Eurotech EUROLAM User manual

Roll to Roll laminator

UserManual

Free Call 1800 30 6161 | info@eurotech.com.au

The Package is made of Steel buckle box and Plywood

board, free of Fumigation.

The package dimensions:

225cm!76cm!81cm

The box shall be disassembled by loosening the buckles around the

edges. !

Tools Needed: HammerFlat"Tip"Screwdrivers!

PACKING INSTRUCTION

Release Main machine from the package bottom:

1. Cut off the belt fixing the Main Machine, and release it out of the package.

2. Cut off the belt fixing the Stand connection beams at the bottom, and pull the beams out and put aside.

3. Remove all the walls of case.

225cm

76cm

81cm

Stand with feet wheels

Stand connection Beams

Fixed on the front part of the

wooden case by two bolts. We

need remove the bolts first to

release the stands.

Fixed on the package bottom, bind by the fasten belt. Air compressor

Packed together with Main machine, fixed by belt

from the bottom, we need cut off the belt to release

the air compressor from the bottom. Then take the

compressor out.

Heating Elements

Packed inside of PVC tubes, fixing by the blue

packing film. The machine just install one unit, the

other one is for standby.

Power Cable

Fixing by the blue packing film.

ACCESSORY BOX CONTAINS:

Bolts

M-8!16mm

Stand Frame Assembly:

Assembling the stand frame is

the first step to built your

laminator.

Both of the Stand frames are

totally the same, which could

be assembled at will.

Take out the bolts M-8×16mm,

and put the stands frame and

the stand beam together, then

screw the bolts into the thread

hole.

Note: PLEASE FASTEN THE BOLTS

THROUGH THE HOLES AT OUTSIDE OF

STANDS WHEN INSTALLING. Just like the

close-up shot showing.

HEXAGONSOCKET BOLTS M-8×16 mm 12 pieces

Round Shim !8×1.5mm 4 pieces

Open end wrench 8mm 2 pieces

Nuts M8 4 pieces

Inner hexagon wrench No.3/4/5/6 1 piece/each

Bolts Gasket 3.5cm×6cm 4pieces

Fuse/15A 1 piece

Fuse/1A 1 piece

Oil-water Separator with fixing screws 1 piece

Feet Pedal 1 piece

Big Fraction Pad 2 Pieces

Small Fraction Pad 2 Pieces

Air Tube 5×8mm 3 m

U-shape Shell(Standby) 2 Pieces

Tension Knob 2 pieces

Slitting head 1 piece

Power Cable 1 piece

INSTALL THE MAIN MACHINE

We need four person to raise the main machine up

from the package bottom. Take care for the holding

position, better on the main frame/table. Just like

the yellow points showed:

Note to align the four fitting holes on top of

stands when dropping.

Then screw the nuts back to fixing the

machine fitting.

Fixing Nut

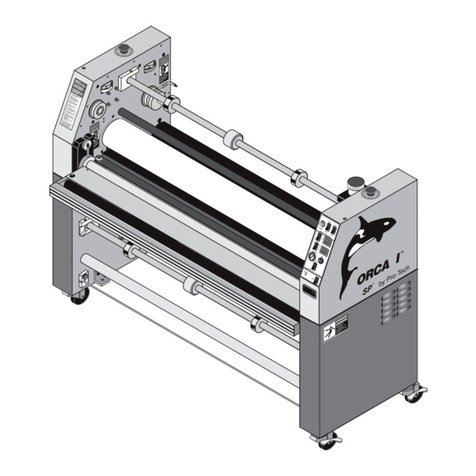

DIAGRAM OF WHOLE MACHINE

• Prints Loading Shaft

• Liner Collecting Shaft

• Upper Roller

• Lower Roller

• Control Panel

• Handle Valve

• Take-up Rod

• Water-Oil Separator

• Tension Knobs

• Finishes Collecting Shaft

• Film Loading Shaft

• Feet Pedal Connector

• Overhaul Window

INSTRUCTION OF CONTROL PANEL/BACK PANEL

!Hot light:

"lighting means the machine roller working under hot state

!Cold light:

"lighting means the machine roller working under cold state

!Ready light:

"lighting means the roller surface temperature has reached the

set value

!Hot/cold switch:

"Control the switch of hot/cold model

!M/A switch:

"under Auto model, the machine can keep running at the speed

set;

"under Manual model, the machine is controlled by the feet

pedal.

!Forward/backward switch:

"Control the direction the roller running, usually used during film

installing.

!Speed adjust button:

"Just adjust the working speed

#About setting:

3UHVVWKH6HWEXWWRQIRUƉUVWWLPHZH

ZLOOHQWHUWKHWHPSHUDWXUHVHWWLQJ

HQYLURQPHQWKHUHZHFDQVHWWKH

WHPSHUDWXUHRIODPLQDWLQJ

3UHVVWKH6HWEXWWRQIRUVHFRQGWLPH

ZHZLOOJRWWKHLQWHUIDFHRILQSXWWLQJWKH

FRGHWKLVLVE\RXUIDFWRU\LJQRUHLW

SOHDVH

3UHVVWKH6HWEXWWRQIRUWKLUGWLPHWR

HQGXS\RXUVHWWLQJ

!3RZHU6ZLWFK

!!"#$%&'%()*%

!!"#$%&+'%()*%

!3RZHU&DEOH

&RQQHFWRU%

3RZHU6XSSO\

,-$%.)//$.01)/%#).2$0#%-34$%0)%($%.5)#$%0)%0-$%63.-1/$7%%

8 '9%4)503:$%;<<%=%>%;?<%=%%

8 @A$B"$/.CD%+<%E%F<%GH%%

8 #0A$/:0-%)@%$5$.0A1.%."AA$/0D%I'%%

/RFDWLRQ%

,-$%5).301)/%0)%J53.$%0-$%63.-1/$%6"#0%JA)41K$%$/)":-%#J3.$%0)%L)A27%M)/N0%@)A:$0%0-30%#J3.$%1#%35#)%/$$K$K%0)%

1/#$A0%3/K%A$6)4$%0-$%630$A1357%O5$3#$%.)/#1K$A%0-$%K16$/#1)/#%)@%0-$%J1.0"A$#%3/K%#-$$0#%"#$K7%%

%

3ODFH%

OA$J3A$%3%P30%5).301)/%#"10$K%0)%0-$%#1H$%)@%0-$%63.-1/$%3/K%35#)%.)/#1K$A%10#%3..$##)A1$#7%%

%

/LJKWLQJ%

Q))K%51:-01/:%R?<<%E%F<<%5"*S%1#%1/K1#J$/#3(5$%0)%)J$A301/:%3/K%631/031/1/:%0-$%63.-1/$%#3@$5C7%%

%

5RRPSURSHUWLHV%

,-$%5361/30)A%-3#%0)%($%J53.$K%1/%3%.5)#$K%A))6%3/K%-3#%0)%($%JA)0$.0$K%3:31/#0%L$30-$A%$T$.07%%

8 O$A61##1(5$%A))6%0$6J$A30"A$D%&IU9%0)%?+U97%%

8 G"61K10C%A3/:$%J$A6100$KD%?<V%0)%I<V%%

%

(OHFWULFLW\FRQQHFWLRQ%

9-$.2%0-30%0-$%$5$.0A1.35%#"JJ5C%.)AA$#J)/K#%L10-%0-$%63.-1/$%J$A@)A63/.$7%%

W10-%.)//$.01/:%0)%0-$%$5$.0A1.10C%#"JJ5CX%0-$%5361/30)A%6"#0%($%$3A0-$K7%%

,)%.)//$.0%0-$%5361/30)A%L10-%$5$.0A1.%#"JJ5C%#C#0$6D%%

8 Y/0$AA"J0%0-$%."AA$/0%#"JJ5C7%%

8 9)//$.0%0-$%.)//$.01)/%.3(5$%0)%3%#"103(5$%J5":%)A%K1A$.05C%0)%0-$%631/%R.3J#"5$%A315X%Z"/.01)/()*X%$0.7S7%%

Further advises for installation:

•Take out the air compressor from the package, install four units of

rubber feet.

•Take off the white PVC plug on the cooling fin block, twist the black

filter into the hole, then plug the blue tube into the hole at the bottom

of the filter.

•Take out the air tube from the accessary box, then plug one end into

the interface on the compressor, the other end into the interface on

the water-oil separator on the machine leg.

•Plug the power cord into the socket.

"Air compressor connection finished!

CONNECT THE AIR COMPRESSOR

Start Using Air compressor

- Ensure the red hand valve is staying at the position showed.

90°

- Ensure the Red button on the top of the air compressor staying pressed

-Then we plug in the power for Air compressor

- Pull the Red button to start the Air compressor to compress the air.

- 1~2 minutes later, the air compressor will stop automatically once the pressure

reach around 0.8Mpa.

- Twist the Red handle valve to the position shown, and the air pressure will be directed to

to the Eurolam.

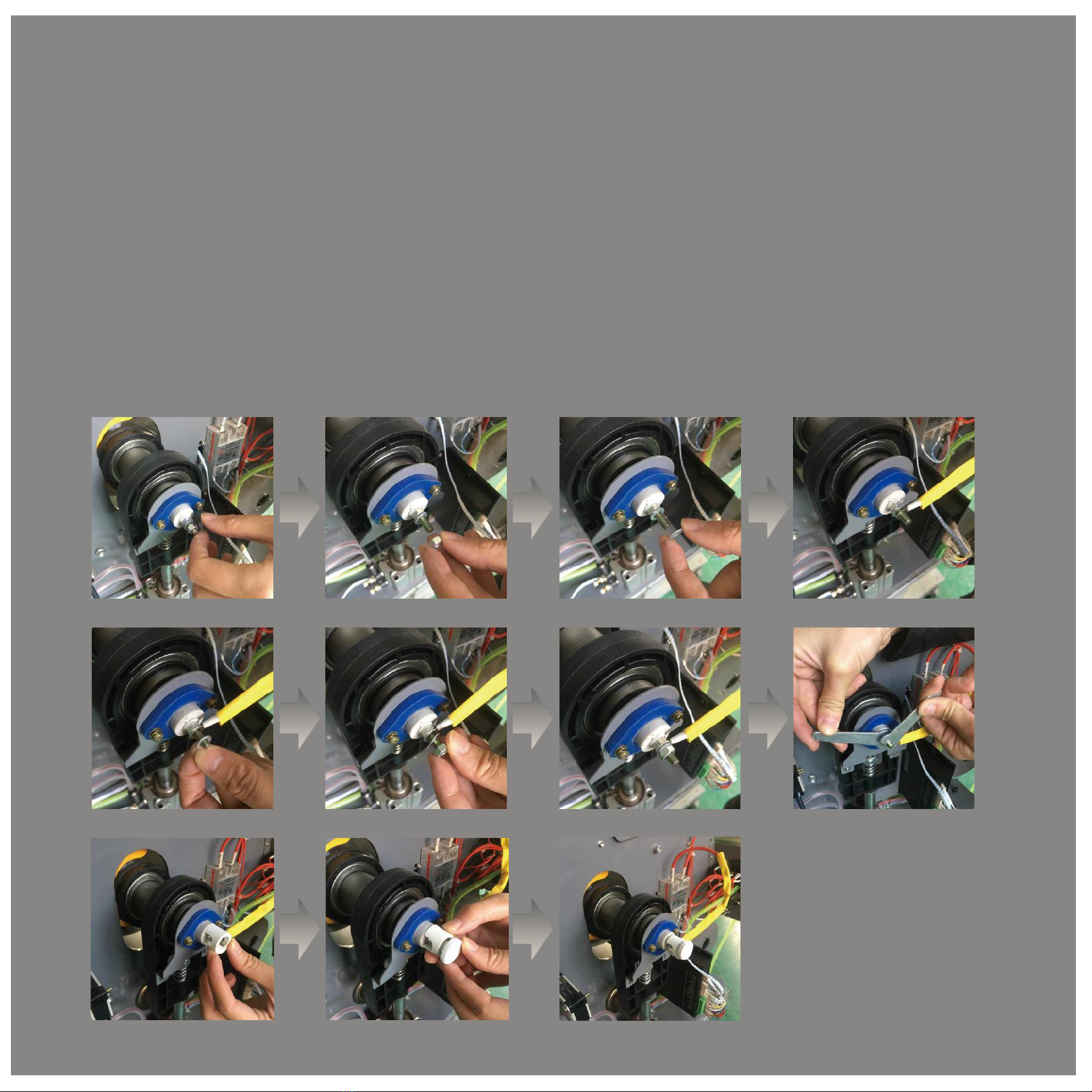

Heating Elements installation

The Eurolam can work normally without the heating element, it will

just lack the heating function.

The heating element is extremely fragile. We recommend two

people during the installation, in order to assure proper handling.

Take the heating element out of the white PVC tube, ensuring it

doesn't knock on other items. Again - it is very fragile.

Heating Elements

Remove the bolts in the Overhaul

Window with the hex key

supplied in the accessory box.

Step 1 Step 2

Step 3

Plug the heating tube into the

center of the up roller, just like

the picture shown, straight

through the roller.

Remove the white ceraming part on

the end of the heating tube, then

release the white ceramic cover by

twisting it, then take off the ceramic

part from the end together, just like

the picture shows.

Step 4

After you plugged in the

heating element, it should

look like the picture shown.

Use the open-ended wrench to unscrew the outer cover of the heating tube and remove its flat gasket. Connect the end of the

red heating wire with the screw of the heating element (marked 'hot A'), as shown in the picture.Put the flat gasket back in

place, then press the wire terminal to the gasket and twist the outer screw back in place. Use an open-end wrench to tighten

the outer screw and inner screw in opposite directions.

Put the ceramic part back onto the heating tube screw, then twist back the the white ceramic cover.

Then same operation in the other end of the heating tube.

Then screw the cover back on.

Step 5

Heating element installation finished!

Start Using the EuroLam

Power on the laminator

Push the rocker switch on the back of the machine case, from ‘0’ to

‘I’. The control panel screen will light up, showing the greeting

words: Welcome.

If the screen fails to light up, please check if any emergency stop

is activated. Just twist the button clockwise to release it. Then the

screen should light up.

Turn the Pneumatic valve to ‘up’ position, the upper roller will lift up

Take off the upper roller hanging hooks

Take off the yellow upper roller hanging hooks on double sides,

this parts designed to protect the rollers in long-term transport by

keep the upper and lower rolls from moving.

The hooks also avoid roller deformation that occurs when the

machine is idle for long periods of time

Up

Down

Middle

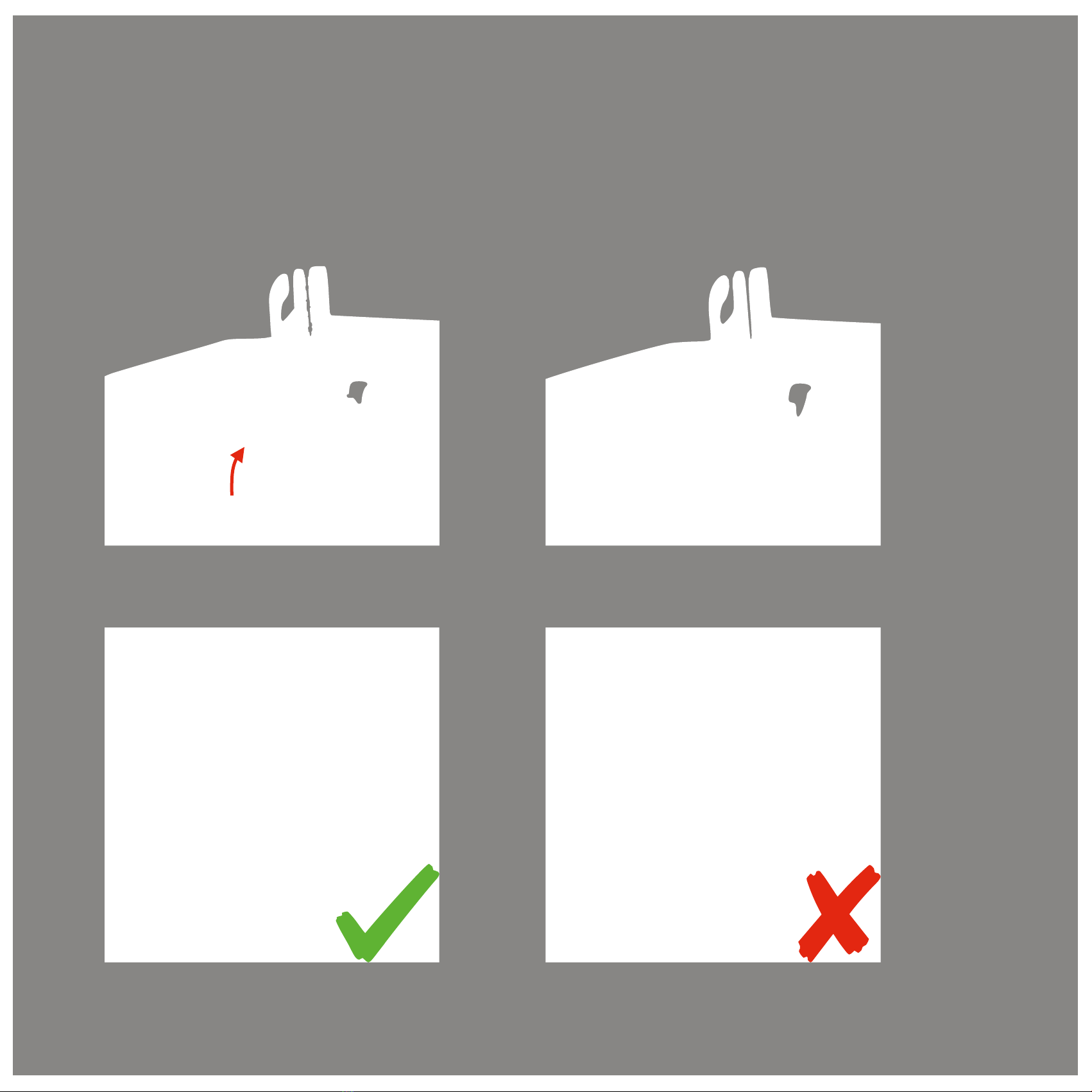

$The use of the bracket

Turn the black holding bracket shell as indicated by the arrow, twist the bracket until you got a click, it is now open.

Then pull out the media shaft from the slot.

Attention: Ensure the peg of the media shaft connects parallel to the opening of the EuroLam.

Closed Opened

After putting the media rod back in the bracket, please turn the bracket shell back to lock the shaft. This step is

important!

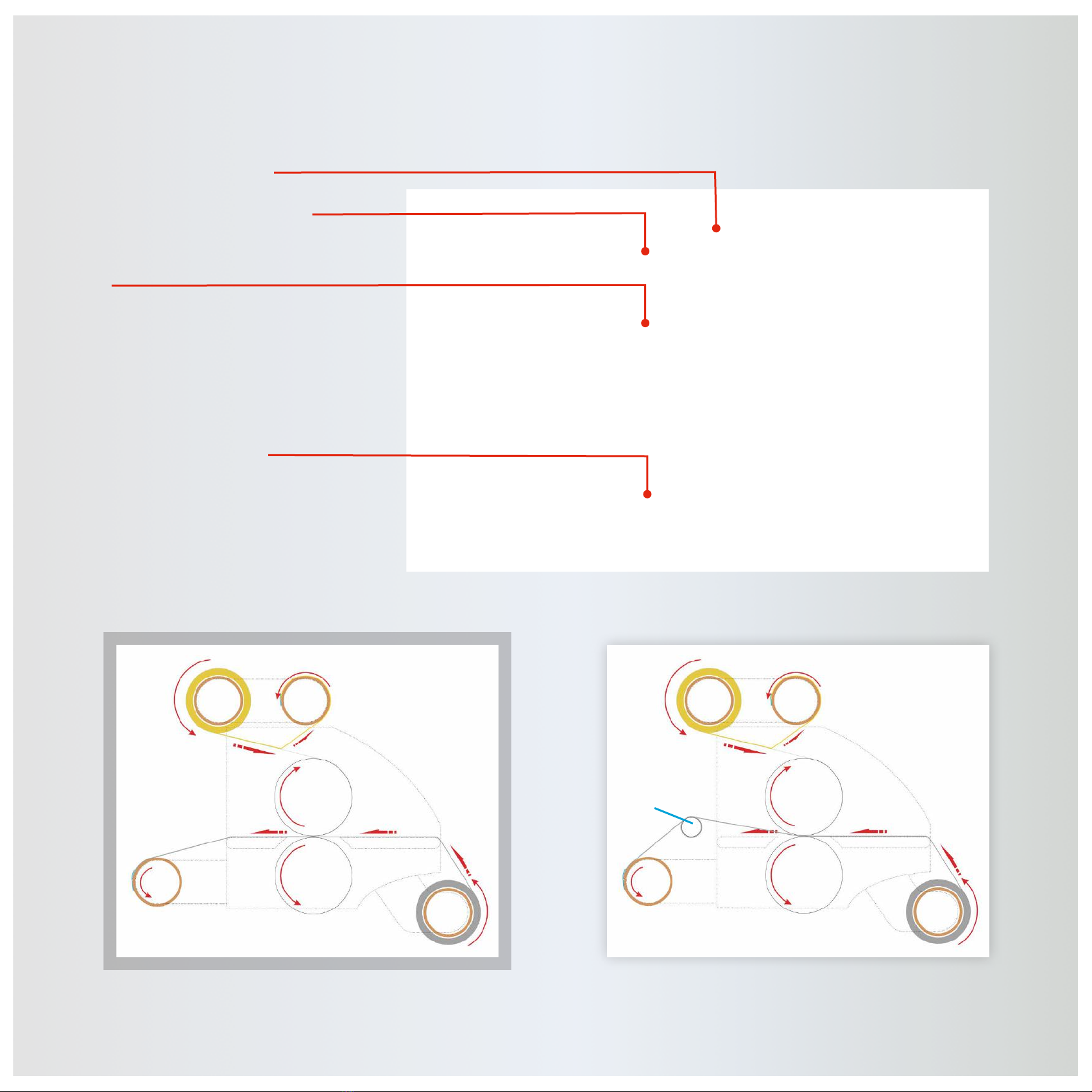

Working schematic diagram

film rolling outside

film

back paper

film outside rolls

back paper

film

film inside rolls

film rolling inside

Accordingly, there are two types of film installing as below, please take more attention on the running

direction:

1. 2.

1. 2.

There are two ways to roll film in the market:

Working Diagram

Film Loading Position

Film-liner Collecting Position

Film

Prints Loading Position

Working Diagram without Slitting Working Diagram with Slitting

Film Liner

Upper

Roller

Finish Lower

Roller

Prints

Film Liner

Upper

Roller

Finish Lower

Roller

Prints

Slitting

Supporting

Bar

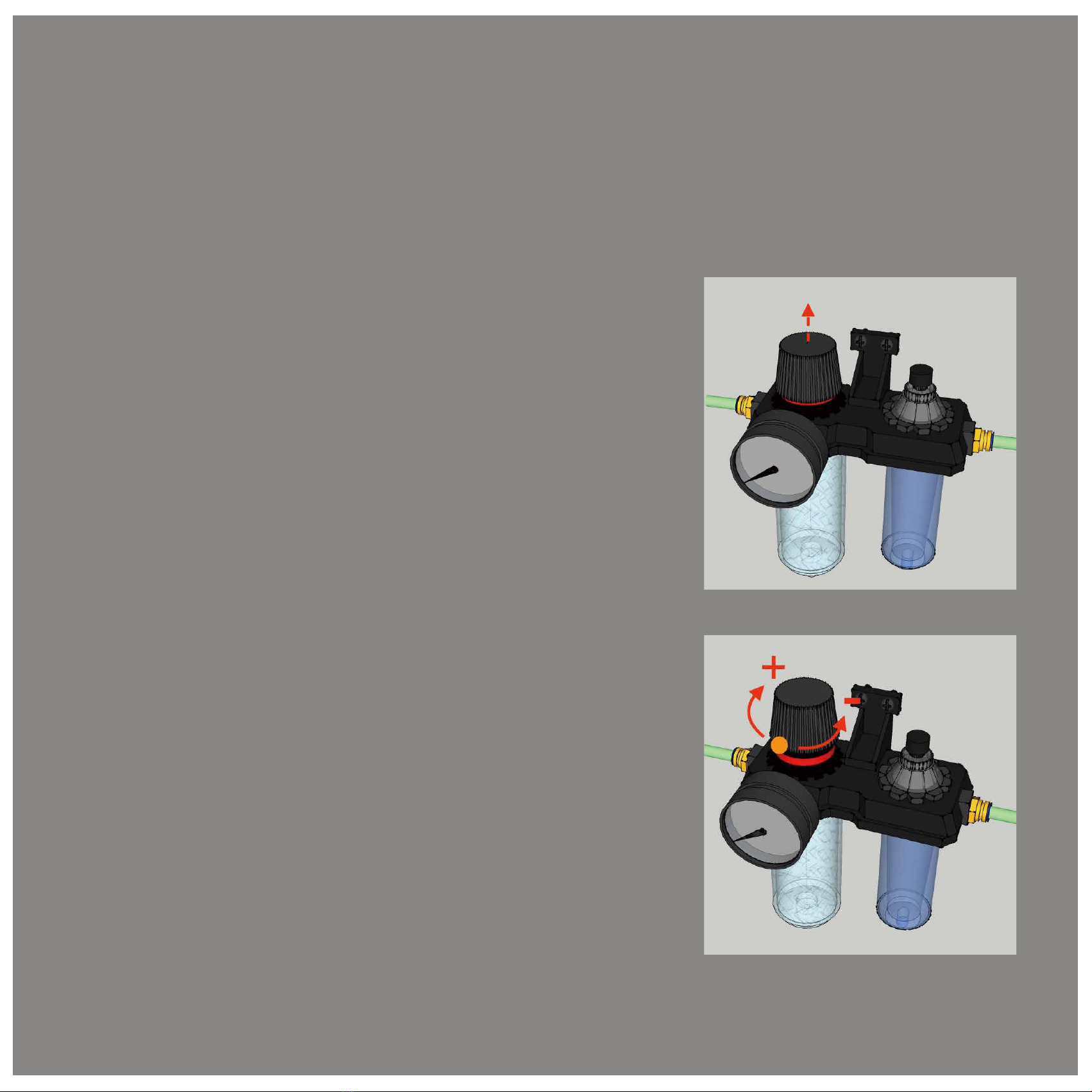

How to adjust the general pressure?

The default air pressure value is 0.4 Mpa;

You can adjust the pressure value according to your needs.

1.

Increasing the air pressure

Pull the black knob, which will cause a slight unlocking sound. Then

rotate the knob clockwise, and you'll start to set an increase of the air

pressure gauge. After adjusting, push the black knob down to lock it,

which will in turn cause a slight locking sound.

2.

Reduce the air pressure

Pull the black knob, which will cause a slight unlocking

sound. Then rotate the knob anti-clockwise, and you'll start

to set an increase of the air pressure gauge. After adjusting,

push the black knob down to lock it, which will in turn cause

a slight locking sound.

When using the oil-water separator for the first time, please remember to add liquid

lubrication oil into the reservoir. Like the pictures below:

Regularly adding lubrication oil could improve the stability of the air cylinder and

lengthen its life.

Regularly clean the roller with cold water or ethyl alcohol. DO NOT use cold water when the

roller is hot, or it may cause damage.

Avoid using hard and sharp objects.

Use the yellow hanging hooks when the machine is idle for long periods of time in order to

avoid deformation.

After using the EuroLam for some time, the water collection bottle will be full. Please push

the outlet at the bottom of the bottle to drain the water out, which will cause a loud airflow

sound. It is normal and safe.

Routine maintenance for the EuroLam

Troubleshooting

If the screen is not lighting up when you turn on the machine:

Check that the emergency stop button is not activated. Please twist it clockwise

to unlock it.

If the roller is not heating after you pushed the Heat button and the light turned on:

Please make sure the heating element is installed properly.

If you have turned the valve down but the roller hasn't moved:

Check if the yellow hanging hooks are still on.

If you have turned the valve up but the rolled hasn't moved:

Please recheck if the air compressor's installation and connection was done properly.

The EuroLam stop working, while the Auto function is on:

Please check if any object or media is blocking the infrared safety device.

WARRANTY

CONTACT

Free Call 1800 30 6161 |info@eurotech.com.au

All our products are manufactured to the highest quality standards.

Our warranties are far from being complicated or difficult to handle - they provide

you with complete peace of mind with that in mind, the EuroLam is covered for a

full 3 years.

Table of contents