Operating Instructions

Non-Contact Safety System CES-A-AEA-02B/CES-A-AEA-04B

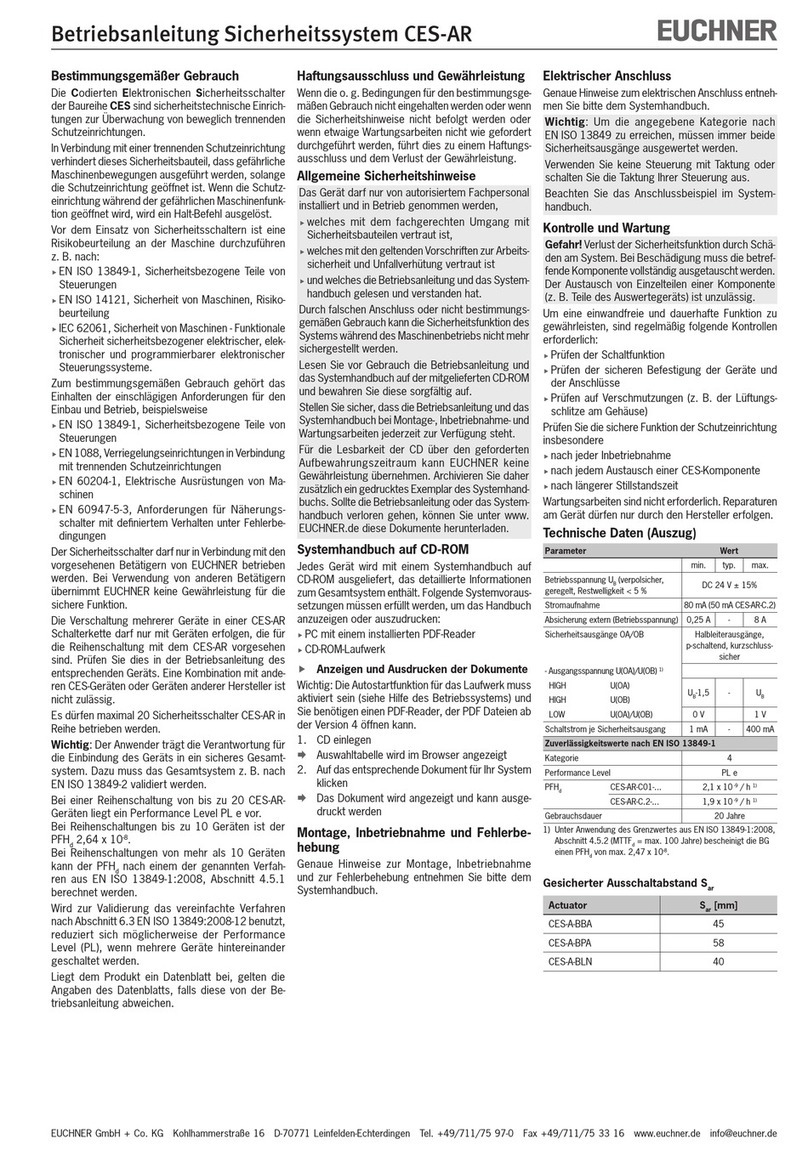

2(translation of the original operating instructions) 2084606-19-09/17

Contents

1. About this document............................................................................................. 4

1.1. Scope............................................................................................................................................4

1.2. Target group ..................................................................................................................................4

1.3. Key to symbols...............................................................................................................................4

1.4. Supplementary documents ..............................................................................................................4

2. Correct use .......................................................................................................... 5

3. Description of the safety function .......................................................................... 6

4. Exclusion of liability and warranty ......................................................................... 7

5. General safety instructions.................................................................................... 7

6. Function............................................................................................................... 8

6.1. Block diagrams CES-A-AEA-…..........................................................................................................9

7. Mounting............................................................................................................ 11

8. Electrical connection .......................................................................................... 12

8.1. Notes about ..........................................................................................................................12

8.2. Safety in case of faults..................................................................................................................12

8.3. Fusing of the power supply and the safety contacts.........................................................................12

8.4. Connection example CES-A-AEA-02B ..............................................................................................13

8.5. Connection example CES-A-AEA-04B ..............................................................................................14

9. Setup ................................................................................................................. 15

9.1. LED indicators..............................................................................................................................15

9.2. Teach-in operation.........................................................................................................................15

9.2.1. Changing the conguration/new actuators ......................................................................16

9.3. Functional check...........................................................................................................................16

9.3.1. Self-test with test input TST ...........................................................................................16

10. System status table ............................................................................................ 18

11. Technical data .................................................................................................... 19

11.1. Evaluation unit CES-A-AEA-02B .......................................................................................................19

11.2. Evaluation unit CES-A-AEA-04B .......................................................................................................21

11.3. Read head CES-A-LNA-…...............................................................................................................23

11.4. Read head CES-A-LNA-SC ..............................................................................................................25

11.5. Read head CES-A-LCA-… ...............................................................................................................27

11.6. Read head CES-A-LQA-SC ..............................................................................................................29

11.7. Read head CES-A-LMN-SC..............................................................................................................31

11.8. Actuator CES-A-BBA/CES-A-BCA.....................................................................................................33

11.9. Actuator CES-A-BQA......................................................................................................................34