Eurospec Push Bar Panic Bolt User manual

1Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Installation Instructions

Modular Push Bar Panic Bolt with Vertical Rods to EN1125

IMPORTANT INFORMATION

PLEASE READ THESE INSTRUCTIONS CAREFULLY

This product is non handed and can be fitted on both left handed and right handed doors.

For internal use only.

Door – Maximum specification of door on which this product should be fitted.

•Maximum weight of door = 200kg

• Maximum height of door = 2500mm

• Maximum width of door = 1300mm (1170mm Bar) – 1100mm (730mm Bar)

This product is designed for peoples safety and complies with EN 1125. Do not modify

the product in anyway other than those outlined in these instructions.

2Modular Push Bar Panic Bolt with Vertical Rods Rev.7

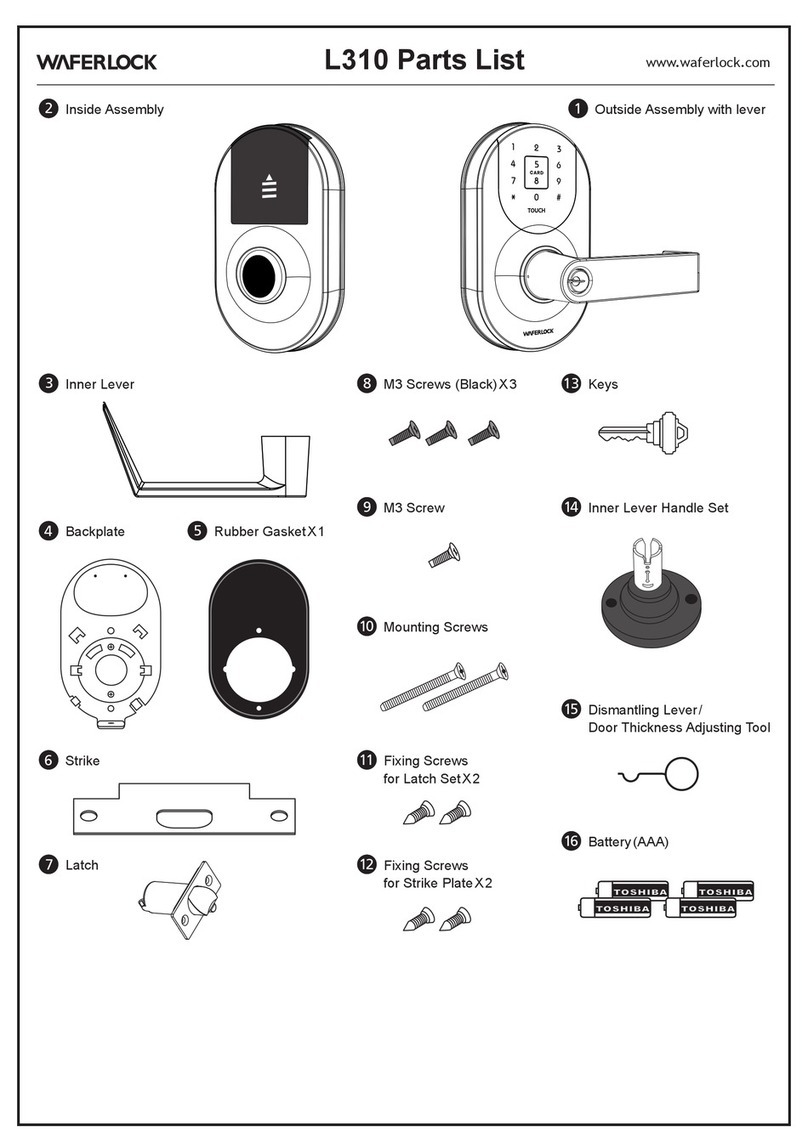

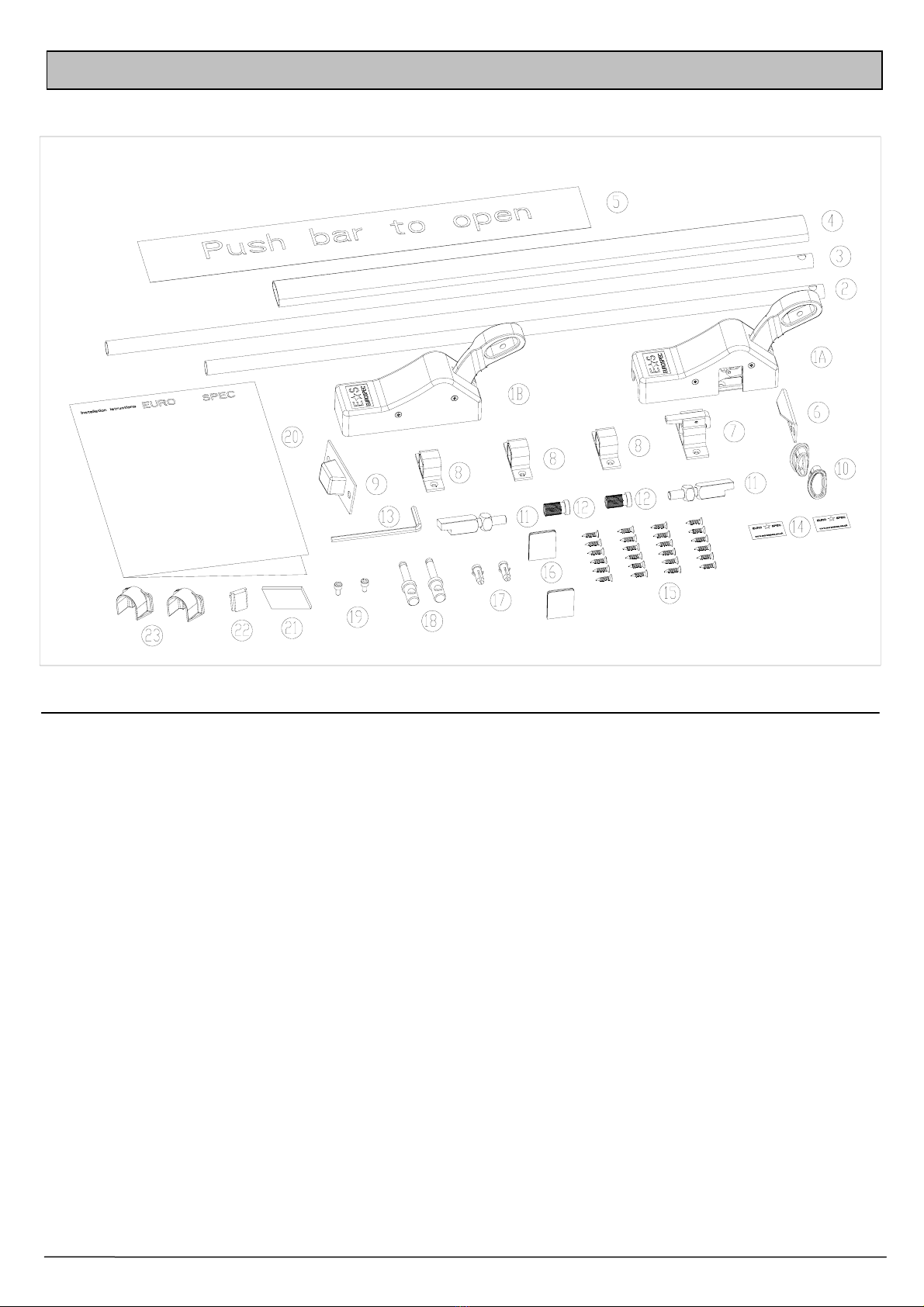

Components 1

Upon unpacking your product you will find the following parts.

(1A) Panic Bolt Box X 1

(1B) End Box X 1

(2) Short Tubular Bottom Rod X 1

(3) Long Tubular Top Rod X 1

(4) Push Bar X 1

(5) Push Bar to Open sign X 1

(6) Top Keep X 1

(7) Top Tripper Guide X 1

(8) Plain Guides X 3

(9) Bottom Keep X 1

(10) Plastic End Caps X 2

(11) Shoot Bolts X 2

PARTS LIST

(12) Knurled Plugs X 2

(13) Allen Key X 1

(14) ES Logo Labels X 2

(15) Screws (for guides, keeps and panic

bolt boxes) X 24

(16) Panic Bolt Box Blanking Covers X 2

(17) Plastic Plugs X 2

(18) Rod Connectors X 2

(19) Socket Headed Cap Screws X 2

(20) Fitting Instruction X 1

(21) 3mm Packer X 1

(22) End Box Bottom Cover X 1

(23) Rod Connector Covers X 2

3Modular Push Bar Panic Bolt with Vertical Rods Rev.7

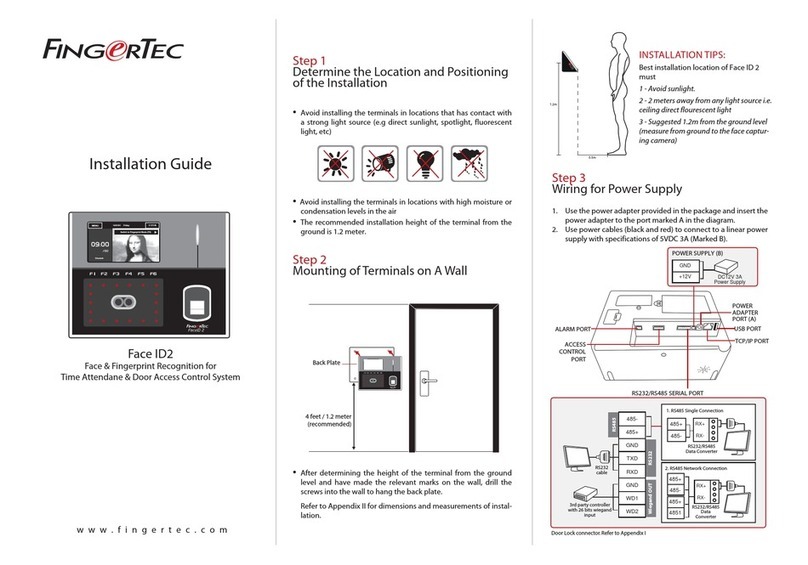

Fitting Guide

2

For single or multi-point locking see diagrams below.

Additional locking devices may be required. Refer to relevant product instructions.

Door Suitability

This Push Bar Panic Latch and any Locking Devices can be fitted on

most wood, steel or aluminium Doors

Door size limitations

Maximum clear opening height = 2450mm.

Minimum clear opening width = 400mm per door.

Single Door Rebated Double Door Non Rebated Double Door

Door shown

with Modular

Push Bar

Panic Latch

Preparation 3

1) Check that the door and frame are in good condition and that the door operates correctly.

2) At a height of 1150 +/- 100mm, obtain the most suitable position for installation depending on

door and frame conditions (This height will be centre line mark for unit follower)

4Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Installation 4

1) Remove 8 cover fixing screws from

main cases (Items 1A and 1B) (See

Fig 4.1)

2) Offer Panic Bolt Box to door in

location obtained at preparation

remembering centre line mark is

follower height

Note: Distance from door frame

edge to Panic Bolt Box must be

Min 10mm

3) Mark 6 fixing holes from obtained position. Fig 4.1

Fig 4.2

5) Measure distances (‘A’ & ‘B’) from the Panic Latch Box (1A).

See Fig 4.2

‘A’ Top of Panic Bolt Box (1A), to underside of door jamb

‘B’ Bottom of Panic Bolt Box (1A), to the final floor level

Fig 4.3

6) Cut tubular rods (Items 2 & 3) to the lengths

measured less 88mm for both. See Fig 4.3

Note: Both rods have pre-drilled holes for

fitting to the Rod connectors (Items 18)

therefore ensure the bars are cut at the

opposite end.

Remove any burrs and insert Knurled plugs

(Items 12) fully into cut ends of rods taking

care to use a wooden block to support the

opposite end when knocking the plugs into

position. See Fig 4.3

Note: If fitting External Locking attachment, rotate

follower to suit hand of door.

Right Hand door, rotate follower fully “clockwise”.

Left Hand door, rotate follower fully “anti-clockwise”.

The External Locking Attachment now needs installing according

to it’s supplied instructions.

4) Secure Panic Bolt Box (1A) to door using 6 screws (Item 15)

5Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Installation – (continued)

4

7) Fit rod connectors to rods using 2 socket

headed cap screws (Items 28). Secure with

supplied Allen key (Item 13) See Fig 4.4

8) Remove Panic Bolt box from door and

insert rod connectors onto angled plates inside

main body See Fig 4.5

Note: The Push bar lever must be

depressed to enable fitting of connectors

Fig 4.4

Fig 4.5

9) Slip over one plain guide (Item 8) onto the top rod

(Item 3) then screw the shoot bolt (Item 11) fully

into the knurled plug (Item 12)

Slip the two remaining plain guides (Items 8)

over the bottom rod (Item 2) then screw the

remaining shoot bolt (Item 6) into the other

knurled plug (Item 12). Ensure both shoot bolts

are fully screwed into the knurled plugs. Do not over

tighten.

Refit the assembled Panic Bolt with rods to the door

and fix two plain guides (Items 8) to door at a central

position on both rods using screws (Items 23) ensuring

vertical alignment with door edge. The other plain guide

does not require fixing at this stage. See Fig 4.6

Fig 4.6

6Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Installation – (continued)

4

10) With the door in the closed position. Fully depress

the Push bar lever and holding the door in a closed

position, adjust the top shoot bolt (Item 11) until a

3-4mm required clearance is achieved from the

underside of frame to top of shoot bolt. The bevel of shoot

bolt must be facing the door (adjust if necessary)

See Figs 4.7 & 4.8

With the door open, slide the top tripper guide (Item 7)

over the top shoot bolt and close the door. Fully depress

the push bar lever, inset 3mm packer to hold the top

shoot bolt. This now gives the position of the top guide.

Mark through and secure into position. Fig 4.7

Fig 4.8

Bevelled edge

2-3mm

11) With the rods held into position by the top tripper,

adjust the bottom shoot bolt to obtain a required

clearance of 2-3mm. See Fig 4.9

Note: Ensure bevelled edge of shoot bolt is facing the door

Slide the remaining plain guide down into position

maintaining a gap of 19mm between the underside of the

guide and threshold. Mark through and secure into

position See Fig 4.7

Fig 4.9

2-3mm

Bevelled edge

7Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Installation – (continued)

4

12) Mortise out for Top and Bottom keeps as shown,

including the clearance depth (approximately 12mm)

for the top shoot bolt when the door is in the closed

position. Adjust keeps as required ensuring that the

shoot bolts are not a loose or tight fit into the keeps.

See Figs 4.10 & 4.11

When the keeps are screwed into position, open and

close the door to ensure the top tripper releases

against the top keep and the bottom rod engages

fully into the bottom keep. Also check the tripper

catch holds the bars open when the door opens.

Top Keep Fig 4.10

Fig 4.11

Bottom Keep

13) Screw End Box on the hinge side of the door

at the distance shown in Fig 4.12, ensuring

the box is vertically aligned and in line

horizontally with the Panic Bolt Box. If the

door is too narrow, remember to leave a 10mm

gap between end box and door frame. Mark

through and secure into position.

14) Place End Box blanking cover (item 22) onto

bottom of metal base, depress arm and fit End

Box cover. Secure with screws.

Insert Panic Bolt Box blanking covers (item 16)

into Panic Bolt Box Cover, depress arm and fit

Latch Box to metal base at the same time

inserting rod connector covers (item 23).

Secure with screws. See Fig 4.13

Note: If the distance in Fig 4.12 is less than

674mm, remove this difference from the bar

15) Insert the Push Bar through the Panic Bolt

lever arms and insert plastic caps at each end

ensuring they are fully pressed into position.

Use the Allen key to secure the Push Bar into

position ensuring the bar is tightly secured.

See Fig 4.13

16) Check the operation of the Bar and rods are

satisfactory.

17) Apply self adhesive ‘Push Bar to Open’ Sign

to door and stick the optional ES logo labels

into the recesses of the Panic Bolt boxes .

Fig 4.12

Fig 4.13

12mm

8Modular Push Bar Panic Bolt with Vertical Rods Rev.7

Operational Instructions

5

Operational Instructions and Maintenance

6

Ensure that the Keeps are secure, clean and free from any obstruction, check that Push Bar Panic

Bolt operates correctly, and periodically apply grease to top and bottom shoot bolts.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE END USER

Stancliffe Street

Mill Hill

Blackburn

BB2 2QR

Tel: +44 (0) 1254 274100

Fax: +44 (0) 1254 274111

Web: www.eurospec.co.uk

This Push Bar Panic Bolt is fitted to comply with EN1125. No instruction of operation is required. For

the end user, the Push Bar Panic Bolt should be easily operated by hand or body pressure in a

panic situation.

Table of contents

Popular Door Lock manuals by other brands

LockState

LockState RemoteLock openEDGE RG Hardware installation

Assa Abloy

Assa Abloy Yale Pro SL Installation and programming instructions

iSysmart

iSysmart ZigBee SGZB05A user manual

Yale

Yale real Living YRC226 Installation and programming instructions

Salto

Salto LA1T05 Series installation guide

Maco

Maco A-TS Assembly instructions