ETI SNOW SWITCH HSC-24 User manual

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

DESCRIPTION

The Snow Switch Model HSC-24, 24-volt Pavement-Mounted Snow

and Ice Sensor reliably detects snow and ice conditions on pavement

surfaces. The HSC-24 pavement sensor ensures that deicing heaters

operate only while needed which minimizes energy costs without

sacricing snow melting effectiveness.

The HSC-24 is designed to be self-contained eliminating the need for

an additional control panel, and it’s independent relay-contact output is

compatible with most heater control systems.

As part of a snow melting system, the HSC–24 sensor will signal for snow

and ice melting at pavement temperatures below 38°F (3.3°C) while

moisture in any form—including water, snow, sleet or ice—is present.

MODEL HSC-24

PAVEMENT-MOUNTED SNOW AND ICE SENSOR

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

2

It’s important for the sensor to be level with the pavement

surrounding it. A Pavement Sensor Housing, ETI part

number 23832 (sold separately), is needed for each

pavement sensor. This housing supports the sensor within

the pavement and includes adjustment screws that allow

proper leveling with the pavement surface.

WHAT’S IN THE BOX

Immediately upon receipt, inspect the container and packing

material for any noticeable damage or missing contents.

From the factory an HSC–24 sensor includes:

1-HSC–24 pavement sensor (PN 25124)

1-Package (1 lb.) duct seal (PN 20763)

3-3/8”-16 × 0.25” hex socket set screws (PN 21630)

3-#8-32 × 0.375” machine screws (PN 11632)

1-3/16” hex key (PN 21631)

1- Installation and Operation Manual (PN 25123)

Unpack the unit, taking care not to damage the packing

materials. Save the shipping container and related

materials until normal operation has been established. In

the event of shipping damage, keep the packing materials

for inspection by the carrier. If any of the contents are

missing or damaged please contact your supplier or ETI

Customer Service.

SENSOR LOCATION

The HSC–24 pavement sensor should be installed in

a location that best represents the typical snow and

ice conditions on the pavement surfaces that are

being deiced.

Position the sensor centered between the heater cables

or tubing. This will allow the sensor to be exposed to a

surface temperature that is typical of the deiced area

without causing abnormal heating of the sensor.

AVOID: BUILDING OVERHANGS, TREES, LOCATIONS

WHERE VEHICLES PARK AND ANY OTHER

OBSTRUCTIONS THAT MAY PREVENT SNOW,

FREEZING PRECIPITATION AND/OR SOLAR

GAIN FROM REACHING THE SENSOR.

AVOID: HOT AIR EXHAUST DUCTS OR OTHER HEAT

SOURCES THAT MAY AFFECT THE SENSOR

AND CAUSE IT TO BE WARMER AND DRIER

THAN THE AREA BEING DEICED.

AVOID: EXPOSURE TO ARTIFICIAL HEAT SOURCES AND

ANIMALS. A SENSOR INSTALLED IN AN AREA

HOUSING ANIMALS (SUCH AS A KENNEL)

OR IN AN AREA WITH A HIGH AMOUNT OF

ANIMAL TRAFFIC MAY RUN MORE OFTEN

THAN DESIRED.

CONSIDER: SITE DRAINAGE IS IMPORTANT. A SENSOR

PLACED IN A LOCATION WHERE THE

DRAINAGE IS BETTER OR WORSE THAN IS

TYPICAL OF THE PAVEMENT INSTALLATION

MAY CAUSE THE SYSTEM TO TURN OFF TOO

SOON OR TO RUN TOO LONG.

CONSIDER: VEHICLE AND PEDESTRIAN TRAFFIC MAY

TRACK MOISTURE AND WET DEBRIS ONTO

THE PAVEMENT SENSOR AND CAUSE THE

SYSTEM TO RUN LONGER. DEPENDING ON

THE FUNCTION OF THE AREA BEING DEICED IT

MAY OR MAY NOT BE DESIRABLE TO EXPOSE

THE SENSOR TO TYPICAL TRAFFIC PATTERNS.

CONSIDER: INSTALLING ADDITIONAL SENSOR HOUSINGS,

IT IS LESS EXPENSIVE THAN DIGGING UP A

PAVEMENT INSTALLATION LATER. INSTALLING

ONE OR MORE EXTRA HOUSINGS WILLALLOW

YOU TO MOVE A SENSOR LATER IF NEEDED.

ALSO, DEPENDING ON THE CONTROL BEING

USED, YOU MAY BE ABLE TO RUN ADDITIONAL

SENSORS TO THE SAME CONTROL.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

3

CONDUIT

After positioning the sensor, install 3/4” conduit from the

sensor housing to the snow melting control. Do not share

the sensor cable’s conduit with any high voltage wiring.

The HSC–24 pavement sensor includes 60’ (18 m) of cable.

Should any additional length of cable be required, ensure

that the splice is made in a junction box appropriate for

the location.

HOUSING INSTALLATION

Follow the instructions in the Pavement Sensor Housing

manual to ensure the housing is installed correctly and

made level with the paving surface.

SENSOR INSTALLATION

Remove the sensor housing cap from the housing unit by

removing the three screws securing it in place. Be sure to

keep the cap for future use should the housing unit need

to be recapped.

Feed your sh tape through the conduit from the control

end. Attach the cable to the sh tape and pull it back

through the conduit, using cable lubricant if necessary.

Be sure there are no kinks in the cable. Leave a few inches

of cable at the pavement sensor end for a service loop.

Inside the Pavement Sensor Housing apply duct sealant

to protect the installation, leaving room for the sensor to

be placed down inside the housing. Knead the supplied

duct sealant until it is pliable. In addition to sealing the

wiring conduit, the duct sealant should occupy space in

the housing so that it will displace water that might enter.

This will minimize the accumulation of water and ice in the

housing and protect against possible ice damage.

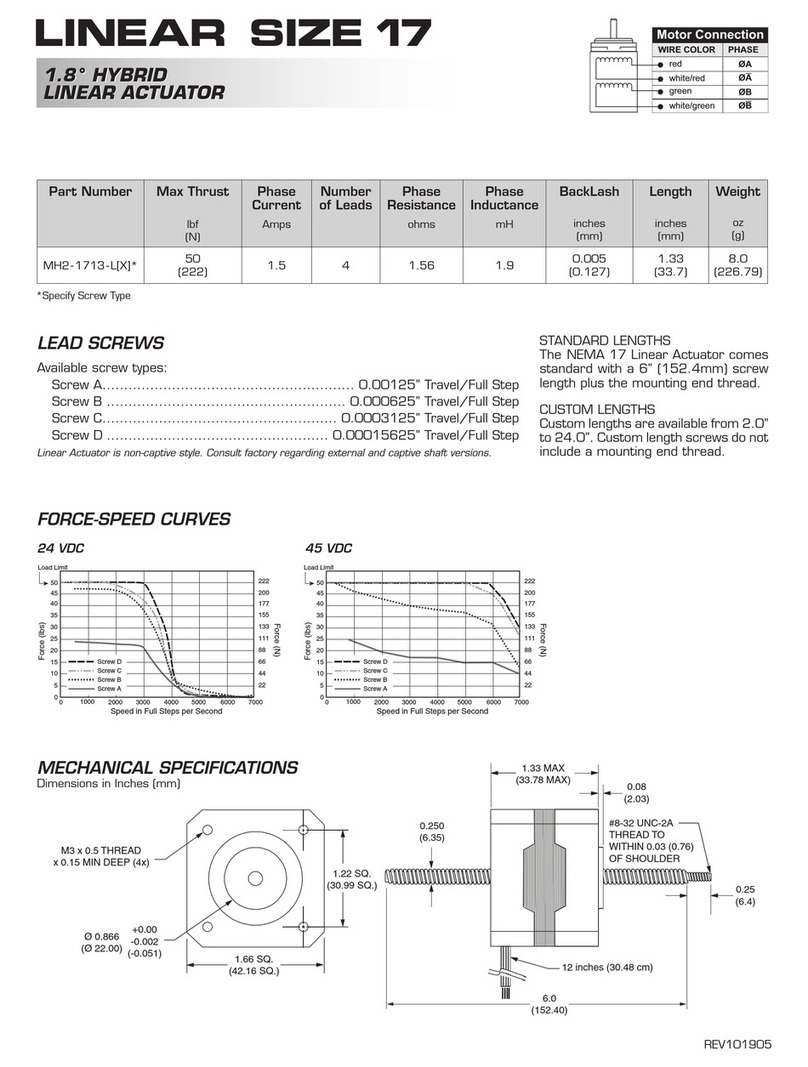

Install the sensor into the housing with its top resting on

the top of the Height Adjustment Ring. Check that all

six holes are properly aligned, and fasten the sensor

to the Height Adjustment Ring with the three Sensor

Retaining Screws.

To promote correct assembly the screws that secure the

housing cap and sensor attachment are positioned to

form the points of an equilateral triangle. The positions of

the height adjustment screws, which level the surface of

the sensor to the surface of the pavement, form the points

of an isosceles triangle.

Adjust sensor to be ush with the pavement around it. To

do this remove the three protective hex screws (Figure

2), when removed you will see the Height Adjustment

Screws. To level the sensor rotate the Height Adjustment

Screws (Figure 3) clockwise to lower the sensor or

counterclockwise to raise it. The housing ange can be

raised up to 0.63”(16 mm) to allow the sensor surface to

be aligned with the pavement surface. When the unit is

level and ush with the pavement, reinstall the protective

hex screws. Failing to level the sensor ush with its

surrounding pavement can result in water pooling which

will cause the sensor to not function properly.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

4

FIGURE 1. HSC-24 Pavement Sensor Installation.

FIGURE 2. Remove protective hex screw to reveal Height

Adjustment Screw.

FIGURE 3. Rotate Height Adjustment Screw clockwise to

lower or counterclockwise to raise sensor.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

5

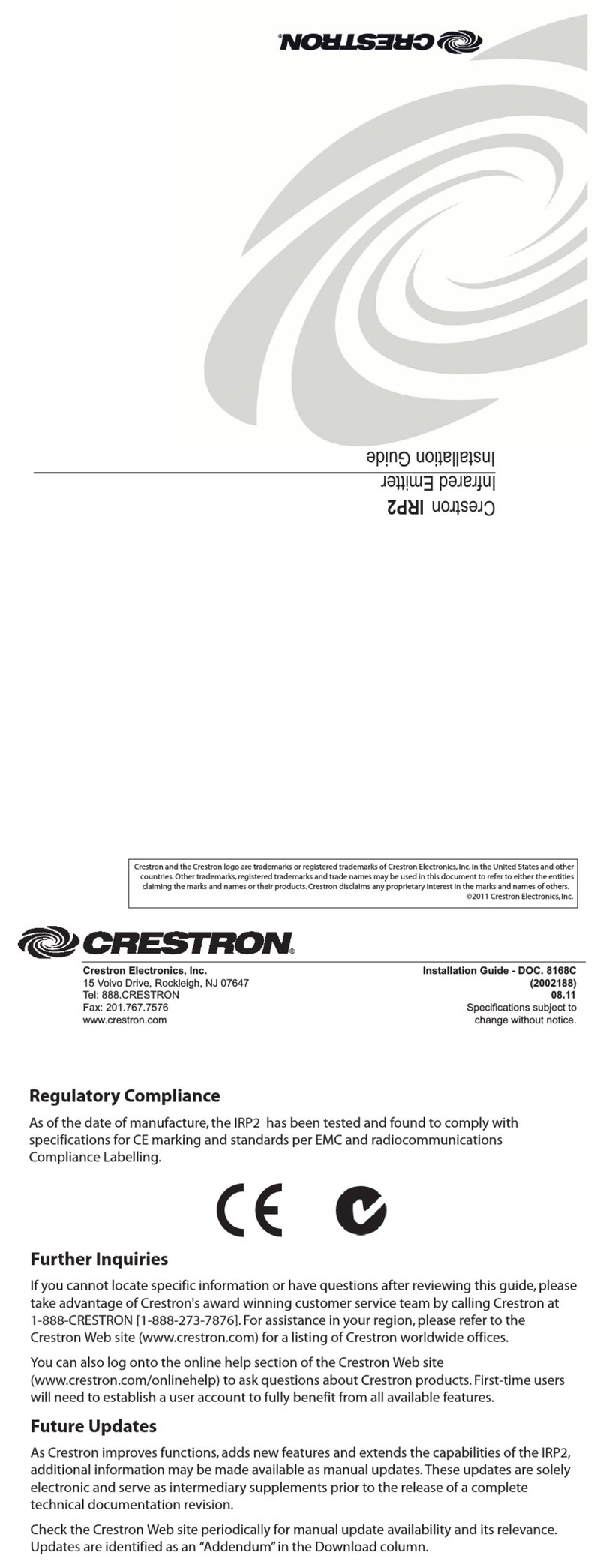

FIGURE 6. Wire connections for dry contact control.

FIGURE 4. Wire connections for 24 ac loads.

FIGURE 5. Wire connections for external relay with 24 ac coil.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

6

WIRING

Be sure to follow NEC and local code for all electrical

connections.

A four-conductor direct-burial wet-environment cable

is required to connect the HSC-24 sensor to the control

panel. The 60-foot cable supplied with the HSC-24 meets

these requirements. This may be extended up to 500 feet

(152m) using 18 AWG 4-wire jacketed cable, or up to

2,000 feet (609m) using 12 AWG 4-wire jacketed cable.

Install all cables through conduit as indicated in the

Conduit section.

Make sure that any cable runs greater than 60 feet are

spliced together either in a suitable water-tight junction

box or in some other water-tight or dry location.

Cable Connections for HSC-24 Snow Switch Pavement

Sensor:

WIRE COLOR FUNCTION

BLACK Ground

RED 24 V Power (AC or full-wave rectied)

BLUE Sensor Output Signal

ORANGE Sensor Output Signal

The HSC-24 can directly operate solenoids, pumps, or

other loads up to a maximum of 60 W or 62 VA.

For applications of this type that operate at 24 V ac, see

Figure 4.

For larger loads, the HSC-24 can operate a separate

relay or contactor. Figure 5 shows the connections for an

external relay with a 24 V ac coil.

Boiler controllers often need a dry contact closure

to control their operation. The wiring for this type of

connection is shown in Figure 6.

TESTING

The sensor installation should be tested before being

placed in service. The HSC-24 has an internal self-test

mode which can be used to help verify correct operation.

A Digital Volt Meter (DVM) is used to test its operation.

1. Verify the supply voltage to the sensor. With the system

turned on, measure the voltage from the sensor’s

black lead to the red lead. By measuring with an AC

range setting and then with a DC range setting, each

type of voltage will be shown on the DVM. Depending

on the controller used, the DVM readings should be

11-12 VAC and 24-28 VDC (with rectied source), 22-

28 VAC and 0 VDC (with pure ac source), or 0 VAC and

22-26 VDC (with pulsed DC source).

2. Meter Connections for Self Test

During self test, the sensor’s internal heater can be

tested using the DVM as a current meter. The sensor

current is measured with the DVM connected in series

with the sensor power lead (the red wire). The meter

can be set to DC amps when the sensor is being

powered by a functioning ETI control panel. It can

be set to AC amps when the unit is powered with a

separate 24 VAC power supply. When the heater is

off, the current will be about 5 mA. When the heater is

on, the current will be about 250 mA.

During self test, the sensor’s output signal can be

tested with a voltmeter while the output lead is

connected to a functioning control panel. The voltage

is measured from the Blue lead to the Orange lead.

When the temperature is above 38°F or the sensor is

dry, the output will be OFF. In this case there will be a

voltage present from Blue to Orange (the voltage will

depend on the system controller).

To call for heat, the blue and orange wires are

connected together by the sensor’s internal

relay. These wires are interchangeable.

NOTE:

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

7

When the output is turned ON, the voltage from Blue

to Orange will be zero volts.

The sensor can also be tested with at least one of

the Blue and Orange leads disconnected, using the

continuity-test mode on the DVM. When the output is

OFF, Blue and Orange will be open; when the output

is ON, they will have continuity.

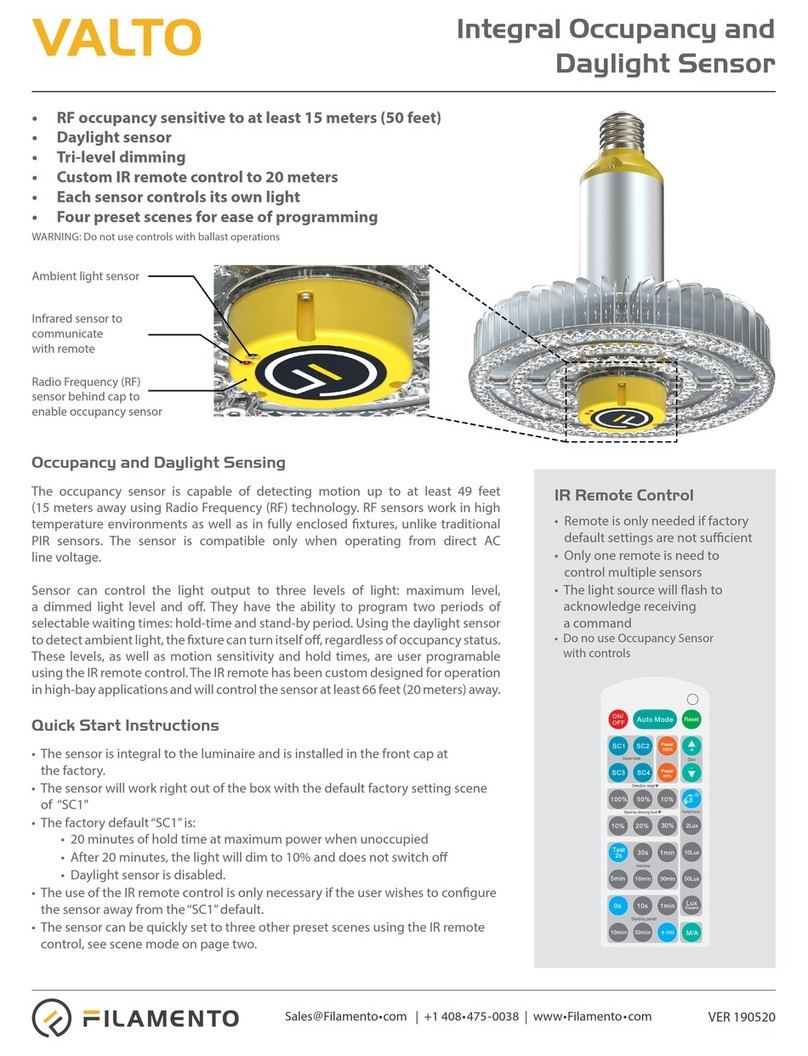

3. After the meter connection is made,initiate the self-test

mode as follows. A system power switch or temporary

connection for the red power lead is needed to allow

briey interrupting the supply voltage to the sensor.

See Figure 5.

a. Power is applied to the sensor.

b. Then between 0.1 second and 4 seconds later,

the power is very briey interrupted – for 50 to

100 milliseconds – and then reapplied. This can be

done with a power switch, using a clip cable, or by

temporarily wiring a normally-closed pushbutton

so that it can be very briey pressed.

c. The power is maintained after that power-up pulse,

and the self-test then begins.

The self-test mode can be identied by the initial

increase in current draw (part 5a, below). If that

does not happen, it may be that self-test mode was

not entered; this happens if the power-off pulse

time is too long. In that case, remove power for at

least two seconds, then repeat the off-pulse

sequence (a-c) described above (Figure 7).

4. After the self-test mode is initiated, the following

action will happen:

a. The heater turns on for three seconds. During this

time, the current draw will increase to 0.25 amps.

This can be monitored with the current meter as

described in part 2.

b. As shown in Figure 7, the output and heater

temperature, measured to the nearest degree F.

One pulse means below 38, 2 means at 38, 3

means above 38, 4 means there is a problem.

c. After that, the unit will go into moisture-sense

mode. At this point, when moisture is sensed, the

output will turn on. When moisture is not sensed,

the output will turn off. This is monitored with the

DVM as described in part 2.

d. Moisture can be simulated with water on the sensor

(at any temperature) or with a metallic object

placed on the sensor to short one of the electrode

disks to the outside rim of the sensor.

When moisture is sensed, in addition to the output

turning on, the heater will begin pulsing with one

second on and two seconds off. You can see that

happening with the current meter.

e. After one minute, the self-test will end, and the

sensor will begin normal operation.

5. As an alternative to the self-test mode, the sensor can

be tested with ice. To do this, place ten pounds (4.54

kg) of crushed ice over the sensor and wait about 20

minutes before observing that a low output voltage (2

volts or less) is indicated by the DVM.When the sensor

temperature goes below 38° F (3.3° C) the sensor’s

output will turn ON and change to a lower voltage. If

the sensor surface temperature is initially very warm

then this procedure may take longer, perhaps 40

minutes or more.

6. With satisfactory results, disconnect the DVM and

restore all sensor wiring connections.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

8

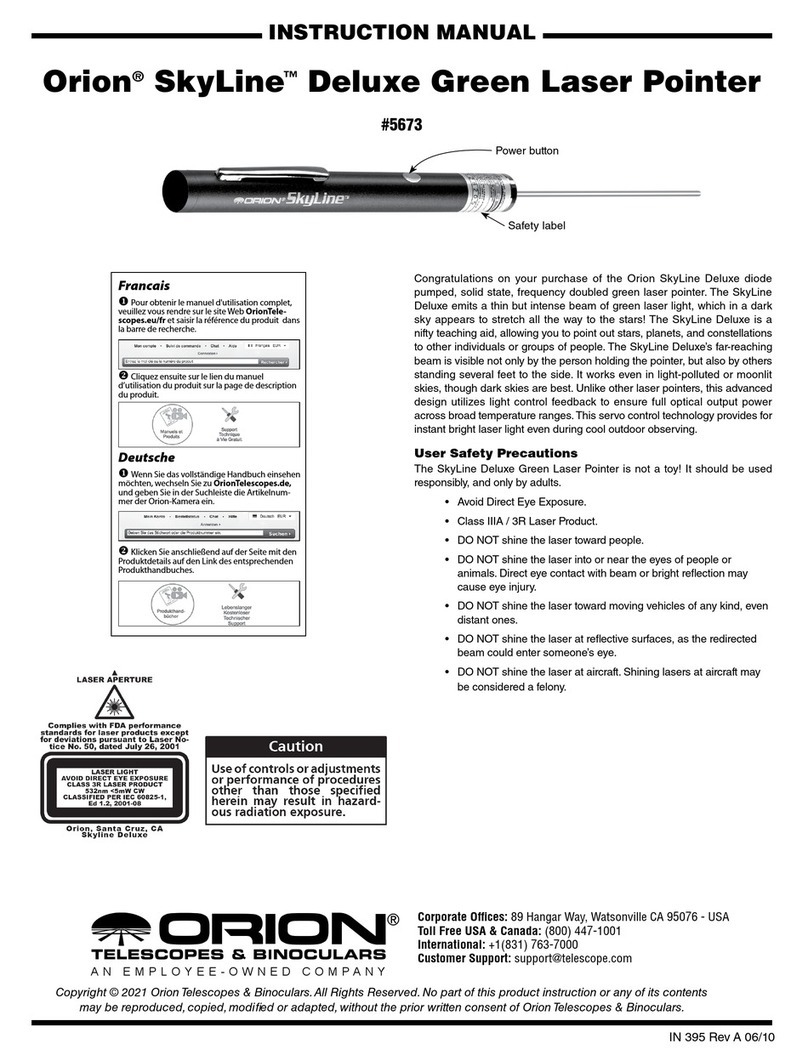

HOLD-ON TIME DISPLAY

The programmed hold time can be determined with this

test. Using the sensor and meters connected as in the self-

test mode (“Testing” section 2), apply power to the sensor

and within four seconds quickly interrupt and restore the

power twice. After a two second delay, the unit will pulse

both the heater and output (one second on, one second

off) n+1 times to indicate the currently congured hold-

on time. This will be repeated 5 times with 3 seconds

between each set of pulses. See Figure 8.

FIGURE 7. Sensor Self-Test Mode.

FIGURE 8. Hold-On Time Display Mode.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

9

HOLD-ON TIME CONFIGURATION

The programmed hold time can be changed with this

procedure. Apply power to the sensor and within four

seconds quickly interrupt and restore the power three

times. After a two second delay, the sensor will send three

quick pulses to indicate it is in hold-on conguration

mode. Interrupt and reapply power to create n+1 quick

pulses to zero volts, where n is the number of hours

(from 0 to 6 hours, 1 to 7 pulses). See Figure 9. The rst

pulse must be within 6 seconds or the process aborts.

There can be up to two seconds between pulses. After

conguring the hold-on time, wait two seconds to initiate

a save of the hold-on time. Once the hold-on time has

been saved the sensor will display the new hold-on time

with the same pattern used during the hold-on time

display mode (Figure 8).

FIGURE 9. Hold-On Time Conguration Mode.

TROUBLESHOOTING

Most issues are due to wiring error or moisture in the

housing. Check for these issues rst. If problem persists

please contact your supplier or ETI Customer Service.

MAINTENANCE

The top of the sensor should be kept reasonably clean

and free of gravel, leaves, mud, or other debris. If paving

material, salt or another residue becomes adhered to the

sensing elements, clean the surface with a Scotch™ Brite

Pad. Do not use metallic or coarse abrasives or detergents.

We recommend that the HSC-24 sensor’s power supply

operate continuously even though you may elect to de-

energize the snow/ice melting system main heaters at the

season’s end. The sensor will consume very little energy

(a small fraction of a watt) and this will enhance the long-

term reliability of the HSC-24 sensor.

RETURNS AND REPLACEMENTS

Equipment cannot be returned for credit once it has

been installed. Environmental Technology will repair or

replace faulty equipment under warranty. Prior to removal

of equipment for warranty return, please contact ETI

Technical Support at for troubleshooting assistance.

Before returning a unit to ETI,obtain a Return Merchandise

Authorization from our Customer Service Department,

available between 8:00 a.m. and 5:00 p.m. Eastern Time. If

possible, use the original container and packing materials

when packing the unit for shipment. It is important to

mark the Return Merchandise Authorization clearly

on the outside of the shipping container so that it may

be correctly processed upon receipt at Environmental

Technology.

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

10

SPECIFICATIONS

General

Area of Use Pavement

Activation Temperature 38˚ F (3.3˚ C)

Hold-on Time User congurable to 0 h, 1 h, 2 h, 3 h, 4 h, 5 h, or 6 h

Default Hold-On Time 0 h up to 3 minutes after snow/ice/water no longer detected or

5 minutes after temperature rises above sense range

Materials Brass with Epoxy and Polyurethane Fill

Weight 0.5 kg (1.1 lb)

Dimensions Top Diameter: 9.84 cm (3.875 in)

Top Thickness: 6.35 mm (0.25 in)

Mounting Depth: 5 cm (2 in)

Electrical

Circuit type NEC Class 2

Supply voltage 24 Vac +/- 15%

Supply Current 5 mA idle, 0.25 A max.

Operating Power 6 W max.

Snow/Ice Sense Response Time 10 to 20 seconds

Output Signal Voltage drop

Output Off Relay Open

Output On (snow/ice present) Relay Closed

Contact Rating 220 Vdc / 250 Vac / 2 A / 60 W / 62 VA max.

Cable Type Direct Burial 4-Conductor 18 AWG

Cable Length 60 ft (18.3 m) included; may be extended:

• Up to 500’ (152m) using 18 AWG 3-wire jacketed cable

• Up to 2,000’ (609m) using 12 AWG 3-wire jacketed cable

Self Test Mode Checks temperature, heater, and sensor grid. Indicates results with output

and current pulses (see manual).

Compatible Controllers APS , EUR, PD Pro, and GF Pro controllers, and other systems which can utilize

contact-closure signaling and provide 24 Vac power.

Environmental

Operating Temperature Range −40 °C to 70 °C (−40 °F to 158 °F)

Snow/Ice Sense Temperature Range −30 °C to 3 °C (−22 °F to 38 °F)

Storage temperature −50°F to 180°F (−45°C to 82°C)

South Bend, Indiana USA | networketi.com DEICING CONTROLLER INSTALLATION MANUAL | PART NO. 25123 REV 0.0

11

ORDERING INFORMATION

ORDER# DESCRIPTION

25125 HSC–24 Pavement-Mounted Sensor

(requires Pavement Sensor Housing)

23832 Pavement Sensor Housing

CONTACT CUSTOMER SERVICE

For assistance, contact Customer Service. Ofce hours are

from 8:00 AM until 5:00 PM ET.

Email: [email protected]

Web: networketi.com

Mail: ETI

1850 North Sheridan Street

South Bend, IN 46628

LIMITED WARRANTY

ETI’s two year limited warranty covering defects in

workmanship and materials applies. Contact Customer

Service for complete warranty information.

DISCLAIMER

ETI makes no representations or warranties, either

expressed or implied, with respect to the contents

of this publication or the products that it describes,

and specically disclaims any implied warranties of

merchantability or tness for any particular purpose. ETI

reserves the right to revise this publication, and to make

changes and improvements to the products described

in this publication, without the obligation of ETI to notify

any person or organization of such revisions, changes or

improvements.

Copyright © 2019 ETI,

®

All rights reserved.

Table of contents

Other ETI Accessories manuals