Eurotruss FL-080 User manual

EUROTRUSS

LIFTERS

FL-080

Front load lifter

Front Loader Series

300 kg / 8,0 m

English - User manual

Deutsch - Bedienungsanleitung

Español - Manual de Usuario

EUROTRUSS

LIFTERS

www.eurotruss.com

2

2

FL-080

300 kg (661.4 lb)

8.00 m (26.24’)

FL-080

Castorweg 2

8938 BE Leeuwarden

The Netherlands

+31 (0) 58 215 88 88

+31 (0) 58 215 81 11

3

EUROTRUSS

LIFTERS

www.eurotruss.com

2

FL-080

300 kg (661.4 lb)

8.00 m (26.24’)

FL-080

Castorweg 2

8938 BE Leeuwarden

The Netherlands

+31 (0) 58 215 88 88

+31 (0) 58 215 81 11

3

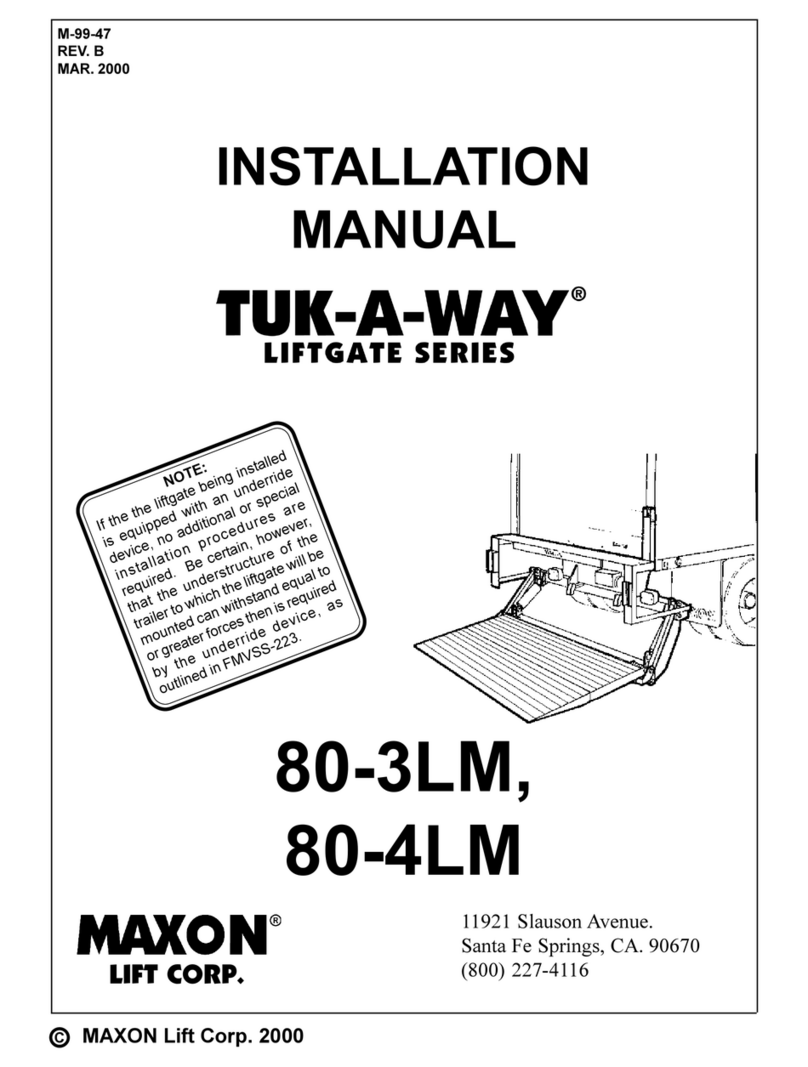

FL-080

FL-080

C

D

EK1366

EK1367

EK1368

EK1369

EK1370

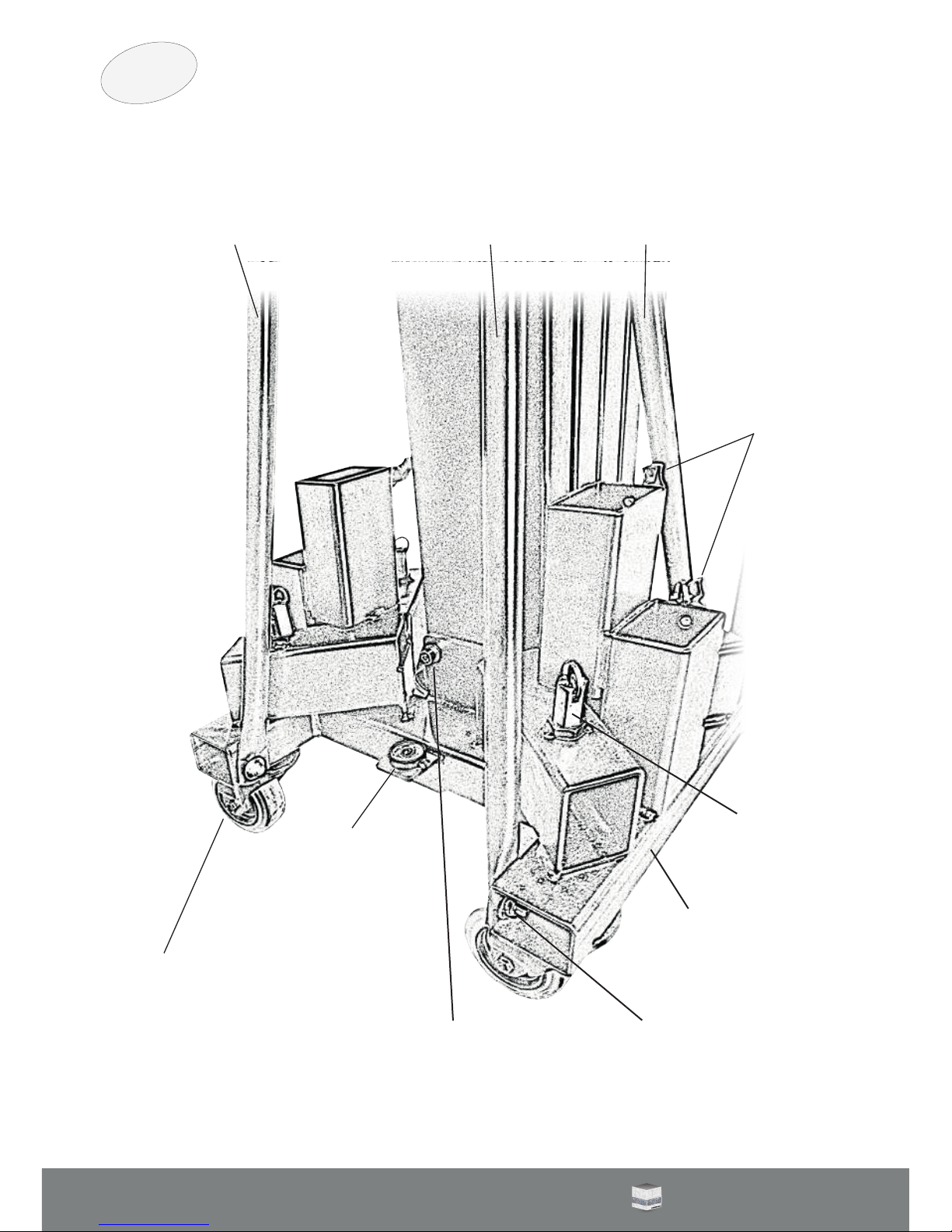

Tramo 2 / Section 2

Tramo 3 / Section 3

Tramo 4 / Section 4

Tramo 5 / Section 5

Tramo 1 / Section 1

Base

EK2159

Brazos de carga /

Forks

EK2196

Soporte Brazos /

Forks support

EK1225

Pata larga FL-080 /

FL-080 Long leg

EK1224

Pata corta FL-080/

FL-080 Short leg

B

A

A - Reenvios de poleas / Pulleys sets

B - Set piezas cabrestante / Winch set

C - Set piezas de la base / Base set

D - Set del estabilizador / Stabilizer set

EK1371

Tramo 6 / Section 6

Carro Lifting carriage

EUROTRUSS

LIFTERS

www.eurotruss.com

4

4

FL-080

FL-080

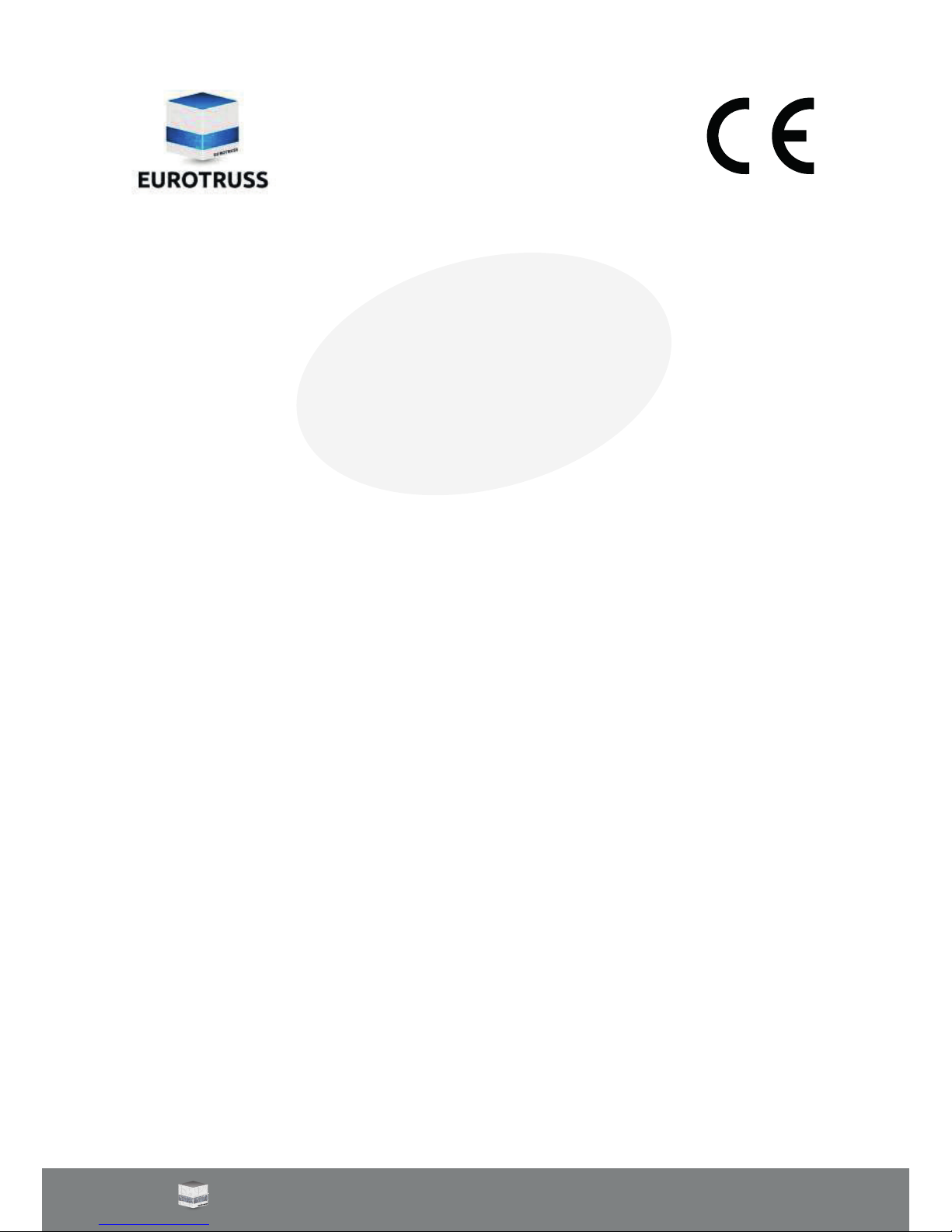

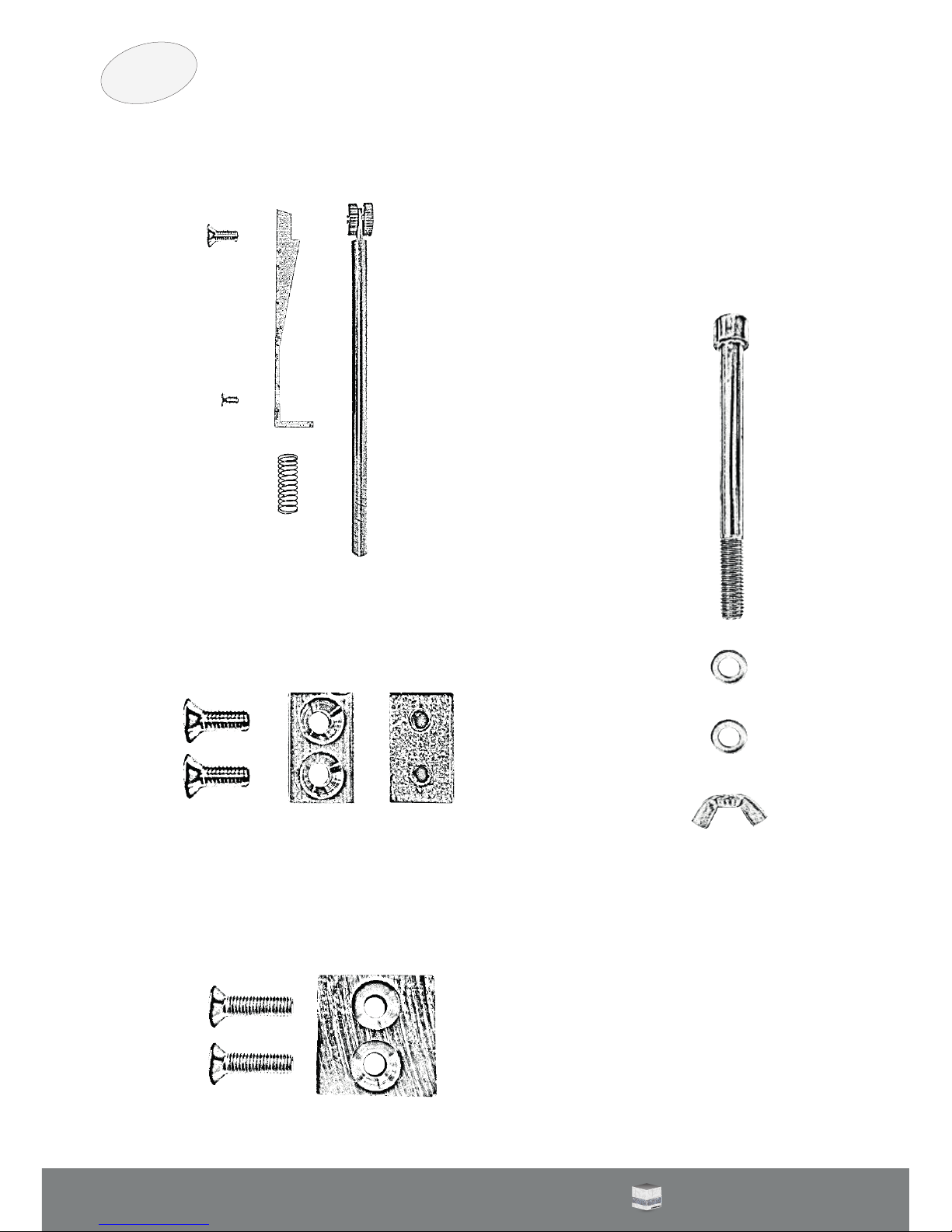

EK2185

Gatillo AET /

AET Lock

EK1029

Tornillo /

Screw

EK8001

Arandela /

Washer EK2138

Taco Gatillo/

Lock rest

EK2156

EK2157

5

EUROTRUSS

LIFTERS

www.eurotruss.com

4

FL-080

FL-080

EK2185

Gatillo AET /

AET Lock

EK1029

Tornillo /

Screw

EK8001

Arandela /

Washer EK2138

Taco Gatillo/

Lock rest

EK2156

EK2157

5

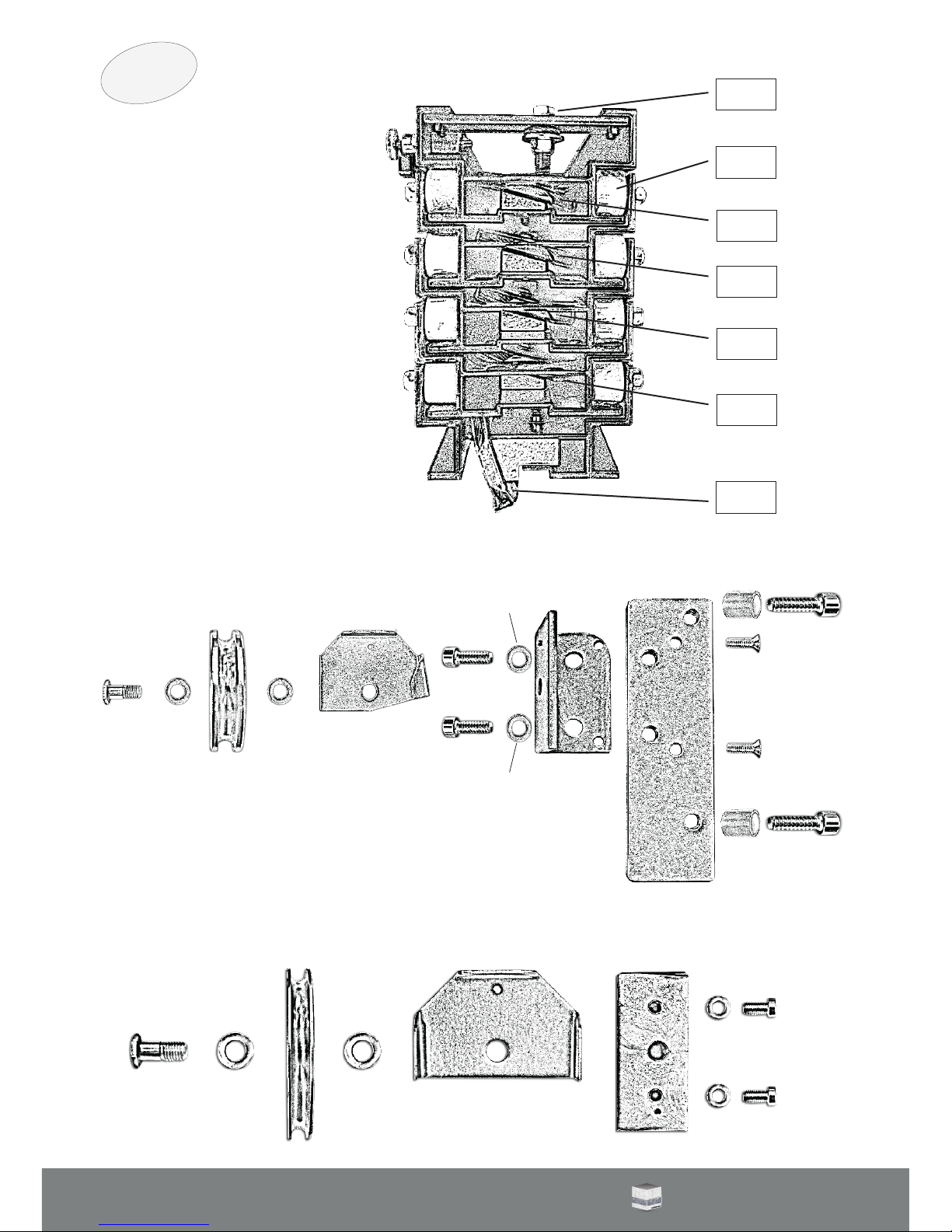

FL-080

FL-080

A.1

A.1 - Reenvío superior Tramo 1 Base / Upper pulley set on Section 1 Base

A.2

A.2

A.2

A

Vista en Planta superior /

Top view A.5

A.2

A.4

A.2 - Reenvío superior Tramos 2 a 5/ Upper pulley set on sections 2 to 5

EK1032

EK8004

EK8004

EK2008 EK2175 EK2179

EK1027

EK1027

EK8001

EK8001

EK2166N

EK2232

EK1032

EK8004

EK8004

EK2233

EK1022

EK8004

EK1015

EK8004

EK1022

EK1030

EK1015

EK1030

EK2234

EK2234

EK2008N

EUROTRUSS

LIFTERS

www.eurotruss.com

6

6

FL-080

FL-080

A.3 - Reenvío inferior / Lower pulley set

A.4 - Fijación nal de cable / Cable xation

EK1032

EK8004

EK8004

EK2008

EK2175

EK2174

EK1027

EK1027

EK1027

EK1027

EK8001

EK8001

EK8001

EK8001

EK8001

EK8001

EK1027

EK1027

A.8

A.9

EK1114

EK1026

EK1026

EK9052 EK8013

EK8004

EK7006

EK1046

EK1033

EK2177

EK8003

EK7002

A.5 - Rodillo Nylon / Nylon roller

A

7

EUROTRUSS

LIFTERS

www.eurotruss.com

6

FL-080

FL-080

A.3 - Reenvío inferior / Lower pulley set

A.4 - Fijación nal de cable / Cable xation

EK1032

EK8004

EK8004

EK2008

EK2175

EK2174

EK1027

EK1027

EK1027

EK1027

EK8001

EK8001

EK8001

EK8001

EK8001

EK8001

EK1027

EK1027

A.8

A.9

EK1114

EK1026

EK1026

EK9052 EK8013

EK8004

EK7006

EK1046

EK1033

EK2177

EK8003

EK7002

A.5 - Rodillo Nylon / Nylon roller

A

7

FL-080

FL-080

A.6 - Freno de Inercia / Inertial break

A.7 - Tornillo jación soporte brazos /

Fixation screw for the forks support

A.8 - Taco tope barras superior / Upper stop piece

EK2146

EK2144

EK1026

EK1004

EK2145

EK2143 EK2142

EK1030

EK1030

EK1043N

EK8009

EK8009

EK7007

A.9 - Taco tope barras inferior / Lower stop piece

EK1042

EK1042

EK2176

A

EUROTRUSS

LIFTERS

www.eurotruss.com

8

8

FL-080

FL-080

B

EK1028

Tornillo / Screw

EK8003

Arandela / Washer

EK7002

Tuerca / Nut

EK2173N

Placa cabrestante /

Winch support plate

EK1036

Tornillo / Screw

EK8006

Arandela / Washer

EK7001

Tuerca / Nut

EK2193

Placa tirantes /

Strut support plate EK4004

Cabrestante /

Winch

EK1036 Tornillo / Screw

EK8001 Arandela / Washer

EK7001 Tuerca / Nut

EK9052

Cable de acero /

Steel cable

9

EUROTRUSS

LIFTERS

www.eurotruss.com

8

FL-080

FL-080

B

EK1028

Tornillo / Screw

EK8003

Arandela / Washer

EK7002

Tuerca / Nut

EK2173N

Placa cabrestante /

Winch support plate

EK1036

Tornillo / Screw

EK8006

Arandela / Washer

EK7001

Tuerca / Nut

EK2193

Placa tirantes /

Strut support plate EK4004

Cabrestante /

Winch

EK1036 Tornillo / Screw

EK8001 Arandela / Washer

EK7001 Tuerca / Nut

EK9052

Cable de acero /

Steel cable

9

FL-080

FL-080

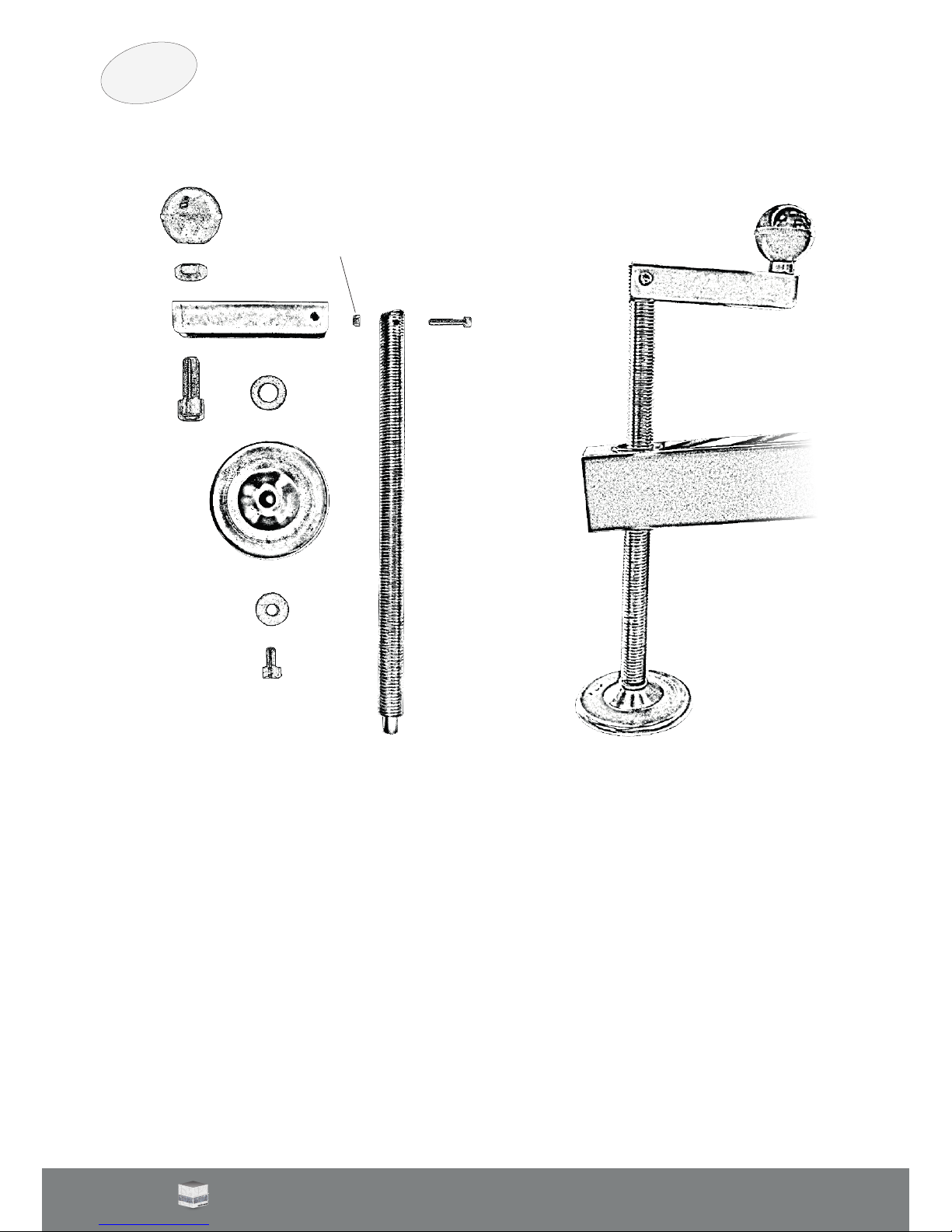

C

EK2119

Tornillo / Screw

Nivel de Burbuja /

Spirit level

EK5004 Rueda /Wheel

Arandela / Washer

EK1022

EK8004

EK2188

Base FL-080

EK2190

Pomo transporte patas /

Transport security knob

Gatillo patas /

Security leg lock

EK2189

EK1028 Tornillo / Screw

EK8003 Arandela / Washer

EK7002 Tuerca / Nut

EK1020 Tornillo / Screw

EK8001 Arandela / Washer

EK7001 Tuerca / Nut

EK2137

Apoyo derecho /

Right strut

EK2136

Apoyo izquierdo /

Left strut

EK2136

Apoyo izquierdo /

Left strut

Tuerca / Nut

EK7006

EUROTRUSS

LIFTERS

www.eurotruss.com

10

10

FL-080

FL-080

D

EK2169

EK7009

EK2168N

Estabilizador completo /

Complete stabilizer kit

EK2170

EK1015 EK8009

EK2171

EK7010

EK1041

EK2172N

EK8006

EK1003

11

EUROTRUSS

LIFTERS

www.eurotruss.com

10

FL-080

FL-080

D

EK2169

EK7009

EK2168N

Estabilizador completo /

Complete stabilizer kit

EK2170

EK1015 EK8009

EK2171

EK7010

EK1041

EK2172N

EK8006

EK1003

11

FL-080

FL-080

LISTA DE REPUESTOS / SPARE PARTS LIST

EK1003 Tornillo allen M8 x 16 / Allen screw M8 x 16

EK1004 Tornillo cónico M5 x 12 / Conic screw M5 x 12

EK1015 Tornillo allen M12 x 25 / Allen screw M12 x 25

EK1020 Tornillo allen M8 x 25 / Allen screw M8 x 25

EK1022 Tornillo allen M12 x 40 / Allen screw M12 x 40

EK1026 Tornillo cónico M8 x 20 / Conic screw M8 x 20

EK1027 Tornillo especial M8 x 16 / Special screw M8 x 16

EK1028 Tornillo allen M10 x 30 / Allen screw M10 x 30

EK1029 Tornillo allen M8 x 35 / Allen screw M8 x 35

EK1030 Tornillo cónico M8 x 25 / Conic screw M8 x 25

EK1032 Tornilloespecialcabezaplana/SpecialatM12screw

EK1033 Tornillo rodillo nylon / Nylon runner screw

EK1036 Tornillo allen M8 x 30 / Allen screw M8 x 30

EK1041 Tornillo allen M6 x 40 / Allen screw M6 x 40

EK1042 Tornillo cónico M8 x 30 / Conic screw M8 x 30

EK1043N Tornillo allen M14 x 200 / Allen screw M14 x 200

EK1046 Tornillo especial M12 x 45 / Special Screw M12 x 45

EK1047 Tornillo allen M12 x 100 / Allen screw M12 x 100

EK1114 Pletinajacióncableconargolla/Cable(withshackle)xationplate

EK1224 PatacortaFL-080/ShortlegFL-080

EK1225 PatalargaFL-080/LonglegFL-080

EK1366 Tramo1(Base)FL-080/Section1(Base)FLS-080

EK1367 Tramo2FL-080/Section2FL-080

EK1368 Tramo3FL-080/Section3FL-080

EK1369 Tramo4FL-080/Section4FL-080

EK1370 Tramo5FL-080/Section5FL-080

EK1371 CarroaluminioTramo6/Aluminiumliftingcarriagesection6FL-080

EK2008 Polea Ø90 / Pulley Ø90

EK2008N PoleaØ90ancha/WidepulleyØ90

EK2119 Niveldeburbuja/Spiritlevelindicator

EK2136 TirantelargoIzquierdo/Longleftstrut

EK2137 TirantelargoDerecho/Longrightstrut

Code/Código Description/Descripción

EUROTRUSS

LIFTERS

www.eurotruss.com

12

12

FL-080

FL-080

LISTA DE REPUESTOS / SPARE PARTS LIST

Code/Código Description/Descripción

EK2138 TacoGatillo/Lockrest

EK2142 Topetramos/SectionTop

EK2143 Toperoscadotramos/Sectionscrewtop

EK2144 Rampafreno/Brakeramp

EK2145 Muelle/Spring

EK2146 Frenodecarro/Carriagebreak

EK2156 Pasador / Pin

EK2157 Clip“R”/“R”Shapeclip

EK2159 Brazodecarga/Liftingfork

EK2166N CubrecablepoleaentradaØ90ancha/CableentrypulleycoverØ90wide

EK2168 EstabilizadorcompletoFL-080/CompleteFL-080stabilizer

EK2169 Bolagrandedeestabilizador/Bigstabilizerball

EK2170 Manivelagrandeestabilizador/Bigstabilizerhandle

EK2171 Platograndeestabilizador/Bigstabilizerplate

EK2172 EsparragoestabilizadorM24x330mm/ThreadedboltM24x330mm

EK2173N Placaporta-cabrestanteFL-080/WinchplateFL-080

EK2174 Macizoporta-poleasinferior/Lowerpulleysupportpiece

EK2175 Cubre cable polea Ø90 / Pulley cover Ø90

EK2176 Tacotopetramosancho/Largestoppiece

EK2177 Rodillonylongrande/Largenylonroller

EK2179 Macizoporta-poleassuperior/Upperpulleysupportpiece

EK2185 GatilloAETDosposiciones/AETLockdualposition

EK2187 BaseEurotrussFL-080/FL-080EurotrussBase

EK2189 Gatillopatas/Securityleglock

EK2190 Pomoaprietetransportepatas/Transportsecurityknobforlegs

EK2193 Placasujeccióntirantes/Strutsupportplate

EK2196 Soportebrazocarga/Forksupport

EK2232 Pletinahierroporta-poleastramo1/Steelplatefor1stsectionpulley

EK2233 Ángulodehierroporta-poleastramo1/Steelanglefor1stsectionpulley

EK2234 CasquilloaluminioØ25x3Long:29mm/AluminiumshellØ25x3mm

EK4004 Cabrestante900kgManivelalarga/900kgWinchLonghandle

EK5004 RuedaØ100(blanca)/WheelØ100(white)

13

EUROTRUSS

LIFTERS

www.eurotruss.com

12

FL-080

FL-080

LISTA DE REPUESTOS / SPARE PARTS LIST

Code/Código Description/Descripción

EK2138 TacoGatillo/Lockrest

EK2142 Topetramos/SectionTop

EK2143 Toperoscadotramos/Sectionscrewtop

EK2144 Rampafreno/Brakeramp

EK2145 Muelle/Spring

EK2146 Frenodecarro/Carriagebreak

EK2156 Pasador / Pin

EK2157 Clip“R”/“R”Shapeclip

EK2159 Brazodecarga/Liftingfork

EK2166N CubrecablepoleaentradaØ90ancha/CableentrypulleycoverØ90wide

EK2168 EstabilizadorcompletoFL-080/CompleteFL-080stabilizer

EK2169 Bolagrandedeestabilizador/Bigstabilizerball

EK2170 Manivelagrandeestabilizador/Bigstabilizerhandle

EK2171 Platograndeestabilizador/Bigstabilizerplate

EK2172 EsparragoestabilizadorM24x330mm/ThreadedboltM24x330mm

EK2173N Placaporta-cabrestanteFL-080/WinchplateFL-080

EK2174 Macizoporta-poleasinferior/Lowerpulleysupportpiece

EK2175 Cubre cable polea Ø90 / Pulley cover Ø90

EK2176 Tacotopetramosancho/Largestoppiece

EK2177 Rodillonylongrande/Largenylonroller

EK2179 Macizoporta-poleassuperior/Upperpulleysupportpiece

EK2185 GatilloAETDosposiciones/AETLockdualposition

EK2187 BaseEurotrussFL-080/FL-080EurotrussBase

EK2189 Gatillopatas/Securityleglock

EK2190 Pomoaprietetransportepatas/Transportsecurityknobforlegs

EK2193 Placasujeccióntirantes/Strutsupportplate

EK2196 Soportebrazocarga/Forksupport

EK2232 Pletinahierroporta-poleastramo1/Steelplatefor1stsectionpulley

EK2233 Ángulodehierroporta-poleastramo1/Steelanglefor1stsectionpulley

EK2234 CasquilloaluminioØ25x3Long:29mm/AluminiumshellØ25x3mm

EK4004 Cabrestante900kgManivelalarga/900kgWinchLonghandle

EK5004 RuedaØ100(blanca)/WheelØ100(white)

13

FL-080

FL-080

LISTA DE REPUESTOS / SPARE PARTS LIST

Code/Código Description/Descripción

EK7001 TuercaM8autoblocante/Auto-blocknutM8

EK7002 TuercaM10autoblocante/Auto-blocknutM10

EK7006 TuercaM12autoblocante/Auto-blocknutM12

EK7007 Tuercamariposaautoblocante/Butterynut

EK7009 TuercaM12/NutM12

EK7010 TuercaM6autoblocante/Auto-blocknutM6

EK8001 ArandelaM8/M8washer

EK8003 ArandelaM10/M10washer

EK8004 ArandelaM12/M12washer

EK8006 ArandelaM8ancha/WideM8washer

EK8009 ArandelaM14/M14washer

EK8013 ArandelaM12ancha/WideM12washer

EK9052 CableFL-080Ø6mm/CableFL-080Ø6mm

EUROTRUSS

LIFTERS

www.eurotruss.com

14

14

FL-080

Operating Instructions - ENGLISH

1 - INTRODUCTION.

Dearuser.ThankyoupurchasingyourEurotrussFL-080lifter.Wehopeyouwillbevery

satisedwithit.

Thismanualhasbeenwrittensothatyoucanunderstandhowtoeffectivelyusethelift

andmostimportantly,sothatyoucanuseitsafely.Itisimportantthatyoufullyreadthe

manualandfollowtheinstructionscarefullybeforeusingyourlift.AllEurotrussliftsun-

dergoaverystrictqualitycontrolprocessduringtheirmanufacture.

SothatyourliftalwaysworksproperlypleaseonlypurchaseoriginalEurotrussparts

fromanauthorizeddistributorordealer.Theuserwaivesallwarrantyrightsifusingparts

otherthanEurotrussoriftheproductismanipulatedinanywaybyanunauthorizedthird

party.

When requesting parts, please refer to the diagrams of this manual and quote the

serial number and year of manufacture located on your lifter.

2 - TECHNICAL SPECIFICATIONS.

Eurotrusslifter,modelFL-080hasbeendesignedforverticallyliftinglighting,trussing

etcintheProfessionalsoundandlightsector.ForvariousEurotrusssupportsavailable

pleaserefertoourwebsitewww.eurotruss.comorcatalogue.

2.1-Max.load:300kg(661.4lb)

2.2-Min.load:25kg(55lb)

2.3-Max.height:8.00m(26.24’)

2.4-Foldedheight:1.99m(6.53’)

2.5-Transportsurface:0.56x0.63x1.99m(1.84’x2.07’x6.53’).

2.6-Shippingdimension:0.57x0.64x2.(1.87’x2.10’x6.56’).

2.7-Worksurface:1.87x1.80m(6.13’x5.90’)

2.8-Weight:185kg(407.86lb)

2.9-Winch:900kgcertied

2.10-Cable:SteelDIN3060.Tensilestrength180kg/mm2.Anti-torsion&anti-corrosion

Ø6mmcablediameter.

2.11-Constructionmaterial:Alluminiumproles6082T6.

2.12-Antirustprotectionprimingpaintbathedblacksteel,coveredwithcuredpolyester

dust.

15

EUROTRUSS

LIFTERS

www.eurotruss.com

14

FL-080

Operating Instructions - ENGLISH

1 - INTRODUCTION.

Dearuser.ThankyoupurchasingyourEurotrussFL-080lifter.Wehopeyouwillbevery

satisedwithit.

Thismanualhasbeenwrittensothatyoucanunderstandhowtoeffectivelyusethelift

andmostimportantly,sothatyoucanuseitsafely.Itisimportantthatyoufullyreadthe

manualandfollowtheinstructionscarefullybeforeusingyourlift.AllEurotrussliftsun-

dergoaverystrictqualitycontrolprocessduringtheirmanufacture.

SothatyourliftalwaysworksproperlypleaseonlypurchaseoriginalEurotrussparts

fromanauthorizeddistributorordealer.Theuserwaivesallwarrantyrightsifusingparts

otherthanEurotrussoriftheproductismanipulatedinanywaybyanunauthorizedthird

party.

When requesting parts, please refer to the diagrams of this manual and quote the

serial number and year of manufacture located on your lifter.

2 - TECHNICAL SPECIFICATIONS.

Eurotrusslifter,modelFL-080hasbeendesignedforverticallyliftinglighting,trussing

etcintheProfessionalsoundandlightsector.ForvariousEurotrusssupportsavailable

pleaserefertoourwebsitewww.eurotruss.comorcatalogue.

2.1-Max.load:300kg(661.4lb)

2.2-Min.load:25kg(55lb)

2.3-Max.height:8.00m(26.24’)

2.4-Foldedheight:1.99m(6.53’)

2.5-Transportsurface:0.56x0.63x1.99m(1.84’x2.07’x6.53’).

2.6-Shippingdimension:0.57x0.64x2.(1.87’x2.10’x6.56’).

2.7-Worksurface:1.87x1.80m(6.13’x5.90’)

2.8-Weight:185kg(407.86lb)

2.9-Winch:900kgcertied

2.10-Cable:SteelDIN3060.Tensilestrength180kg/mm2.Anti-torsion&anti-corrosion

Ø6mmcablediameter.

2.11-Constructionmaterial:Alluminiumproles6082T6.

2.12-Antirustprotectionprimingpaintbathedblacksteel,coveredwithcuredpolyester

dust.

15

FL-080

Operating Instructions - ENGLISH

2.13-AutomaticEurotrussTrigger(AET)oneachsectionwhichautomaticallyslotsinto

thesectionsduringelevation,lockingtheminplace.

2.14-Anchorofthelegsbysafetycatches.

2.15-Adjustablestabilizerplatesinthelegswithnonsliprubberbasesupport.

2.16-Spiritlevelforverticalalignment.

2.17-Swivelwheelsfortransportingtheliftertoitsworkingposition.

3 - SAFETY GUIDELINE.

3.1-Situatethetoweronasolidandatsurface.

3.2-Checkthatthelegsarefullyinsertedandsecuredintotheirhousingwiththesafety

locks.

3.3-Ensurethatthelifterisinaverticalpositionandusethespiritlevellocatedonthe

baseproletocheck.Ifnecessary,adjustitsalignmentwiththeplatesbyturningthe

handleintheappropriatedirection.

3.4-Checkthatthetowerislockedinitsworkingpositionwiththesafetylock.

3.5-Whenusedoutdoors,placethetoweronahardsurfaceandifnecessarysecureit

againstexcesswindforceviacablebraces.

3.6-Donotuseladdersnorleanthemagainstthelifter.

3.7-Becarefulwithanycables,prominentobjectsetc.placedabovethetower.

3.8-Donotstandunderneaththeload.

3.9-Donotmovethetowerwhenitiselevatedorloaded.

3.10-Beforeusingthetower,checktheconditionofthecable.Thismustbefreeofcuts

andfrays.Neverusedamagedcables.

3.11-Neverdismountthewinchhandleoranyelementofthewinchunderanycircum-

stance.

3.12-Oncethetowerisset-upinitsworkingpositionwerecommendedthewinchhan-

dleislockedtoavoidanyoneinterferingwithit.

3.13-Theminimumloadforasafeoperationofthebrakeis25kg.Thebrakewillnot

functionwithoutthisminimumload.

3.14-Donotgreaseorlubricatethebrakemechanismofthewinch.

3.15-Thisliftcannotlifthumanbeings.

3.16-Fortransportationitisnecessarytoretractallprolesandlockthemwiththe

correspondingsafetylock.

EUROTRUSS

LIFTERS

www.eurotruss.com

16

16

FL-080

Operating Instructions - ENGLISH

4 - OPERATION.

4.1-Placethetoweronaatandsolidsurfacewhereitisgoingtobeused.

4.2-Removethelegsfromtheirtransportsupportsandinsertthemintheirworkingpo-

sition.Checkthattheyarefullyinsertedandxedwiththeirsafetylock.

4.3-Ensurethatthelifterisinaverticalpositionandusethespiritlevellocatedonthe

baseproletocheckthebubbleiscentred.Ifnecessary,adjustitsalignmentwiththe

stabilizerplatesbyturningthehandleintheappropriatedirection.

4.4-Changetheforkstotheirhorizontalworkingpositionandxthemwiththefastener

pins,placetheloadontheforksusingaEurotrussAccessoryifnecessary,andensure

thatthetowerisonlyusedtoliftloadsvertically.Theminimumloadis25kg.

NEVERRAISETHETOWERSECTIONSWITHOUTLOAD.

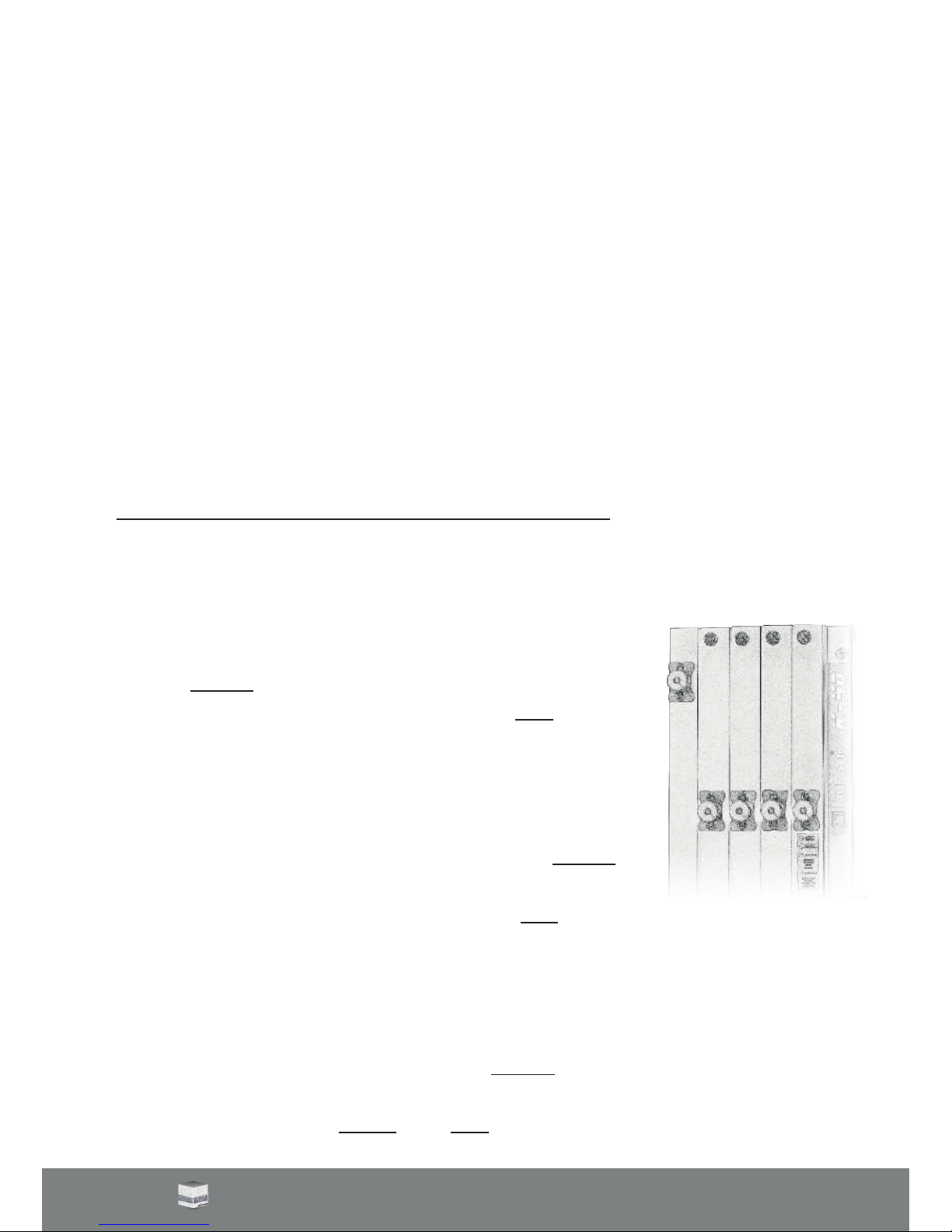

1

2 3 4 5

4.5 - Elevation:

4.5.1-EnsurethatalltheAETlocksareinthe

BLOCKposition.

4.5.2-Changethenº1 AETlocktotheLIFTposition.

4.5.3-Turnthehandleclockwisetoraisethelifting

carriageofthetower.

4.5.4-Whenyouhavereachedthedesiredheight,

xthe nº1 AETlockinbyturningthehandleanti-

clockwise.Changethenº1 AETlocktotheBLOCK

position.

4.5.5-Changethenº2 AETlocktotheLIFTposition.

4.5.6-Turnthehandleclockwisetorisethenextsectionofthetower.

4.5.7-Whenyouhavereachedthedesiredheight,xthenº2 AETlockinby

turningthehandleanti-clockwise.

Checkthatthenº2 AET lockhasintroducedintoitscorrespondinghole.

Andchangethenº2 AETlocktotheBLOCKposition.

4.5.8-Repeatthesestepstoraiseallthesectionsofthetower,changingall

theAET locksleftorderlytotheLIFTpositionandturningthehandleclockwise.

17

EUROTRUSS

LIFTERS

www.eurotruss.com

16

FL-080

Operating Instructions - ENGLISH

4 - OPERATION.

4.1-Placethetoweronaatandsolidsurfacewhereitisgoingtobeused.

4.2-Removethelegsfromtheirtransportsupportsandinsertthemintheirworkingpo-

sition.Checkthattheyarefullyinsertedandxedwiththeirsafetylock.

4.3-Ensurethatthelifterisinaverticalpositionandusethespiritlevellocatedonthe

baseproletocheckthebubbleiscentred.Ifnecessary,adjustitsalignmentwiththe

stabilizerplatesbyturningthehandleintheappropriatedirection.

4.4-Changetheforkstotheirhorizontalworkingpositionandxthemwiththefastener

pins,placetheloadontheforksusingaEurotrussAccessoryifnecessary,andensure

thatthetowerisonlyusedtoliftloadsvertically.Theminimumloadis25kg.

NEVERRAISETHETOWERSECTIONSWITHOUTLOAD.

1

2 3 4 5

4.5 - Elevation:

4.5.1-EnsurethatalltheAETlocksareinthe

BLOCKposition.

4.5.2-Changethenº1 AETlocktotheLIFTposition.

4.5.3-Turnthehandleclockwisetoraisethelifting

carriageofthetower.

4.5.4-Whenyouhavereachedthedesiredheight,

xthe nº1 AETlockinbyturningthehandleanti-

clockwise.Changethenº1 AETlocktotheBLOCK

position.

4.5.5-Changethenº2 AETlocktotheLIFTposition.

4.5.6-Turnthehandleclockwisetorisethenextsectionofthetower.

4.5.7-Whenyouhavereachedthedesiredheight,xthenº2 AETlockinby

turningthehandleanti-clockwise.

Checkthatthenº2 AET lockhasintroducedintoitscorrespondinghole.

Andchangethenº2 AETlocktotheBLOCKposition.

4.5.8-Repeatthesestepstoraiseallthesectionsofthetower,changingall

theAET locksleftorderlytotheLIFTpositionandturningthehandleclockwise.

17

FL-080

Operating Instructions - ENGLISH

WARNING: The tower can be left in any intermediate height if necessary. Just make

sure that the AET locks are always xed and introduced. In the unlikely event of cable

breaking the AET locks will ensure that the tower stays UP and SECURE.

Your security is our main concern.

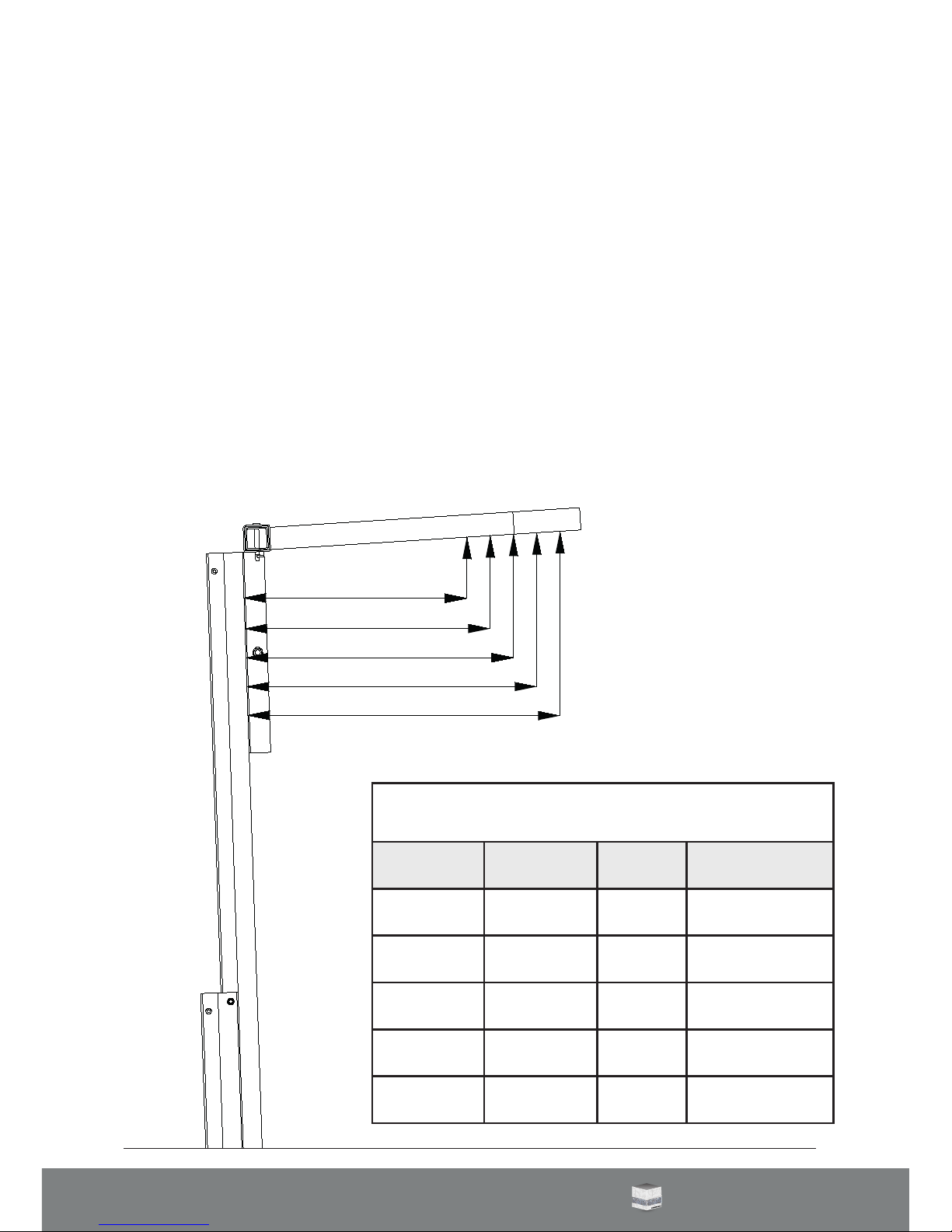

IMPORTANT - HOW TO PLACE THE LOAD ON THE LIFTER

Alwaysloadasclosetothetoweraspossible.

Followtheinstructionofthenextpicturetoplacetheloadcorrectly,thediagramshows

theloadoutofthegravitycenter,withdistancestotheliftingcarriageatamaximum

lifting.Noticethatthemaximumloaddiminishesaccordingtothedistancefromthebody

ofthetower.

X2

X3

X4

X5

X1

FL-080

POSITION DISTANCE LOAD PERCENTAGE

X1 30 cm 300kg 100%

X2 40 cm 285kg 95%

X3 50 cm 267kg 89%

X4 60 cm 210kg 70%

X5 70 cm 165kg 55%

EUROTRUSS

LIFTERS

www.eurotruss.com

18

18

FL-080

Operating Instructions - ENGLISH

4.6 - Descent:

4.6.1-Tofoldthetowerdown,rst,turnthehandleofthewinchclockwiseto

tightenthesteelcable.

4.6.2-Oncethecableistense,pulloutthenº5 AETlock,mantainitalwaysin

LIFTpositionbutkeepitout.

4.6.3-WhileyoukeeptheAETlockout,turnthehandleanti-clockwisetobring

downthecorrespondingsectionofthetower.

4.6.4-Oncethesectionhasbeenbroughtdown,releasethenº5 AETlock,

andpulloutthenº4 AETlock.

4.6.5-WhileyoukeepthenextAETlockout,turnthehandleanti-clockwiseto

bringdownthenextsection.

4.6.6-Keeprepeatingthesesteps,pullingoutalltheAETlocksleftinorder

whileyouturnthehandleanti-clockwise.

4.6.7-Oncethetowerhasbeenfoldeddown,placealltheAETlocksinthe

BLOCKposition.

4.7 - Transport:

Turnthehandleofthestabilizerstoreleasetensiononthelegsinordertopullthemout.

Then,placethelegsintheirtransportcompartmentslocatedatthebaseofthetower.

Pullouttheforksandplacetheminverticalposition.Thetowerwillbereadyfortransport.

5 - MAINTENANCE.

5.1-Allcablesmustbecheckedregularly.Faultycablesmustbereplacedimmediately.

Donotusethelifterwithfaultycablesasitispotentiallyverydangerous.OnlyuseDIN

3060cables,suppliedfromanauthoriseddealer.

5.2-Thelifterisdeliveredexfactorycompletelygreased.Dependingonitsmechanical

Usethough,werecommendthatthecrownwheelofthewinch,thepads&bushings

ofthedriveshaft,thehandlethreadandtheprolesoftheliftareperiodicallygreased.

ATTENTION:

Do not apply oil or grease to the brake mechanism. The brake discs have been pre-grea-

sed with a special heat and pressure resistant grease. To avoid malfunction to the winch

19

EUROTRUSS

LIFTERS

www.eurotruss.com

18

FL-080

Operating Instructions - ENGLISH

4.6 - Descent:

4.6.1-Tofoldthetowerdown,rst,turnthehandleofthewinchclockwiseto

tightenthesteelcable.

4.6.2-Oncethecableistense,pulloutthenº5 AETlock,mantainitalwaysin

LIFTpositionbutkeepitout.

4.6.3-WhileyoukeeptheAETlockout,turnthehandleanti-clockwisetobring

downthecorrespondingsectionofthetower.

4.6.4-Oncethesectionhasbeenbroughtdown,releasethenº5 AETlock,

andpulloutthenº4 AETlock.

4.6.5-WhileyoukeepthenextAETlockout,turnthehandleanti-clockwiseto

bringdownthenextsection.

4.6.6-Keeprepeatingthesesteps,pullingoutalltheAETlocksleftinorder

whileyouturnthehandleanti-clockwise.

4.6.7-Oncethetowerhasbeenfoldeddown,placealltheAETlocksinthe

BLOCKposition.

4.7 - Transport:

Turnthehandleofthestabilizerstoreleasetensiononthelegsinordertopullthemout.

Then,placethelegsintheirtransportcompartmentslocatedatthebaseofthetower.

Pullouttheforksandplacetheminverticalposition.Thetowerwillbereadyfortransport.

5 - MAINTENANCE.

5.1-Allcablesmustbecheckedregularly.Faultycablesmustbereplacedimmediately.

Donotusethelifterwithfaultycablesasitispotentiallyverydangerous.OnlyuseDIN

3060cables,suppliedfromanauthoriseddealer.

5.2-Thelifterisdeliveredexfactorycompletelygreased.Dependingonitsmechanical

Usethough,werecommendthatthecrownwheelofthewinch,thepads&bushings

ofthedriveshaft,thehandlethreadandtheprolesoftheliftareperiodicallygreased.

ATTENTION:

Do not apply oil or grease to the brake mechanism. The brake discs have been pre-grea-

sed with a special heat and pressure resistant grease. To avoid malfunction to the winch

19

FL-080

Operating Instructions - ENGLISH

brake, no other products must be used except the original provided by the company. It

is not necessary to grease the brake discs.

5.3-Yourliftershouldbeinspectedatleastonceayearbyaspecialized/authorized

servicecentre.

5.4-OnlyoriginalEurotrusssparepartsmustbeusedtoguaranteethereliabilityand

operationalsafetyofyourlifter.Theusershallloseallwarrantyclaimsifheusesanything

otherthanoriginalsparepartsormodiesthisproductinanyway.

5.5-Incaseasparepartisrequiredpleaseindicatethereferencenumberwhichcanbe

foundinthesparepartslistatthebackofthismanual.

6 - WARRANTY.

AllEurotrussliftscomewith2yearswarranty.Thiswarrantyperiodisfromthedateof

purchase.Eurotrusswillrepairanydefectproductcausedbyeitherfaultymaterialsor

poorworkmanshipfreeofchargewithinthisperiodaslongasthepartsarettedbyan

authorizedEurotrussdealer.Shouldtheproducthavebeenmanipulatedinanywayor

arepairattemptedbyanunauthorizeddealerthewarrantywillbeinvalid.Thiswarranty

doesnotcoverdamageoccurredbyimproperuse.

7 - CERTIFICATIONS

BGV-C1

BGG-912

ECConformityDeclarationpursuanttothe

ECMachineryDirectives89/392/CEand

98/37/CE:Manuallifters

Eurotrussreservestherighttomakeanymodication/alterationtotheliftwithoutprior

notice.Anymodication/alterationwouldbeaninnovation,intendedtoimprovethepro-

duct.

Eurotruss BV

Castorweg 2 - 8938BE Leeuwarden

The Netherlands

+31(0)58 215 88 88

Table of contents

Other Eurotruss Lifting System manuals

Popular Lifting System manuals by other brands

EAE

EAE EE-6604BWF Installation, operation, and parts manual

R. Beck Maschinenbau

R. Beck Maschinenbau HS 1200 FH operating manual

WPG

WPG P110T04DC3 operating instructions

Tommy Gate

Tommy Gate G2 dual drive G-330 Mounting instructions

morse

morse 400A-96SS-125 Operator's manual

TESA

TESA Auto lift system Installation & operation manual

Sinoboom

Sinoboom 1018RD Maintenance manual

Arjo

Arjo Maxi Sky 440 Instructions for use

ThyssenKrupp

ThyssenKrupp HOMEGLIDE STAIRLIFT user manual

RGC

RGC HL5-7K instructions

Rotary

Rotary SM65-51 Operation and maintenance manual

Challenger Lifts

Challenger Lifts CL4P9S Installation, operation & maintenance manual