Euro Towers EUROFOLD User manual

EUROFOLD

TUV CERTIFIED QUALITY SYSTEM

TO ISO 9001:2015

CONFORMING TO EN 1004 2020

EUROPEAN STANDARD

TOWER MAX SAFE WORKING LOAD 750K | PLATFORM MAX SAFE WORKING LOAD 250KG

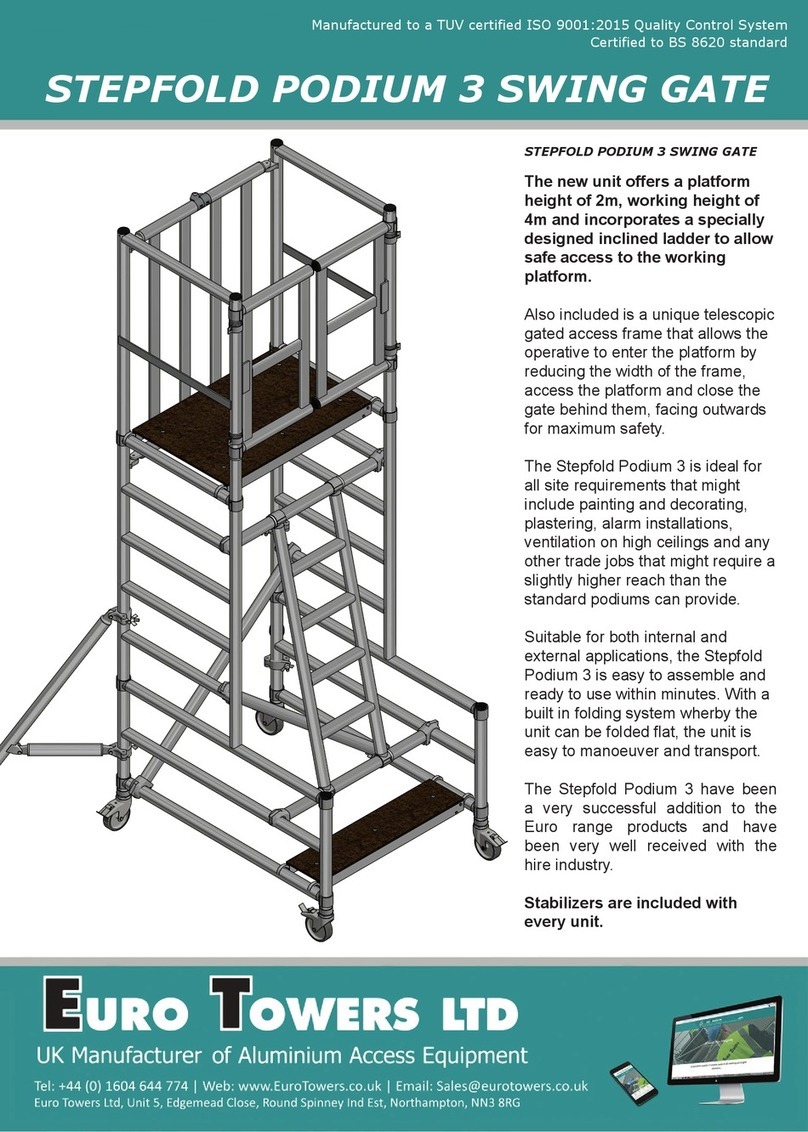

Trapdoor Platform

Toe-Board Set

4 Rung Frame

Stabiliser

Horizontal Brace

Castor

Diagonal Brace

Folding Base

Guardrail Frame

Euro Towers Ltd, Unit 5 Edgemead Close, Round Spinney, Northampton, NN3 8RG

MANUFACTURED BY EURO TOWERS LTD

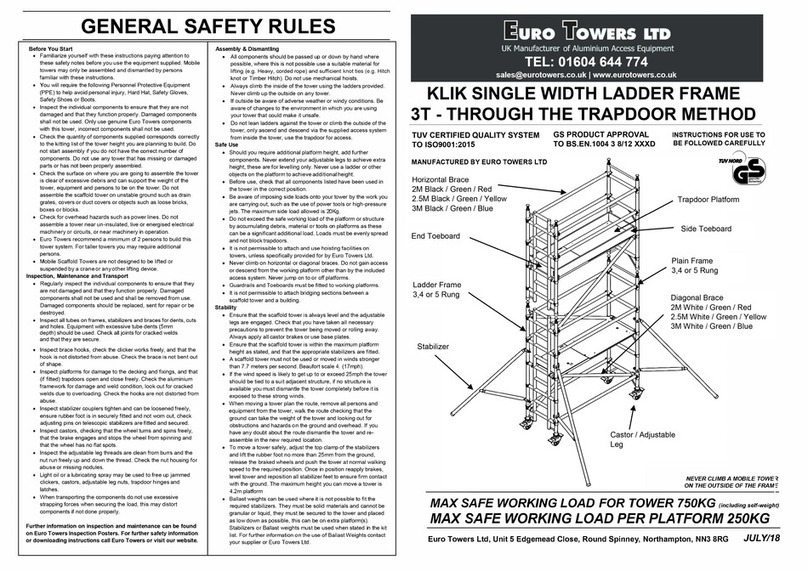

GENERAL SAFETY RULES

Before You Start

1. Familiarise yourself with these instrucons paying aenon to these safety

notes before you use the equipment supplied. Towers may only be assembled

and dismantled by a COMPETENT person familiar with these instrucons.

2. User training courses cannot be a substute for instrucon manuals but only

complement them.

3. This product shall only be used according to the instrucon manual.

4. Only original Euro Towers components specied in this manual shall be used.

5. It is recommended that this user manual be used in conjuncon with a suitable

risk assessment and method statement relave to the project.

6. This instrucon manual shall be available to the USER at ALL mes. Erecon,

alteraon or dismantle of the tower should not be aempted unless the manual

is present.

7. This mobile access and working tower shall only be used according to this

manual without any modicaon.

8. Mobile access and working towers shall only be used in accordance with

naonal regulaons.

9. You will require the following PPE and Tools to help avoid personal injury, Hard

Hat, Safety Gloves, Safety Shoes/Boots, Hi Vis vest/jacket and spirit level.

10. As part of your risk assessment do not erect, move or dismantle your tower in

excessive weather condions including heavy rain, sleet or snow that can aect

your an slip surfaces. Also avoid working in extreme heat and high winds.

11. Ensure you selected the correct plaorm height tower in relaon to the desired

working height (usually 2m) to avoid overreaching and other unsafe pracces.

12. Inspect all individual components before use to ensure quanty, compability,

any damages and all parts funcon correctly. Damaged or incorrect components

shall NOT be used.

13. Check the quanty of components supplied corresponds correctly to the king

list of the tower height you are planning to build. Do not start assembly if you

do not have the correct number of components. Do not use any tower that has

missing or damaged parts or has not been properly assembled.

14. Erect an exclusion zone and place warning signs if applicable to you.

15. It is recommended that a minimum of two person erect, alter and dismantle a

Tower but during the risk assessment addional person(s) may be required to

perform the task safely.

Inspecon, Maintenance and transport

16. Regularly inspect the individual components to ensure that they are not dam-

aged and funcon properly. Damaged components shall be isolated, tagged and

removed from use. They should be replaced and sent for repair or scrap.

17. Inspect all tube on frames, stabilisers and braces for dents, cuts and holes,

damaged equipment should be isolated, tagged and removed from use. Check

all joints for cracked welds and that they are secure.

18. Inspect Brace Hooks, check the clicker is funconing correctly and the hook is

not distorted from abuse. Check the brace is not bent/dented.

19. Inspect Plaorm for damage to the decking and xings and that (if ed)

trapdoor open and close freely and the hinge is secure. Check the aluminium

framework for damage and for cracked welds that may be damaged due to

overloading. Check the hooks are not distorted from abuse and the wind lock

clips are aached and funconing properly.

20. Inspect Stabiliser couplers can be ghtened and loosened freely. Ensure rubber

foot is securely ed and not worn out. Check adjusng pins on telescopic

stabilisers are ed.

21. Inspect castors, checking that the wheel turns and spins freely, that the brakes

engage and stops the castor from spinning. Ensure the castor has no at spots

and has a SWL.

22. Inspect the adjustable leg threads are clear of burrs and the nut runs freely up

and down the thread. Check the nut housing for abuse or missing nodules.

23. Light oil or lubricang spray may be used to free up jammed, clickers, castors,

adjustable leg nuts, stabiliser couplers, trapdoor hinges and latches.

24. Do not put excessive loads on the components during storage.

25. When transporng the components do not use excessive strapping forces when

securing the load, this may distort and damage components.

Assembling and Dismantling

26. Check ground condions are suitable for erecng and moving the tower and

the ground can take the loads imposed by the tower including weight of

equipment and persons. Do not assemble tower on unstable ground such as

drain, manhole covers, compacted ll or any other hazards highlighted during

the risk assessment.

27. Check for level and slope of the area where the tower is to be erected, moved

and dismantled is within the levelling height of the adjustable legs.

28. Check for obstrucons that could prevent erecon, moving and dismantling of

the tower safely.

29. Check for overhead hazards such as power lines. Do not assemble a tower near

uninsulated, live or energised electrical machinery or circuits, or near machinery

or plant that is in operaon.

30. Ensure the Tower is level. Castor wheels should remain LOCKED unless moving

the Tower. Adjustable legs are used for levelling the Tower. NEVER use to

gain addional height. Extra height is gained by using addional compable

components. Other items such as ladders, steps, boxes etc should never be used

to gain addional height.

31. All components should be passed up or down by hand where possible, where this

is not possible use a suitable material for liing (e.g. Heavy corded rope) and suf-

cient knot es (e.g. hitch knot or mber hitch) DO NOT use mechanical hoists.

32. Towers MUST always be climbed from the inside for access and egress using the

Integrated ladders or designated rungs. NEVER climb the outside of a Tower.

33. Do not lean ladders against a tower or climb the outside. Climb the ladder from

the inside as per the supplied access system and use the trapdoor for access and

egress.

34. Never climb on Diagonal or Horizontal braces or jump on to or o plaorms.

35. Working is only permied on a plaorm with a complete side protecon includ-

ing guardrails and toe boards.

36. Aer assembly or alteraon, the following minimum informaon shall be dis-

played on the tower: (A) The name and contact details of the person responsible

(B) If the tower is ready for applicaon or not (C) The load class and the uniformly

distributed load (D) If the mobile access and working tower is intended for indoor

use only (E) The date of assembly

Safe Use & Loadings

37. Before use, check that all components listed in the kit list have been used in the

Tower in the correct posion.

38. Care should be taken when using Power Tools or Jet washing or anything specic

to your job that could imply side loads and cause the tower to overturn. Maxi-

mum permied side load must not exceed 30kg (300n)

39. When liing components or materials keep within the base of the Tower. Ensure

the total weight of the User(s) any debris, materials being lied does not exceed

the Safe Working Load (SWL) of an individual plaorm (250kg) or the overall

structure (750kg) Loads must be uniformly distributed on the working plaorm

and not block trapdoors.

40. Mobile access and working towers designed in accordance with EN1004-1 are not

anchor points for personal fall arrest equipment.

41. Work should only be completed from one Working Plaorm at any me complete

with Guardrails and Toe Boards to prevent persons and materials falling from the

tower. Work should not be aempted from any other part of the tower including

stairs or braces.

42. The maximum number of person(s) permied on the working plaorm at any

me should not exceed the SWL (250kg). This should include any tools and or

materials

43. You should never stand on an unprotected plaorm (guardrails must be in place)

44. Consider measures to secure the tower when le unaended.

Stability & Moving

45. Ensure the Tower is level and the adjustable legs are engaged. Check that you

have taken all necessary precauons to prevent the Tower being moved or rolling

away. Always apply ALL brakes or use base plates for stac towers or inclined

surfaces.

46. Ensure that the scaold tower is within the maximum plaorm height as stated

and that the appropriate stabilisers are ed to suit. *Refer to king list.

47. A scaold tower should not be used or moved in wind speeds stronger than

17mph (7.7meters per second) (Beaufort force 4). If wind speeds exceed this,

consider tying the tower to a rigid structure or dismantling before it is exposed

to the strong winds.

48. Beware of the potenal wind factors where there is a possibility for the

tunnelling eect of open-ended buildings, unclad building and at the corners of

buildings

49. NEVER t sheets or cladding to a Tower. Such items can act as a sail and impose

extreme horizontal load onto a tower causing it to overturn.

50. When moving a tower plan the route, removing any obstrucons, ensuring the

ground can take the weight of the tower. Beware of so and uneven ground. Pay

aenon for

overhead hazards and ensure that all materials and persons are removed from

the Tower. If there are any doubts about the route, then dismantle and erect in

new locaon.

51. Towers should only be moved manually by pushing at the base of the tower at a

usual walking speed. The Tower height should be reduced to 4m if all 4 stabilisers

are in place and 2m if less than 4 stabilisers are in place. Stabilisers are raised

approximately 25mm clear of the ground and then castors are unlocked and the

tower can be moved.

52. When the Tower is reposioned reapply the brakes on castor wheels and the

tower shall be levelled using the adjustable legs for both horizontal and vercal

alignment. The

stabilisers can then be lowered making rm contact with the ground.

53. Towers should NEVER be lied or suspended by a crane or moved by mechanical

means

54. Towers are not designed to be used as a means to enter or exit other structures

55. Towers are not designed to be used as a means of edge protecon

56. All towers should be inspected before use.

Further informaon on inspecon and maintenance can be found on Euro Towers

inspecon posters. For further safety informaon or downloading instrucons call

Euro Towers or visit our website. www.eurotowers.co.uk

EUROFOLD KIT LIST

PLEASE NOTE

Only to be used on at surfaces unless equiped with adjustable legs.

If temporary platforms are used during assembly, reposition them during dismantling.

MOVING A TOWER Remove people and materials from the tower, and lower the tower to 4m if all 4

stabilisers are in place. If not then reduce tower height to 2m. Adjust and raise the stabilizers 25mm from the

ground, ensure the couplers are tight, and push from at or near the base by manual eort only, never use

mechanical means. Recheck level and reposition stabilisers before use.

PPE REQUIRED: Hard Hat, Safety Gloves, Safety Boots/Shoes, Hi-Viz Vest/Jacket

TOOLS REQUIRED: Spirit Level

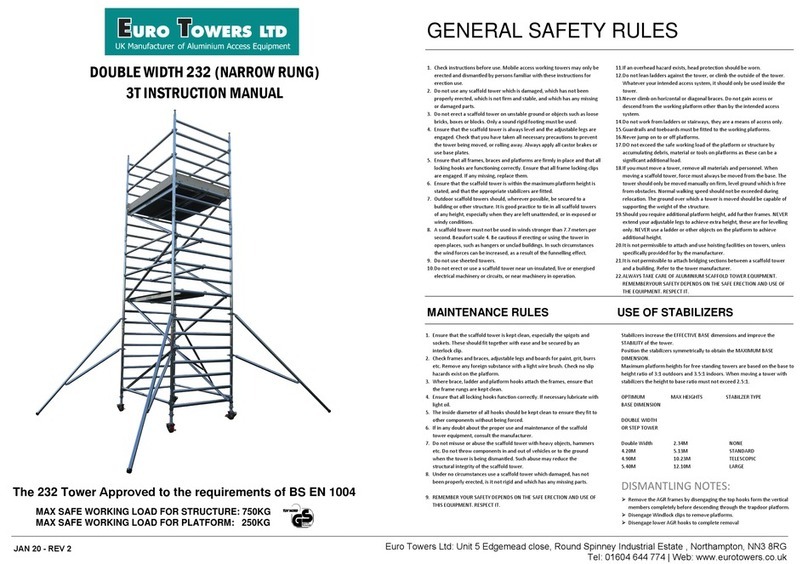

STABILISERS

Stabilisers increase the eective base dimensions

and imrpove the stability of the tower. Position the

stabilisers symmetrically to obtain the maximum

base dimension.

Maximum distance

between platforms

shall not exceed

2.25m. Except the

distance to the

rst platform max

3.40m

Do not bridge

between towers.

Maximum inclination

for movement. Note

the maximum angle

allowed is dened by

the manufacturer

Do not build, dismantle

or attempt to work on

an access tower if the

wind speed

exceeds 17MPH

Maximum inclination

for movement. Note

the maximum angle

allowed is dened by

the manufacturer

Do not stand on an

unguarded platform

Do not lift the

tower with mechanical

equipment

Do not use the tower

for access and egress

to other structures

Do not suspend the

tower

Do not lift heavy ob-

jects from the tower

Do not move the

tower with people or

materials on it

Do not use ladders,-

boxes or other objects

to gain extra height

Do not climb the outside of the tower

1. Ensure all castors are rmly tted to the

folding frame. Then open folding frame and

engage toggle clamps.

When tted with adjustable legs, level your

tower using a spirit level as a guide.

2. Fit one horizontal brace to the vertical

above the rst rung of the unit, on the

opposite side of the folding gate (Front side).

3. Fit your 4 rung frames to the base frame 4. Fit one diagonal brace on the front side

starting from the 3rd rung to the 7th.

5. Fit your trapdoor platform to the 7th rung. 6. Fit 4 stabilisers at earliest opportunity

keeping lower arms as horizontal as

possible ideally 45 degrees.Stabilisers are

xed onto the frame uprights in each corner

by the attached couplers.

4.2M Step By Step Assembly Instructions

11. Fit 4 horizontal braces to form a

guardrail in the seated position using the

3T Method. Position above the rungs of

your guardrail frames.

12. Fit your toe-board set.

DISMANTLE TOWER IN REVERSE EXCEPT WHEN

DISMANTLING THE HANDRAILS.

UNCLIP THE 4 HOOKS ON THE OPPOSITE SIDE OF

LADDER FRAME FROM THE SEATED POSITION.

9. Add 2 more diagonal braces 2 rungs

above your platform.

10. Fit your next trapdoor platform to the

3rd rung down from the top. This will be the

top rung of your TT4F.

7. Fit 4 horizontal braces to form a

guardrail in the seated position using the

3T Method (Through The Trap). Position

above the 10th rung and below the 9th

using the locator nut.

NEVER STAND ON AN UNPROTECTED PLATFORMNEVER STAND ON AN UNPROTECTED PLATFORM

8. Add further frames once you are fully

guarded in.

Table of contents

Other Euro Towers Construction Equipment manuals