Installation and Operation Handbook Contents

2208e and 2204e Controller Handbook Part No. HA026696 Issue 3.0 Nov-03 a-1

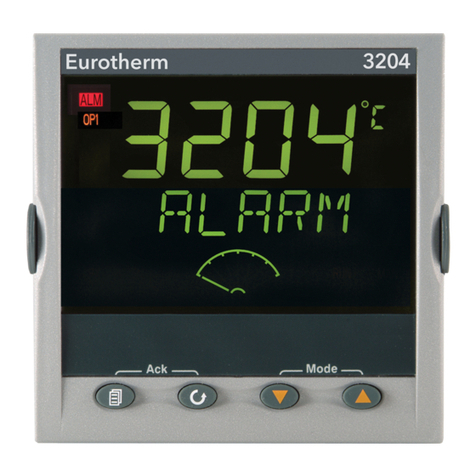

MODELS 2208e and 2204e

TEMPERATURE CONTROLLERS

INSTALLATION AND OPERATION HANDBOOK

1 Chapter 1 OPERATION Page

1.1 FRONT PANEL LAYOUT................................................................1-2

1.2 GETTING STARTED.......................................................................1-4

1.2.1 Viewing The Process Value and Setpoint............................................1-4

1.2.2 To Adjust The Setpoint........................................................................1-4

1.2.3 Viewing The Display Units...................................................................1-5

1.2.4 Use Of The “SCROLL” Button .......................................................1-5

1.2.5 Use Of The ‘PAGE’ Button .............................................................1-6

PARAMETER LISTS.................................................................................1-7

1.4 MANUAL OR AUTOMATIC CONTROL..........................................1-8

1.4.1 Selecting Auto/Manual Operation........................................................1-8

1.4.2 How To Manually Adjust Output Power ...............................................1-9

1.5 SUMMARY.......................................................................................1-9

1.6 Selecting SETPOINT 1 OR SETPOINT 2.....................................1-10

1.7 RAMP DWELL FUNCTION ...........................................................1-11

1.7.1 To Set up a Ramp/Time Program......................................................1-11

1.7.2 To Run the Program..........................................................................1-12

1.7.3 Power Failure During Program Run...................................................1-12

1.8 LOCATION OF PARAMETERS - BLOCK DIAGRAM ..................1-13

1.9 NAVIGATION DIAGRAM (Part A) .................................................1-14

NAViGATION Diagram (Part B)..............................................................1-15

1.10 parameter tables............................................................................1-16

1.10.2 Alarm List.......................................................................................1-17

1.10.3 Autotune List..................................................................................1-17

1.10.4 PID List...........................................................................................1-18

1.10.5 Setpoint List...................................................................................1-19

1.10.6 Input List ........................................................................................1-20

1.10.7 On/Off List......................................................................................1-20

1.10.8 Output List......................................................................................1-21

1.10.9 Communications List......................................................................1-21

1.10.10 Access List.....................................................................................1-21

1.11 ALARMS.....................................................................................1-22

1.11.1 Types of Alarm Used in the 2200...................................................1-22

1.12 ALARM RELAY OUTPUT ..........................................................1-23

1.12.1 SETTING ALARM LEVELS............................................................1-24

1.12.2 ALARM INDICATION AND ACKNOWLEDGEMENT .....................1-25

1.12.3 DIAGNOSTIC ALARMS .................................................................1-26