EURA SD20-G Series User manual

About this manual

■ Description of technical terms

The terms in this manual are defined as follows:

Servodrive is used to drive and control servo motor.

Servo System means a servo control system that includes the combination of a servodrive, servo motor with a host

computer and peripheral devices.

Parameters include monitoring parameter and setting parameters. Monitoring parameters can only be checked,

but not be modified, and setting parameters can be checked and modified, which includes function parameters and

data parameters.

■ Common symbol

The following symbols are used for convenience.

1. Instruction

P: position mode

Pt:position pulse mode

ALL: all modes

Pr:internal register position mode

S: speed mode

Sr:internal register speed mode

Sz:analog speed mode

T: torque mode

Tr:internal register torque mode

Tz:analog torque mode

2. Usage of backslash (/)

Backslash is used in the wiring diagram. It describes the default logic of I/O interface.

For input signal (DI terminal), balckslash means, when input circuit is ON status, the input signal is valid, i.e. the

default logic is positive logic. Without blackslash means, when input side is OFF status, the input signal is valid,

i.e. the default logic is negative logic.

For output signal (DO terminal), backslash means output side circuit is common-opened, and when the signal is

output, the output side circuit is closed. Without backslash means output side circuit is common-closed, and when

the signal is output, the output side circuit is opened.

3. Others

NC: no connection

N/A: no unit

SD20-G Series

2

I NOTES FOR SAFE OPERATION..............................................................................................8

II MODEL SELECTION................................................................................................................. 11

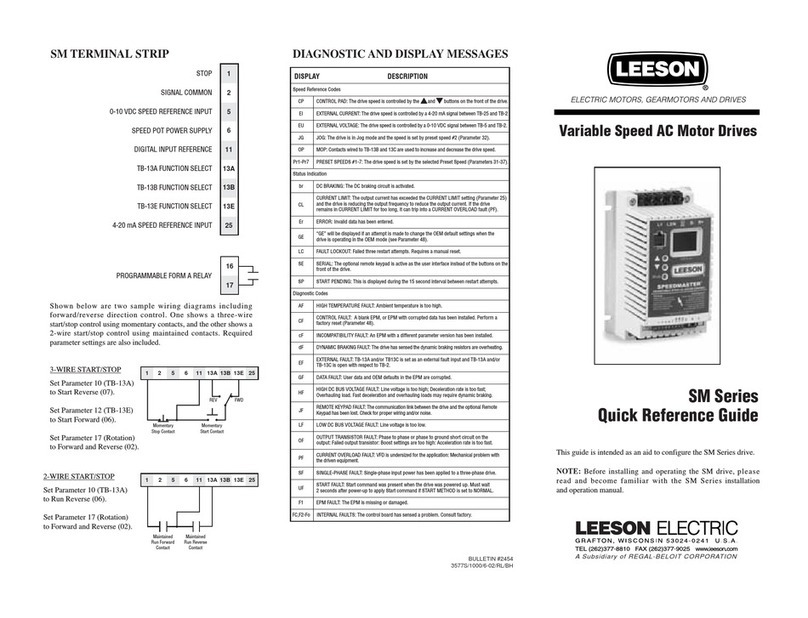

2.1 SERVO DRIVE INTRODUCTION.................................................................................................... 11

2.1.1 SERVO DRIVE NAMEPLATE..................................................................................................... 11

2.1.2 CONNECTION TO PERIPHERAL DEVICES .................................................................................12

2.1.3 SERVO DRIVE SPECIFICATION..................................................................................................13

2.1.4 CONNECTION TO PERIPHERAL DEVICES .................................................................................16

2.2 SERVO MOTOR...........................................................................................................................17

2.2.1 SERVO MOTOR NAMEPLATE AND MODEL.................................................................................17

2.2.2 SERVO MOTOR COMPONENT ...................................................................................................18

2.2.3 SERVO MOTOR MODEL............................................................................................................19

2.3 COMBINATION OF SERVOMOTORAND SERVODRIVE....................................................................22

2.4 INPUT FILTER MODELAND DIMENSIONS .....................................................................................25

III INSTALLATION........................................................................................................................32

3.1 SERVO DRIVES INSTALLATION....................................................................................................32

3.1.1 INSTALLATION CONDITIONS....................................................................................................32

3.1.2 INSTALLATION PROCEDURE AND MINIMUM CLEARANCES .......................................................33

3.1.3 SERVO DRIVE DIMENSION.......................................................................................................34

3.2 SERVO MOTOR INSTALLATION....................................................................................................39

3.2.1 INSTALLATION LOCATION .......................................................................................................39

3.2.2 INSTALLATION CONDITIONS .................................................................................................39

3.2.3 PRECAUTIONS ON SERVO MOTOR INSTALLATION.....................................................................42

3.2.4 SERVO MOTOR DIMENSION .....................................................................................................43

IV WIRING ......................................................................................................................................47

4.1 MAIN CIRCUIT WIRING...............................................................................................................49

4.1.1 MAIN CIRCUIT TERMINALS .....................................................................................................49

4.1.2 MAIN CIRCUIT TERMINAL WIRING ..........................................................................................52

4.1.3 TYPICAL MAIN CIRCUIT WIRING EXAMPLES ............................................................................55

4.1.4 PRECAUTION FOR MAIN CIRCUIT WIRING................................................................................57

4.2 ENCODER WIRING......................................................................................................................58

4.2.1ABSOLUTE ENCODER CONNECTOR TERMINAL LAYOUT ...........................................................58

4.2.2 RESOLVER ENCODER CONNECTOR TERMINAL LAYOUT............................................................59

SD20-G Series

3

4.2.3 INCREMENTAL ENCODER CONNECTOR TERMINAL LAYOUT......................................................58

4.3 I/O SIGNAL WIRING .................................................................................................................59

4.3.1 POSITION COMMAND INPUT SIGNALAND FUNCTION ...............................................................63

4.3.2ANALOG COMMAND INPUT SIGNALAND FUNCTIONS...............................................................68

4.3.3ANALOG OUTPUT SIGNALAND FUNCTIONS .............................................................................68

4.3.4 DIGITAL INPUT SIGNALAND FUNCTIONS .................................................................................69

4.3.5 ENCODER FREQUENCY-DIVISION OUTPUT SIGNALAND FUNCTION ..........................................72

4.3.6 COMMUNICATION WIRING ......................................................................................................74

4.3.7 WIRING WHEN USING MORE THAN ONE SERVOS......................................................................75

4.3.8ABSOLUTE VALUE ENCODER...................................................................................................77

4.4 SERVO DRIVE AND SERVO MOTOR WIRING .................................................................................79

4.4.1 ENCODER WIRING...................................................................................................................79

4.4.2 POWER CABLE OF SERVO DRIVE AND SERVO MOTOR...............................................................82

4.5 EMC.........................................................................................................................................83

4.5.1 DEFINITION ............................................................................................................................83

4.5.2 INSTALLATION ENVIORNMENT ...............................................................................................83

4.5.3 SELECTION AND INSTALLATION OF PERIPHERAL EMC DEVICES.............................................84

4.5.4 SHIELDED CABLE .................................................................................................................84

V. OPERATION AND PARAMETERS......................................................................................86

5.1 KEYPAD DESCRIPTION ...............................................................................................................86

5.2 KEYPAD OPERATING PROCEDURE ..............................................................................................87

5.2.2 PARAMETERS INSTRUCTIONS..................................................................................................88

5.3 KEYPAD OPERATING PROCEDURE...............................................................................................90

5.3.1 EXAMPLE OF MONITOR FUNCTION PARAMETER ......................................................................90

5.3.2 EXAMPLE OF AUXILIARY PARAMETERS USAGE........................................................................91

5.3.3 PARAMETER SETTING .............................................................................................................92

VI.RUN……………………………………………………………………………………………....92

6.1 BASIC PARAMETERS SETTING ....................................................................................................97

6.1.1 BEFORE RUNNING...................................................................................................................97

6.1.2 POWER ON ...........................................................................................................................97

6.1.3 PARAMETERS SETTING..........................................................................................................100

6.1.4 SETTING THE OVERTRAVEL LIMIT FUNCTION.......................................................................105

6.1.5 JOG OPERATION PROCEDURE ................................................................................................107

6.1.6 TIMING SEQUENCE CONTROL................................................................................................108

SD20-G Series

4

6.1.7 SETTING THE BRAKING......................................................................................................... 110

6.2 SPEED MODE ........................................................................................................................... 114

6.2.1 PARAMETERS SETTING.......................................................................................................... 114

6.2.2 SOFT START ..........................................................................................................................122

6.2.3 SCURVE SMOOTHNESS FUNCTION......................................................................................123

6.2.4 ZERO CLAMP FUNCTION .....................................................................................................124

6.2.5 SPEED OUTPUT SIGNAL ......................................................................................................124

6.3 TORQUE MODE......................................................................................................................128

6.3.1 PARAMETERS SETTING .......................................................................................................128

6.3.2 SOFT START ..........................................................................................................................133

6.3.3 SPEED LIMITING AT TORQUE MODE.....................................................................................134

6.3.4 LIMITING TORQUE .............................................................................................................134

6.3.5 RELATED OUTPUT.................................................................................................................136

6.4 POSITION PULSE MODE ............................................................................................................136

6.4.1 PARAEMETERS SETTING........................................................................................................137

6.4.2 SETTING ELECTRONIC GEAR ................................................................................................. 154

6.4.3 POSITION COMMAND FILTER................................................................................................. 157

6.4.4 SOFT START OF POSITION COMMAND ....................................................................................157

6.4.5 POSITION COMMAND INHIBIT FUNCTION...............................................................................158

6.4.6 COMMAND PULSE CLEAR FUNCTION.....................................................................................158

6.4.7 FREQUENCY-DIVISION OUTPUT FUNCTION............................................................................159

6.4.8 HOMESEARCHMODE............................................................................................................163

6.4.9MECHANICAL ORIGIN SEARCH FUNCTION ............................................................................169

6.4.10 FIXED LENGTH INTERRUPT FUNCTION ...............................................................................171

6.4.11 DO OUTPUT RELATED TO POSITION PULSE ..........................................................................173

6.4.12 FULL CLOSED LOOP FUNCTION ...........................................................................................174

6.4.13 GANTRY SYCHRON FUNCTION ...........................................................................................177

6.4.14 ELECTRONIC CAM (E-CAM)FUNCTION..............................................................................181

6.5 DUAL MODE............................................................................................................................192

6.5.1 USER PARAMETER SETTING................................................................................................192

6.5.2 INTERNAL SPEED AND POSITION PULSE DUAL MODE ..........................................................193

6.5.3ANALOG SPEED AND POSITION PULSE DUAL MODE.............................................................194

6.5.4 ANALOG SPEED AND INTERNAL REGISTER POSITION DUAL MODE........................................195

6.5.5 INTERNAL SPEED AND INTERNAL REGISTER POSITION DUAL MODE......................................196

6.5.6 TOREQUE MODE AND POSITION PULSE DUAL MODE.......................................................... 197

SD20-G Series

5

6.5.7 TORQUE MODE AND INTERNAL REGISTER POSITION DUAL MODE .....................................198

6.5.8 POSITION PULSE AND INTERNAL REGISTER POSITION DUAL MODE....................................199

6.5.9 INTERNAL SPEED AND ANALOG SPEED DUAL MODE ..........................................................200

6.5.10 SPEED AND TORQUE DUAL MODE ......................................................................................200

6.5.11ANALOG TORQUE AND INTERNAL REGISTER TORQUE DUAL MODE ...................................200

6.6AUXILIARY FUNCTION.............................................................................................................201

6.6.1 SOFTWARE VERSION......................................................................................................201

6.6.2 SETTING PASSWORD......................................................................................................202

6.6.3SERVO DRIVE STATUS DISPLAY………………………………………………………202

6.6.4 CONTROLMODE OF FAN ...............................................................................................205

6.6.5 PARAMTER COPY............................................................................................................206

6.6.6 REVERTING TO MFR’SVALUE......................................................................................206

6.6.7 MOTOR PROTECTION FUNCTION…………………………………………………….206

6.6.8 TORQUE UNREACHED PROTECTION CONTROL.......................................................................208

6.6.9 DI TERMINALS FILTER FUNCTION......................................................................................208

6.6.10 OTHER OUTPUT SIGNALS ...................................................................................................210

6.6.11 FRICTION TORQUE COMPENSATION …………………………………………….…..….208

6.6.12 GRAVITY TORQUE COMPENSATION…………………………………………………………..209

6.6.13 INPUT POWER PHASE-LOSS PROTECTION…………………………………………………...210

6.6.14 ENCODER DISCONNECTION PROTECION…………………………………………………….210

6.6.15 OTHER OUTPUT SIGNALS……………………………………………………………………….210

6.7 HIGH-SPEED COUNTER FUNCTION ........................................................................................214

6.7.1 OVERVIEW..........................................................................................................................214

6.7.2 HIGH-SPEED COUNTING.......................................................................................................214

6.8 BUILT-IN PLC FUNCTION ........................................................................................................220

6.8.1 SUMMARY............................................................................................................................220

6.8.2 SERVO BUILT-IN PLC SOFTWARE ACCESS AREA...................................................................221

6.8.3 BUILT-IN PLC PROGRAM DESIGN.........................................................................................226

6.8.3.1 DATA MOVE INSTRUCTION................................................................................................226

6.8.3.2ARITHMETIC INSTRUCTION................................................................................................227

6.8.3.3 LOGIC INSTRUCTION .........................................................................................................235

6.8.3.4 PROGRAM CONTROL INSTRUCTION ...................................................................................239

6.8.4 BUILT-IN PLC PARAMETERS.................................................................................................244

6.8.5 BUILT-IN PC/PLC USE AND APPLICATION EXAMPLE............................................................247

6.8.6 BUILT-IN PLC COMMUNICATION OPERATION.......................................................................252

SD20-G Series

6

6.8.6.1 MODBUSADDRESS.........................................................................................................252

6.8.6.2 DEBUG FUNCTION OF BUILT-IN PLC............................................................................252

VII. ADJUSTMENTS ....................................................................................................................253

7.1 SUMMARY...............................................................................................................................253

7.2 INERTIAIDENTIFICATION.........................................................................................................254

7.2.1 OFFLINE INERTIAIDENTIFICATION........................................................................................254

7.2.2 ONLINE INERTIAIDENTIFICATION.........................................................................................256

7.3 GAIN ADJUSTMENT .................................................................................................................258

7.3.1 SUMMARY............................................................................................................................258

7.3.2AUTOMATIC GAIN ADJUSTMENT ..........................................................................................259

7.3.3 MANUAL GAIN ADJUSTMENT...............................................................................................261

7.3.4 GAIN SWITCH.......................................................................................................................263

7.4 VIBRATION INHIBITION............................................................................................................266

7.4.1 VIBRATION INHIBITION FUNCTION .......................................................................................266

7.4.2 LOW-FREQUENCY VIBRATION INHIBITION FUNCTION...........................................................267

VIII LIST OF PARAMETERS .....................................................................................................268

8.1 .1 MONITOR FUNCTION GROUP(LO-□□) ..........................................................................268

8.1.2 UTILITY FUNCTION GROUP (SO-□□) ..................................................................................271

8.1.3 MAIN FUNCTION GROUP (PO-□□□)..........................................................................279

8.1.4 MOTOR FUNCTION GROUP(HO-□□□)........................................................................310

8.1.5 ALARM RECORD PARAMETERS(HO2□□~HO3□□).................................................312

8.1.6 HIGH-SPEED COUNTER PARAMETERS(PL□□□)..............................................................315

ⅨMAINTENANCE AND INSPECTION....................................................................................330

9.1ALARM AND TROUBLE SHOOTING AT START.............................................................................330

9.1.1 POSITION CONTROL MODE....................................................................................................330

9.1.2 SPEED CONTROL MODE.........................................................................................................332

9.1.3 TORQUE CONTROL MODE......................................................................................................333

9.2ALARM CODE AND POSSIBLE CAUSE ........................................................................................334

9.3ALARM DISPLAY TABLE AND TROUBLE SHOOTING..................................................................335

9.3.1 OTHER MALFUNCTIONS........................................................................................................339

X COMMUNICATION .................................................................................................................340

SD20-G Series

7

10.1 COMMUNICATION..................................................................................................................340

10.1.1 MODBUS GENERAL..........................................................................................................340

10.1.2 MODBUS PROTOCOL........................................................................................................340

10.1.3 PARAMETER RELATED TO COMMUNICATION .......................................................................344

XIAPPENDIX................................................................................................................................346

11.1 ENCODER CABLE SELECTION .................................................................................................346

11.1.1ABSOLUTE ENCODER CABLE...............................................................................................346

11.1.2 INCREMENTAL ENCODER CABLE .........................................................................................347

11.1.3 RESOLVER ENCODER CABLE ...............................................................................................348

11.2 CONTROL CABLE ...................................................................................................................348

11.3 POWER CABLE.......................................................................................................................349

11.4 OTHER CABLE .......................................................................................................................350

11.5 MOTOR AND MATCHED CABLE ...............................................................................................350

SD20-G Series

8

I Notes for safe operation

Read this manual thoroughly before checking products on delivery, storage and transportation, installation, wiring,

operation and inspection, and disposal of the servo drives.

WARNING

·Do not touch terminals for five minutes after voltage resistance test.

·Do not touch terminals for five minutes after the power is turned off. Residual voltage may cause

electric shock.

·Never touch any rotating motor parts while the motor is running.

·Never touch the inside of the SERVOPACKs.

·Follow the procedures and instructions for trial operation precisely as described in this manual.

·Do not remove the front cover, cables, connectors, or optional items while the power is ON.

·Do not damaged, press, exert excessive force or place heavy objects on the cables.

·Do not change the max speed value (Po002) except special purpose. Failure to observe this warning

may result in damaged to products.

·Do not come close to the machine Immediate after resetting momentary power loss to avoid an

unexpected restart. Take appropriate measures to ensure safety against an unexpected restart.

·Do not modify products. Failure to observe this warning may result in injury or damage to products.

·MCtt (electromagnetic contactor) and NFB (no fuse breaker) must be installed between main circult

power (L1/R, L2/S, L3/T for 3-phase).

SD20-G Series

9

Storage and Transportation

CAUTION

·Do not store or install the product in the following places:

1. Locations subject to direct sunlight.

2. Locations subject to temperatures outside the range specified in the storage or installation

temperature conditions.

3. Locations subject to humidity outside the range specified in the storage or installation temperature

conditions.

4. Locations subject to corrosive or flammable gases.

5. Locations subject to dust, salts or iron dust.

6. Locations subject to exposure to water, oil, or chemicals.

7. Locations subject to shock or vibration.

·Do not hold the product by the cables or motor shaft while transporting it.

·Do not place any load exceeding the limit specified on the packing box.

Installation

CAUTION

·Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

·Do not step on or place a heave object on the product.

·Do not cover the inlet or outlet ports and prevent any foreign objects from enternign the product.

·Be sure to install the product in the correct direction.

·Provide the specified clearances between the SERVOPACK and the control panel or with other

devices.

·Do not apply any strong impact.

SD20-G Series

10

Wiring

CAUTION

·Do not connect a three-phase power supply to the U, V, or W output terminals.

·Connect U, V and W of servo drive directly to U, V, and W of servo motor, avoid using contactor in

between.

·Securely connect the power supply terminals and motor output terminals.

·Do not connect servo drive for 220V directly to 400V voltage.

·Do not bundle or run power and signal lines together in the same duct. Keep power and signal lines

separated by at least 30 cm.

·Use twisted-pair shielded wires or mult-core twisted pair shielded wires for singal and encoder

cables.

·The maximum length is 3m for reference input lines and the maximum length is 20m for encoder

cables.

·Take appropriate and sufficient countermeasures for each form of potential interference when

installing systems in the following locations.

Locations subjects to static electricity or other forms of noise.

Locations subjects to strong electromagnetic fields and magnetic fields.

Locations subjects to possible exposure to radioactivity.

·Repair or maintain the servo drive only after the CHARGE indication on the servo drive goes off.

Maintenance and Inspection

CAUTION

·Repair or maintenance of the servo drive can be performed only by qualified personnel.

·Please cut off all connection between servo drive with resistor before performing an insulation test

of resistor.

·When replacing the servo drive, resume operation only after transferring the previous servo drive

parameters to the new servo drive or computer.

·Do not attempt to change wiring while the power is ON.

·Do not disassemble the servo motor.

SD20-G Series

11

II Model selection

2.1 Servo drive introduction

2.1.1 Servo Drive Nameplate

M2

Product series

- G 102 T3 M2

M4

M5 420

x

210 x

234

218

x

100 x

203

380

x

185 x

215

M6 270 x 234

498x

SD20

MM4 336150 203

x x

Product usage

Fieldbus type

E

Power 201

102

Input Voltage

380V

T3

Frame size

(WxHxD)

F0

Communication

Modbus

EtherCAT

F5

D20

Encoder type

Resolver

D20

D50

D51

14-core 2500 ppr incremental encoder

8-core 2500 ppr incremental encoder

B3

Braking

B1/ default

Dynamic braking

S2

T2

1-phase 220V

3-phase 220V

M3

195

x

48 x

175

M3(5.5kW)

195

x

75 x

175 218

x

100 x

203

M1

Bake type

B3

B3

B1

B1

B1

B1

B1

B1

B1

B3

3-phase

(No built-in braking resistor)

D52

D70

D71

4-core 23-bit incremental encoder

4-core 17-bit absolute encoder

4-core 23-bit absolute encoder

101

(No built-in braking resistor)

(No built-in braking resistor)

(No built-in braking resistor)

(No built-in braking resistor)

GGeneral

... ...

100W

200W

1KW

CANopen

F4

F0/default

Energy consumption braking

(built-in braking resistor)

B2

B3

B6

Energy consumption braking

+Dynamic braking

Energy consumption braking

(external braking resistor)

Fig 2.1.1 Servo Drive naming rule

Note: Servo drives of M1-MM4 structure have no buit-in filter, use can select external filter to satisfy EMC R3

standard. Full details are given in chapter 2.4. Servo drives of M4-M6 structure have optional built-in R3 filter,

it depends on user’s selection.

SD20-G Series

12

EURA DRIVES ELECTRIC CO., LTD

MODEL

INPUT AC3PH 220V 50/60Hz

OUTPUT

3PH 4.5A0~220V

Model Name

Capacity

Specification

Output

Specification

Barcode

0~400Hz

SD20-G102T2M2

OPTION F0D20B3

AC

MATCHED

MOTOR SMSA-102F33ED

BAR CODE

SW NO. 1.04 BS NO. 2.001 Made in China

Fig 2.1.2 Servo Drive nameplate

2.1.2 Connection to Peripheral Devices

Panel operator

Each part name of Servo drive

Serial communication port(CN1)

Encoder interface (CN2)

I/O signal terminal (CN3)

Signal terminals such as command input, monitor output etc.

Refer to 4.3- I/O signal wiring

Charge indicator

Light on when connecting main circuit power.

Light will keep on for a while after cutting off

the power, because there still is residual voltage

in the capacitance of main circuit.

Do not touch the power terminal to avoid electric

shock when light on.

Main-circuit power input terminal

AC input terminal of main circuit power supply.

Refer to 4.1- Main circuit wiring

Control power input terminal

AC input terminal of control power supply.

Refer to 4.1- Main circuit wiring

Servo motor terminal

Connected to the driving cable of servo motor.

Refer to 4.4.2-Main circuit wiring.

Braking resistor terminal

Built-in or external braking terminals.

Refer to 7.1.7-Energy-loss brake

Ground terminal

Ground connection of servo motor and servo drive.

Make sure to earthed to avoid electric shock.

DC choke terminal

Terminal connected to DC choke.

Refer to 4.1-Main circuit wiring

Used to serial communicate with PC, PLC, CNC etc.

Refer to 6.2-Communication specification

Connected with encoder of servo motor.

Refer to 4.2-encoder wiring

S-ON RUN ALM

Consist of 5 digital tube, 4 pressing keys and 2 LED.

It is used to set control parameter, display the status

of servo drive and operational monitoring etc.

Refer to 5.1- Operation instruction

Fig 2.1.3 Connection to Peripheral Devices

SD20-G Series

13

2.1.3 Servo drive specification

1) Electrical specification

a)220V servo drive

Name

M1

M2

M3

M4

Servo drive

SD20-G

101

201

401

751

102

122

182

302

452

552

752

Continuous

output current

Arms

1.2

1.5

2.8

3.5

4.5

6.0

8.0

12

17

25

35

Max output

current

Arms

3.6

4.2

8.4

9.8

12.6

16.8

22.4

33.6

47.6

70

98

Power of

main circuit

1-phase/3-phase AC 220V -15~+10% 50/60Hz

Power of

control circuit

1-phase/3-phase AC 220V -15~+10% 50/60Hz

Braking type

External braking resistor

Built-in braking resistor.

b) 380V/400V servo drive

Name

M2

M3

MM4

M4

M5

M6

Servo drive

SD20-G

102

152

202

302

452

552

752

113

153

183

223

303

373

Continuous

output current

Arms

3

3.5

6.0

8.0

10.

0

12.0

20

23

32

38

44

60

75

Max output

current

Arms

8.4

9.8

16

19.

2

28

33

56

64

80

95

110

150

187

Power of main

circuit

1-phase/3-phase AC 380V -10~+10% 50/60Hz

Power of control

circuit

Without control circuit

Braing type

Built-in braking resistor.

External braking resistor

2)Technical specification

A. Basic specifications

Items

Contents

Power supply

S2/T2

220VAC -15~+10% 50/60Hz

T3

380/400VAC -10~+10% 50/60Hz

SD20-G Series

14

Control mode

Pt Position pulse mode Pr Internal register position mode _

Sz Analog speed mode Sr Internal register speed mode

Tz Analog torque mode Tr Internal register torque mode

Regenerative braking

Built-in or External (External braking should be selected and purchased)

Control

characteristic

Control mode

PMSM

Frequency response

1.2KHz

Speed fluctuation

±0.01%(VC, load fluctuation 0 to 100%)

Speed control range

1:10000

Input pulse frequency

1. 500KHz (differential drive); 200KHz (Open collector)

2. At high-speed pulse circuit, receiving frequency is

4MHZ.(Differential)

Input signal

Control input

Servo on, Alarm reset, Pulse clear, Pulse prohibited, Forward run prohibited,

Reverse run prohibited, Forward torque limit, Reverse torque limit, Internal

speed selection, Internal position triggered, “Home” searching triggered, Zero

speed CLAMP

Speed Feedback

1. Absolute encoder.

2. Incremental encoder.

3. Resolver

Output

signal

Control output

Servo ready, Servo alarm activated, At positioning completed, At speed

reached, Electromagnetic brake control, Rotation Detection, At speed limit,

Homing completed, At torque limit, and so on.

Encoder signal

frequency-division

output

1. Encoder Z phase open-collector output.

2. Encoder signal output (A, B Z Line Driver) frequency-division output

3. Z pulse time extend function.

Position

control

Input mode

1. A phase+B phase 2. Forward pulse+Reverse pulse

3. Pulse+Direction 4. Internal register

Electronic gear

1. 0.01≤ B / A ≤100

2. Two groups electronic gear can be selected by users.

Analog speed control

-10V~+10V analog speed signal input, the voltage scope can be set by

function code.

Analog torque control

-10V~+10V analog torque signal input, the voltage scope can be set by

function code.

Acceleration/Deceleration

Accele/decele time is set to 1~30000ms(related to 0←→rated speed)

Communication

1. RS485 communication port is connected with PC, to set control

parameters and to monitor servo.

2. CANopen or EtherCAT can be selected as option.

Parameters

setting

Keypad

The parameters are set by keypad, which is displayed by 5LEDs.

PC/PLC

RS485 communication can set parameters by some PC/PLC software.

Monitor function

Output current, PN voltage, motor speed, motor feedback pulse, motor

feedback rotation, given pulse, given pulse error, given speed, given torque,

analog speed given and analog torque given.

Protection function

Overvoltage, Undervoltage, Overload, Overcurrent, Encoder error,

Overspeed, Abnormal pulse control command, Emergency stop, Servo

SD20-G Series

15

overheat, Input power phase loss, Regeneration error, Overposition.

Applicable load inertia

Lower than 5 times of servo motor inertia.

B. Performance index

Control

mode

Specification

Speed

mode

Soft start

0~30S (Acceleration time and deceleration time can be set).

Input signal

Input voltage

DC±10V/ rated speed (It is default setting, which can be

changed by function code)

Input impedance

About 50K

Circuit time

parameter

About 52us

Internal

register speed

3 kinds of speed are combined by SD-S1 and SD-S2, the running direction is

controlled by SD-DIR (positive/negative logic is set by function code).

Position

mode

Specification

Feedforward

compensation

0~100% (resolution is 1%)

Positional

accuracy

1 command unit

Input signal

Pulse form

Select one from “direction +pulse” or “90° phase difference

orthogonal pulse”, or“forward pulse + reverse pulse”.

Input form

Differential input, open-collector input.

Input pulse

frequency

1. Optocoupler input

Differential driver: max frequency is 500KHZ;

Collector driver: max frequency is 200KHZ;

2. Differential chip input, the max frequency is 4MHZ

Electronical

gear

0.01≤B/A≤100

Output signal

Output form

A phase, B phase, Z phase: differential driver output

Z phase open collector output.

Frequency-divi

sion ratio

A, B phase frequency-division output except Z phase

Control signal

Pulse

command clear

Bias pulse can be cleared by external signal.

Built-in power

+24V (100mA)

Torque

mode

Input signal

Input voltage

DC±10V/ rated torque (It is default setting, which can be

changed by function code)

Input impedance

About 50K

Circuit time

parameter

About 52us

SD20-G Series

16

2.1.4 Connection to Peripheral Devices

Three phase AC power (for 1 phase 220v,

only L1 and L3 should be connected)

Breaker

Braking

resistor

Electromagnetic brake relay

(common-open)

EMI filter

Contacter

Input choke

DC choke

Servo Motor

24V power supply

Used to protect power wire

RS 485

communication

interface

MODBUS

PC / PLC

PLC, CNC command

controller

For electromagnetic

brake motor

Encoder interface

( Optional)

( Optional)

(Optional)

( Optional)

*This connection is forbidden for 380V, 3 phase option

Fig 2.1.5 Servo drive system

Note)

For 220V input servo drive, L1C and L2C should be connected to power supply.

For 380V input servo drive, L1C and L2C are forbidden to connect.

SD20-G Series

17

2.2 Servo motor

2.2.1 Servo motor nameplate and model

SM F102

-E

SA D

33

SM series

Rated speed

SA

MA

MB

3000rpm

2000rpm

1500rpm

1000rpm

Rated power

201

401

751

...

200W

400W

750W

...

C

D

Shaft

Smooth shaft with C hole

B

E

Optional

With brake and no fan

J

K

3

5

Flange Size

80 Flange

7

A

3Bus voltage

300V

Servo motor

Keyway shaft with C hole

Without brake and fan

With fan ,without fan

With brake and fan

110Flange

130Flange

180Flange

6600V

2 60 Flange

LA

Encoder type

Resolver

R

F

G

14-core 2500 ppr

incremental encoder

8-core 2500 ppr

incremental encoder

H

S

T

4-core 23-bit

incremental encoder

4-core 17-bit

absolute encoder

4-core 23-bit

absolute encoder

C17-bit magnetic

encoder

Fig 2.2.1 Servo motor naming rule (for 180 flange and below 180 flange motor)

SD20-G Series

18

SM R

0110 E

17 D6 E

Servo motor

SM series

Rated speed

15

17

20

1500rpm

1700rpm

2000rpm

Rated power

0075

0110

0180

...

7.5KW

11KW

18KW

...

C

D

Shaft

Smooth shaft

Keyway

E

F

Flange size

180 Spigot

200 Spigot

6Bus voltage

600V

F L

EBrake

Without brake

F

N

Cooling mode

Air cooling fan

Without cooling fan

S.L Design code

Design code

Encoder type

Resolver

R

F

G14-core 2500 ppr incremental encoder

8-core 2500 ppr incremental encoder

H

S

T

4-core 23-bit incremental encoder

4-core 17-bit absolute encoder

4-core 23-bit absolute encoder

C17-bit magnetic encoder

Fig 2.2.2 Servo motor naming rule (for 180 spigot and 250 spigot motor)

Motor

nameplate

TYPE:SMMA-102F37EDM

Barcode

Mn= 5Nm In= 5A

nN/nmax

= 2000/2300r/min

IMB 5

IP 65 TH.CI.B

Motor Model

Product No.

Rated Current

BEMF

Rated Speed Max Speed

InstallationMode Insulation Grade

Rated Torque

KE= 68V/1000 r/ min

Fig2.2.3 Servo motor naming rule (below 7.5kw)

Magnetic filed angle:

PMSM

SM17-0110R6EEDFS

Un: 400V Tn:64 N.m

Fan voltage: 220 V

Pn:11kw

Nn: 1700r/ min

Code:TH. CI. F IP54

In:23A

Date:

Fig 2.2.4 Servo motor nameplate (above 11kw)

【Note】

1. Please refer to the chapter in the 《3.2.4 servo motor dimension》for flange dimension.

2. 11KW and above 11kw servo motor can be mounted by flange and base, user can choose mounting method

SD20-G Series

19

according to requirement.

2.2.2 Servo motor component

Encoder outlet

Encoder

Motor shell

Motor shaft

Flange

Motor power line outlet

Fig 2.2.5 Name of part of servo motor

2.2.3 Servo motor model

1) 220V motor model

Motor modelnote

Rated power

Rated torque

Rated current

Rotation inertia

W

N·m

A

10-4Kg·m2

SMS series

3000r/min

SMSA-201*32***

200

0.64

1.2

0.17

SMSA-401*32***

400

1.27

2.8

0.29

SMSA-751*33***

750

2.39

3.5

1.82

SMSA-102*33***

1000

3.5

4.5

2.9

SMSA-122*35***

1200

4

5

6.9

SMSA-152*37***

1500

5

7.5

12.2

SMSA-182*35***

1800

6

8

10.1

SMSA-232*37***

2300

7.7

10

18.2

SMSA-302*37***

3000

10

15.5

24.2

SMS series

2500r/min

SMSB-102*33***

1000

3.82

4

2.9

SMM series

2000 r/min

SMMA-801*35***

800

4

3.5

6.9

SMMA-851*37***

850

4

4

10.8

SMMA-102*37***

1000

5

5

12.2

SMMA-122*35***

1200

6

5

10.1

SMMA-132*37***

1300

6

6

15

SD20-G Series

20

SMMA-152*37***

1500

7.7

7.5

18.2

SMMA-202*37***

2000

10

10

24.2

SMMA-312*37***

3100

15

14

34.9

SMMA-352**3A***

3500

17.2

16

55.3

SMMA-452*3A***

4500

21.5

19

74.8

SMM series

1500 r/min

SMMB-122*37***

1200

7.7

5

18.2

SMMB-152*37***

1500

10

6

24.2

SMMB-232*37***

2300

14.6

10

34.9

SMMB-272*3A***

2700

17.2

11

55.3

SMMB-302*3A***

3000

19

12

66.3

SMMB-432*3A***

4300

27

16

84.8

SMMB-552*3A***

5500

35

24

119.5

SMMB-752*3A***

7500

48

32

133

SML series

1000 r/min

SMLA-102*37***

1000

10

4.5

24.2

SMLA-152*37***

1500

14.3

7

34.9

SMLA-292*3A***

2900

27

12

84.8

SMLA-372*3A***

3700

35

16

119.5

2) 380V motor model

Motor modelnote

Rated power

Rated

torque

Rated

current

Rotation

inertia

W

N·m

A

10-4Kg·m2

SMS series

3000 r/min

SMSA-751*63***

750

2.39

2

1.82

SMSA-102*63***

1000

3.5

3

2.9

SMSA-122*65***

1200

4

4

6.9

SMSA-152*67***

1500

5

5

12.2

SMSA-182*65***

1800

6

6

10.1

SMSA-232*67***

2300

7.7

7

18.2

SMSA-302*67***

3000

10

8

24.2

SMM series

2000 r/min

SMMA-801*65***

800

4

2.5

6.9

SMMA-851*67***

850

4

3

10.8

SMMA-102*67***

1000

5

3

12.2

SMMA-122*65***

1200

6

3.5

10.1

This manual suits for next models

29

Table of contents

Popular Servo Drive manuals by other brands

Metronix

Metronix smartServo BL 4000-D Series Mounting instructions

Allen-Bradley

Allen-Bradley 2097-V31PR0 installation instructions

Leadshine

Leadshine 2ELD2-CAN Series user manual

Mitsubishi

Mitsubishi MR-JE series instruction manual

Mannesmann Rexroth

Mannesmann Rexroth Indramat DDC Series Applications manual

Technosoft

Technosoft iPOS360X MX-CAN Technical reference