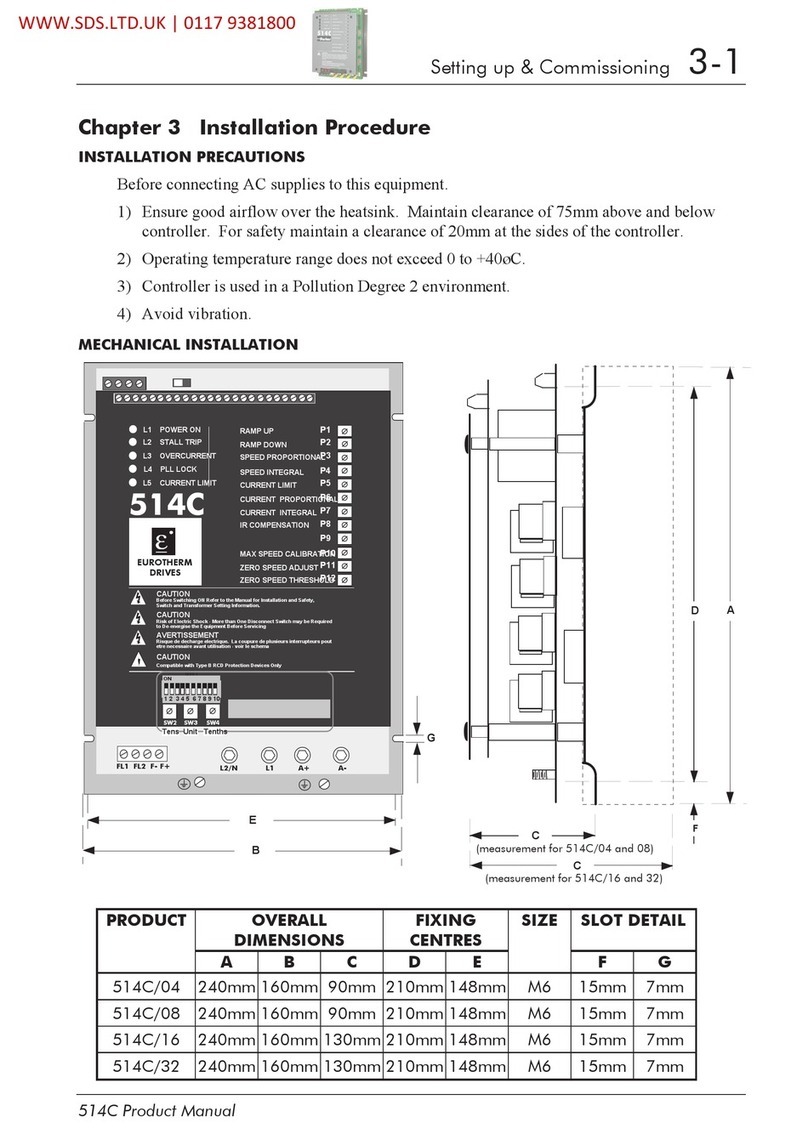

INSTALLATION: Ensure that mechanically secure fixings are used as recommended.

Ensure that cooling and air flow around the product are as recommended.

Ensure that cables and wire terminations are as recommended and clamped to required torque.

Ensure that the installation and commissioning of this product are carried out by a competent person.

Ensure that the product rating is not exceeded.

CAUTION: When power is removed from the product it must not be re-applied for a period of 30 seconds

to allow the inrush limit circuit to operate correctly.

APPLICATION RISK: The integration of this product into other apparatus or system is not the

responsibility of Eurotherm Drives Ltd as to its applicability, effectiveness or safety of operation or of other

apparatus or systems.

Where appropriate the user should consider some aspects of the following risk assessment.

RISK ASSESSMENT: Under fault conditions or conditions not intended.

1. The motor speed may be incorrect.

2. The motor speed may be excessive.

3. The direction of rotation may be incorrect.

4. The motor may be energised (unless the installation specifically prevents unexpected or unsequenced

energisation of the motor).

In all situations the user should provide sufficient guarding to prevent risk of injury and/or additional

redundant monitoring and safety systems.

NOTE: During power loss the product will not operate as specified.

MAINTENANCE: Maintenance and repair should only be performed by competent persons using only the

recommended spares (or return to factory for repair). Use of unapproved parts may create a hazard and risk of

injury.

WHEN REPLACING A PRODUCT IT IS ESSENTIAL THAT ALL USER DEFINED

PARAMETERS THAT DEFINE THE PRODUCT'S OPERATION ARE CORRECTLY

INSTALLED BEFORE RETURNING TO USE. FAILURE TO DO SO MAY CREATE A HAZARD

AND RISK OF INJURY.

PACKAGING: The packaging is combustible and if disposed of in this manner incorrectly may lead to the

generation of toxic fumes which are lethal.

WEIGHT: Consideration should be given to the weight of the product when handling.

REPAIRS: Repair reports can only be given if sufficient and accurate defect reporting is made by the user.

Remember, the product without the required precautions can represent an electrical hazard and risk of injury, and

that rotating machinery is a mechanical hazard and risk of injury.

PROTECTIVE INSULATION:

1. All exposed metal insulation is protected by basic insulation and bonding to earth i.e. Class 1.

2. NOTE: Earth bonding is the responsibility of the installer.

3. All signal terminals are SELV, i.e., protected by double insulation (Class 2). The purpose of this protection is to

allow safe connection to other low voltage equipment and is not designed to allow these terminals to be

connected to any unisolated potential. Ensure all wiring rated for highest system voltage.

NOTE: Thermal sensors contained within the motor are to be double insulated.

WALL MOUNTING: - To maintain compliance with the European Low Voltage Directive standards VDE 0160

(1994)/EN50178(1998) only units supplied and fitted with the UL Type 1 top cover are to be mounted on the

wall.

RCDs - Compatible with Type B RCDs only.