ETT Olfactometer 2 User manual

ETT Olfactometer & ETTDirectControl

The First Paradigm

Manual and Tutorial

Revision 2021.1

2

© Emerging Tech Trans, LLC

3

© Emerging Tech Trans, LLC

Table of Contents

The First Paradigm...................................................................................................................................... 5

Warnings................................................................................................................................................. 5

Software Installation (ETTDirectControl) ................................................................................................ 5

Access to our installer......................................................................................................................... 5

Download............................................................................................................................................ 6

Software overview................................................................................................................................ 10

Manual Mode.................................................................................................................................... 10

Paradigm Designer............................................................................................................................ 10

Updater / Settings............................................................................................................................. 12

Help................................................................................................................................................... 14

Connecting the Device.......................................................................................................................... 16

Before the first power up.................................................................................................................. 16

ETT Olfactometer 2........................................................................................................................... 17

ETT Olfactometer S & ETT Olfactometer C........................................................................................ 19

Prerequisites......................................................................................................................................... 21

The paradigm.................................................................................................................................... 21

Preparing the odorants..................................................................................................................... 21

Connecting the tubing....................................................................................................................... 22

Flow rate adjustments ...................................................................................................................... 24

Creating a simple paradigm.................................................................................................................. 25

Creating a new paradigm.................................................................................................................. 25

Configuring an olfactory condition.................................................................................................... 27

Configuring the visual component.................................................................................................... 29

Managing, cloning and adjusting groups........................................................................................... 31

Assembling paradigm........................................................................................................................ 32

Labeling conditions for data analysis ................................................................................................ 32

Group randomizer............................................................................................................................. 32

Triggered start .................................................................................................................................. 33

Recording the respiratory signal ....................................................................................................... 33

Test run............................................................................................................................................. 33

4

© Emerging Tech Trans, LLC

Inspecting the data file ..................................................................................................................... 36

Using Triggers in ETTDirectControl ....................................................................................................... 39

TTL IN (Externally triggered start) ..................................................................................................... 39

Respiratory Trigger............................................................................................................................ 40

Beyond basics ................................................................................................................................... 42

Cleaning the odorant carrier..................................................................................................................... 46

Before we start:.................................................................................................................................... 46

Cleaning the carrier top........................................................................................................................ 46

Cleaning the bottles.............................................................................................................................. 50

Cleaning the tubing............................................................................................................................... 50

Odorant flow setup................................................................................................................................... 52

Carrier Setup......................................................................................................................................... 52

Check valve layout in the odorant carrier............................................................................................. 52

Typical air flow configuations ............................................................................................................... 53

Configuration for multiple channels at once......................................................................................... 55

Setting up multiple channels within ETTDirectControl ......................................................................... 56

ETT EEG Trigger Interface.......................................................................................................................... 57

Hardware setup .................................................................................................................................... 57

System overview............................................................................................................................... 57

Software Setup ..................................................................................................................................... 58

Prerequisites..................................................................................................................................... 58

EGI NetStation................................................................................................................................... 58

ETT Direct Control............................................................................................................................. 60

5

© Emerging Tech Trans, LLC

The First Paradigm

Warnings

1. This device is for research use only!

2. The main device / the actual ETT Olfactometer is not MRI compatible.

3. Only the ETT Odorant carrier, tubing, respiratory belt and the applicator/nose piece are MRI

compatible and thus allowed into the magnet room.

4. Feed all tubing through an appropriately sized wave guide to avoid damage to it.

Software Installation (ETTDirectControl)

Access to our installer

For registered users, we are offering all our software as a download on our website

(emergingtechtrans.com). Access will be provided during the purchase of the device via email contact

with our support. Additional accounts can be created at any time upon request to

support@emergingtechtrans.com.

With access to our support section (Figure 1) there are two to three different versions of

ETTDirectControl accessible. Depending on your request, we can unlock specific preview version access.

All installer packages describe supported operating systems and contain all necessary dependencies in

the package. Should it be required, we are also providing links to the driver and library packages below

separately.

It should be noted that the previous stable version, while still actively maintained is limited in its

features to support our users that are still using Windows XP. To use all new features, download the

current stable / release version. Please look at the Meaning of Update Rings on page 13, to find out

more about each version.

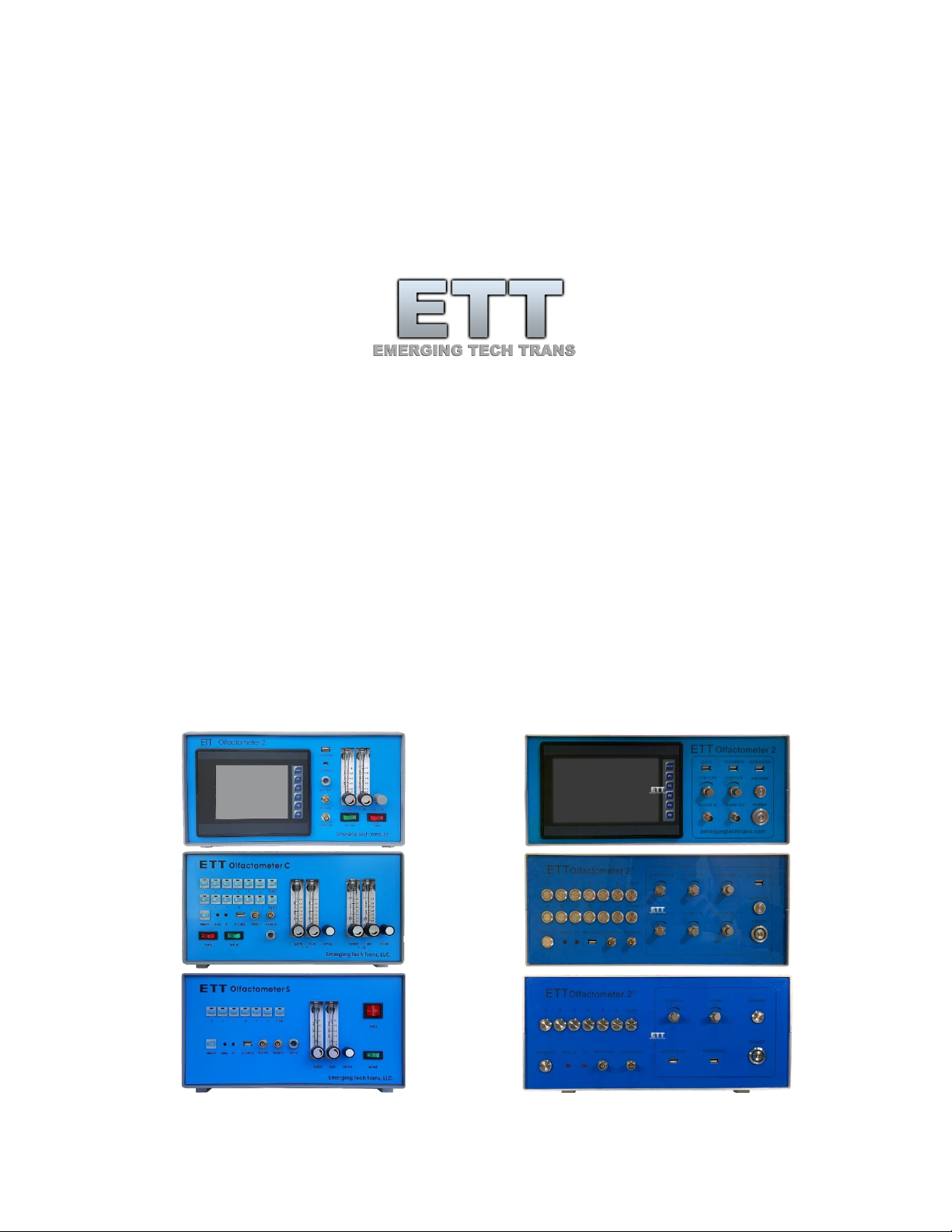

This manual suits for next models

4

Table of contents