PRECAUTIONS FOR THE SAFETY OF OPERATORS AND TECHNICIANS

-The machine must not be used by non-authorised personnel who have not been trained to use it properly or by people

who are under the influence of substances that could alter their nervous reflexes (alcohol, psycho pharmaceuticals,

drugs etc.)

-Do not use the machine in inflammable areas or where there is the danger of explosions

-Do not collect material that is alight or anything else that could cause a fire.

-Do not remove protections or guards when the machine is in operation.

-Do not use the machine to clean objects.

-Do not start to perform maintenance operations with parts in movement

-Protect eyes and ears when using compressed air or water guns for cleaning the machine.

-To raise the machine make use of devices that are adequate to bear the weight of the machine itself.

-Do not cause flames or sparks around the machine.

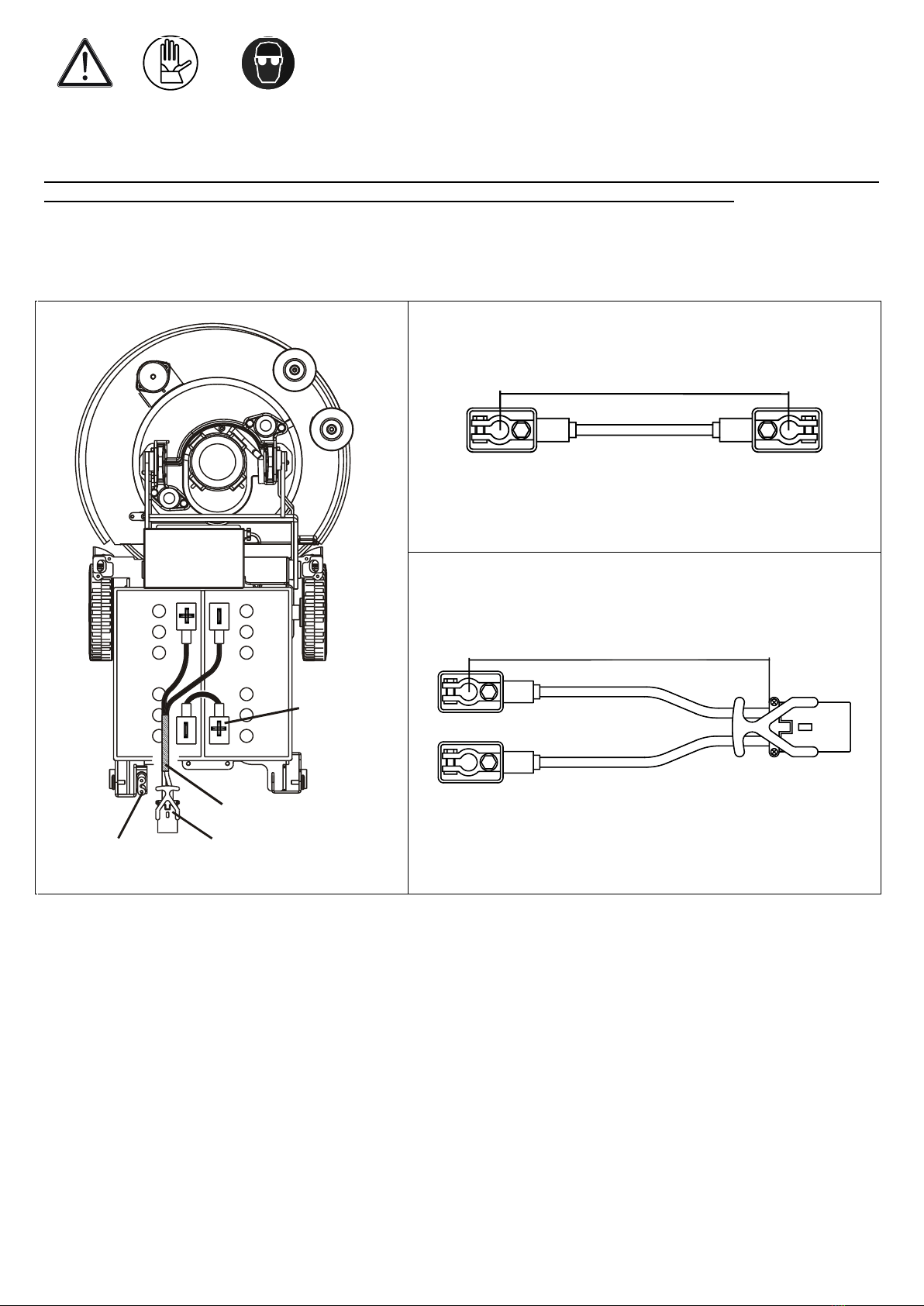

-Disconnect the battery cables before working on the electrical circuit.

-Avoid contact with battery acid

-Move carefully over uneven or crumbling paving and on slopes.

-Slow down on slopes and slipping surfaces

-Make sure the machine is not exposed to rain and weather conditions, whether in motion or still.

-Temperature of usage of the machine has to be kept within + 5 °C / + 40 °C.

-Humidity has to be kept within 30% / 80 %.

UPDATING OF THE USER’S MANUAL

When large-scale modifications are made to the machine or new parts are installed, the updated documentation must be

sent to the Dealer along with the purchased part or as an update of the manual

OBLIGATIONS OF THE EMPLOYER OR OWNER OF THE MACHINE

The employer or owner of the machine is responsible for giving the User’s Manual to all the personnel who are going to

have to use the machine.

The employer or owner of the machine also undertakes to update the manual with the documentation that the

Manufacturer will send if modifications are made to the machine.

RESPONSIBILITIES OF THE OPERATOR

- The operator is responsible for the day-to-day servicing of the machine

- The operator must care for the machine and keep it in good operating condition

- The operator must inform his or her superior or the technical department when scheduled maintenance is requested in

the case of damage or breakage.

- The operator must not carry people, animals or objects on the machine.

- When moving the machine, observe the safety measures for circulation.

- The machine cannot be used for toxic-harmful materials.

- Never let people get close to the machine’s sphere of action.

- Never leave the sweeper with the key and the emergency switch inserted.

- Engage the hand brake

- If the machine malfunctions, have a look at the procedures shown in the various chapters.

- Never collect pieces of string, wire or anything else that could damage the brushes by winding around them.

- Never suck up pieces of wood, plastic waste etc. as they may clog the vacuum pipe.

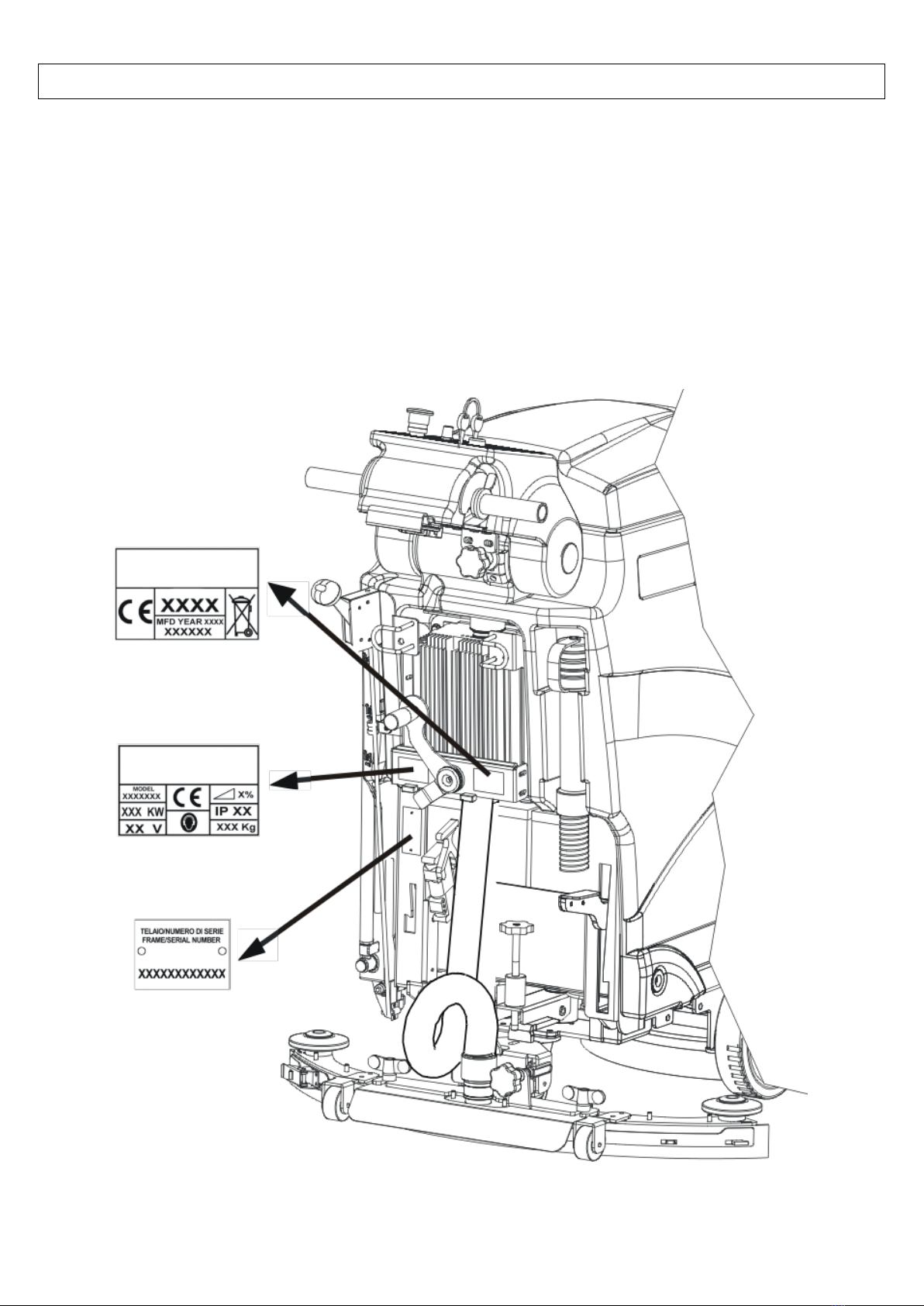

- Never remove or alter the plates on the machine.