3200 Series

Part No HA028651 Issue 7.0 Apr-09 3

11.10 Control Parameters........................................................................................................................................55

11.11 Auto-tune Configures R2G .............................................................................................................................57

11.12 Example: To Configure Heating and Cooling .................................................................................................58

11.12.1 Effect of Control Action, Hysteresis and Deadband .............................................................................................................................59

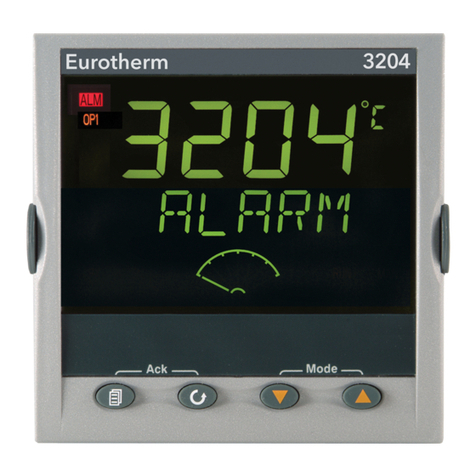

12. Alarms ............................................................................................................................................60

12.1 Types of Alarm...................................................................................................................................................60

12.1.1 Alarm Relay Output .......................................................................................................................................................................................62

12.1.2 Alarm Indication .............................................................................................................................................................................................62

12.1.3 To Acknowledge An Alarm ..........................................................................................................................................................................62

12.2 Behaviour of Alarms After a Power Cycle ...........................................................................................................63

12.2.1 Example 1 .........................................................................................................................................................................................................63

12.2.2 Example 2 .........................................................................................................................................................................................................63

12.2.3 Example 3 .........................................................................................................................................................................................................63

12.3 Alarm Parameters ..............................................................................................................................................64

12.3.1 Example: To Configure Alarm 1 ................................................................................................................................................................65

12.4 Diagnostic Alarms ..............................................................................................................................................66

12.4.1 Out of Range Indication ...............................................................................................................................................................................66

13. Timer/Programmer .........................................................................................................................67

13.1 Timer Parameters...............................................................................................................................................67

13.2 Programmer .......................................................................................................................................................69

13.2.1 Threshold..........................................................................................................................................................................................................69

13.2.2 Run/End Digital Outputs...............................................................................................................................................................................70

13.2.3 Event Outputs..................................................................................................................................................................................................70

13.2.4 To Configure the Programmer....................................................................................................................................................................71

13.3 Example: To Configure a Dwell Timer as a Simple Two Step Programmer...........................................................72

14. Recipe.............................................................................................................................................75

14.1 To Save Values in a Recipe .................................................................................................................................75

14.2 To Save Values in a Second Recipe.....................................................................................................................75

14.3 To Select a Recipe to Run...................................................................................................................................76

14.3.1 List of Default Recipe Parameters:.............................................................................................................................................................76

15. Digital Communications..................................................................................................................77

15.1 Digital Communications Wiring ..........................................................................................................................77

15.1.1 EIA232................................................................................................................................................................................................................77

15.1.2 EIA485 (2-wire)................................................................................................................................................................................................77

15.1.3 Wiring EIA422 or 4-wire EIA485 .................................................................................................................................................................77

15.2 Digital Communications Parameters...................................................................................................................78

15.2.1 Broadcast Communications .........................................................................................................................................................................79

15.2.2 Broadcast Master Communications...........................................................................................................................................................79

15.2.3 Wiring Connections........................................................................................................................................................................................79

15.3 Example: To Set Up Instrument Address.............................................................................................................80

15.4 DATA ENCODING ...............................................................................................................................................80

15.5 Parameter Modbus Addresses.............................................................................................................................81

16. Calibration...................................................................................................................................... 91

16.1 To Check Input Calibration.................................................................................................................................91

16.1.1 Precautions.......................................................................................................................................................................................................91

16.1.2 To Check mV Input Calibration..................................................................................................................................................................91

16.1.3 To Check Thermocouple Input Calibration.............................................................................................................................................91

16.1.4 To Check RTD Input Calibration.................................................................................................................................................................92

16.2 Offsets ...............................................................................................................................................................92

16.2.1 Two Point Offset.............................................................................................................................................................................................92

16.2.2 To Apply a Two Point Offset .......................................................................................................................................................................93

16.2.3 To Remove the Two Point Offset...............................................................................................................................................................93

16.3 Input Calibration................................................................................................................................................94

16.3.1 To Calibrate mV Input...................................................................................................................................................................................94

16.3.2 To Calibrate Thermocouple Input .............................................................................................................................................................95

16.3.3 To Calibrate RTD Input .................................................................................................................................................................................96

16.3.4 To Calibrate mA Outputs .............................................................................................................................................................................97

16.3.5 To Calibrate Remote Setpoint Input .........................................................................................................................................................98

16.3.6 CT Calibration..................................................................................................................................................................................................99

16.3.7 To Return to Factory Calibration ...............................................................................................................................................................99

16.4 Calibration Parameters.......................................................................................................................................100

17. Configuration Using iTools.............................................................................................................. 101

17.1 Loading an IDM..................................................................................................................................................101