1

User Information

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 DE-70771 Lein elden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de in o@euchner.de

Emergency Stop Safety Relay ESM-BA2..

V1.1.0

•

Cyclical monitoring of the output contacts

•

Indication of the switching state via LED

•

2 start behaviors possible:

- Monitored manual start

- utomatic start

•

Up to PL e, SILCL 3, category 4

Correct Use The ESM-BA2.. is a universal emergency stop safety s itching

device ith t o safe relay outputs that can quickly and safely

stop the moving parts of a machine or system in case of danger.

Applications for the ESM-BA2.. include single or dual-channel

emergency stop circuits and guard monitoring on machines and

systems.

Features

•

2 safe, redundant relay outputs

•

Connection of:

- Emergency stop buttons

- Safety switches

- Non-contact safety switches

- OSSD-Outputs

•

Single and dual-channel operation possible

•

Feedback loop for monitoring downstream contactors or

expansion modules

Function

The emergency stop safety switching device ESM-BA2.. is

designed for safe isolation of safety circuits according to

IN EN 60204-1 and can be used up to safety category 4,

PL e according to IN EN ISO 13849-1.

The internal logical system closes the safety contacts when

the start button is pressed.

When the emergency stop circuit is opened, the positively

driven safety contacts are opened and safely switch the

machine off. It is ensured that a single fault does not lead

to a loss of the safety function and that every fault is detec-

ted by cyclical self-monitoring no later than when the sys-

tem is switched off and switched on again.

Electrical

Connection

•

When the 24 V version is used, a safety transformer

according to EN 61558-2-6 or a power supply unit with

electrical isolation from the mains must be connected.

•

External fusing of the safety contacts must be provided.

•

A maximum length of the control lines of 1000 meters

with a line cross section of 0.75 mm2 must not be excee-

ded.

•

The line cross section must not exceed 2.5 mm2.

•

If the device does not function after commissioning, it

must be returned to the manufacturer unopened. Ope-

ning the device will void the warranty.

Installation

As per IN EN 60204-1, the device is intended for installa-

tion in control cabinets with a minimum degree of protection

of IP54. It is mounted on a 35-mm IN rail according to

IN EN 60715 TH35.

Safety Precautions

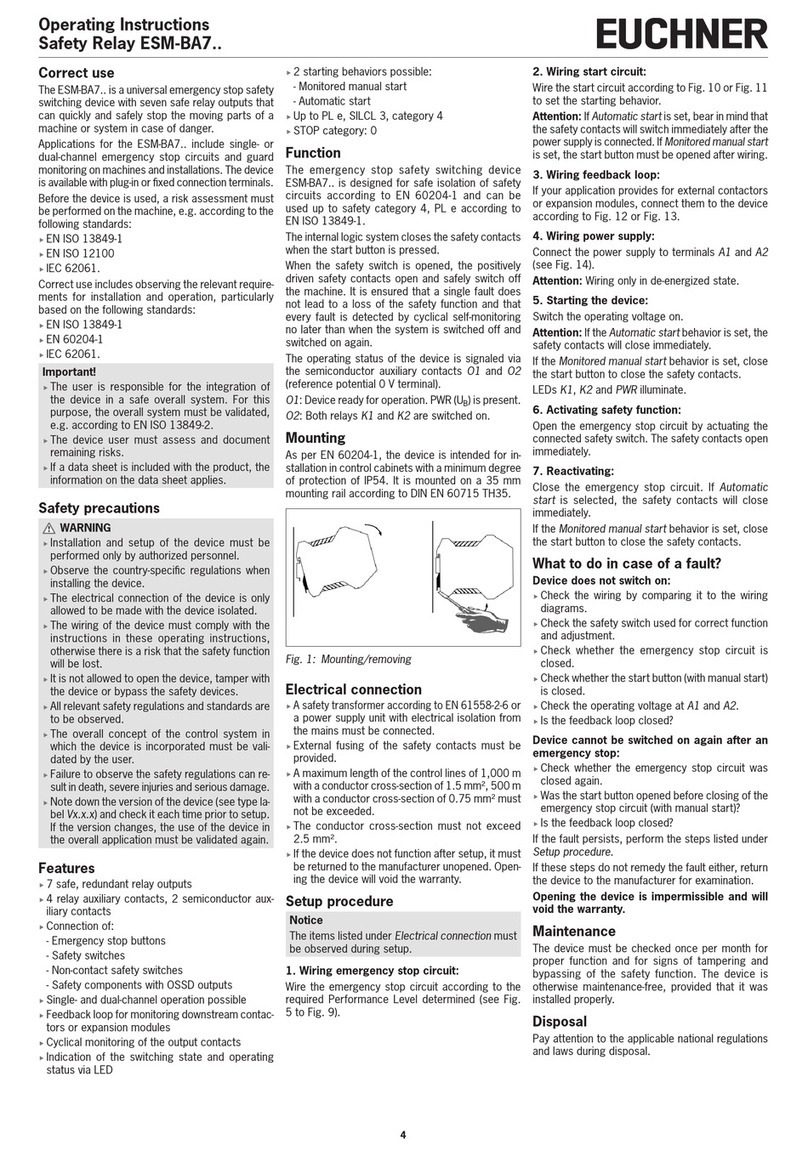

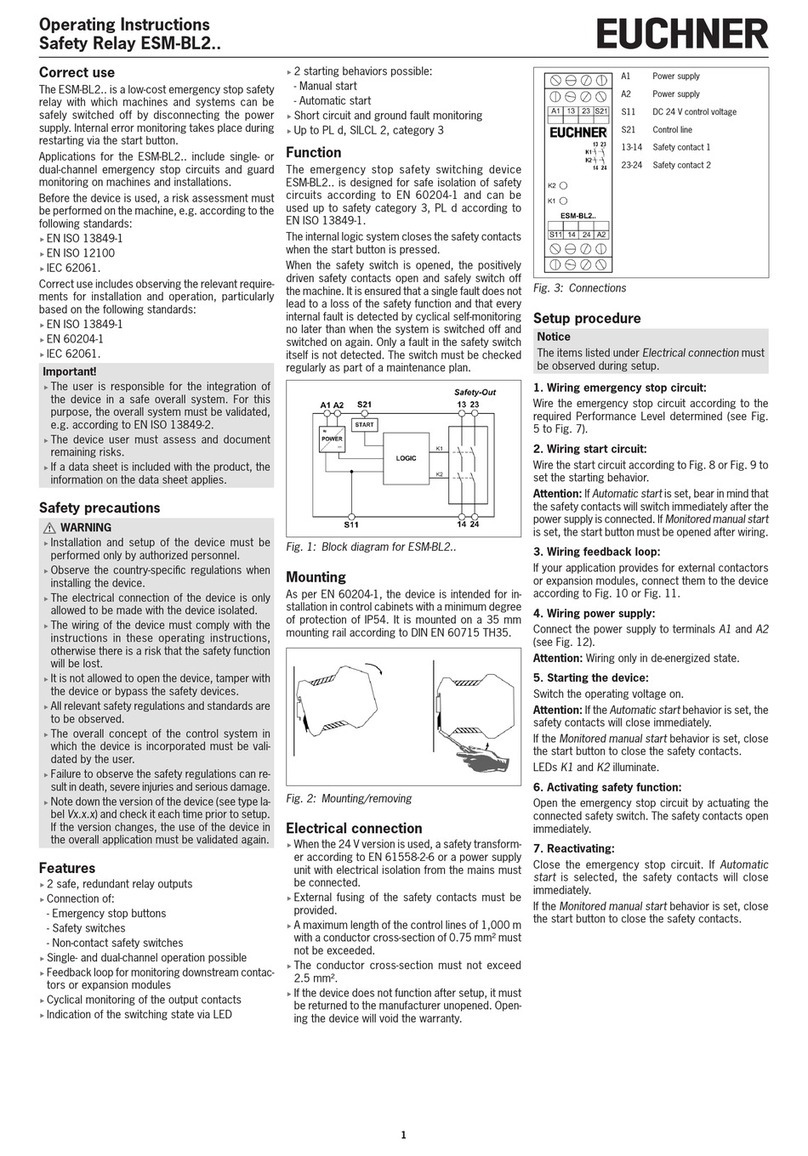

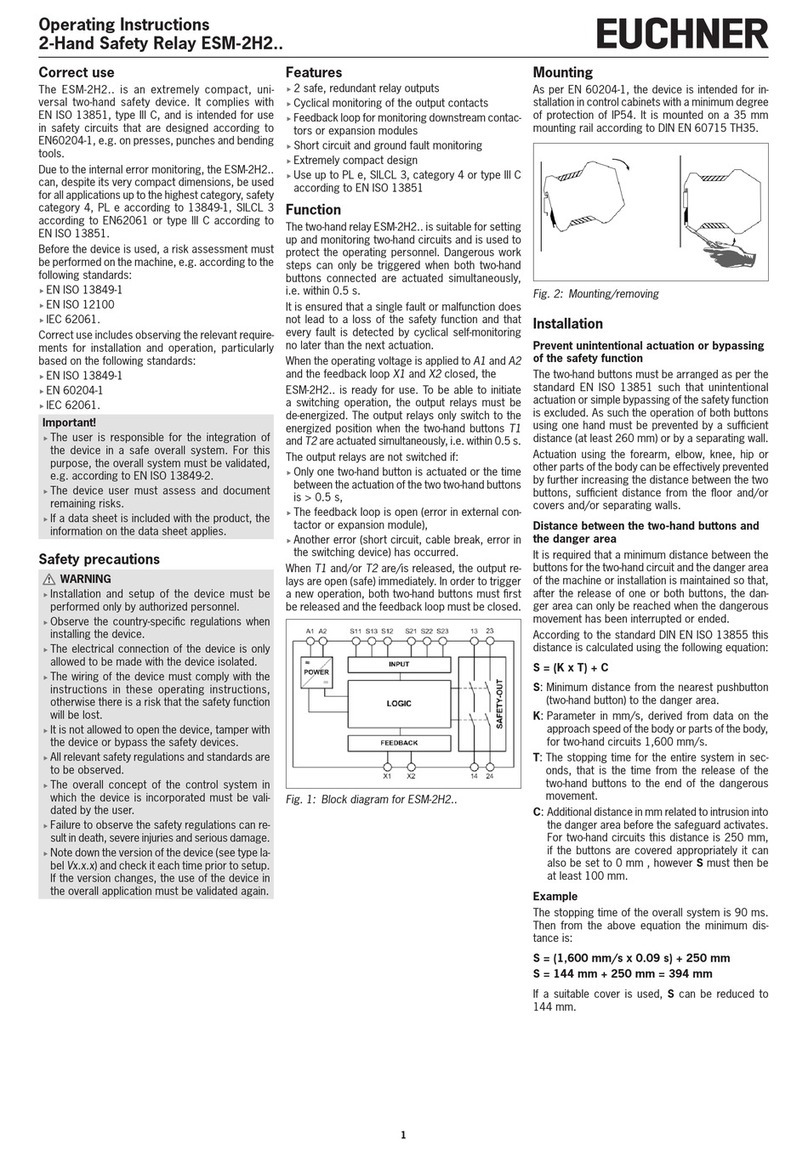

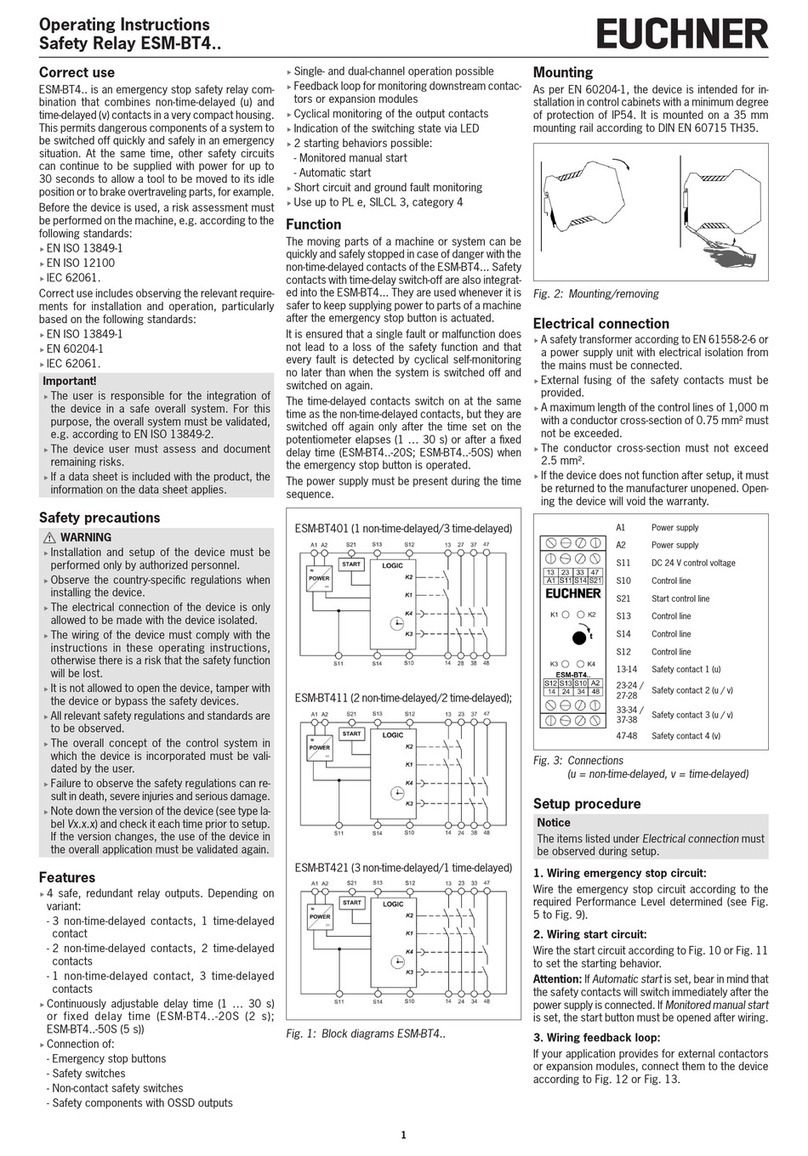

Fig. 1 Block diagram ESM-BA2..

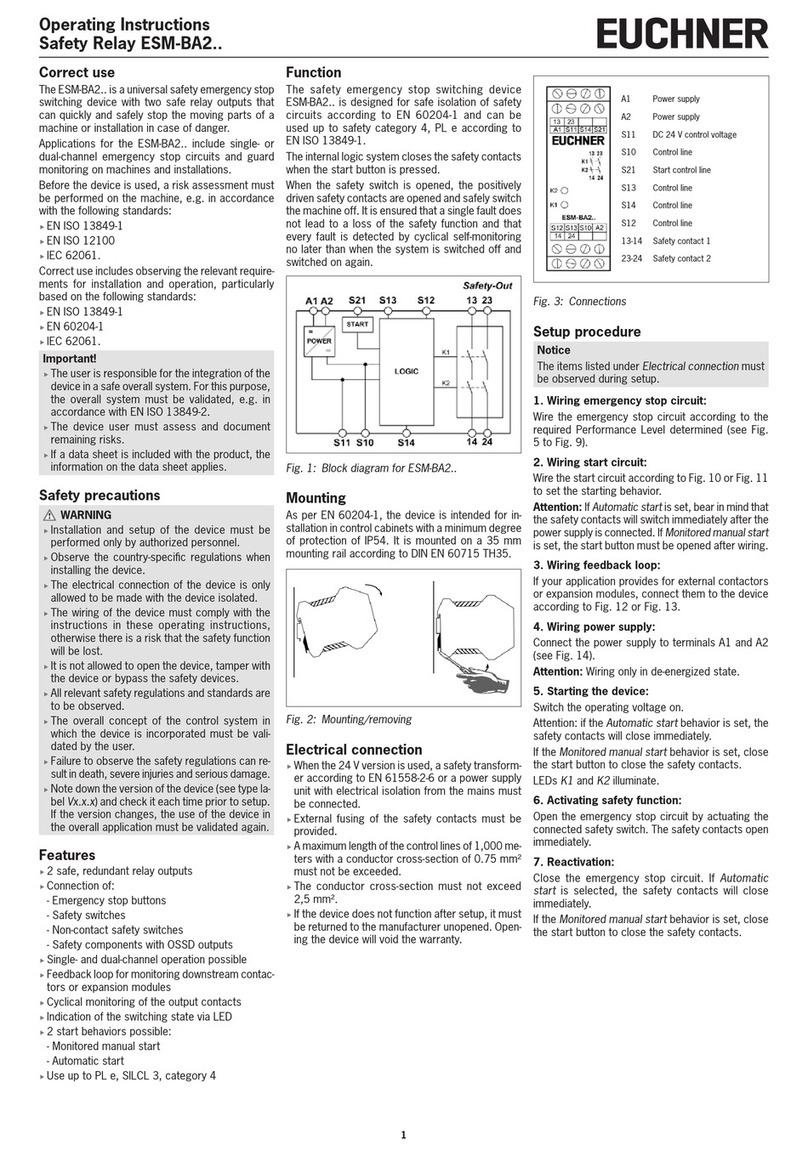

Fig. 2 Installation / removal

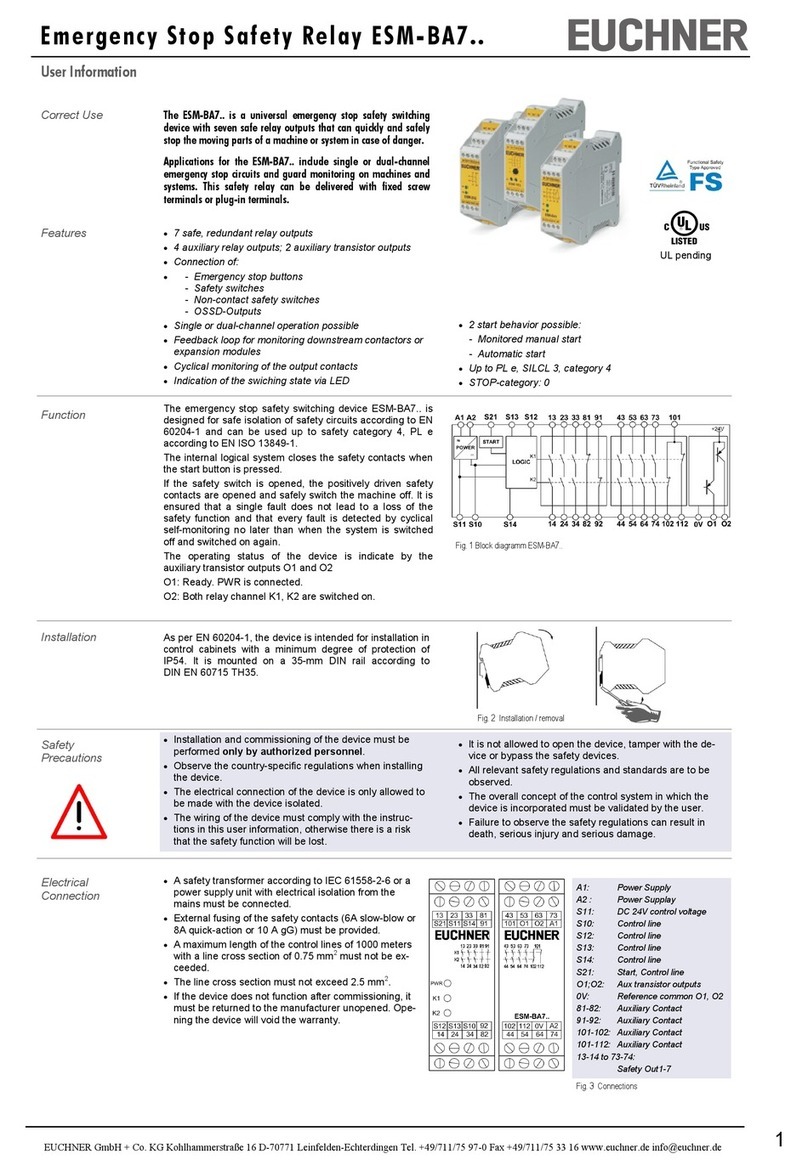

Fig. 3 onnections

1: Power supply

2. Power supply

S11: DC 24 V control voltage

S10: Control line

S21: Start control line

S13: Control line

S14: Control line

S12: Control line

13-14: Safety contact 1

23-24: Safety contact 2

•

All relevant safety regulations and standards are to be

observed.

•

The overall concept of the control system in which the

device is incorporated must be validated by the user.

•

Failure to observe the safety regulations can result in

death, serious injury and serious damage.

•

Note down the version of the product (see label “Vx.x.x”)

and check it prior to every commissioning of a new de-

vice. If the version has changed, the overall concept of

the control system in which the device is incorporated

must be validated again by the user.

•

Installation and commissioning of the device must be

performed only by authorized personnel.

•

Observe the country-specific regulations when installing

the device.

•

The electrical connection of the device is only allowed to

be made with the device isolated.

•

The wiring of the device must comply with the instruc-

tions in this user information, otherwise there is a risk

that the safety function will be lost.

•

It is not allowed to open the device, tamper with the

device or bypass the safety devices.