Euroseal Infinity_EN_rev00 – 04-10-2019

INTRODUCTION

GENERAL NOTES ON DELIVERY

When the unit is delivered, check the state of the packaging (keep the packaging for future use).

Open the packaging and check that:

- the delivered unit corresponds to technical specifications;

- there are no obvious signs of damage.

In case of damage or missing parts, inform immediately either the shipping agent, the dental depot or

Euronda S.p.A.

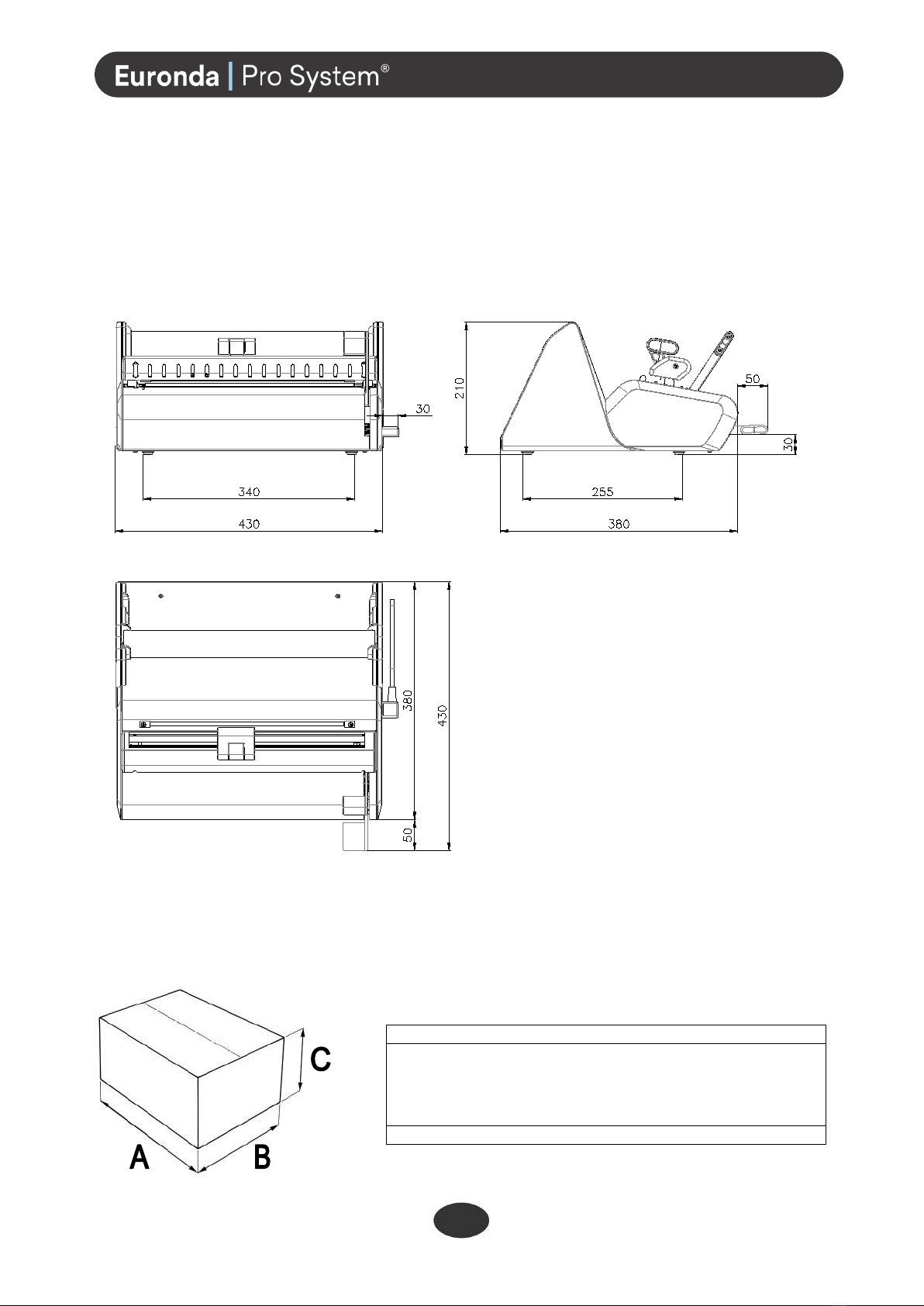

All of the dimensions listed in this manual are not binding.

The sketches and any other consigned documents regarding this machine are property of Euronda S.p.A.,

which reserves all rights. They can not be made available to any third parties.

It is forbidden to reproduce all or part of the text or illustrations.

GENERAL INSTRUCTIONS

The purpose of this manual is to give instructions on:

- correct installation;

- the safe and efficient use of the unit;

- routine maintenance.

The unit must be used according to the procedures contained in the manual and only for the purpose for

which it was designed.

CAUTION

•The intended protections could be compromised if the unit is used in ways other than those specified by

the manufacturer.

•Only use the original power lead supplied with the unit.

•Pursuant to article 33 of regulation 1907/2006 (REACH), we hereby confirm that the heating element of

the unit contains boric acid CAS NO. 10043-35-3. However, this substance cannot enter into contact

with the user or the sterilised tools, as it is sealed inside the heating element. There are therefore no

associated risks or special precautions to implement during normal use.

The operator is the person who physically uses the unit for the purpose for which it has been designed.

The responsible authority is the person or group responsible for the use and routine maintenance of the

unit and for operator training. The responsible authority is legally responsible for the installation, operation

and use of the unit.

The manufacturer shall not be held responsible for any running problems or any breakages or injuries

caused by the unit if it is used incorrectly or not maintained properly.

Intended use: This manual is an integral part of the product and must be kept near the unit for quick and

easy consultation. The unit is designed for use by professional, qualified persons only. The unit must be

used for its intended purpose only.

EUROSEAL®Infinity: unit used to seal rolls and pouches made of laminated paper/polyethylene for

packing sterilised tools used in the medical, veterinary, podology and tattoo sectors.

Not suitable for rolls of other materials.