&RQWHQWV

&RQWHQWV##############################################################################################################3DJH

&RQW18

&KDSWHU#4 *(77,1*#67$57('

,QWURGXFWLRQ 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 404

2SWLRQDO#(TXLSPHQW 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111404

(TXLSPHQW#,QVSHFWLRQ11111111111111111111111111111111111111111111111111111111111111111111111111111111111 404

$ERXW#WKLV#0DQXDO 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 405

,QLWLDO#6WHSV1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111405

+RZ#WKH#0DQXDO#LV#2UJDQLVHG 11111111111111111111111111111111111111111111111111111111111111111111111111111111111405

&KDSWHU#5 $1#29(59,(:#2)#7+(#&219(57(5

&RPSRQHQW#,GHQWLILFDWLRQ11111111111111111111111111111111111111111111111111111111111111111111111111111 504

8QGHUVWDQGLQJ#WKH#3URGXFW#&RGH11111111111111111111111111111111111111111111111111111111111111111 505

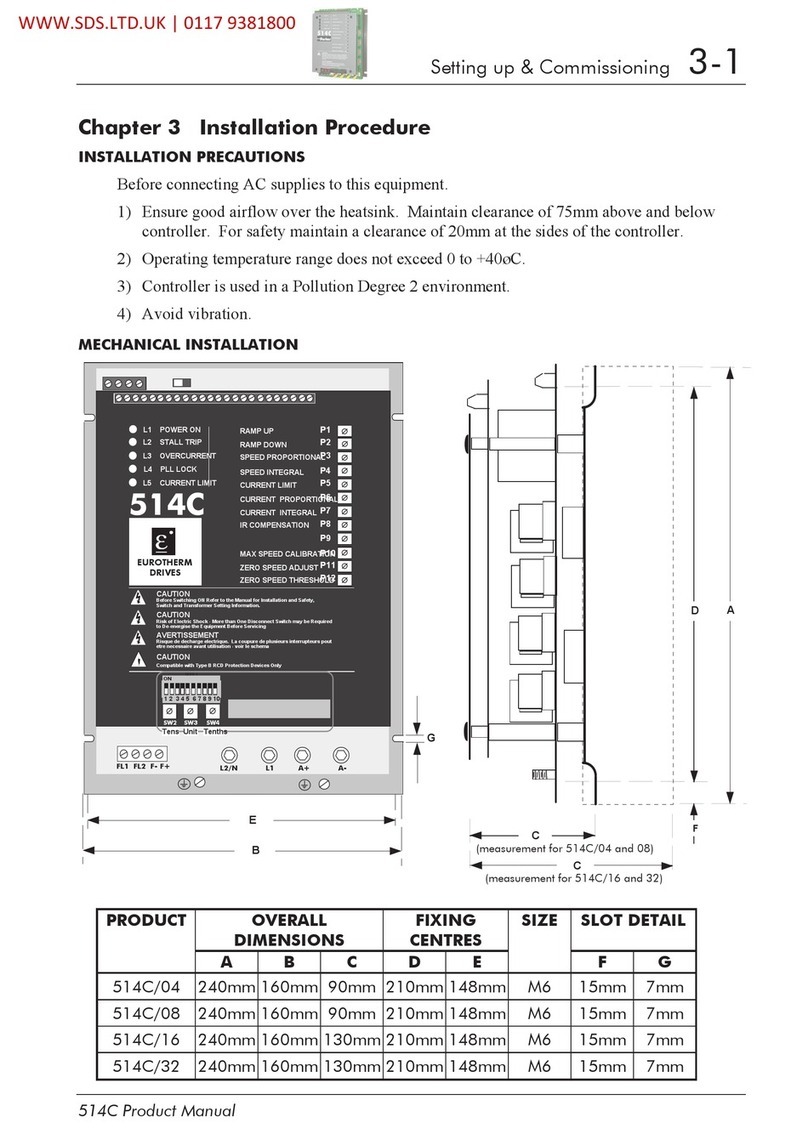

&KDSWHU#6 ,167$//,1*#7+(#&219(57(5

0HFKDQLFDO#,QVWDOODWLRQ 11111111111111111111111111111111111111111111111111111111111111111111111111111111 604

0RXQWLQJ#WKH#&RQYHUWHU 111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111605

• )LOWHU#,QVWDOODWLRQ 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111605

(OHFWULFDO#,QVWDOODWLRQ111111111111111111111111111111111111111111111111111111111111111111111111111111111111 607

5HFRPPHQGDWLRQV 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111607

&KDSWHU#7 23(5$7,1*#7+(#&219(57(5

3UH0,QVWDOODWLRQ#3ODQQLQJ11111111111111111111111111111111111111111111111111111111111111111111111111111 704

%DVLF#:LULQJ#'LDJUDPV 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111704

• %DVLF#&RQQHFWLRQ 111111111111111111111111111111111111111111111111111111111111111111111111111111111111704

6HWWLQJ08S#)#&RPPLVVLRQLQJ 11111111111111111111111111111111111111111111111111111111111111111111111 705

2SWLRQ#6ZLWFKHV111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111705

• 6SHHG#)HHGEDFN#6FDOLQJ 1111111111111111111111111111111111111111111111111111111111111111111111111705

• 6SHHG#)HHGEDFN#6RXUFH 11111111111111111111111111111111111111111111111111111111111111111111111111705

• =HUR#2XWSXW#6RXUVH 11111111111111111111111111111111111111111111111111111111111111111111111111111111705

• &XUUHQW#6FDOLQJ111111111111111111111111111111111111111111111111111111111111111111111111111111111111111705

• &XUUHQW#0RWRU#6FDOLQJ11111111111111111111111111111111111111111111111111111111111111111111111111111706

3RWHQWLRPHWHUV11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111706

%DVLF#6HWWLQJ08S#3URFHGXUH11111111111111111111111111111111111111111111111111111111111111111111111111 707

• &RQWUROOHU11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111707

• 0RWRU 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111707

3UHSDUDWLRQ 111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111707

• 0DFKLQH 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111707

• &RQWUROOHU11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111707

• 3RZHU08S 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111708