EURO EP900BSX User manual

-

2

RECORD HERE FOR EASY REFERENCE

Model Colour

Serial Number Installation Date

Dealer's Name and Address

GENERAL INFORMATION

Getting to know your new cooker

Th nk you for choosing one of our products.

Our cookers re of simple, r tion l design. They re

constructed to the best st nd rds to ensure good

service nd outst nding s fety.

Ple se re d this m nu l c refully; it will provide ll the

dvice needed to llow you to obt in the best results

from the very first d y.

ATTENTION:

- Before using the appliance do not forget to remove the

protecting parts of the appliance.

WHEN YOU CALL FOR SERVICE

When you call for service or order parts for your unit be

sure to give:

1. MODEL

2. SERIAL NUMBER

3. COLOUR

4. PART NAME and/or description of problem

5. YOUR FULL NAME ADDRESS and HOME TELEPHONE

NUMBER and BUSINESS TELEPHONE NUMBER IF

APPROPRIATE.

ENVIRONMENTAL WARNING

W ste p ck ging

Do not throw the packaging of your appliance into the dustbin

but pick out the different materials (for instance foil paperboard

polystyrene) according to the local rules for rubbish elimination.

This appliance must only be used for the purpose of domestic

cooking.

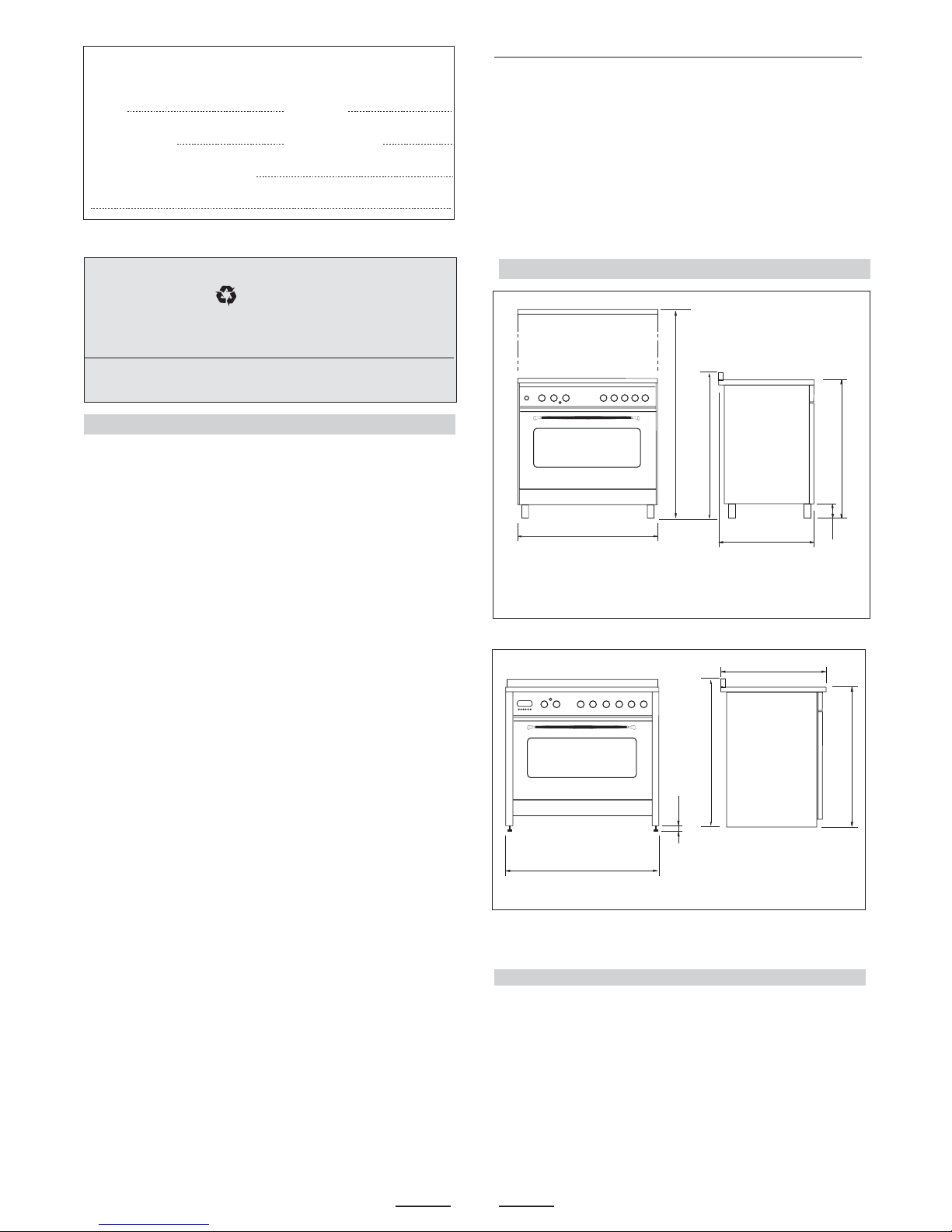

OVERALL DIMENSIONS

SECTION FOR THE QUALIFIED TECHNICIAN

WARNING -Accessible parts will become hot when in use.

To avoid burns and scalds children should be kept away.

X

1450/1500

600

h*

850/900

910/960

PROVISION FOR VENTILATION

INSTALLATION

The room where the Cooker is installed should have permanent

ventilation as follows:

Ventilation must be in accordance with AS5601/AG 601 - Gas

Installations. In general the appliance should have adequate

ventilation for complete combustion of gas proper flueing and to

maintain temperature of immediate surroundings within safe limits.

-

Do not install in a bed-sitting room a bathroom or shower room.

If there is another fuel burning appliance in the same room a

higher level of ventilation will be required you should consults

" the safety requirements".

In addition to the above during prolonged use opening a window

in the same room is recommended. This will avoid the build up

of excessive moisture and condensation.

- WARNING:

A steam cleaner is not to be used cleaning this appliances.

- WARMING

DO NOT place inflammable materials or plastic utensils in the

warming drawer.

- WARNING -

In order to prevent accidental tipping of the appliance for example

by a child climbing onto the open oven door the stabilizing means

must be installed.

- WARNING

Before you use the appliance for the first time check that the

plastic films protecting some parts (fascia panel parts in stainless

steel etc.) have been removed.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT

OR IN CARAVANS IT SHALL NOT BE USED AS A SPACE

HEATER

DO NOT MODIFY THIS APPLIANCE.

- WARNING

This appliance is not intended for use by persons (including

children) with reduced physical sensory or mental capabilities

or lack of experience and knowledge unless they have been

given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they do not play

with the appliance.

Young children and infirm persons should not be left

unsupervised in the vicinity.

Servicing shall be carried out only by authorised personnel.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE

WHILE IT IS IN OPERATION.

Not for use in marine craft caravans or mobile homes

unless each burner is fitted with a flame safeguard.

h* =

Adjustment

110 / 160

X

mod. 196 = 895 mm

X

mod. 190 = 895 mm

X

mod. 106 = 1000 mm

600

900

960

h* =

Adjustment

max 15 mm

1000

h*

POSITIONING

Important: Fix the chain located next to the gas connection on

both sides of the cooker to the wall to prevent the cooker from

tilting. Both chains must be securely fixed.

Make sure that the wall surface behind the Cooker is non-

combustable (will not catch fire).

Where a painted surface is adjacent a fire retardent paint surface

is recommended. Wallpaper wood or fabric should not be used

behind or next to the cooker.

Any adjoining wall surface (side or rear) situated within 200mm

of any hob burner must be a suitable non-combustible material

from the edge for a height of 150mm for the entire length

of the cooker.

Any combustible construction above the cooker must be at least

650mm above the maintop. Ensure that a power and gas supply

are nearby. The Cooker should be located carefully so that the

heat produced by it has plenty of space to escape. The diagram

below shows an ideal configuration.

If the cooker is being fitted next to cupboards or adjoing wall

surfaces which are within 200mm from the edge of the hob

burner and of a suitable non-combustible material as specified

Note:

The cooker is fitted with 4 legs for an eventual alignment in height

with the furniture ( fig. 1 A or 1 B a ording to the models ).

3

min.100 mm

min. 650 mm

min. 400 mm

"0" mm "0" mm

REG.

MAX

160mm

REG. MAX 15mm

Cle r nces to combustible m teri ls

No part of any adjoining wall surface can be made of combustible

materials. The protection of combustible materials

required by Clause 5.12.1.1 of AS5601-2004 is the fixing of 5 mm

thick ceramic tiles to the surface or attaching fire resistant

material to the surface and covering with sheet metal with a minimum

thickness of 0.4 mm.

Cle r nces to non- combustible m teri ls

min. 650 mm

"0" mm "0" mm

min "60" mmmin "60" mm min "60" mm

non- combustible materials

non- combustible materials

in AS5601 then ensure that a distance of at least 6cm is left

between the edge of the cooker and the non-combustible

material. This gap is to allow plenty of space for the heat

produced by the cooker to escape on each side of the cooker.

min.10 mm

TO FIX THE COOKER TO THE REAR WALL

WARNING - For safety reasons and to prevent tipping of the appliance

these stabilizing means must be installed.

The cooker is equipped with 2 chains fixed on each side at the rear of

the cooker near the top (see Fig. A). The chains are fitted with spring

clips which must be clipped to the screw eyes provided with the cooker.

Install the screw eyes as follows :

1. Drill four 6mm holes (position 1 - 2 - 3 - 4) in the wall

as in Fig. A.

2. Insert part R into the holes then screw in the screw eyes part

G see Fig. B.

Note: If the part provided is not suitable for the wall material please

use an appropriate device to ensure secure holding of the screw

eyes to the wall.

3. Bring the cooker near the wall and clip the chains on the

screw eyes as in Fig. C.

IMPORTANT: If the cooker is moved for ny re son

(e.g. m inten nce) resulting in the cooker being unclipped from the

w ll, the cooker must be re-clipped to the w ll t the completion of

the t sk.

If the cooker is placed on a base measures have to be taken to prevent

it from slipping off the base.

OK NO

Fig. 1 A

Fig. 1 B

Fig. B Fig. C

G

wall

wall

Fig. A

76 mm550 mm

G R Hole

55 mm

ch in

Position

1

Position

2

55 mm

Position

3

Position

4

4

SPECIAL NOTE

After installation or any servicing operation always ensure that

the appliance is gas sound and that the components are now

operating correctly. Items removed during servicing should be

replaced in the reverse order to their removal.

In order to change the work-top injectors it is necessary to act as

follows:

- remove the grids

- remove burners

and flame-spreaders.

GAS CONNECTION

Should conform to gas utility regulations e.g. AS5601 Gas

installations; also refer to rangehood manufacturers

recommendations.

Check gas pressure note the correct setting from the data plate

sealed inside the front appliance drawer .

This appliance from the factory suitable for NATURAL gas but if

necessary can be adjusted for U-LPG by authorised person.

*

IT IS RECOMMENDED THAT A SERVICE TAP AND UNION BE

FITTED ADJACENT TO THE APPLIANCE INLET TO FACILITATE

FUTURE SERVICING.

5 burner models: set the burner pressure to 1kPa for Natural Gas

and 2.75kPa for U-LPG with the wok burner operating a full rate.

For commissioning of the appliance with the Oara 97

regulator for Natural Gas the test point pressure should

be 1.00kPa with all burners operating on HIGH.

Apply a manometer to the test nipple and reset the regulator if

necessary. Do not forget to replace the test nipple screw and to

leave the instructions book with the user.

VERY IMPORTANT FOR THE INSTALLER

Do not attempt to turn or stress threaded elbow of the manifold:

you risk damage to this part of the gas appliance which may void

the manufacturers warranty.

Before Le ving - Check all connections for gas leaks with soap

and water. DO NOT use a naked flame for detecting leaks. Ignite

all burners to ensure correct operation of gas valves burners and

ignition. Turn gas taps to low flame position and observe stability

of the flame.

When satisfied with the cooker please instruct the user on the

correct method of operation.

In case the appliance fails to operate correctly after all checks

have been carried out refer to the authorised service provider in

your area.

GAS CONVERSION AND ADJUSTMENT

When used with natural gas all burners have been preset at our

factory and further adjustment should not be necessary. Conversion

kits to other gases are available from the place of purchase. Do

not attempt to fit the conversion kit yourself. Conversion to U-LPG

gas should only be carried out by an authorized technician.

GAS ADJUSTEMENTS

- change the injectors

- adjust the minimum flow

When converting from Natural Gas to U-LPG ensure that

the NG regulator is removed and replaced with the Test Point

Assembly. A gas regulator suitable for a supply pressure of 2.75kPa

should be part of the gas tank supply and should be adjusted with

the wok burner operating at maximum.

REPLACEMENT OF THE INJECTORS

When required to operate on other gas replace the injectors in

accordance with information referred to in chart below.

other relevant statutory code band regulations. If you have some

doubts please contact the authorities for confirmation concerning

the characteristics of the gas and electricity output.

The appliance is generally preset for natural gas (so no other

adjustment is necessary) ensure regulator is fitted for N.G.

Ensure that all foreign matter has been cleared from the gas

supply line and also purge all air from the gas system. Connect

to regulator tighten and check the installation to ensure no gas

leaks occur.

accordance with the manufacturers installation instructions

relevant local fitting regulations municipal building regulations

the AS5601 code for gas burning appliances and equipment and

and 695mm from the floor (depends on adjustment of feet).

The appliance shall be installed by an authorized person in

For the adjustments to U-LPG please operate as specified in the

paragraph GAS CONVERSION AND ADJUSTMENT (pag 4).

The Gas Connection is male 1/2" BSP and is situated at the right

hand rear of the appliance approximately 40mm from the side

This appliance can be connected with rigid pipe as specified in

AS5601 table 3.1 or with an AGA approved Class B or D flexible

hose with 10mm I.D. and 1.2m max. length in accordance with

AS5601 for a 'high level connection'.

The hose should not be subjected to abrasion kinking or permanent

deformation and should be able to be inspected along its entire

length. Unions compatible with the hose fittings must be used and

connections tested for gas leaks. The fixed consumer piping outlet

should be at approximately the same height as the cooker

connection point pointing downwards and approximately 150mm

to the side of the cooker.

The hose should be clear of the floor when the cooker is in the

installed position.

Ensure that the chain prevents stress on the hose assembly when

the cooker is moved out of its normal operating position. TA B . 1

Natural Gas 1.00 kPa

0.90 Auxiliary 4.0

1.20 Semi-rapid 7.1

1.50 Rapid 11.0

1.60 TC 12.5

U - LPG 2.75 kPa

0.53 Auxiliary 3.7

0.73 Semi-rapid 7.0

0.95 Rapid 11.7

1.00 TC 12.9

NG Regulator LP Test point

adaptor

Regulator

1.55 TC 12.0

with GC & GL & YP pan supports

0.95 TC 12.0

1.50 fish 11.0

0.93 fish 11.4

with GE & GP pan supports

with GC & GE & GP & GL & GU pan supports

1.35 Rapid 9.1

with YP pan supports

with GE & GP & GL pan supports

1.45 fish 10.4

with YP pan supports

0.87 Rapid 10.2

Jet mm Ø Burners Power MJ/h

Jet mm Ø Burners Power MJ/h

with GC & GE & GP & GL & YP & GU

pan supports

NOTE:

GE = Enameled Steel pan supports

GL = Light Cast Iron pan supports

YP = Light Cast Iron pan supports (evolution)

GP = Heavy Cast Iron pan supports

0.80 fish 8.5

GC = Flat heavy cast iron pan supports

GU = Flat heavy cast iron pan supports

1.00 TC 1 12.7

1.63 TC1 12.7

with GC & GE & GP & GL & YP & GU

pan supports

with GC & GL & YP pan supports

with GE & GP pan supports

with GC & GE & GP & GL & GU pan supports

with YP pan supports

with GE & GP & GL pan supports

with YP pan supports

with GC & GE & GP & GL & YP & GU

pan supports

with GC & GE & GP & GL & YP & GU

pan supports

5

- change the injector (see Fig. C) and replace it with another one

suitable for the new type of gas (see tab. 1)

Fig. C

Z

Fig. 2BFig. 2A

MINIMUM FLOW ADJUSTMENT FOR HOB-TOP TAPS

In order to adjust the minimum flame setting proceed as follows:

switch the burner on and set the knob at the minimum position

. Remove the knob from the tap place a small bladed screwdriver

down the centre of the tap shaft (fig. 2A).

Attention: on taps with a security valve the minimum adjusting

screw «Z» is on the body of the gas tap (fig. 2B).

Unscrew the adjusting screw in order to increase the flow or screw

it to decrease the flow.

The correct adjustment is obtained when the flame has a length

of about 3 or 4 mm.

For butane/propane gas the adjusting screw must be screwed

in thigt.

Make sure that the flame does not go out turning quickly from the

max. flow to the minimum flow .

Refit the knob again.

2nd SECTION FOR THE USER

WARNING:

Children should be kept away while the oven or grill is in use

since accessible parts become hot.

- Do not use oven base panel as a shelf make use of the oven

shelves.

- To avoid splattering and smoke position collecting tray under

the grill with some water in it.

- Always turn pan handles to the side or to the back of the hob.

If they are left out into the room they can easily be hit or reached

by children this knocking the pan off the hob.

- Dont let children sit down or play with the oven door. Do not

use the drop down door as a stool to reach above cabinets.

- Once your cooking is over make sure to close the main gas

supply.

WARNING

* This appliance is not intended for use by young children or

infirm persons without supervision.

* Young children should be supervised to ensure that they do

not play with the appliance.

BURNERS PANS

fl min. fl max

AUXILIARY 80 mm 160 mm

SEMI-RAPID 120 mm 200 mm

RAPIDE 200 mm 230 mm

TRIPLE CROWN 230 mm 260 mm

- 1 Minute Tour -

Be s fe

Please read the rest of the instruction book which contains

important information to help you use the appliance safely and

efficiently.

G s nd Electricity on

Make sure that the gas supply is turned on and that the appliance

is plugged in and switched on. The ignitor needs electricity.

In case there is no electric current the burner can also be lighted

using a match.

It is recommended that pans suitable to the size of the burner

should be used as follows:

- WARNING -

In order to prevent accidental tipping of the appliance for example

by a child climbing onto the open oven door the stabilizing means

must be installed.

ELECTRICAL CONNECTION

The appliance must be installed by a suitably qualified person in

accordance with these instructions and with the requirements of

the Australian Wiring Rules AS/NZS 3000.

Fixed wired installations are to be provided with suitable isolation

means in accordance with the said rules.

Any plug socket installed for the purpose of connecting the appliance

to supply must be readily accessible when the appliance is installed.

Before making the connection make sure that:

1) the safety circuit-breaker and the electrical system are able to

withstand the load of the appliance (see nameplate).

2) the power supply system has an earth connection in good

working order in accordance with the regulations in force;

IMPORTANT

The wires in the mains lead are coloured in accordance with the

following code:

GREEN & YELLOW.........................................................EARTH

BLUE...........................................................................NEUTRAL

BROWN ...............................................................................LIVE

Electric power ..1 5 mm2 3 core cable (15 amp. Fuse required).

Should conform to local authority requirements.

Also refer to rangehood manufacturers recommendations.

This appliance is supplied with a plug & cord simply plug into a

3 pin household socket outlet witch is properly earthed.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The flexible mains lead and plug must not be in contact with hot

surfaces.

Table of contents