Operating Instructions

Safety Relay with IO-Link ESM-CB

2(Translation of the original operating instructions) 2522722-01-05/19

Contents

1. About this document............................................................................................. 4

1.1. Scope............................................................................................................................................4

1.2. Target group ..................................................................................................................................4

1.3. Key to symbols...............................................................................................................................4

1.4. Supplementary documents ..............................................................................................................4

2. Correct use .......................................................................................................... 5

3. Description of the safety function .......................................................................... 6

3.1. Monitoring of sensor circuits...............................................................................................6

3.2. Starting behavior ............................................................................................................................6

4. Exclusion of liability and warranty ......................................................................... 7

5. General safety precautions ................................................................................... 7

6. Function............................................................................................................... 8

6.1. IO-Link communication and functions ................................................................................................8

6.1.1. Enabling from the non-safety-related control system..............................................................8

6.1.2. Chain reset........................................................................................................................8

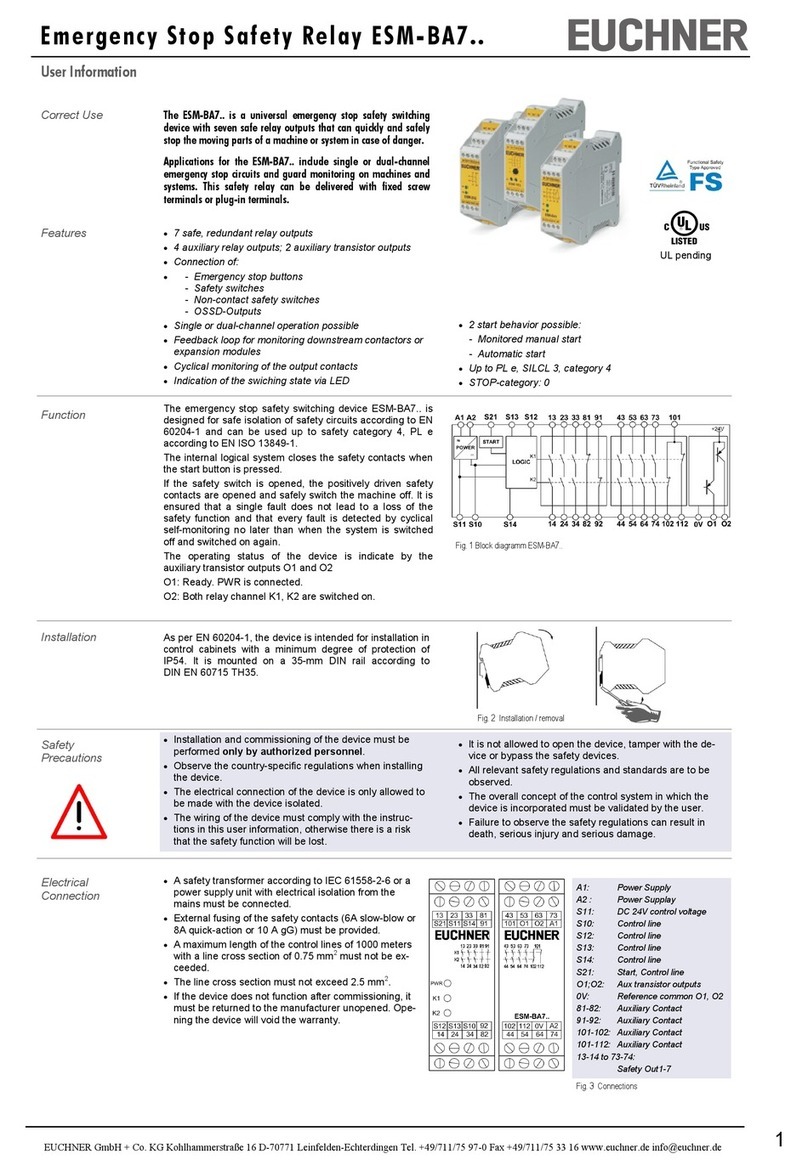

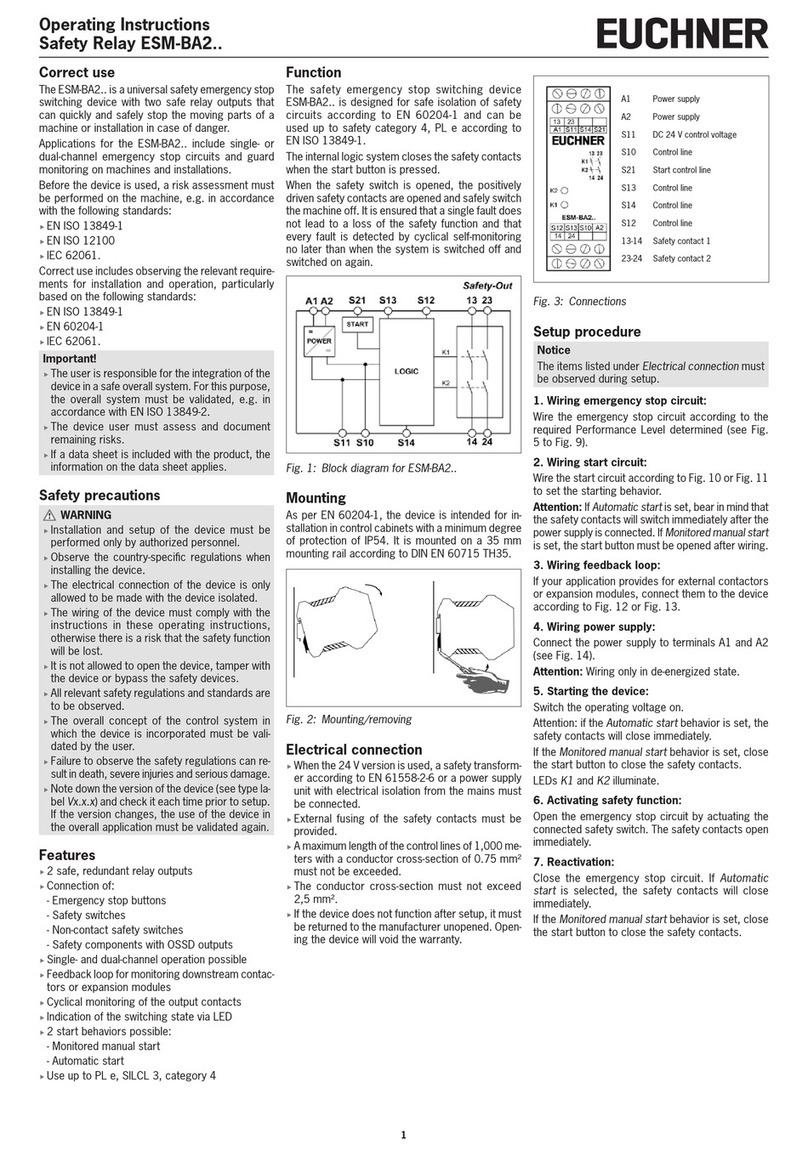

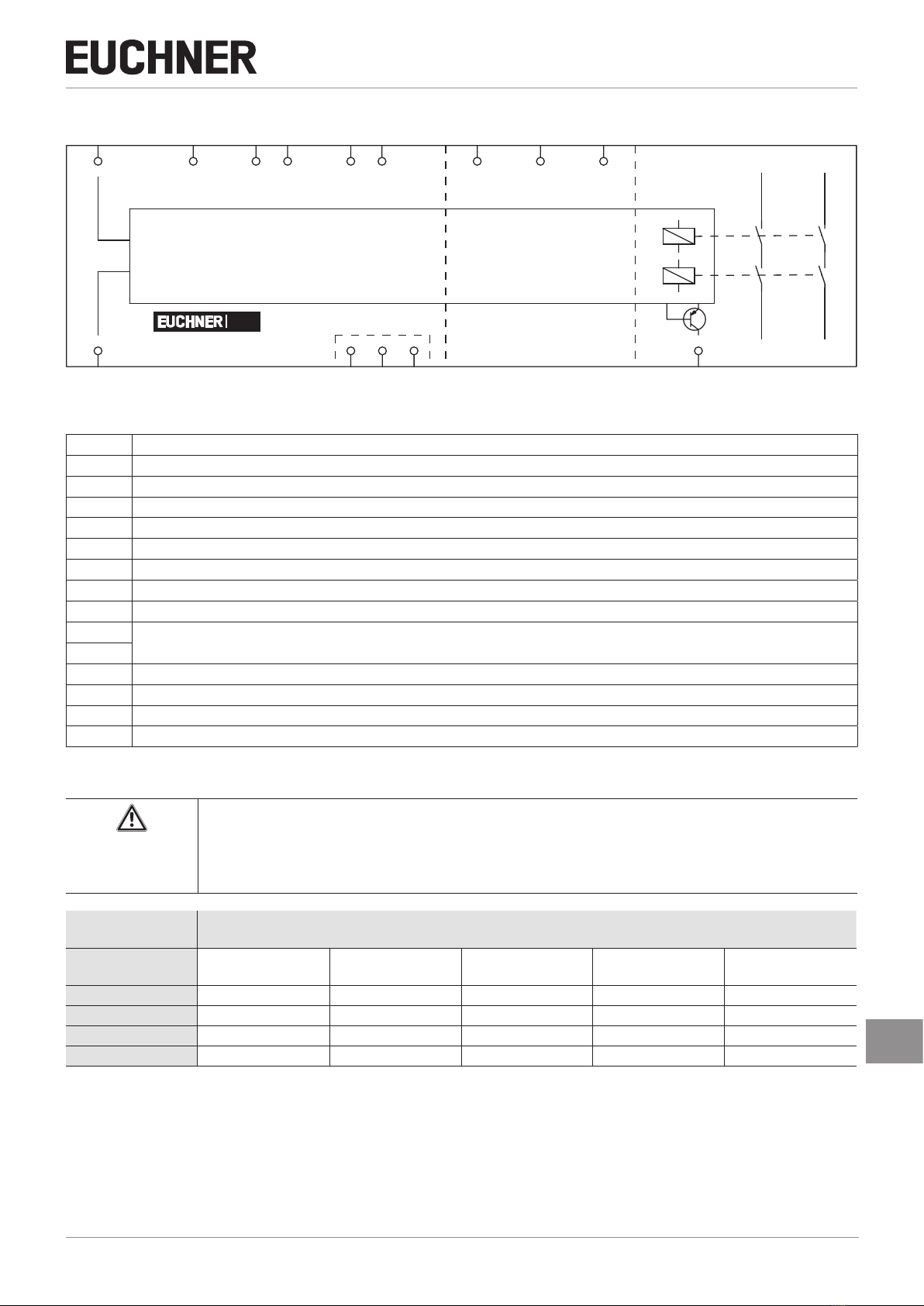

6.2. Block diagram ................................................................................................................................9

6.2.1. Insulation coordination........................................................................................................9

6.3. Communication and functions with BR safety switches.....................................................................10

6.3.1. Diagnostic data................................................................................................................10

6.3.2. Hot plugging – replacing a BR safety switch.......................................................................10

6.4. Function of monitoring output OM ..................................................................................................10

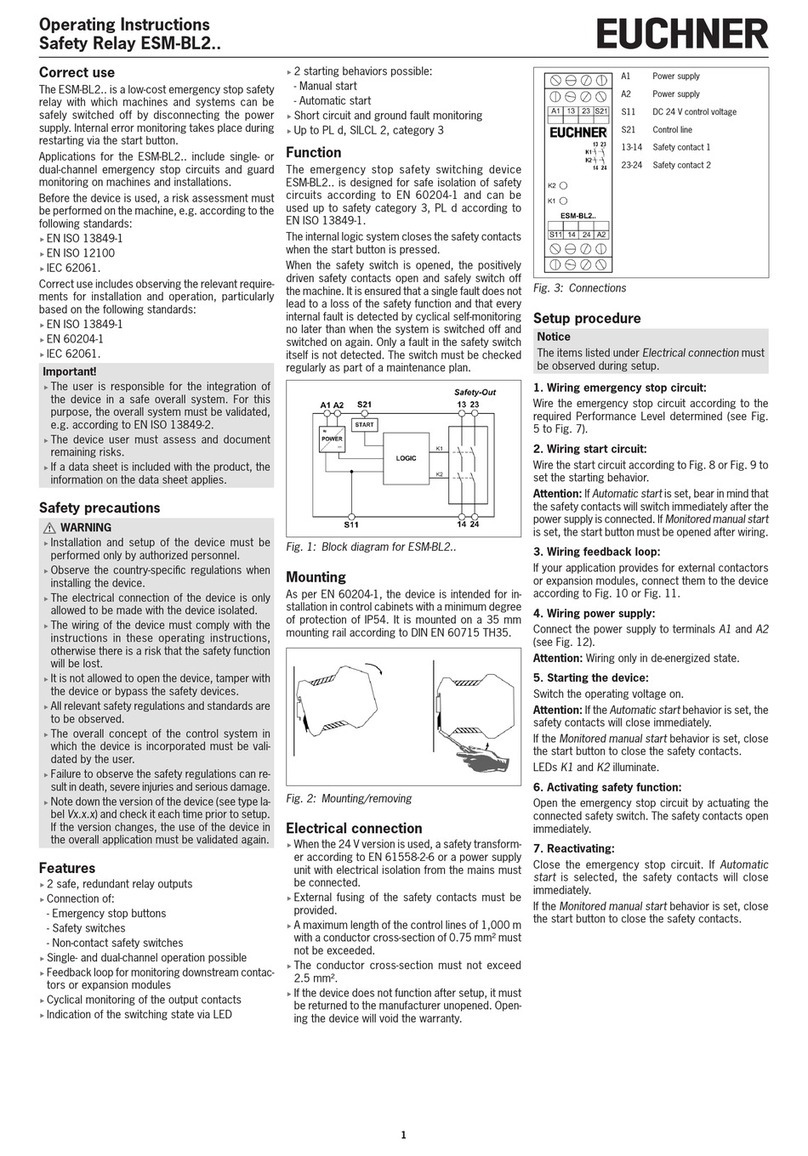

7. Mounting............................................................................................................ 11

8. Electrical connection .......................................................................................... 12

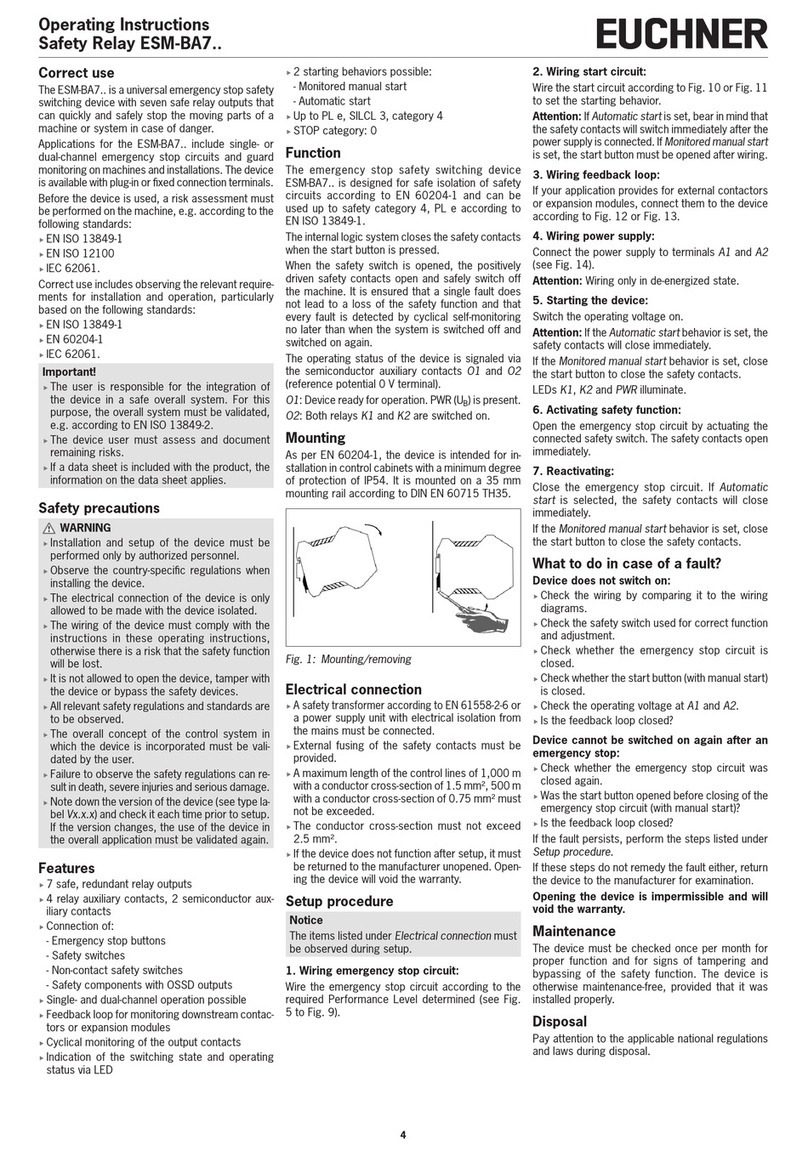

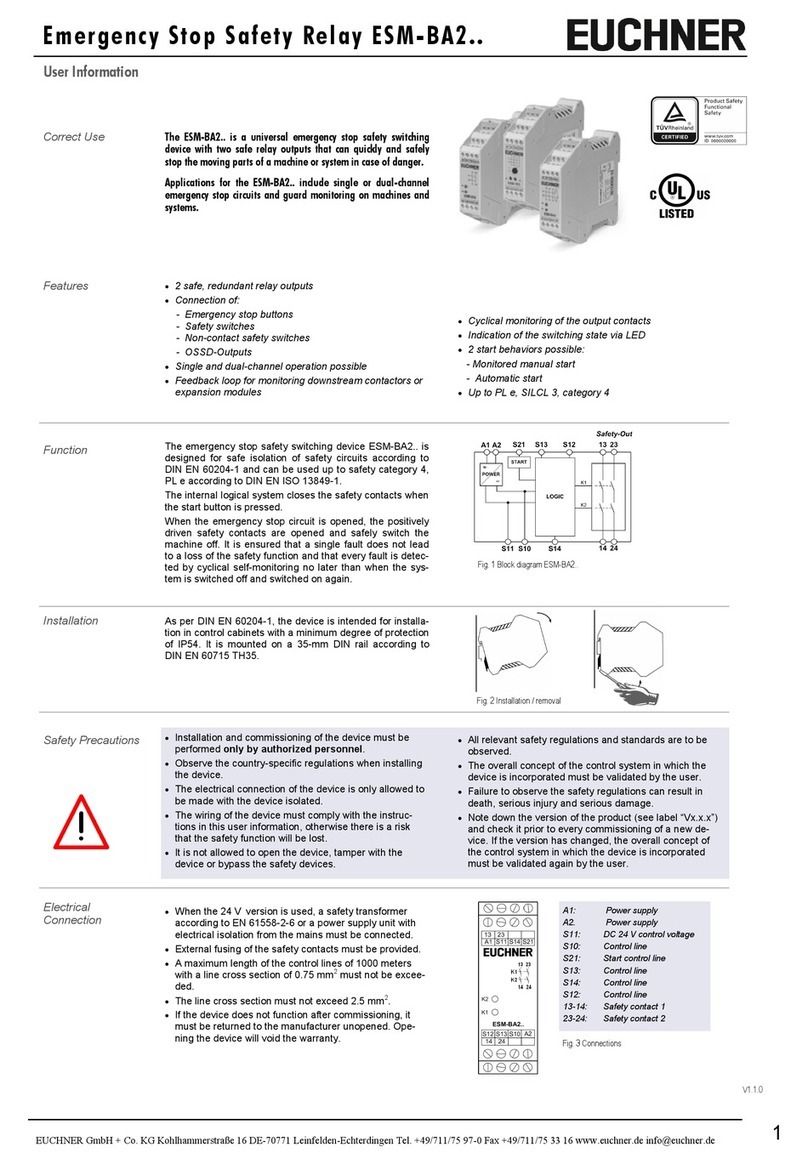

8.1. Terminal assignment .....................................................................................................................13

8.2. Signaling device connection variants ..............................................................................................14

8.2.1. Sensor circuit S1 ..................................................................................................14

8.2.2. Sensor circuit S2.............................................................................................................14

8.3. Start circuit and feedback loop connection variants.........................................................................15

8.4. Notes about ..........................................................................................................................16

9. Application example ........................................................................................... 16

9.1. Dual-channel monitoring of emergency-stop pushbutton and safety switch chain with IO-Link ...............16

10. Setup ................................................................................................................. 18

11. Calculating the power dissipation ........................................................................ 19

12. Function test ...................................................................................................... 20