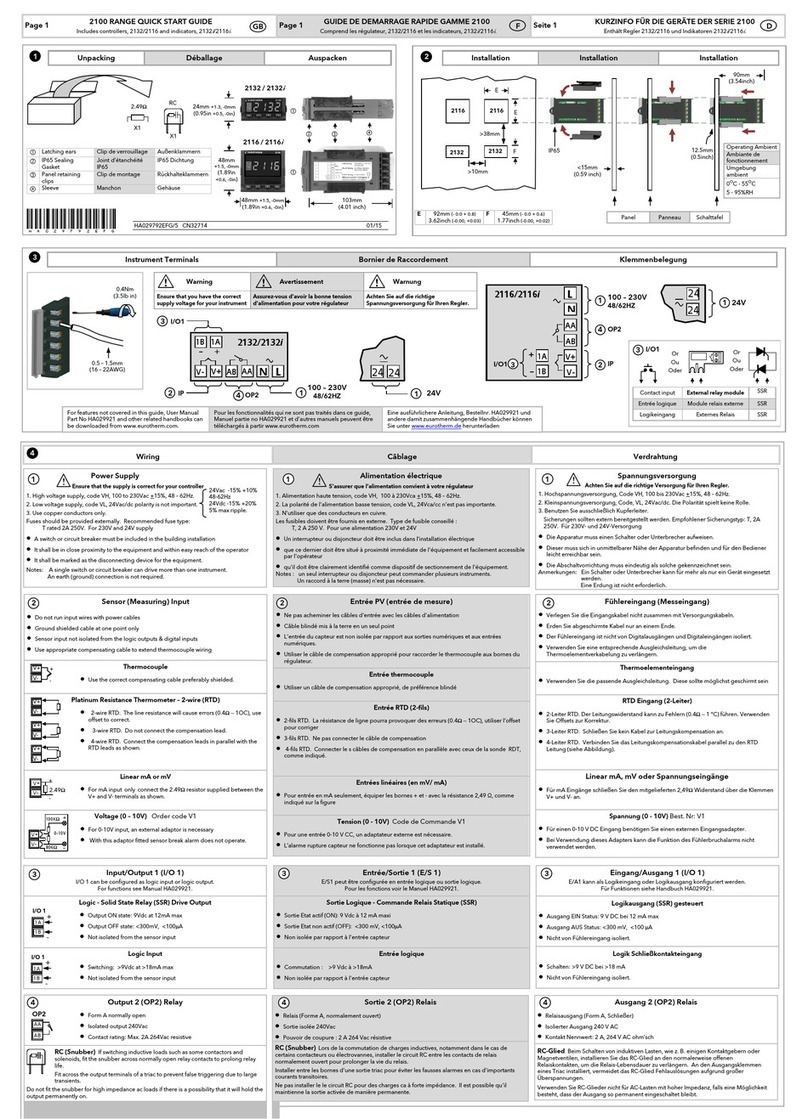

Switch On

If the Controller is new and has not previously

been configured it will start up showing the ‘Quick

Start’ codes. This is a built in tool which enables

you to configure the input type and range, the

output functions and alarms.

!Incorrect configuration can result in

damage to the process and/or personal injury

and must be carried out by a competent person

authorised to do so. It is the responsibility of

the person commissioning the instrument to

ensure the configuration is correct.

To Configure Parameters in Quick

Start Mode

With ‘QckStart’ selected, press to scroll

through a list of parameters.

Edit the parameters using Vor .

When the required choice is selected a brief blink

of the display indicates that it has been accepted .

The first parameter is ‘Units’.

This parameter is associated

with Loop 1 ‘LP1’ and resides

in the ‘PV Input’ list as shown.

Continue setting up the paras presented until the

‘Finished’ view is displayed.

If all parameters are set up as required press V

or to select ‘Yes’.

The loop(s) are set to Auto on exit from Quick

Start and the controller re-starts in operator level

2.

The ‘HOME’ display is shown - see ‘Normal

Operation’.

☺If you wish to edit parameters again do not

select ‘Yes’ but continue to press .

All available parameters are shown in the following

tables.

Quick Start Parameters - Fixed Build Parameters shown in bold are defaults.

Group Parameter Value Availability

LP1

PV Input

Units

Engineering units for the PV. (C, F, K

options change the displayed units)

C, F, K

V. mV, A, mA, pH, mmHg, psi, Bar, mBar, %RH, %, mmWG, inWG, inWW, Ohms,

PSIG, %O2, PPM, %CO2, %CP, %/sec, Vacuum, sec, min, hrs, None

Always

LP1

PV Input

Resolution

Decimal point position for the PV

XXXXX, XXXX.X, XXX.XX, XX.XXX, X.XXXX Always

LP1

PV Input

Range Type

To select the linearisation algorithm

required and the input sensor.

Thermocouple: J, K, L, R, B, N, T, S, PL2, C, CustC1(2&3)

RTD: Pt100

Linear: 0-50mV, 0-5V, 1-5V, 0-10V, 2-10V, 0-20mA, 4-20mA

Always

LP1

PV Input

IO Type

Only shown if custom curve is selected

Thermocpl, RTD, Pyrometer, mV40, mV80, mA, Volts, HIZVolts, Log10

LP1

PV Input

Range High/Low

Max /min. display range and SP limits

Depends on Range type selected. Default 1372/-200 Always

LP1

Loop

Loop 1 Channel 1, control type (normally

Heat)

PID, VPU, VPB, Off,

OnOff

Always

LP1

Loop

Loop 2 Channel 2, control type (normally

Cool)

PID, VPU, VPB, Off,

OnOff

VPU = Boundless valve position control. This does not

need a feedback potentiometer

VPB = Bounded valve position control. Requires a

feedback potentiometer

Always

LP2

PV Input

Source

Defines where the PV input is wired to

None, FixedPV, Module6 (Module6 is available only if an analogue input module

is fitted).

If a dual loop

controller

The LP1 parameters listed above are repeated for LP2 if the LP2 PV Input is configured.

Logic function (input or output)

To configure the function of Logic IO which

can be an output or an input.

Not Used, Lp1 Ch1, Lp1 Ch2, Lp2 Ch1, Lp2 Ch2,

Alarm1 to 8, AnyAlarm, NewAlarm, ProgEvnt1 to 8,

LP1SBrkOP, LP2SBrkOP*, LPsSBrk*, (outputs)

LP1 A-M, LP1 SPsel, LP2 A-M, LP2 SPsel, AlarmAck,

ProgRun, ProgReset, ProgHold (Inputs)

[Note 1] [Note 2]

* LP2 and LPs (both loops) only shown if

the second loop is configured.

Programmer options only available if the

controller is a programmer/controller.

Init

LgcIO LA

Min OnTime (if configured as a control OP) Auto, or 0.01 to 150.00 [Note 2] [Note 3]

The above two parameters are repeated for the LB Logic I/O (LgcIO LB)

Init

RlyOP AA

AA Relay output

function

This relay is always fitted.

Not Used, Lp1 Ch1, Lp1 Ch2, Lp2 Ch1, Lp2 Ch2, Alarm 1 to 8, Any

Alarm, New Alarm, ProgEvnt1 to 8, LP1SBrkOP, LP2SBrkOP*, LPsSBrk*.

Always if the instrument Is ordered as a

programmer/controller. [Note 4]

Init

RlyOP AA

AA Relay Min OnTime Auto, or 0.01 to 150.00 [Note 2] [Note 3]

Note 1) Parameters only appear if the function has been turned on, eg If ‘Control Channel 1’ = ‘Off’, ‘Chan 1’ does not appear in this list. When a control

channel is configured for valve positioning, LgcIO LA and LgcIO LB act as a complementary pair. If, for example, Chan 1 is connected to LgcIO LA

(valve raise) then LgcIO LB is automatically set to Chan 1 (valve lower). This ensures the valve is never raised and lowered simultaneously.

The same complementary behaviour also applies to dual output modules and channels A and C of triple output modules

Note 2) If any input function, for example Chan 1, is connected to another input it will not appear in this list

Note 3) Is available if the Control Channel is not On/Off and is allocated to the LA, LB or AA output as applicable

Note 4) For valve position control Chan 1 or Chan 2 will not appear in this list. Valve position outputs can only be dual outputs such as LA and LB or dual

relay/triac output modules

To Re-enter Quick Start Mode

If you have exited from Quick Start mode (by selecting ‘Yes’ to the ‘Finished’ parameter) and you need to make further changes, the Quick start mode can be entered again at any time.

1. Hold down then power up the controller. Keep this button pressed until the ‘Startup’ - ‘Goto QckStart’ screen is displayed.

2. Press to enter the quick start list. You will then be asked to enter a passcode.

3. Use Vor Wto enter the passcode – default 4. If an incorrect code is entered the display reverts to the ‘Quick Start’ view.

It is then possible to repeat the quick configuration as described previously.

Note: The Quick Start view contains two additional parameters - ‘Cancel’ and ‘Config’.

Select Cancel to revert to normal operating mode.

Config will allow full configuration mode to be entered (after entering the correct pass code). Configuration is described in the Engineering Manual HA027988.

Quick Start Parameters -Alarms Parameters shown in Bold are defaults.

Group Parameter Value Availability

None No alarm type configured

Abs High/Low Absolute high/low

Init

Alarm 1 to 8

Type

Dev High/ Low/ Band

Deviation high/ low/ band

Always

None Not connected

PV Input Connected to main process variable does not appear if Alarm Type = Deviation

LP1/2 PV Connected to Loop 1/2 process variable

Init

Alarm 1 to 8

Source

Module1 - Module6 Connected to an analogue input module and only of the Alarm Type is not a deviation alarm

Always if Type ≠None

PV Input and ModX Ip do not

appear if Type = Deviation

Init

Alarm 1 to 8

Setpoint To adjust the alarm threshold within the range of the source. Always if Type ≠None

None No latching

Auto Automatic

latching

The alarm continues to be active until both the alarm condition is removed AND the alarm is

acknowledged. The acknowledgement can occur BEFORE the condition causing the alarm is removed.

Manual Manual latching The alarm continues to be active until both the alarm condition is removed AND the alarm is

acknowledged. The acknowledgement can only occur AFTER the condition causing the alarm is removed.

Init

Alarm 1 to 8

Latch

Event Alarm beacon does not light but any output associated with the event will activate and a scrolling message will appear.

Always if Type ≠None

No Continue back around the quick configuration listFinished Exit

Yes Go to normal operation. The loop(s) are set to Auto on exit from quickstart mode and the controller re-starts in Level 2.

Quick Start Parameters - Plug in I/O Modules

The controller automatically displays parameters applicable to the module fitted - if no module is fitted in a slot then it does not appear in the list.

Each module can have up to three inputs or outputs. These are shown as A, B or C after the module number and this corresponds to the terminal numbers on the back of the instrument. If the I/O is single only A

appears. If it is dual A and C appears if it is triple A, B and C appear.

Note: If an incorrect module is fitted the message ‘Bad Ident’ will be displayed.

Module type Parameter Value Availability

Change over relay (R4)

2 pin relay (R2)

Triac output (T2)

Dual Relay (RR)

Dual triac output (TT)

Relay (Triac) function

Not Used

All parameters the same as RlyOP AA, including Min OnTime if the OP is a relay

Always (if the module is fitted)

Single Logic Output (LO)

Triple Logic Output (TP)

Logic Out function Not Used

All parameters the same as RlyOP AA

Always (if the module is fitted)

Not Used Module fitted but not configured

LP1/2 Ch1/2OP Loop 1/2 Channel 1/2 control output

LP1/2 SP Tx Loop 1/2 setpoint retransmission

LP1/2 PV Tx Loop 1/2 PV retransmission

LP1/2 ErrTx Loop 1/2 error retransmission

DC Output function

LP1/2 PwrTx Loop 1/2 output retransmission

Range Type 0–5V, 1-5V, 1–10V, 2–10V, 0-20mA, 4-20mA

DC Output (D4)

DC Retransmission (D6)

Display High/low 100.0/0

Always (if the module is fitted).

Note: If a Dual DC Output module is fitted, it cannot be

configured using the Quick Start Code. To configure this module

refer to the Engineering Manual part no. HA027988.

Not Used Module fitted but not configured

LP1/2 A-M Loop 1/2 Auto/manual

LP1/2 SPsel Loop 1/2 SP select

LP1/2 AltSP Loop 1/2 Alternative SP select

AlarmAck Alarm acknowledge

Triple Logic Input (TL)

Triple Contact Input (TK)

Logic In function

ProgRun/Reset/Hold

Programmer run/reset/hold

A function can only be allocated to one input. eg if AlarmAck is

configured on X*A it is not offered for the other inputs

* is the module number.

LP2 does not appear if loop 2 is not configured.

Not Used Module fitted but not configured

LP1/2 AltSP Loop 1/2 alternative setpoint

LP1/2 OPH/L Loop 1/2 remote OP power max/min

Analogue IP function

LP1/2 V1/2Pos To read valve position from the feedback potentiometer loop 1/2

LP1/2 V1Pos and LP1/2 V2Pos only appear if Loop 1 or 2 and the

control channel 1 or 2 is set to VPB.

Alt/SP does not appear if the programmer option is supplied.

LP2 does not appear if loop 2 is not configured.

Range Type Thermocouple: J, K, L, R, B, N, T, S, PL2, C. RTD: Pt100

Linear: 0-50mV, 0-5V, 1-5V, 0-10V, 2-10V, 0-20mA, 4-20mA Not shown if analogue IP function not used

Analogue Input (AM)

Display High/low 100.0/0.0 These parameters only appear for Linear Range

Not Used Module fitted but not configured

LP1/2 AltSP Loop 1/2 Alternative setpoint

LP1/2 OPH/L Loop 1/2 output power maximum/ minimum

Potentiometer Input (VU) Pot Input function

LP1/2 V1/2Pos To read valve position from the feedback potentiometer loop 1/2

LP1/2 V1Pos and LP1/2 V2Pos only appear if Loop 1 or 2 and the

control channel 1 or 2 is set to VPB.

Alt/SP does not appear if the programmer option is supplied.

LP2 does not appear if loop 2 is not configured.

Transducer Power Supply (G3) TdcrPSU function 5 Volts or 10 Volts Always (if the module is fitted)

Transmitter power supply (MS) No parameters. Used to show the ID of the module if fitted

Normal Operation

Switch on the controller. Following a brief self-test sequence, the controller will start up

in AUTO mode and show the ‘HOME’ display in Operator Level 2 (following Quick Start).

If the controller is configured as a dual loop instrument the start up view shows a

summary of the two loops.

Note: Views shown in this guide are for 3504 and represent typical examples.

Beacons

OP1 Illuminates when output 1 is ON (normally heating)

OP2 Illuminates when output 2 is ON (normally cooling or alarm)

MAN Illuminates when manual mode active. If the HOME display is showing the dual loop overview, MAN

illuminates if Loop 1 is in manual. If the Loop 1 or Loop 2 overviews are being displayed MAN applies to the

loop being displayed.

REM Illuminates when alternative setpoint is active

SPX Illuminates when setpoint 2 is active

ALM If an alarm occurs the red alarm beacon flashes together with a message showing the source of the alarm,

for example ‘AnAlm1 - Abs Hi’ (the latter can also be a customised message). When acknowledged the

alarm message disappears. If the alarm condition is still present the beacon lights continuously. For non-

latched alarms it will extinguish when the alarm is cleared.

RUN Illuminates when the programmer running – flashing indicates End

HLD Illuminates when the programmer is in Hold (frozen)

J Flashes when J Channel digital communications is active

H Flashes when H Channel digital communications is active

IR On when infra red communications is enabled and flashes when infra red communications is active

Operator Buttons

A/MAN

This button

can be

disabled

Toggles the selected loop between Auto and Manual operation.

In Manual the controller output power is adjusted by the user using W

Vbuttons. The input sensor is still connected and reading the PV but

the control loop is open. ‘MAN’ will be indicated.

In Auto the controller automatically adjusts the output to maintain

control, ie the loop is closed.

The controller will power up in the mode it was in when it was powered

down.

PROG To select the programmer summary page

RUN/

HOLD

This button

can be

disabled

Press once to select a program. Press again to run the selected program.

‘RUN’ will be indicated in the top banner of the display.

Press again to hold a program. ‘HLD’ will be indicated

Press and hold for at least two seconds to reset a program.

‘RUN’ will flash at the end of a program

‘HLD’ will flash during holdback

+

‘ACK’. Press these buttons together to acknowledge an alarm.

Press to select new PAGE headings

Press to select a new parameter in the page

W

Press to decrease an analogue value, or to

change the state of a digital value.

V

Press to increase an analogue value, or to

change the state of a digital value

(Any parameter value can

be changed if it is

preceded by v)

Shortcut Key Presses

Backpage Press followed by c. With held down continue to press cor d

to scroll page headers backwards or forwards.

Backscroll When in a list of parameters, press 4followed by c.With 4held down

continue to press cor dto scroll parameters backwards or forwards.

Jump to HOME

display Press + 4

To Set The Required Temperature (Setpoint)

In the view above, press Wor Vto lower or raise the setpoint value of Loop 1.

The new setpoint is accepted when Wor Vis released and is indicated by a brief flash of the setpoint value.

To change Loop 2 setpoint, press . Loop 2 SP value is preceded by v. Press Wor Vas above to

change the value.

A momentary press of either button will show the setpoint in use, e.g. SP1.

Current access level Lev1; Lev2; or Lev3 (3504 only)

Press to scroll through further parameters

including programmer status details

Process Variable (PV) Loo

If the controller is configured as a

dual loop the HOME displays will

vary as shown here:-