Geelseweg,

80

|

2250

|

Olen

|

BELGIUM

|

T

el.

+32

(0)

14

25

92

83

|

henr

y

[email protected] |

www

.dumor

.be

3

Temp setting button Up/ Down

(d)

Hot / Cold selector

LED temp display

(e) with last setting memory note that the sensor is very sensitive and will display any small change

in the roll temp.

The roll temp will tend to reduce when laminating due to the heat being transferred to the substrate.

In this case its important to have the film and substrate at least 24°C or too much heat will be sucked away from the

roll and the adhesion and lamination performance will diminish.

Speed selector from 1 to 9 (9 = approx 3m/min)

(f)

Note lamination is a very precise job

- It is easy to get a poor result due to :

- Wrong film used

- Wrong temp=> no adherence or if too high burning the print

- Wrong speed => poor adherence

- Wrong substrate (too much silicone or coating)

- Wrong pressure (larger bubbles)

- Dusty substrate (film will have micro bubbles)

- Powder on substrate (film will not adhere)

- Dust in the air (will make bubbles under the film)

- The room should be almost a “clean room environment“ for a good result

- Don’t blame the machine for the above mistakes !!!

Cold lamination all models

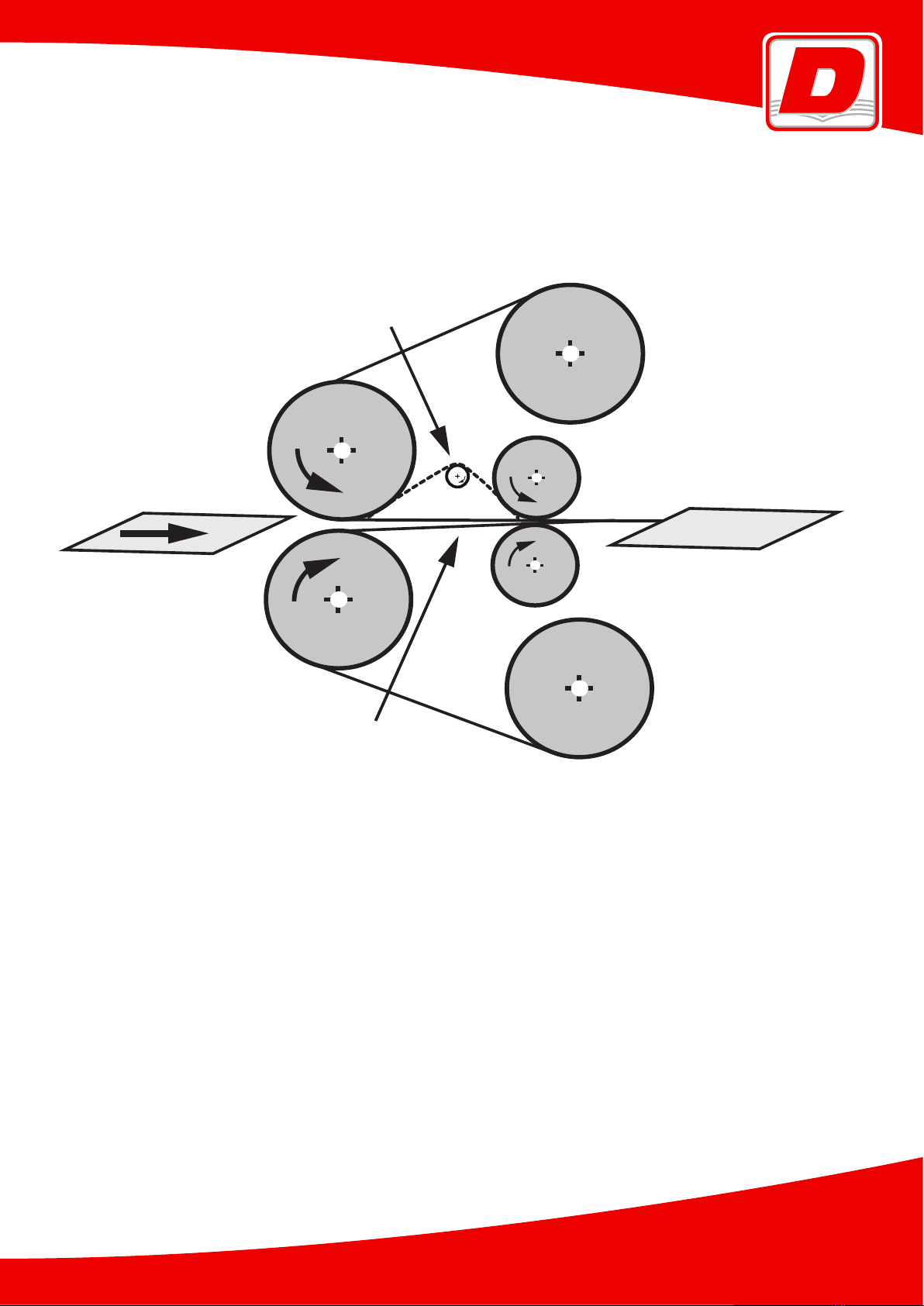

The film is threaded through the rollers avoiding the de curlers (straight through) ( see the machine diagram) making

sure that the sticky side of the film is always kept away from the roll surface!

The two films must be in line with each other (not offset)

Keep at least 1 meter of free space at the exit of the machine to allow the film to run out !

The film is already tacky at room temp

Lower the upper roll to meet the lower roll and start the machine up (forward button).

For cold lamination a higher pressure setting on the lever will be needed to chase out bubbles.

- Run some film through the machine until the tension is steady (seen by having a wrinkle free web).

In the case of using a paper backing use the rewinder on the 110 model to take up the paper.

If the wrinkles do not disappear fast you have not well aligned the track of the film or there is not enough brake

tension.

Once the film is running well and wrinkle free, align and slide in the substrate to be covered.

For encapsulation leave about 1 cm between the sheets.

Once finished raise the rolls.

Never store the unit under roller pressure or you will get flat spots on the rolls !