Euromag Eurosonic 2000 User manual

Wall-Mount Ultrasonic Flow Meter

EUROSONIC 2000

User Manual

READ AND KEEP THESE INSTRUCTIONS

TD 203-0-ENG

EUROSONIC 2000

EUROMAG | 3

INDEX

1. INTRODUCTION

1.1 Preface

1.2 Features

1.3 Flow measurement principle

1.4 Packaging list

1.5 Optional parts

1.6 Typical applications

1.6.1 Applications sorted by industry / process

1.7 Product identification

1.8 Specifications

2. INSTALLATION AND MEASUREMENT

2.1 Unpacking

2.2 Installation considerations

2.2.1 Mounting the main unit

2.2.2 Installing transducers

2.2.3 Distance from main unit to transducer

2.2.4 Cables

2.2.5 Power supply wiring

2.2.6 Other electrical connections

2.3 Power up

2.4 Keypad

2.5 Menu windows

2.6 Menu window list

2.7 Steps to configure the parameters

2.8 Transducer mounting allocation

2.9 Transducers wiring

2.10 Transducers installation

2.11 Installation check-up

2.11.1 Signal strength

2.11.2 Signal quality

2.11.3 Total transit time and delta time

2.11.4 Transit time ratio

7

7

7

8

8

9

9

9

9

10

13

13

13

13

13

14

14

14

14

15

16

16

17

18

19

20

20

21

21

22

22

22

4 | EUROMAG

EUROSONIC 2000

3. HOW TO

3.1 How to check if the instrument works properly

3.2 How to check the liquid flowing direction

3.3 How to change units systems

3.4 How to select a flow rate unit

3.5 How to use the totalizer multiplier

3.6 How to turn on / off the totalizers

3.7 How to reset the totalizers

3.8 How to restore the factory default setups

3.9 How to use the damper to stabilize the flow rate

3.10 How to use the low-flow cut off function

3.11 How to conduct zero calibration

3.12 How to change the scale factor

3.13 How to use the password locker

3.14 How to use the keypad locker

3.15 How to use scheduled data output

3.16 How to use 4-20ma current loop output

3.17 How to output analogue voltage signal

3.18 How to use the frequency output

3.19 How to use the totalizer pulse output

3.20 How to produce an alarm signal

3.21 How to use the oct output

3.22 How to use the relay output

3.23 How to use the built-in buzzer

3.24 How to modify the built-in calendar

3.25 How to adjust the lcd

3.26 How to use the RS232 serial interface

3.27 How to view the totalized flow

3.28 How to connect analogue input signals

3.29 How to compensate the flow not measured during offline

3.30 How to use the working timer

3.31 How to use the manual totalizer

3.32 How to use the batch process controller

3.33 How to calibrate the analogue output

3.34 How to check the ESN

4. MENU WINDOW DETAILS

23

23

23

23

23

24

24

24

24

24

24

24

25

25

25

25

25

26

26

26

27

28

28

28

28

29

29

29

29

30

30

30

30

30

31

33

EUROMAG | 5

INDEX

5. TROUBLESHOOTING

5.1 Introduction

5.2 Power-on errors

5.3 Working status errors

5.4 Other problems and solutions

6. COMMUNICATION PROTOCOL

6.1 RS232 connector pin-out

6.2 RS232 wiring

6.3 Communication protocol

6.3.1 Basic commands

6.3.2 Protocol prefix usage

6.4 The M command and the ASCII codes

6.5 Programming examples

7. MEASUREMENTS OF THERMAL AND OTHER

PHYSICAL PARAMETERS

7.1 Introduction

7.2 Wiring analogue inputs

7.3 Thermal energy measurement

7.4 Configure analogue measurement ranges

7.5 Read input analogue values from a network computer

8. WARRANTY AND SERVICE

8.1 Warranty

8.2 Service

45

45

45

46

47

49

49

50

50

50

52

53

53

55

55

55

56

57

57

59

59

59

6 | EUROMAG

9. APPENDIX

9.1 Wiring diagram and outline drawings

9.2 Clamp-on transducer installation guide

9.2.1 Choose installation method

V-method installation

Z-method installation

W-method installation

9.2.2 Transducer spacing

9.2.3 Prepare the pipe surface

9.2.4 Prepare the transducers

9.2.5 Install the transducers

9.2.6 Fine tune the installation

9.3 Standard pipe dimensions

9.4 Sound speed tables

61

61

63

63

63

63

63

63

64

64

64

65

65

66

EUROSONIC 2000

EUROMAG | 7

INTRODUCTION

1. INTRODUCTION

1.1 PREFACE

The wall-mount product family is designed to be installed in a fixed location for long-term flow

measurement.

The flow meter is based on transit-time flow measurement principle. It measures the flow rate of liquid in a

closed pipe by using a pair of clamp-on or wetted ultrasonic transducers. In general, the liquid should be full in

the pipe, and should contain no or small amount of particles or air bubbles. Examples of applicable liquids are:

water (hot water, chilled water, city water, sea water, etc.); sewage; oil (crude oil, lubricating oil, diesel oil, fuel

oil, etc.); chemicals (alcohol, acids, etc.); waste water; beverage, liquid food, solvents and other liquids.

The utilizes state-of-the-art technologies such as advanced signal processing, low-voltage transmitting,

small signal receiving, self-adaptation, the latest electronics, etc., to achieve high accuracy and reliable

performance. Besides, the EUROSONIC 2000 product provides versatile output interfaces, both analogue and

digital, which can be easily used by a host computer or a flow controller.

1.2 FEATURES

• Better than 1% linearity.

• ±0.2% of repeatability.

• ±1% of accuracy at velocity above 0.6ft/s (0.2m/s).

• Positive / negative / net flow totalizer.

• Proprietary low-voltage transmission and self-adaptation technologies.

• Anti-interference design.

• Dual CPU. 100 Pico-second time measurement resolution.

• Operates with all Euromag transducers.

• Die-cast aluminium weather-resistant enclosure (standard version).

• Able to measure electrically conductive and non-conductive liquids.

• RS-232 interface. Complete communication protocol for instrument networking.

• Can be used as a flow RTU.

• Up to 5 channel 12 bits analogue 4-20mA input

• 1 channel programmable 4-20mA output

• 2 channel programmable digital output (isolated OCT and Relay)

• Frequency output.

• Internal batch process controller.

• 2x20 letters backlight LCD display. 4x4-key, tactile-feedback membrane keypad.

8 | EUROMAG

EUROSONIC 2000

1.3 FLOW MEASUREMENT PRINCIPLE

The ultrasonic flow meter is designed to measure

the velocity of liquid within a closed conduit. It uses

the well-know transit-time measurement principle,

plus our proprietary signal processing and ultrasonic

transceiving technologies.

As shown in Figure 1, they utilize a pair of ultrasonic

transducers which are mounted on the pipe upstream

and downstream respectively. Each transducer

functions as both ultrasonic transmitter and receiver.

The main unit operates by alternately transmitting and

receiving a coded burst of sound energy between the

two transducers. The transit-times in the upstream

direction as well as in the downstream direction are

measured. The difference of the two transit times is

directly and exactly related to the velocity of the liquid

in the pipe.

TRANSIT TIME FLOW MEASUREMENT PRINCIPLE

The flow rate is then computed by combining the

velocity information with pipe parameters and a

scale factor. The scale factor is normally determined

by calibration in factory.

Three types of transducers can be used with the main

unit in order to cover the range of diameters from

15 to 6000mm. The transducers can be mounted in

V-method where the sound transverses the pipe fluid

twice, or in W-method where the sound transverses

the pipe fluid four times, or in Z-method where the

transducers are mounted on opposite sides of the

pipe and the sound crosses the pipe fluid once. The

selection of the mounting methods depends on pipe

and liquid characteristics.

1.4 PACKAGING LIST

• EUROSONIC 2000 main unit,

240VAC/8-36VDC 1 unit

• EST-M1-type clamp-on transducer

for 2”~28” pipe 1 pair

• Dedicated shielded transducer cable 5 Meters

• Potting Mix, Silicon compound 1 tube

• Clamp-on fixture 1 set

• Couplant 1 unit

• User’s Manual 1 unit

• 4-20mA Analogue Output Module 1 channel

• Relay Output Module 1 channel

V= x

MD

sin 2Ø

∆T

Tup • Tdown

O

SPACING

DOWNSTREAM TRANSDUCER

UPSTREAM TRANSDUCER

FLOW

Tup

Tdown

REFERENCES

Øis the angle between the sound path and the flow direction

Mis the number of times the sound traverses the flow

Dis the pipe diameter

Tup is the time for the beam travelling from upstream the

transducer to the downstream transducer

Tdown is the time for the beam travelling from the downstream

transducer to the upstream transducer

∆T = Tup – Tdown

f. 1

EUROMAG | 9

INTRODUCTION

1.5 OPTIONAL PARTS

• EST-S1-type clamp-on transducer for small pipe

(0.5”~4”)

• EST-L1-type clamp-on transducer for large pipe

(12”~240”)

• Analogue Input Modules (3 channels)

1.6 TYPICAL APPLICATIONS

The flow meter can be applied to a wide range of pipe

flow measurements. Applicable liquids include pure

liquids as well as liquid with small quantity of tiny

particles. Examples are:

• Water (hot water, chilled water, city water, sea

water, waste water, etc.);

• Sewage with small particle content;

• Oil (crude oil, lubricating oil, diesel oil, fuel oil,

etc.);

• Chemicals (alcohol, acids, etc.);

• Plant effluent;

• Beverage, liquid food;

• Ultra-pure liquids;

• Solvents and other liquids

1.6.1 APPLICATIONS SORTED BY INDUSTRY / PROCESS

• Water and waste water management;

• Water and waste water treatment plants;

• Power plants, such as nuclear power plants and

hydraulic power plants;

• Mining and metallurgy plants;

• Petroleum process monitoring and control;

• Chemical process monitoring and control;

• Pulp and paper process monitoring and control;

• Food and beverage processing;

• Marine maintenance and operation;

• Pipeline leakage detection;

• HVAC, hydronic balancing;

• Energy supply and production systems;

• Flow measurement networking.

1.7 PRODUCT IDENTIFICATION

Each set of the series flow meter has a unique

product identification number or ESN (electronic

serial number) written into the software that can only

be modified with a special tool by the manufacturer.

In case of any hardware failure, please provide this

number which is located on menu window M61 when

contacting the manufacturer.

10 | EUROMAG

1.8 SPECIFICATIONS

Main Unit

Linearity

Accuracy

Repeatability

Velocity

Measurement Period

Display

Keypad

Units

Outputs

Input

Others

Enclosure

Transducer

Clamp-on

Better than ±1%.

±1% of reading at rates >0.6 ft/s (0.2m/s). Assume a fully developed flow profile.

±0.2%.

±0.03 ~ ±105 ft/s (±0.01 ~ ±30 m/s), bi-directional

0.5s

LCD with backlight. 2x20 letters.

4x4-key membrane keypad with tactile feedback

English (U.S.) or metric.

Analogue output: 4-20mA or 0-20mA current output. Impedance 0~1kΩ. Accuracy 0.1%.

Isolated OCT output: for frequency output (0~9,999Hz), alarm driver, or totalizer pulse

output, ON/OFF control, etc.

Relay output 1A@125VAC or 2A@30VDC. For ON/OFF control, alarm driver, totalizer

output, etc.

Internal Alarm (Buzzer): user programmable.

External Alarm Driver: alarm signal can be transmitted to Relay or OCT output terminals

to drive an external alarm.

RS-232 serial port.

Five channel 4-20mA current inputs for signals such as temperature, pressure, liquid

level, and etc.. Accuracy 0.1%.

Two of the five input channels are wired to terminal blocks. The remaining three

channels are optional.

Capable of offline compensation for flow totalizer, automatic / manual selectable.

Self-diagnosis.

Automatically record the following information:

• The totalizer data of the last 64 days / 64 months / 5 years;

• The power-on time and corresponding flow rate of the last 64 power on and off

events. Allow manual or automatic flow loss compensation

• The instrument working status of the last 64 days

Die-cast aluminum enclosure.

Protection Class: IP65 (NEMA 4X). Weather-resistant.

Size: 9.88”x7.56”x3.15” (251x192x80mm3) for standard version

S1-type: for pipe size 1”~4” (DN30~DN100mm)

M1-type: for pipe size 2”~28”(DN50~DN700mm)

L1-type: for pipe size 11”~240”(DN300~DN6,000mm)

EUROSONIC 2000

EUROMAG | 11

Liquids

Liquid Types

Liquid Temp

Suspension

concentration

Pipe

Pipe Size

Pipe Material

Pipe Straight run

Cable

Shielded transducer cable. Standard length 15’ (5m). Can be extended to 1640’ (500m). Contact the manufacturer for

longer cable requirement.

Cable should not be laid in parallel with high-voltage power lines, neither should it be close to strong interference source

such as power transformers.

Environment

Temperature

Humidity

Power

AC 110 V; AC: 240V; DC: 8VDC~36V to be defined at order stage. Power consumption: < 2W

Weight

Standard main unit: 6.6lb (3kg)

Virtually all commonly used clean liquids.

Liquids with small quantity of tiny particles may also be applicable.

Particle size should be less than 75um, particle concentration less than 10,000ppm.

Liquids should contain no or very minor air bubbles.

Examples are chilled/hot water, sea water, waste water, chemical liquids, oil, crude oil,

alcohol, beer, etc.

32˚F - 212˚F (0˚C - 100˚C) for clamp-on transducer.

Higher temperatures can be accommodated. Consult the manufacturer for assistance.

32˚F - 302˚F (0˚C - 150˚C) for wetted transducer.

< 10,000ppm and particle size less than 80um.

May contain very small amount of air bubbles.

1” ~ 240” (DN25mm ~ DN6,000mm).

All metals, most plastics, fiber glass, etc. Allow pipe liner.

15D in most cases, 30D if a pump is near upstream, where D is pipe diameter.

Main unit: 14˚F ~ 158˚F (-10˚C ~ 70˚C)

Clamp-on transducer: -22˚F ~ 212˚F (-30˚C ~ 100˚C)

Main unit: 85% RH

Transducer: water-submersible, water depth less than 10’ (3m)

INTRODUCTION

12 | EUROMAG

EUROSONIC 2000

EUROMAG | 13

INSTALLATION AND MEASUREMENT

2. INSTALLATION AND MEASUREMENT

2.1 UNPACKING

Please unpack the shipping box and check the parts and documents against the packing slip. If there is

something missing, the device is damaged, or something is abnormal, please contact us immediately and do

not proceed with the installation.

2.2 INSTALLATION CONSIDERATIONS

This section provides guidelines for installing the main unit (electronics enclosure) and its transducers.

2.2.1 MOUNTING THE MAIN UNIT

The main unit electronics (standard version) are housed in an IP65 (NEXA 4X) weather-resistant and dust-tight

enclosure. Therefore, the main unit can be installed indoors and outdoors. Usually, it is mounted in a meter

shed or on a location where one can easily access for meter testing and servicing. Please refer to

Appendix

9.1

for the enclosure dimensions.

2.2.2 INSTALLING TRANSDUCERS

First, you need to select a proper installation site. For this, one usually needs to consider the accessibility of

the location, operating space needed for the installation, safety code compliance, etc. In addition, flow and

pipe conditions near the installation site are also very important. Please refer to

section 2.8

for site selection

details.

Then, follow the installation guidelines given in

Appendix 9.2

for installing clamp-on transducers.

WARNING!

THE FLOW METER CAN BE USED

TO MEASURE THE FLOW OF MANY

LIQUIDS. SOME OF THE LIQUIDS

MAY BE HAZARDOUS. IT IS VERY

IMPORTANT THAT YOU COMPLY

WITH LOCAL SAFETY CODES AND

REGULATIONS IN INSTALLING AND

USING ELECTRONIC DEVICES IN

YOUR AREA.

2.2.3 DISTANCE FROM MAIN UNIT TO TRANSDUCER

In general, the closer the transducer to the main unit,

the better the signals. All major cable suppliers can

supply up to 1640ft (500m) long transducer cable as

per specifications.

2.2.4 CABLES

The flow meter utilizes a double-balanced driving

technique for high performance ultrasonic

transimission and receiving. It requires twisted

shielded cable for the transducer. We recommend to

use the cable supplied by the manufacturer. If you

want to do the transducer cabling yourself please

contact the manufacturer in advance.

Try not route the transducer cable along with high

current AC lines. Avoid strong interference sources.

Make sure the cables and cable connections are

protected from weather and corrosive conditions.

2.2.5 POWER SUPPLY WIRING

The user normally selects the type of power supply

when the order is placed. There are three types

of power supply options, 110VAC, 220VAC and

8-36VDC. You must make sure the power supply

type of your flow meter matches the power source to

which the flow meter will be connected.

Open the flow meter enclosure. On the lower right

corner (refer to the figures in Appendix 9.1), you

should see three terminal blocks which pins are

labelled as 11, 12 and 13. Normally, pin 13 should

be connected to your Earth ground. Make sure your

Earth ground is good. Pins 11 and 12 should be

connected to Neutral and Line, respectively.

If 8-36VDC power source is used, its positive lead

and negative lead should be connected to pin 24 and

23 respectively.

Please refer to

Appendix 9.1

for more wiring

information.

2.2.6 OTHER ELECTRICAL CONNECTIONS

Wiring RS232 Port

Refer to

sections 6.1, 6.2

and

Appendix 9.1

for

details.

Wiring 0/4-20mA Output

Using standard twisted-pair wiring. Refer to

Appendix

14 | EUROMAG

WARNING!

WARNING!

THE TRANSDUCERS MAY HAVE

STATIC CHARGES ACCUMULATED

DURING TRANSPORTATION.

BEFORE CONNECTING THE

TRANSDUCERS TO THE MAIN

UNIT, PLEASE DO DISCHARGE

THE TRANSDUCERS IN A

SAFE AREA BY SHORTING

THE CENTRE CONDUCTOR

OF THE TRANSDUCER CABLE

CONNECTORS TO THE METAL

SHIELD OF THE CONNECTOR.

BE CAREFUL ABOUT THE POWER

SUPPLY TYPE OF YOUR FLOW

METER AND THE POWER SUPPLY

WIRING! CONNECTING TO A

WRONG TYPE POWER SOURCE

OR IMPROPER CONNECTION OF

LINE POWER COULD DAMAGE

THE FLOW METER. IT MAY ALSO

CAUSE HAZARDOUS VOLTAGE AT

ENCLOSURE, THE TRANSDUCER,

FLOW CELL, AND ASSOCIATED

PIPING.

NOTE

WITH 8-36 V DC POWER SUPPLY

THE 4-20MA OUTPUT MAY NOT

BE AVAILABLE, EXCEPT SPECIAL

INSTRUCTION WAS GIVEN WHEN

THE ORDER WAS PROCESSED.

EUROSONIC 2000

9.1

for details.

Wiring 0/4-20mA Inputs

There are five analogue input channels which

can be used to accommodate five channels of

analogue input signals. Two of them are wired to

terminal blocks (pin 65, 64 and 63). You can assign

temperature, pressure and other physical signals to

those channels. An internal 24VDC is provided for

loop-powered transmitters.

Using standard twisted-pair wiring. Refer to

Chapter

7

for details.

Wiring Alarms

Using standard twisted-pair wiring. Refer to

sections

3.21 and 3.22

for details.

2.3 POWER UP

The flow meter does not have power ON/OFF switch.

When it is connected to power, it will start to run

automatically.

After the power is turned on, the flow meter will

run a self-diagnostic program, checking first the

hardware and then the software integrity. If there is

any abnormality, corresponding error messages will

be displayed. (Please refer to

chapter 5

for error code

explanations.)

After successful internal checks, the flow meter

will display menu window #01 (short for M01), or

the menu window which was active at last power

off. It will also start the measurements by using the

parameters configured last time by the user or by the

initial program.

The flow measurement program always operates in

the background of the user interface. This means that

the flow measurement will keep running regardless

of any user menu window browsing or viewing. Only

when the user enters new pipe parameters will the

flow meter change measurement to reflect the new

parameter changes.

When the power is turned on or new pipe parameters

are entered, the flow meter will enter into a self-

adjusting mode to adjust the gain of the receiving

circuits so that the signal strength will be within a

proper range. By this step, the flow meter finds the

best system gain which matches the pipe material

and fluid type. The user will see the progress by

the number s1, s2, s3 and s4, located on the upper

left corner of the LCD display. If the self-adapting

process is completed successfully, letter “#R” will

be displayed.

When the user adjusts the position of the installed

transducers, the flow meter will re-adjust the signal

gain automatically.

Any user-entered configuration value will be stored in

the NVRAM (non-volatile memory), until it is modified

by the user.

EUROMAG | 15

WARNING!

BEFORE CONNECTING THE DEVICE

TO POWER SOURCE, PLEASE DO A

FINAL CHECK TO MAKE SURE ALL

THE WIRINGS ARE CORRECT AND

ALL THE LOCAL SAFETY CODES

ARE FOLLOWED.

INSTALLATION AND MEASUREMENT

16 | EUROMAG

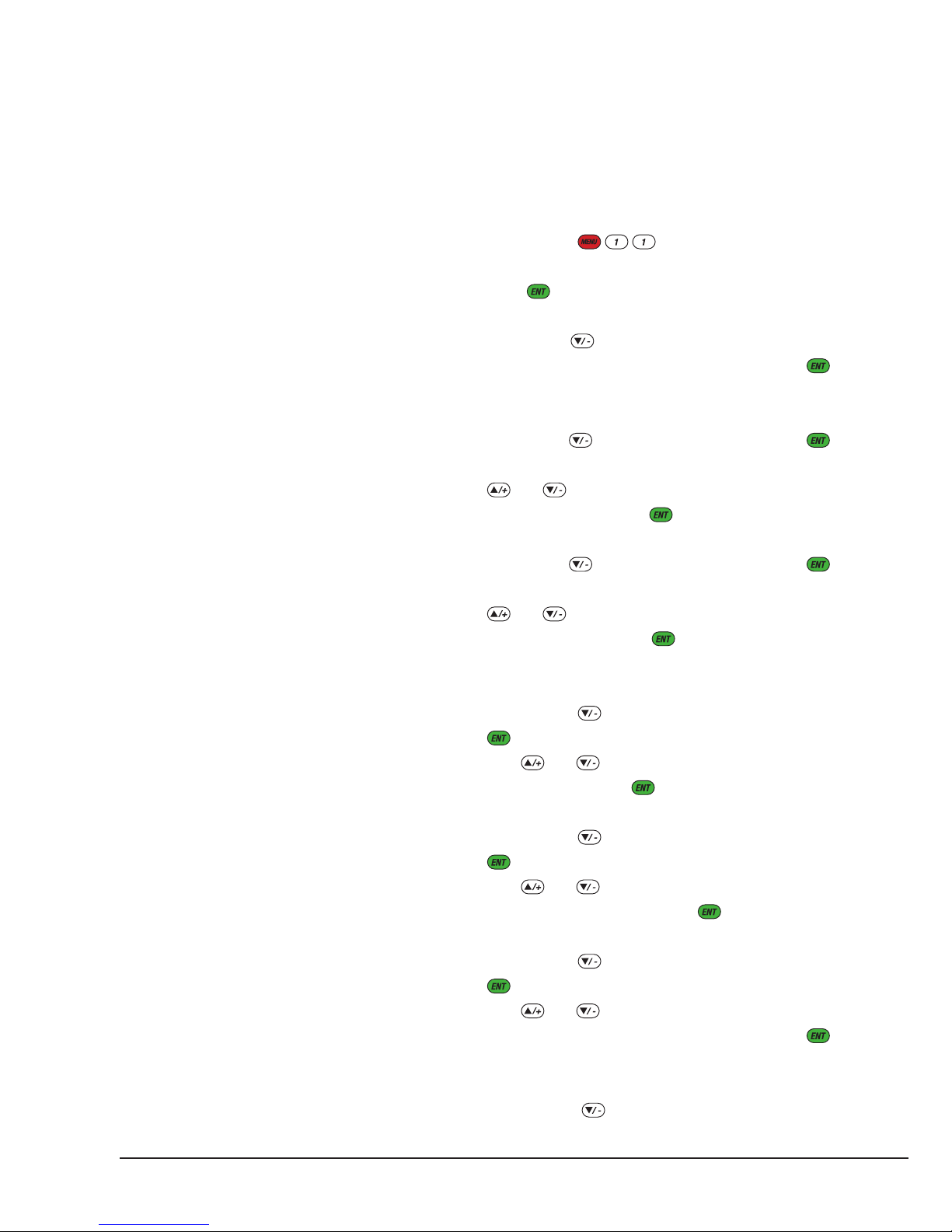

2.4 KEYPAD

The keypad of the flow meter has 16 keys (Figure 2).

Keys ~ and are keys to enter numbers.

Key is the going UP key when the user wants to

go to the upper menu window. It also works as “+”

key when entering numbers.

Key is the going DOWN key when the user wants

to go to the lower menu window. It also works as the

“–” key when entering numbers.

Key is the backspace key when the user wants to

go left or wants to backspace the left character that

is located to the left of the cursor.

Key is the ENTER key for any input or selections.

Key is the key for the direct menu window jump

over. Whenever the user wants to proceed to a certain

menu window, the user can press this key followed

by a 2-digit number.

The key is shortened as the ‘M’ key hereafter

when referring to menu windows.

Key-pressing induced beep sound can be enabled /

disabled in menu window M77.

2.5 MENU WINDOWS

The flowmeter user interface comprises about 100

independent menu windows that are numbered by

M00, M01, M02, …, M99, M+0, M+1, etc.

There are two methods to visit a menu window:

1) Direct jump in. Simply press the key followed

by a 2-digit number. For example, if you want to visit

menu window M11 for pipe outer diameter, press the

following three keys consecutively, .

2) Press the or key. Each time of the

key pressing will lead to the lower-numbered menu

window. For example, if the current window is on

M12, the display will go to window M11 after the

key is pressed once.

You do not need to remember all the menu windows.

Just remember the most commonly used window

numbers and the approximate window number

of some uncommonly used windows would be

sufficient. You can always use and keys to

find the right window.

There are three different types of menu windows:

1) Menu windows for number entering, e.g., M11 for

setting up pipe outer diameter.

2) Menu windows for option selection, e.g., M14 for

the selection of pipe materials.

3) Results display windows, e.g., window M00 for

displaying flow rate, etc.

f. 2

EUROSONIC 2000

EUROMAG | 17

For number entering windows, the user can directly

press the digit keys if the user wants to modify the

value. For example, if the current window is on M11,

and the user wants to enter 219.2345 as the pipe

outer diameter, then, the flowing keys should be

pressed: .

For option selection windows, the user should first

press the key to get into option selection mode.

Then, use , , or digit key to select the right

option. Consequently, press the to make the

selection.

For example, assume your pipe material is stainless

steel and you are currently on menu window M14

which is for the selection of pipe materials (if you

are on a different window, you need to press

first in order to enter into the M14 window.)

You need to press the key to get into the option

selection mode. Then, either press the and

keys to make the cursor on the line that displays “1.

Stainless Steel”, or press the key directly. At the

end, press again to make the selection.

Generally, the key must be pressed to get into

the option selection mode for option modifications.

If the “Locked M47 Open’ message is indicated on

the bottom line of the LCD display, it means that the

modification operation is locked out. In such cases,

the user should go to M48 to have the instrument

unlocked before any further modification can be

made.

2.6 MENU WINDOW LIST

M00~M09 windows for the display of the

instantaneous flow rate, net totalizer value, positive

totalizer value, negative totalizer value, instantaneous

flow velocity, date time, current analogue input

values, current working status, etc.

M10~M29 windows for entering system parameters,

such as pipe outer diameter, pipe wall thickness,

liquid type, transducer type, transducer installation

method, etc. Transducer installation spacing is

then calculated according to those parameters and

displayed on one of the windows.

M30~M38 windows for flow rate unit selection and

totalizer configuration. User can use these windows

to select flow rate unit, such as cubic meter or liter,

as well as to turn on / off each totalizer, or to reset

the totalizers.

M40~M49 windows for setting response time,

zeroing / calibrating the system, locking / unlocking

keypad, changing network address ID, password,

etc.

M50~M89 windows for digital and analogue outputs,

such as scheduled output, RS232 output, relay

output, analogue current loop output, LCD, frequency

output, alarm output, analogue inputs. Besides, there

are also windows for configuring analogue inputs,

date / time, and day/month/year accumulator.

M90~M94 windows for displaying diagnostic data,

including the installation triplet. Those data are very

useful when doing a more accurate measurement.

M95 Upon entering into this window, the circular

display function is started automatically. The

following windows will be displayed one by one, each

window will stay for about 4 seconds: M95 ->M00

-> M01 -> M02 -> M03 -> M04 -> M05 -> M06 ->

M07 -> M08 -> M09 -> M90 -> M95.

M+0~M+9 windows for some additional functions,

including a single precision calculator, display of the

total working time, and display of the time and the

flow rate when the device is turned on and turned off.

INSTALLATION AND MEASUREMENT

18 | EUROMAG

EUROSONIC 2000

Other menu windows are used for factory

debugging.

For detailed explanation of the above windows please

refer to

chapter 3 “How to”

and

chapter 4 “Menu

Window Details”

.

2.7 STEPS TO CONFIGURE THE PARAMETERS

In order to make the flowmeter work properly, the

user must follow the following steps to configure the

system parameters:

1) Pipe size and pipe wall thickness

For standard pipe, please refer to

Appendix 9.4

for

outer diameter and wall thickness data. For non-

standard pipe, the user has to measure these two

parameters.

2) Pipe materials

For non-standard pipe material, the sound speed

of the material must be entered. Please refer to

Appendix 9.5

for sound speed data.

Forstandardpipematerialsandstandardliquids,thesound

speed values have already been programmed into the flow

meter, therefore there is no need to enter them again.

3) Liner material, its sound speed and liner thickness,

if there is any liner.

4) Liquid type (for non-standard liquid, the sound

speed of the liquid should be entered.)

5) Transducer type.

6) Transducer mounting methods (the V-method and

Z-method are the common methods)

7) Check the transducer distance displayed on window

M25 and install the transducers accordingly.

Example: For standard (commonly used) pipe

materials and standard (commonly measured) liquids,

the parameter configuration steps are as following:

1) Press keys to enter into M11 window.

Input the pipe outer diameter through the keypad and

press key.

2) Press key to enter into M12 window. Input the

pipe thickness through the keypad and press

key.

3) Press key to enter into M14 window. Press

key to get into the option selection mode. Use keys

and to scroll up and down to the proper pipe

material, and then press key.

4) Press key to enter into M16 window. Press

key to get into the option selection mode. Use keys

and to scroll up and down to the proper liner

material, and then press key. Select “No Liner”,

if there is no liner.

5) Press key to enter into M20 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

liquid, and then press key.

6) Press key to enter into M23 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

transducer type, and then press key.

7) Press key to enter into M24 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

transducer mounting method, and then press

key.

8) Press key to enter into M25 window. The

transducer installation distance will be displayed

EUROMAG | 19

INSTALLATION AND MEASUREMENT

on the window. Based on this distance and the

transducer installation method selected above, install

the transducers on the pipe (refer to

Appendix 9.2

for

more installation details.)

9) After installation is completed, check if the triplet

(signal strength S, signal quality Q and transit-time

ratio R) are in the right range. Press keys

to enter into M90 window for visiting S and Q and

press to visit R.

10) Press to enter into window M01 to

visit the measurement result.

2.8 TRANSDUCER MOUNTING ALLOCATION

The first step in the installation process is to select an

optimal location for installing the transducers in order

to make the measurement reliable and accurate. A

basic knowledge about the piping and its plumbing

system would be advisable.

An optimal location would be defined as a long

straight pipe line full of liquid that is to be measured.

The piping can be in vertical or horizontal position.

The following table shows examples of optimal

locations.

Principles to select an optimal location:

1) Pipe must be full of liquids at the measurement

site.

2) No heavy corrosion of deposition inside of the

pipe.

3) Must be a safe location.

4) The straight pipe should be long enough to

eliminate irregular-flow-induced error. Typically, the

length of the straight pipe should be 15 times of the

pipe diameter. The longer the better.

The transducers should be installed at a pipe section

where the length of the straight pipe at upstream side

is at least 10D and at downstream side is at least 5D,

where D stands for pipe outer diameter.

5) If there are flow disturbing parts such as pumps,

valves, etc. on the upstream, the straight pipe length

should be increased (refer to figure 3 for more

details.) The disturbance strength are in the following

order (low to high): Single Bend -> Pipe Reduction /

Enlargement -> Outflow Tee -> Same Plane Multiple

Bends -> Inflow Tee -> Out of Plane Multiple Bends

-> Valve -> Pump.

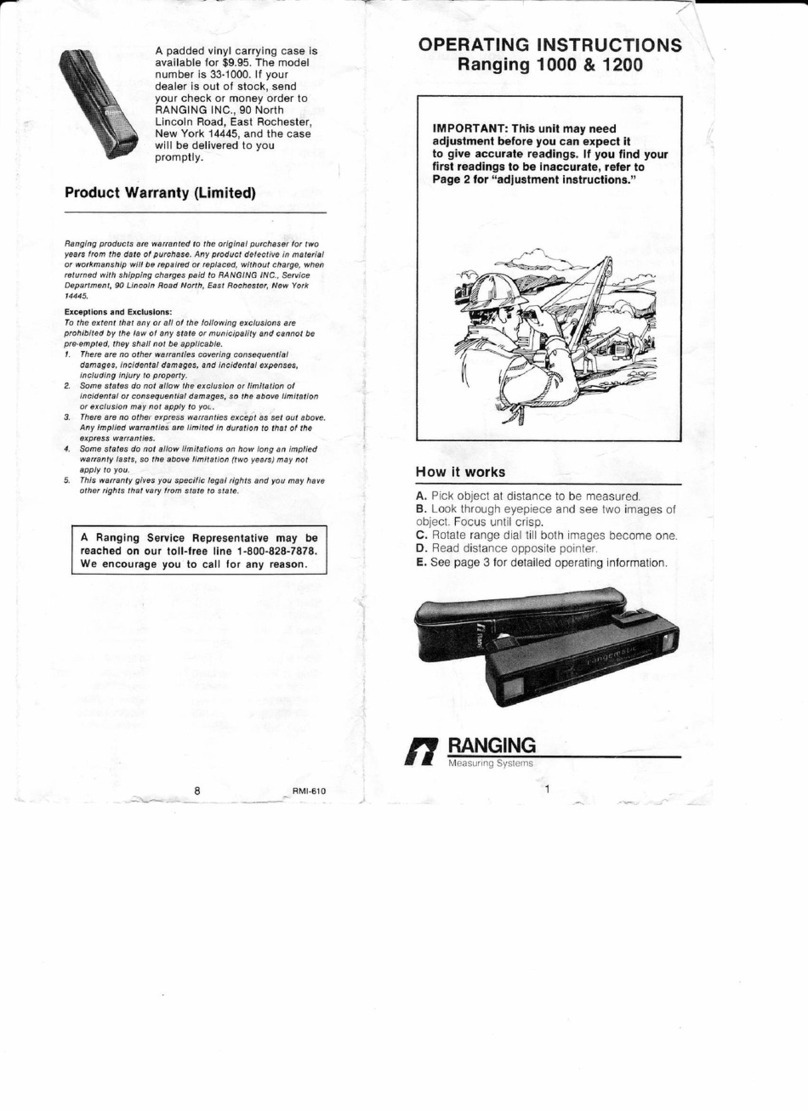

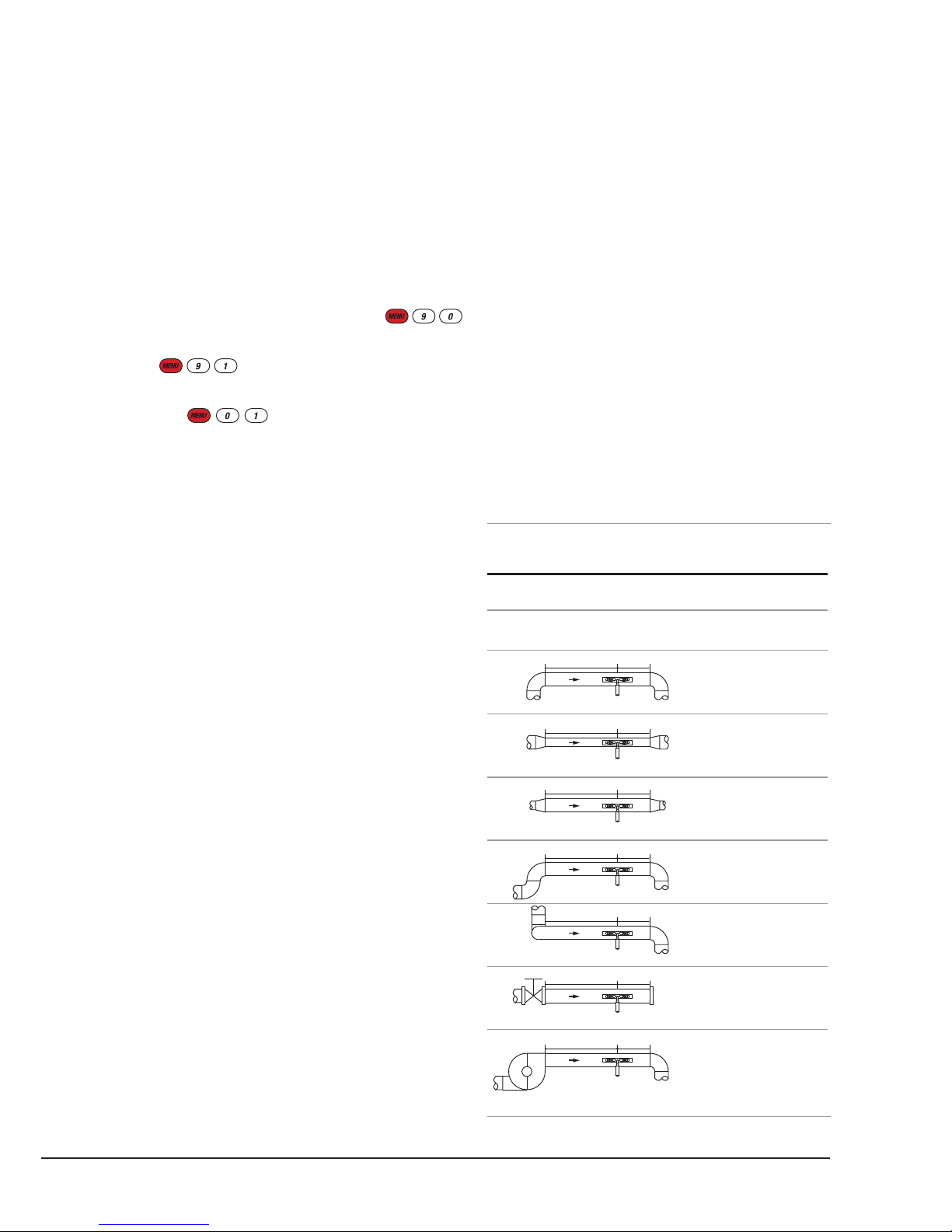

INSTALLATION SITE SELECTION

PIPING CONFIGURATION

AND TRANSDUCER POSITION

UPSTREAM

DIMENSION

Lup x

Diameters

10D

10D

10D

12D

20D

20D

30D

Ldown x

Diameters

5D

5D

5D

5D

5D

5D

5D

DOWNSTREAM

DIMENSION

f. 3

Lup

Lup

Lup

Lup

Lup

Lup

Lup

Ldown

Ldown

Ldown

Ldown

Ldown

Ldown

Ldown

20 | EUROMAG

EUROSONIC 2000

6) Make sure that the temperature on the location does

not exceed the range for the transducers. Generally

speaking, the closer to the room temperature, the

better.

7) Select a relatively new straight length of pipe line

if it is possible. Old pipe tends to have corrosions and

scale, which could affect the results. If you have to

work on an old pipe, we recommend you to treat the

corrosions and depositions as if they are part of the

pipe wall or as part of the liner. For example, you

can add an extra value to the pipe wall thickness

parameter or the liner thickness parameter to take

into account the deposition.

8) Some pipes may have a kind of plastic liner

which creates a certain amount of gaps between

liner and the inner pipe wall. These gaps could

prevent ultrasonic waves from direct travelling. Such

conditions will make the measurement very difficult.

Whenever possible, try to avoid this kind of pipe. If

you have to work on this kind of pipe, try our plug-

in transducers that are installed permanently on

the pipe by drilling holes on the pipe while liquid is

running inside.

9) When select the measurement site, you may need

to consider where to mount the flow meter main

unit. Normally, the EUROSONIC 2000 electronics are

housed in a weather-resistant enclosure. It can be

mounted in a meter shed, or a location that allows

easy access to the flow meter for programming and

servicing.

10) When select the measurement site, you may

also need to consider how to install the transducers.

Make sure you have enough spatial space for easy

operation.

2.9 TRANSDUCERS WIRING

Since the flowmeter utilizes balanced topology

for high-performance ultrasonic transmitting and

receiving, it is recommended to use high-frequency

twisted cable with shielding as the transducer cable

in order to guarantee the signal quality. Please refer

to

section 2.2

and

Appendix 9.1

on how to wire

transducers to the flow meter terminals.

2.10 TRANSDUCERS INSTALLATION

The transducers used by the flowmeter series

ultrasonic flow meter are made of piezoelectric

crystals both for transmitting and receiving ultrasonic

signals through the wall of liquid piping system. The

measurement is realized by measuring the travelling

time difference of the ultrasonic signals. Since

the difference is very small, the spacing and the

alignment of the transducers are critical factors to the

accuracy of the measurement and the performance

of the system. Meticulous care should be taken for

the installation of the transducers.

Clamp-on transducer installation steps:

1) Locate an optimal position where the straight

pipe length is sufficient (see the previous section),

and where pipes are in a favourable condition, e.g.,

newer pipes with no rust and ease of operation.

2) Calculate the transducer spacing. Just enter

the pipe, fluid and transducer information through

menu M11 to M24, the flow meter will calculate the

transducer spacing automatically. The value will be

shown in M25. Marking the transducer installation

spots on the pipe according to this spacing value.

3) Clean any dust and rust on the spot where the

transducers are to be installed. For a better result,

Table of contents

Other Euromag Measuring Instrument manuals