1

Operating Instructions

2-Hand Safety Relay ESM-2H2..

Correct use

The ESM-2H2.. is an extremely compact, uni-

versal two-hand safety device. It complies with

ENISO13851, typeIIIC, and is intended for use

in safety circuits that are designed according to

EN60204-1, e.g. on presses, punches and bending

tools.

Due to the internal error monitoring, the ESM-2H2..

can, despite its very compact dimensions, be used

for all applications up to the highest category, safety

category4, PLe according to 13849-1, SILCL3

according to EN62061 or typeIII C according to

ENISO13851.

Before the device is used, a risk assessment must

be performed on the machine, e.g. according to the

following standards:

fENISO13849-1

fENISO12100

fIEC62061.

Correct use includes observing the relevant require-

ments for installation and operation, particularly

based on the following standards:

fENISO13849-1

fEN60204-1

fIEC62061.

Important!

fThe user is responsible for the integration of

the device in a safe overall system. For this

purpose, the overall system must be validated,

e.g. according to ENISO13849-2.

fThe device user must assess and document

remaining risks.

fIf a data sheet is included with the product, the

information on the data sheet applies.

Safety precautions

WARNING

fInstallation and setup of the device must be

performed only by authorized personnel.

fObserve the country-specic regulations when

installing the device.

fThe electrical connection of the device is only

allowed to be made with the device isolated.

fThe wiring of the device must comply with the

instructions in these operating instructions,

otherwise there is a risk that the safety function

will be lost.

fIt is not allowed to open the device, tamper with

the device or bypass the safety devices.

fAll relevant safety regulations and standards are

to be observed.

fThe overall concept of the control system in

which the device is incorporated must be vali-

dated by the user.

fFailure to observe the safety regulations can re-

sult in death, severe injuries and serious damage.

fNote down the version of the device (see type la-

bel Vx.x.x) and check it each time prior to setup.

If the version changes, the use of the device in

the overall application must be validated again.

Features

f2 safe, redundant relay outputs

fCyclical monitoring of the output contacts

fFeedback loop for monitoring downstream contac-

tors or expansion modules

fShort circuit and ground fault monitoring

fExtremely compact design

fUse up to PLe, SILCL3, category4 or typeIIIC

according to ENISO13851

Function

The two-hand relay ESM-2H2.. is suitable for setting

up and monitoring two-hand circuits and is used to

protect the operating personnel. Dangerous work

steps can only be triggered when both two-hand

buttons connected are actuated simultaneously,

i.e. within 0.5s.

It is ensured that a single fault or malfunction does

not lead to a loss of the safety function and that

every fault is detected by cyclical self-monitoring

no later than the next actuation.

When the operating voltage is applied to A1 and A2

and the feedback loop X1 and X2 closed, the

ESM-2H2.. is ready for use. To be able to initiate

a switching operation, the output relays must be

de-energized. The output relays only switch to the

energized position when the two-hand buttons T1

and T2 are actuated simultaneously, i.e. within 0.5s.

The output relays are not switched if:

fOnly one two-hand button is actuated or the time

between the actuation of the two two-hand buttons

is >0.5s,

fThe feedback loop is open (error in external con-

tactor or expansion module),

fAnother error (short circuit, cable break, error in

the switching device) has occurred.

When T1 and/or T2 are/is released, the output re-

lays are open (safe) immediately. In order to trigger

a new operation, both two-hand buttons must rst

be released and the feedback loop must be closed.

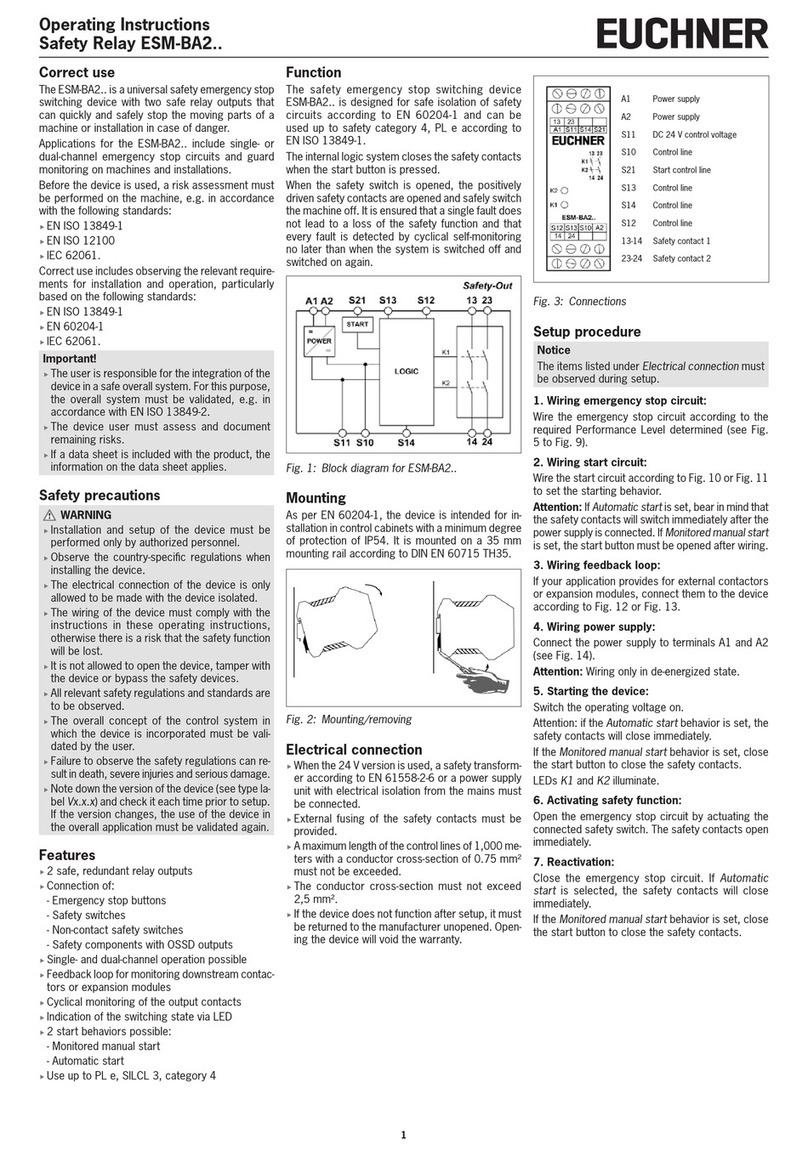

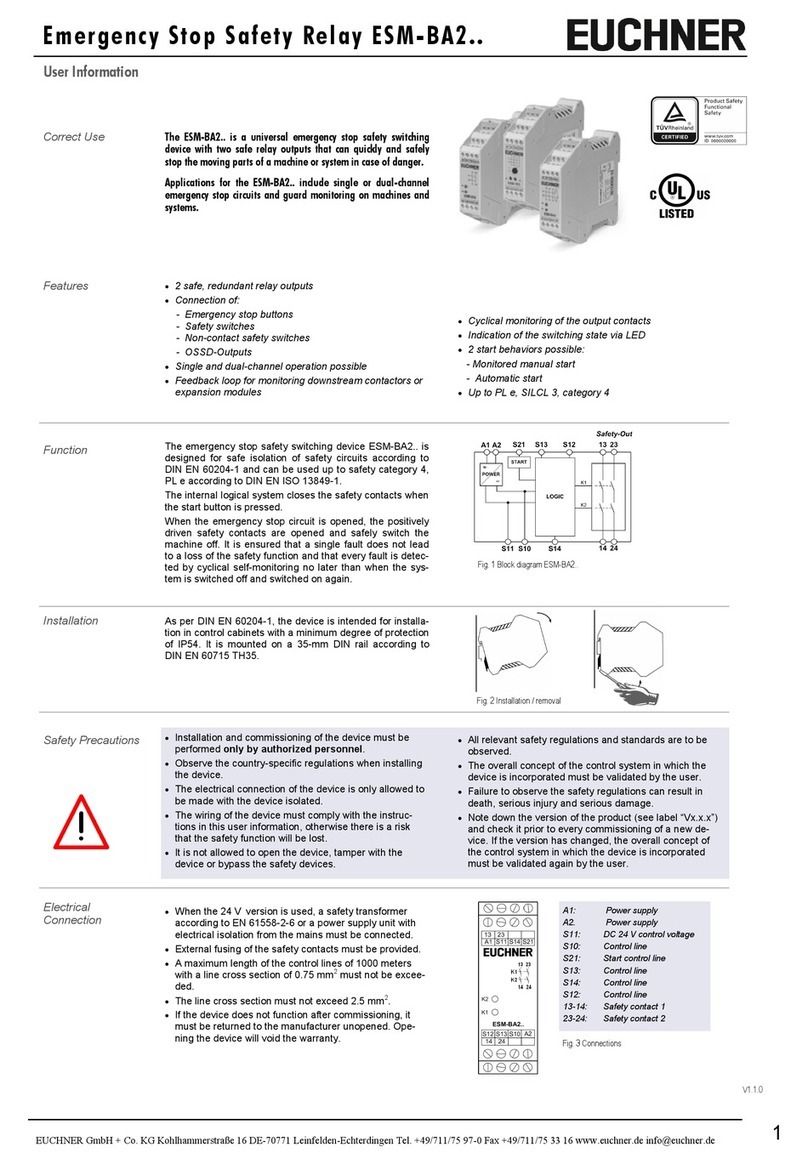

Fig. 1: Block diagram for ESM-2H2..

Mounting

As per EN60204-1, the device is intended for in-

stallation in control cabinets with a minimum degree

of protection of IP54. It is mounted on a 35 mm

mounting rail according to DINEN60715TH35.

Fig. 2: Mounting/removing

Installation

Prevent unintentional actuation or bypassing

of the safety function

The two-hand buttons must be arranged as per the

standard ENISO 13851 such that unintentional

actuation or simple bypassing of the safety function

is excluded. As such the operation of both buttons

using one hand must be prevented by a sufcient

distance (at least 260mm) or by a separating wall.

Actuation using the forearm, elbow, knee, hip or

other parts of the body can be effectively prevented

by further increasing the distance between the two

buttons, sufcient distance from the oor and/or

covers and/or separating walls.

Distance between the two-hand buttons and

the danger area

It is required that a minimum distance between the

buttons for the two-hand circuit and the danger area

of the machine or installation is maintained so that,

after the release of one or both buttons, the dan-

ger area can only be reached when the dangerous

movement has been interrupted or ended.

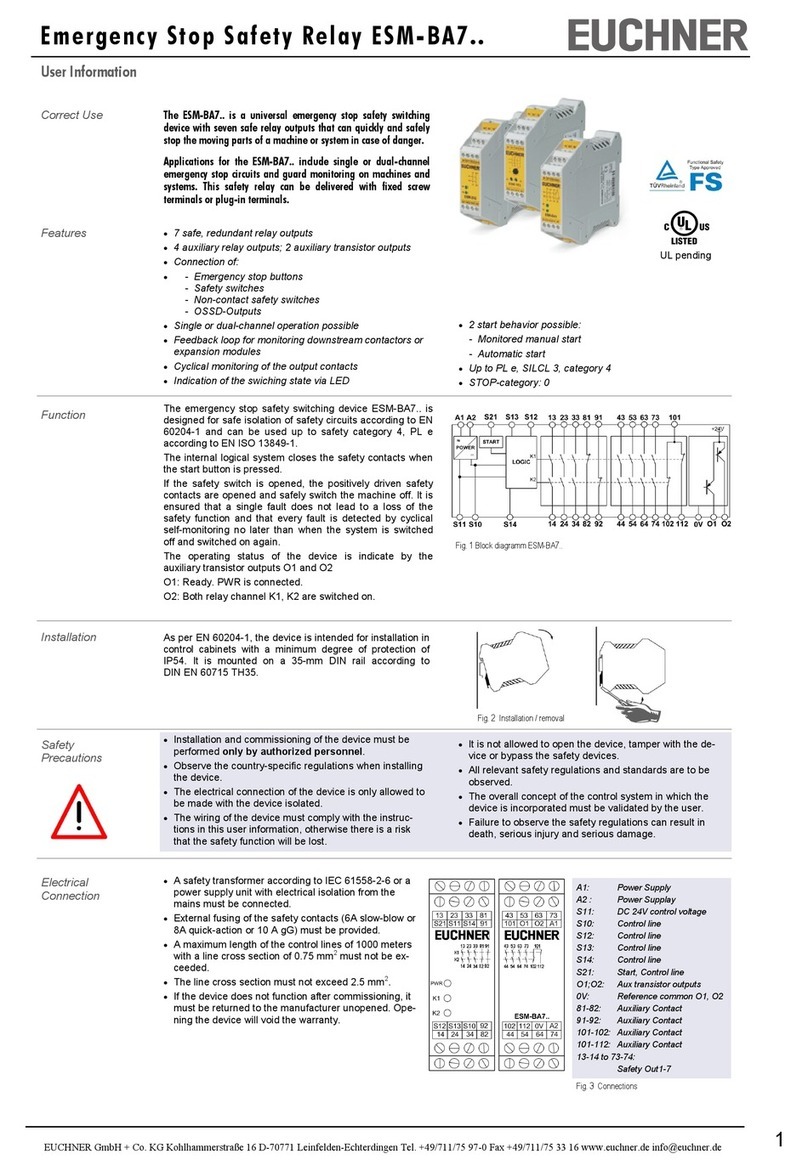

According to the standard DIN EN ISO 13855 this

distance is calculated using the following equation:

S = (K x T) + C

S: Minimum distance from the nearest pushbutton

(two-hand button) to the danger area.

K: Parameter in mm/s, derived from data on the

approach speed of the body or parts of the body,

for two-hand circuits 1,600mm/s.

T: The stopping time for the entire system in sec-

onds, that is the time from the release of the

two-hand buttons to the end of the dangerous

movement.

C: Additional distance in mm related to intrusion into

the danger area before the safeguard activates.

For two-hand circuits this distance is 250mm,

if the buttons are covered appropriately it can

also be set to 0mm , however Smust then be

at least 100mm.

Example

The stopping time of the overall system is 90ms.

Then from the above equation the minimum dis-

tance is:

S = (1,600 mm/s x 0.09 s) + 250 mm

S = 144 mm + 250 mm = 394 mm

If a suitable cover is used, Scan be reduced to

144mm.