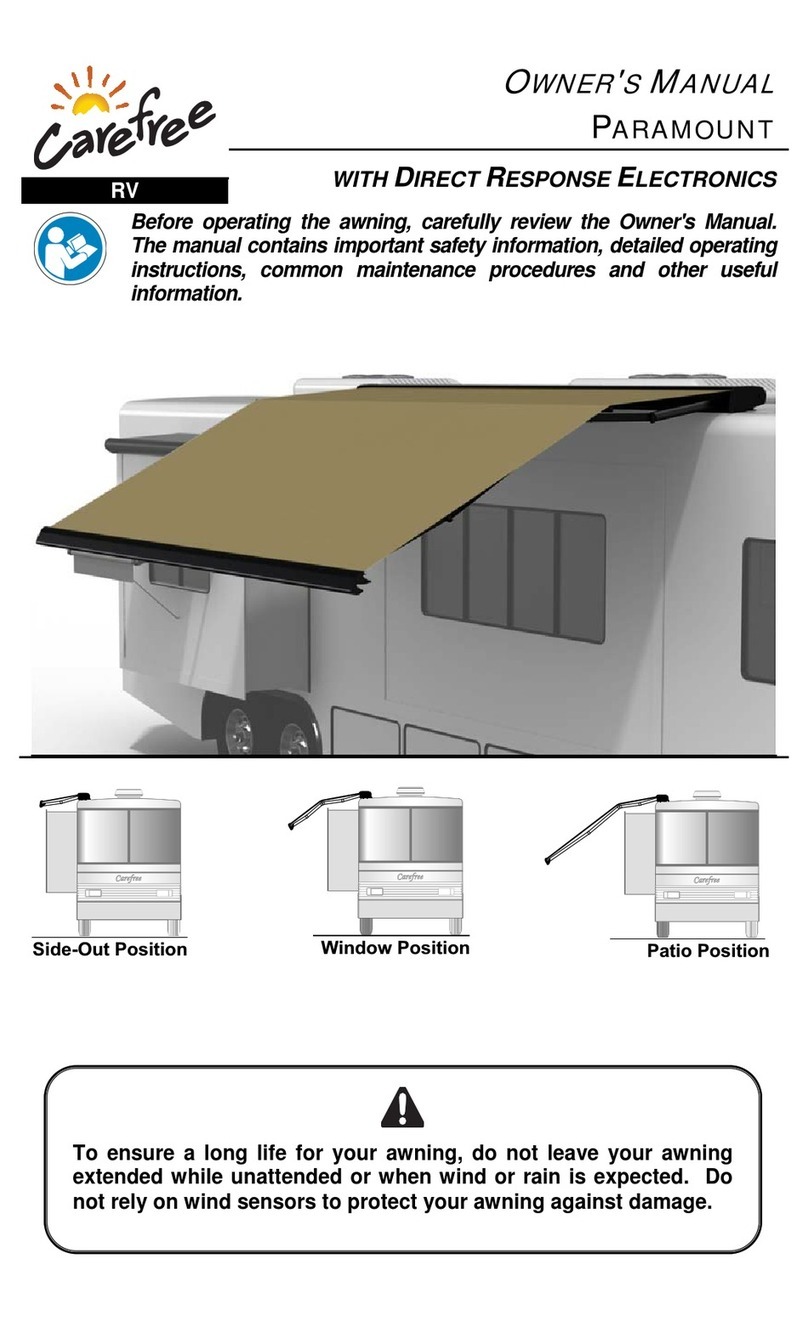

Power Filter Module and

Switch with electrical leads

removed (reference)

Disconnect evaporator

tray air hose from “Y”

assembly here. (step 3)

Humidity Sensor Assembly

Hose to Evaporator Tray

Figure 1a. THE ADH NETCOM AUTOMATIC AIR DEHYDRATOR

HUMIDITY SENSOR ASSEMBLY IN AN AC UNIT.

Figure 1b. THE ADH NETCOM AUTOMATIC AIRDEHYDRATOR

HUMIDITY SENSOR ASSEMBLY IN A DC UNIT.

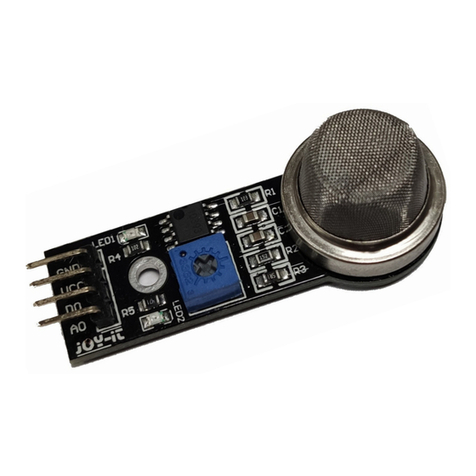

Figure 2. THE TWO HUMIDITY SENSOR AIR HOSES.

(some components removed for greater clarity)

Disconnect evaporator

tray air hose from “Y”

assembly here. (step 3)

Air In hose (90° fitting)

Air Out hose

(Straight fitting)

Humidity sensor

electrical connector

(on PC board)

For technical help, questions or comments concerning this

product or any ETI product contact Customer Service 8:00 a.m. -

5:00 p.m. Eastern Time.

networketi.com

ETI

1850 North Sheridan Street

South Bend, IN 46628

Email:

Web:

Mail:

CONTACTING CUSTOMER SERVICE

ETI’s two year limited warranty covering defects in workmanship

and materials applies. Contact Customer Service for complete

warranty information.

LIMITED WARRANTY

ETI makes no representations or warranties, either expressed or

implied, with respect to the contents of this publication or the

products that it describes, and specifically disclaims any implied

warranties of merchantability or fitness for any particular

purpose. ETI reserves the right to revise this publication, and to

make changes and improvements to the products described in

this publication, without the obligation of ETI to notify any person

or organization of such revisions, changes or improvements.

DISCLAIMER

4

Before putting the new humidity sensor on the tie wrap

mounts, connect the two leads from the new humidity

sensor. Reversing the process in step 6, push in on either

orange release tab then insert either humidity sensor

lead into that terminal. It does not matter which lead

goes to which terminal. Release the tab to secure the

lead. Repeat this process for the other lead. Tug gently

on each lead to make sure it is firmly connected.

Place the new humidity sensor onto the two tie wrap

mounts from which the original assembly was removed.

Before securing the new humidity sensor in place, rotate

the sensor on the two mounts so that the two air hoses

reach their respective 90° and straight fittings. The

longer hose is the Air Out hose and connects to the

lower or straight fitting.

The shorter hose is the Air In hose and connects to the

upper or 90° fitting. There is no right or wrong angle for

the humidity sensor itself in terms of function. All that

matters here is that both air hoses reach and connect

securely to the two sensor fittings.

Once the angle of the humidity sensor is determined

based on the position of the fittings to the hoses, secure

the new humidity sensor in place by feeding the two tie

wraps from the kit through the slot in each mount,

knurled side up, wrap the tie wraps together, then cut off

the excess from each tie wrap.

Reconnect the “Y” section of the tubing assembly which

runs to the evaporator tray and which was disconnected

in step 3.

As described in the Note on page 3, if any components

were moved or removed for better access to the

humidity sensor, replace them in their original location

and position at this time. Restore all connections. When

connecting the three electrical leads to the power filter

module on AC units, make sure to connect them to the

same terminals from which they were removed.

Reinstall the top panels using the hardware removed in

Step 2.

Restore machine power.

7.

8.

9.

10.

11.

12.

13.

HUMIDITY SENSOR ASSEMBLY REPLACEMENT PROCEDURE | PART NO. 24104 REV B.0

HUMIDITY SENSOR ASSEMBLY

REPLACEMENT PROCEDURE

MODEL ADH

Other manuals for NETCOM ADH

8

This manual suits for next models

1

Other ETI Accessories manuals