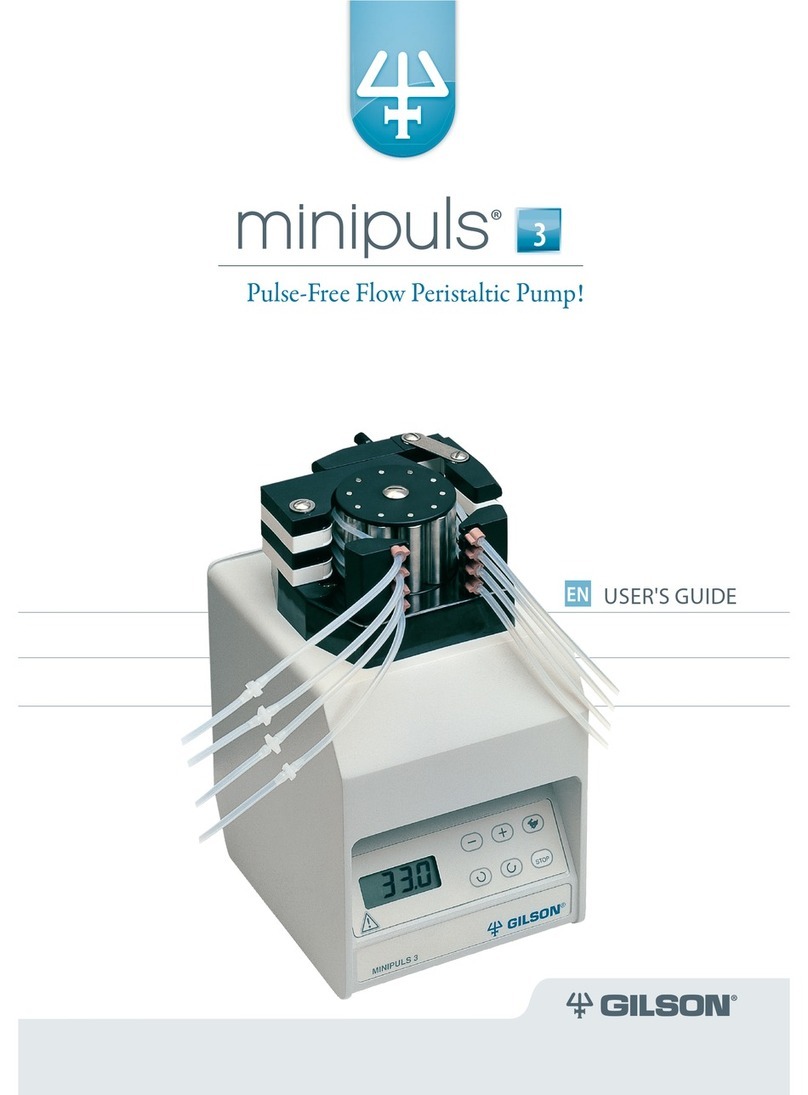

Eurovacuum EV Series User manual

Eurovacuum

Installations and

Operating manual

EV Series

Vacuum pumps

Models 0010 - 0750

Single Stage Oil Sealed Rotary Vane Pump

Eurovacuum EV Series

Single Stage Oil Sealed Rotary Vane Pumps

Eurovacuum Company is offering its various products to meet industrial vacuum needs.

Eurovacuum Company is founded in 2006, with over 30 year experiences in the vacuum

Industry its founders have een putting there est efforts continuously to produce high quality

Oil Sealed Rotary Vane Pumps, with diverse range of capacity for use in printing, food

processing, packaging, plastic moulding, vacuum lifting, hospitals and la oratories or other

industrial application.

Application Examples

• Car industry

• Food industry

• Furnaces and plants

• Laser technology

• Medicinal technology

• Metallurgy

• Power engineering, long-distance energy

• Space simulation

• Vacuum coating

Advantages to the User

• High pumping speed also at low pressures

• Low noise level

• ntegrated exhaust filter, Discharge Air 99.9% Oil Free

• No oil loss owing to the integrated oil return line

• Air-cooling, no water required

• Low space requirement, easy to install

• Spin-on Oil Filter on all sizes from EV-0030

• Maintenance-friendly

• Compact design

• Anti-Suckback valve to secure the vacuum

in the system

• High water vapour tolerance

• Direct drive, Design requires no belts

• Wide range of accessories available for

easy adaptation

Eurovacuum Head office

Tel. +31-(0)854890993

Einsteinstraat 58 info@eurovacuum.eu

2811 E Reeuwijk http://www.eurovacuum.eu

The Netherlands

Anti-suckback valve Inlet flange with filter screen

Integrated

exhaust

filters

Exhaust

pressure

gauge

High efficiency

Motor

Oil level Low oise Level

sight glass

Gas ballast Valve Efficient Air Cooling

Contents

It is mandatory that these operating instructions be read and

understood prior to the vacuum pump installation and start-up.

1.0 INSTALLATION

1.1 Unpacking

1.2 Location

1.3 Power Requirements

1.4 Vacuum Connections

1.5 Oil Filling

2.0 SA ETY

2.1 General Notices

2.2 Warning Label and explanation

2.3 Location of Labels

3.0 OPERATION

3.1 Start-up

3.2 Stopping the pump

3.3 Gas Ballast

3.4 Check Valve (Built -in)

3.5 Exhaust Filter Pressure Gauge (optional)

4.0 MAINTENANCE

4.1 Pump Oil (level/type/quantity/change)

4.2 nline (inlet) Filter

4.3 Exhaust Filter

4.4 Gas ballast filter

4.5 Maintenance Chart

4.6 Gasket Kit, Overhaul Kit and other parts and accessories

5.0 PROBLEM SOLVING

6.0 TECHNICAL DATA

Version A3; March 2017

INSTALLATION AND OPERATING MANUAL

This manual is written to cover EV-Series Model vacuum pumps. The model number is stamped into

the nameplate. The number will appear as follows :

EV-xxxxL; EV-xxxxNM, EV-xxxxF, EV-xxxxG or EV-xxxxH

Please identify the model number and serial number when ordering parts.

Versions:

L: 20 mbar - With Oil Return Line w/o float valve from oil sump to inlet port of inlet flange.

NM: 2 mbar - With Oil Return Line from oil sump to end plate.

F, G, H: 0,5mbar or lower - Oil Return Line with float valve from oil sump to inlet port of inlet flange.

1.0 INSTALLATION

1.1 Unpacking

nspect the box and pump carefully for any signs of damage incurred in transit. Since all pumps are

ordinarily shipped from our regional warehouse, such damage is the normal responsibility of the

carrier and should be reported to them.

The vacuum pump is bolted to the skid with studs that are connected through the rubber feet of the

pump. Remove the nuts from the underside of the crate and remove the pump. Unscrew the studs

from the rubber feet.

The inlet and exhaust of the pump are covered with caps to prevent dirt and other foreign

substances from entering the pump. Leave these caps in place until you are ready to pipe the pump

to your equipment.

1.2 Location

nstall the pump in a horizontal position on a level surface so that the pump can be evenly supported

on its rubber feet. Leave 30cm of access around the pump to allow proper cooling. Also adequate

ventilation must be provided for the fans, radiator and motor.

Allow access to the oil sight glass in order to inspect the oil level and the exhaust port for easy

access to change the exhaust Filters.

Do not tip the pump over if filled with oil.

1.3 Power Requirements

A schematic diagram for the electrical motor terminal connections is located in the junction box of

the motor or on the motor nameplate. Typical wiring for Three Phase Motors is as below:

Wiring Scheme- Single Phase Motor

The motor must be connected according to the electrical codes through a fused switch in order to

protect the motor against electrical or mechanical overload conditions. The overload of the motor

starter must be set at a level equal to the full load motor current listed on the motor nameplate.

f the pump is supplied with a motor starter it is preset at the factory according to customer

specifications. t is advisable to check that these settings are in line with the voltage at your location.

f the voltage is different, please contact Eurovacuum for motor and starter information.

Correct direction of rotation is marked by an arrow on the motor fan housing and is counter

clockwise when looking at the motor from the motor's fan side.

After electrical connections have been made, but prior to filling with oil, the rotation of the

motor should be checked. If backward, reverse any two leads of the three phase at the power

connection.

1.3 Vacuum Connections

Use a pipe size that is at least the size of the pump inlet connections. Smaller lines result in a

reduced pump capacity.

Pumps operating in parallel on a common main line should have a manual or automatic operated

shut-off valve or positive action check valve, installed in the suction line adjacent to the pump

suction flange. The built-in anti-suck back valve should not be used as a shut-off valve for the

vacuum system. Remove the protective cap from the inlet port prior to connection of pump to the

system.

Should process gas contain dust or other foreign particles, a suitable in line (inlet) filter should be

connected to the inlet port. Consult Eurovacuum for recommendations.

The vacuum piping should be designed to ensure that no liquids such as condensate or liquid

carried over from the process can reach the pump. f this possibility exists, a knock-out liquid

separator should be installed. Consult Eurovacuum for recommendations.

f an exhaust manifold is connected, install a drip leg and drain near the pump exhaust to prevent

exhaust condensation from entering the exhaust box. The following thread sizes are standard on the

Eurovacuum pumps (NPT thread is available upon request)

Pump Model Inlet Size Exhaust Size

EV-0010/0016/ 0021 ½" G 1¼” G or Open Grid

EV-0030/0040 1¼" G 1¼" G

EV-0063/0100 1¼" G 1¼" G

EV-0160/0215 2" G 2" G

EV-0175/0250/0300 2" G 2" G

EV-0450/0500/0630/0750 3" G 3" G

1.4 Oil illing

The pump is shipped without oil. After level installation and correct rotation has been established, fill

the pump with recommended vacuum pump oil through the oil fill port. Oil level should be at the 3/4

positions on the oil sight glass.

Non-detergent oil should be used. We recommend original Eurovacuum Vacuum Pump oil.

Eurovacuum oil is a high quality vacuum oil that will provide longer running time between oil

changes, better lubrication at high operating temperatures and prolongs the life of the exhaust filter

elements. Oil detergent additives can cause exhaust filters to become clogged and shorten their

service life.

Depending on the ambient temperature around the pump, following oil is recommended.

Ambient Temp. Type of Oil For Model

0ºC~ 30ºC EV-Mineral Oil-32 EV-0010, 0016 & 0021

< 0ºC EV-Mineral Oil-32

EV-0030 till EV-0750 0ºC~ 30ºC EV-Mineral Oil-100

> 30ºC or < 0ºC EV-Syntheti Oil-500

Ordering information on Eurovacuum oil:

Mineral oil Mineral oil Synthetic oil Foodgrade oil

EV-mineral 32 EV-mineral 100 EV-synthetic 500 EV-foodgrade 100

Article number Article number Article number Article number

1 ltr can 100110 100100 100200 100300

5 ltr can 100112 100102 100202 100302

20 ltr can 100113 100103 100203 100303

The following table gives the approximate quantities of oil required for each model.

Pump Model Capacity (ltr)

EV-0010/0016/0021 0,5

EV-0030/0040 1,4

EV-0063 2,5

EV-0100 2,7

EV-0160/0215 7,0

EV-0175/0250/0300 7,0+

EV-0450/0500/0630/0750 19,0

Do not add oil with pump running or through the inlet or exhaust ports! Do not overfill.

2.0 SA ETY

Please read the following safety notice carefully before operating the pump.

2.1 General Notices

- Understand fully this installation and operating manual before operation.

- The other person except authorized operator should not operate the pump

- When the pump is not properly working, it should be stopped immediately.

- Eurovacuum shall have no liability for any accident and failure arising from no compliance with

instructions in this manual.

2.2 Warning labels and its explanation

Following warning labels are shown and attached on EV-series pumps

2.2.1 Read and Understand a manual:

Read and understand operator’s manual before using this machine

2.2.2 Burn Hazard:

Hot surface. Do not touch.

2.2.3 Loud noise Hazard:

Loud noise hazard. Ear protection must be worn.

2.2.4 Hazardous Voltage:

Disconnect power before opening. Contact causes severe electrical shock

2.3 Location of the labels

The labels of 2.2.1 Read and Understand a manual, 2.2.2 Burn Hazard and 2.2.3 Loud noise

Hazard shall be shown on the oil sump top of EV-series pump.

The label of 2.2.4 Hazardous Voltage shall be shown on the cover of motor’s terminal box

3.0 OPERATION

3.1 Start-up

Check rotation of the motor as described in paragraph 1.3 Power Requirements.

Fill the pump with oil as described in paragraph 1.5 - Oil Filling

Start the pump with the inlet closed. Run the pump for a few minutes and then shut down. Check the

oil level again and make sure the oil level is between the 3/4 marks and full on the upper oil sight

glass.

Add oil, if necessary. Pump oil should only be added when the pump is off and circulating oil has

sufficient time to return to the oil sump.

f the ambient temperature is below 10°C, it is recommended to use a heater with thermostatic

control to warm up oil to room temperature. f necessary, the heater with control can be used to

keep the oil temperature at operating temperature for immediate start up with system where water

vapor comes in. Please consult Eurovacuum or representative for installation of a heater with

control.

3.2 Stopping the pump

To stop the pump, turn off the power. A built in anti-suck back valve will prevent oil from the oil

reservoir being sucked back into the cylinder after the pump is shutdown.

Do not utilize the anti-suck back valve as a check valve. Consult Eurovacuum for proper

check valves.

3.3 Gas Ballast

Most EV-series pumps are equipped with gas ballast. The gas ballast valve is located between the

inlet port and the exhaust box. ts main function is to prevent water vapour from condensing in the

pump that causes emulsification of the oil resulting in possible pump failure.

n applications, when the quantity of water vapour is moderate, it is recommended to run the pump

for 10 to 30 minutes to its normal operating temperature (about 75˚C), prior to going on process with

suction line shut off. The pump should also be operated off process for 10 to 30 minutes prior to shut

down. A slight air bleed (purge) is recommended during these 10 to 30 minute cycles to prevent the

vapour from condensing in the pump.

3.4 Check Valve (Built-In)

EV-series pumps are equipped with Built-in Check Valve. The valve is located in the inlet flange

housing, which is in the upper part of Pump module to prevent oil back to inlet side (system) when

the pump is running off.

(However, it is recommended to install separate check valve in the line of inlet if necessary)

3.5 Exhaust Pressure Gauge

This gage shall be installed on the Oil fill Plug for easy checking of status of saturation of the

exhaust filter.

f the reading is 0,6 Bar or higher, you need to change the exhaust filter(s) with new one(s).

4.0 MAINTENANCE

EV-Series vacuum pumps require very little maintenance. To ensure optimum performance, the

following maintenance steps should be followed:

4.1 Pump Oil

4.1.1 Oil Level

Under normal circumstances it should not be necessary to add oil between oil changes. A

significant drop in oil level means there is either an oil leak, a defective exhaust filter or O-ring, or

a leaking anti-suck back valve. f the pump is smoking excessively, the exhaust filter may be

installed improperly.

t is normal for the oil to be foamy or lightly coloured in an operating pump. This may be normal

aeration of the oil. f the oil appears milky or dark coloured, it is contaminated or burned and must

be changed.

Check the oil level only when the pump is shut off. Replenish oil if it drops below the ¼ mark of the

sight glass.

Caution: Do not add oil while the pump is running, since hot oil can escape from the oil fill port.

4.1.2 Oil Type and Quantity

See section 1.5 - Oil Filling - for details on oil type and quantity

4.1.3 Oil Change

Oil life is dependent on the operating conditions. A clean and dry air stream and operating

temperatures below 100˚C are ideal. When using proper Vacuum Pump Oil, it is recommended to

change the oil every 500-1000 operating hours or after half year. Oil life can be shorter than 500

hours if the pumps are operated under unfavorable operating conditions Oil change frequency is

dependent upon the application and ambient temperature. t is recommended that the customer

monitor the condition of the oil during this period.

Caution: Always change the oil when the pump is off but still at working temperature.

hen disposing of used oil, please observe the relevant environmental regulations.

4.1.4 Oil Spin-On ilter

Replace automotive-type spin on filter at every oil change.

Pump Model Part No.

EV-0030 ~ EV-0100 006010000

EV-0160 ~ EV-0300 050010000

EV-0450 ~ EV-0750 120010000

4.2 Inline (Inlet) ilter

Check inline (inlet) filter on a weekly basis. The filter cartridge should be cleaned or replaced when

dirty. Consult Eurovacuum for replacement element information.

Caution: Depending on the mounting position of the filter, be careful not to allow

accumulated foreign material to fall in the pump suction inlet when removing the filter

cartridge. Horizontal filter installation is recommended to prevent this.

4.3 Exhaust ilter

Replace these filters every 9 to 18 months of operation or as necessary. The service life of these

filters varies depending upon the application and frequency of oil change. t is necessary to change

these filters only when they become clogged. ndications of clogged filters are smoke or oil mist

coming from the exhaust of the pump, higher than normal motor current, and the exhaust pressure

gauge reading 0,6 bar or greater.

Pump Model Part No. No. required

EV-0010 ~ EV-0021 002012000 1 pc

EV-0030F 0060120B0 1 pc

EV-0040F ~ EV-0100F 0060120B0 2 pc

EV-0160F 0430120A0 1 pc

EV-0160G 0430120B0 1 pc

EV-0215F 0430120A0 2 pc

EV-0215G 0430120B0 2 pc

EV-0175F ~ EV-0300F 0500120A0 4 pc

EV-0450F ~ EV-0750F 1200120A0 8 pc

n cases where the vacuum level of the process is causing a large quantity of oil mist exhausting from

the pump, it is possible to mount the 1200120A0 filters inside of the EV-0175, 0250 & 0300 pumps.

Do not clean or re-use these filters. ilters must be disposed of in a proper way as they might

contain toxic substances carried over from the process. Replace O-rings on filter when

changing.

4.4 Gas ballast filter

Replace or clean the filter every as necessary or annually.

Type: 1) EV-0030 to 0100: Gas ballast without valve with paper filter - Replace paper filter

2) EV-0160 to 0750: Gas ballast with valve & sponge filter – Clean/replace the sponge filter

4.5 Maintenance Chart

Daily : visually check oil level and colour.

Weekly : inspect inline (inlet) filter and check oil leaks from the vacuum pump.

Monthly : check the exhaust filter function

( f oil mist at exhaust, replace the exhaust filter with O-ring).

Every 2- 6 month : drain and discard oil from pump while hot. Refill with fresh oil.

Every 9-18 month : replace exhaust filter elements with O-ring and gas ballast filter.

Every 500 ~ 2000 operating hours:

Change the oil and oil filter. n version of float valve with oil return line,

check the float valve’s operating conditions.

For motor - See the motor manufacture's manual for periodic motor maintenance.

The operating life of the pump is greatly enhanced based on the oil quality and condition of

the filters. Periodic maintenance will ensure a reliable operating vacuum pump.

4.6 Gasket Kit, Overhaul Kit and other Parts

A gasket kit contains a full set of gaskets and O-rings

A Overhaul (Maintenance) kit contains a set of gaskets, O-rings, vanes, bearing, bearing sleeves,

shaft seals and taper pins, oil filter and exhaust filter(s).

A Service kit contains motor coupling insert(s), filters, seals for filter exchange & oil exchange.

Other parts are available. Please consult Eurovacuum parts department for information.

5.0 PROBLEM SOLVING

5.1 Problem

Pump does not reach end pressure. This is the lower absolute (best vacuum) when running with the

inlet closed.

5.1.1 Possible Cause

Oil condition is most often the cause of not reaching end vacuum.

Remedy : drain oil from pump and refill with fresh oil. Run pump with fresh oil for 15 minutes

then take new pressure reading.

5.1.2 Possible Cause

nlet screen clogged with debris.

Remedy : clean screen and check inlet filter element.

5.1.3 Possible Cause

Shaft seal leak

Remedy : replace shaft seal from overhaul kit, or call Eurovacuum for exchange program.

5.1.4 Possible Cause

Vane stuck in rotor slot.

Remedy : drain oil with flushing oil. Run pump for 15 minutes and drain. Replace fluid with

fresh oil, exhaust filter, and spin on filter.

- replace vane from overhaul kit or call Eurovacuum for exchange program

5.1.5 Possible Cause

Anti-suck back valve stuck in closed position due to oil contamination.

Remedy : disassemble valve and screen, clean as required. Drain old oil and replace with fresh

oil.

5.1.6 Possible Cause

No oil or low oil level in reservoir.

Remedy : shut down pump, drain balance of oil and refill with fresh oil.

5.1.7 Possible Cause

Vacuum fitting or hose is not leak tight.

Remedy : check hose and pipe connections for leaks.

5.1.8 Possible Cause

Radial clearance between rotor and cylinder are no longer adequate.

Remedy : overhaul pump or call Eurovacuum for exchange program.

5.1.9 Possible Cause

Float Valve does not close well.

Remedy : check the condition of float valve, and adjust the nozzle position or repair it.

5.2 Problem

Pump runs very noisy.

5.2.1 Possible cause

Coupling insert is worn.

Remedy : replace coupling insert in motor/pump coupling.

5.2.2 Possible Cause

Vanes stuck

Remedy : follow flush procedure from 5.1.4 or replace vane or call Eurovacuum for exchange

program.

5.2.3 Possible Cause

Bearing noise

Remedy : replace bearings or call Eurovacuum or exchange program.

5.3 Problem

Pump starts, but labours and draws high amperage.

5.3.1 Possible Cause

Oil is too viscous.

Remedy : drain and change with fresh oil or correct oil with recommended viscosity.

5.3.2 Possible Cause

Exhaust filter is clogged

Remedy : replace exhaust filters, maintain proper oil condition, oil level and use Vacuum pump oil.

- make sure inlet filter is operational preventing particulate carryover.

5.3.3 Possible Cause

Loose connection in motor terminal box wired for wrong voltage.

Remedy : check wiring diagram for proper connections; tighten or replace loose connections.

5.3.4 Possible Cause

Foreign particles in pump. Broken vanes or seized bearings.

Remedy : overhaul pump or call Eurovacuum for exchange program.

5.3.5 Possible Cause

Pump is overfilled with oil or wrong kind of oil is in pump.

Remedy : drain oil; use correct type of Vacuum pump oil.

5.3.6 Possible Cause

Pump runs in wrong direction.

Remedy : check for correct rotation. f incorrect, switch any two leads.

5.4 Problem

Pump will not start.

5.4.1 Possible Cause

Supply voltage is not proper or is overloaded. Motor starter overload settings are too low or

improper; fuses are burned; wire size is too small or too long causing a voltage drop.

Remedy : check voltage supply; overload settings in motor starter for size and settings

according to motor nameplate. nstall proper size wire. f ambient temperature is high,

use the next larger size overloads or adjust settings 5% above motor nameplate valve.

Remedy : turn pump fan by hand. f it will not turn, remove motor from pump and check motor

and pump separately. Repair or replace if needed or call Eurovacuum for exchange

program.

5.4.2 Possible Cause

Oil temperature is below 12°C or oil is too viscous due to contamination.

Remedy : Heat the pump and oil, or change the oil.

5.5 Problem

Pump smokes at the exhaust side or expels oil droplets from the exhaust.

5.5.1 Possible Cause

Exhaust filters are not properly installed with O-ring; Filter media is damaged.

Remedy : check exhaust filter placement and replace if needed.

5.5.2 Possible Cause

Exhaust filters are clogged with foreign particles.

Remedy : replace filter and O-ring.

5.5.3 Possible Cause

Oil is not re-circulating properly.

Remedy : check oil quality and make certain oil lines are clean.

5.6 Problem

Pump is running too hot. (Typical operating temperature of the EV-Series pump is 50°C ~ 95°C)

5.6.1 Possible Cause

Not enough oil in the oil reservoir or oil is badly burned or carbonized.

Remedy : check upper part of oil sump (open the exhaust filter cover) if there is the oil filled and

not re-circulated to the inlet side of pump, check the condition of float valve (in Oil Sump or Float

Valve Box), and adjust the nozzle position or change the float if float is not float well, or check oil

return line if it is not clogged or not.

Remedy : drain oil and refill with proper Eurovacuum oil; change oil more frequently.

5.6.2 Possible Cause

Not enough air ventilation to the pump

Remedy : clean radiator and motor fins. Make certain a sufficient amount of fresh air is

supplied to the pump.

5.7 Problem

Pump will not operate (seized up).

5.7.1 Possible cause

Pump operated without oil and vanes broke

Remedy : Call Eurovacuum for exchange program

5.7.2 Possible Cause

Liquid carry over into pump cylinder broke vanes while pump was running.

Remedy : nstall knock-out pot at inlet of pump

6.0 TECHNICAL DATA

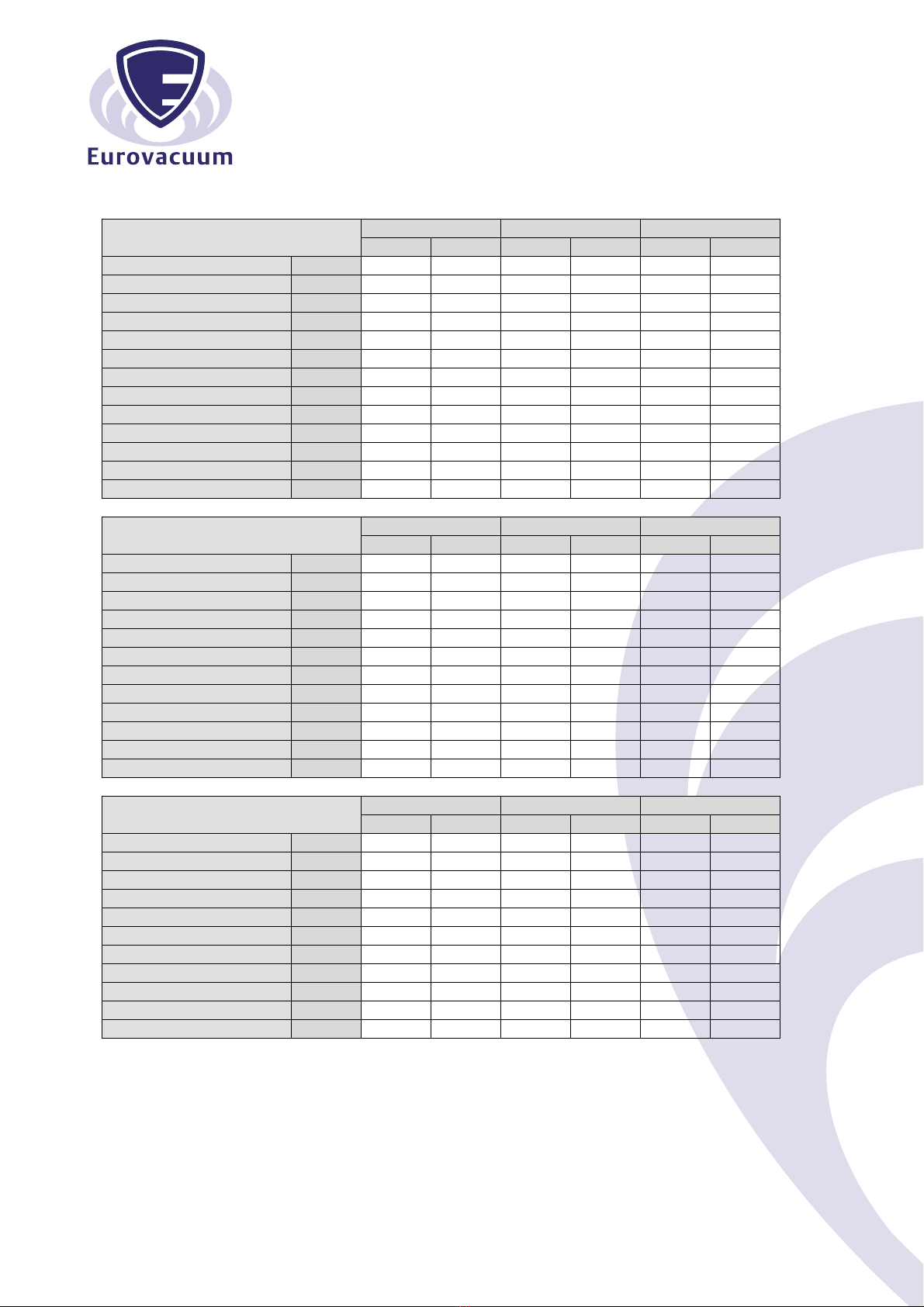

Technical Data EV-0010 EV-0016 EV-0021

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Nominal displacement

m

3

/h

10

12

16

19

20

24

Ultimate pressure NM type

mbar

2

2

2

2

2

2

L type

mbar

20

20

20

20

20

20

Motor power

phase

kW

0,4

0,4

0,

55

0,

7

5

0,

75

0,9

Motor power

1

phase

kW

0,4

0,4

0,

7

5

0,

7

5

0,9

0,9

Nominal speed

rpm

1450

1740

1450

1740

2870

480

Noise leve

l

dB(A)

57

59

58

60

60

62

Operating temperature

°C

77

77

80

80

85

85

Oil capacity

ltr

0,5

0,5

0,5

0,5

0,5

0,5

Weight

kg

2

0

20

22

22

20

20

Admissible ambient temp.

°C

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

Connection Inlet

G(BS

P)

½”

½”

½”

½”

½”

½”

Outlet

G(BSP)

½”

½”

½”

½”

½”

½”

Technical Data EV-0030F EV-0040F EV-0063F

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Nominal displacement

m

3

/h

0

6

4

0

48

6

7

5

Ultimate pressure

mbar

0,

1

0,

1

0,

1

0,

1

0,

1

0,

1

Motor power

phase

kW

0,9

1,1

1,1

1,5

1,5

2,2

Motor power

1

phase

kW

1,5

1,5

1,5

1,5

-

-

Nominal speed

rpm

1450

1740

1450

1740

1450

1740

Noise level

dB(A)

64

67

64

67

65

68

Opera

ting temperature

°C

76

76

78

78

85

85

Oil capacity

ltr

1,

4

1,

4

1,

4

1,

4

2,

5

2,

5

Weight

kg

47

47

5

5

6

4

6

4

Admissible amb

ient temp.

°C

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

Connection Inlet

G(BSP)

1¼”

1¼”

1¼”

1¼”

1¼”

1¼”

Outlet

G(BSP)

1¼”

1¼”

1¼”

1¼”

1¼”

1¼”

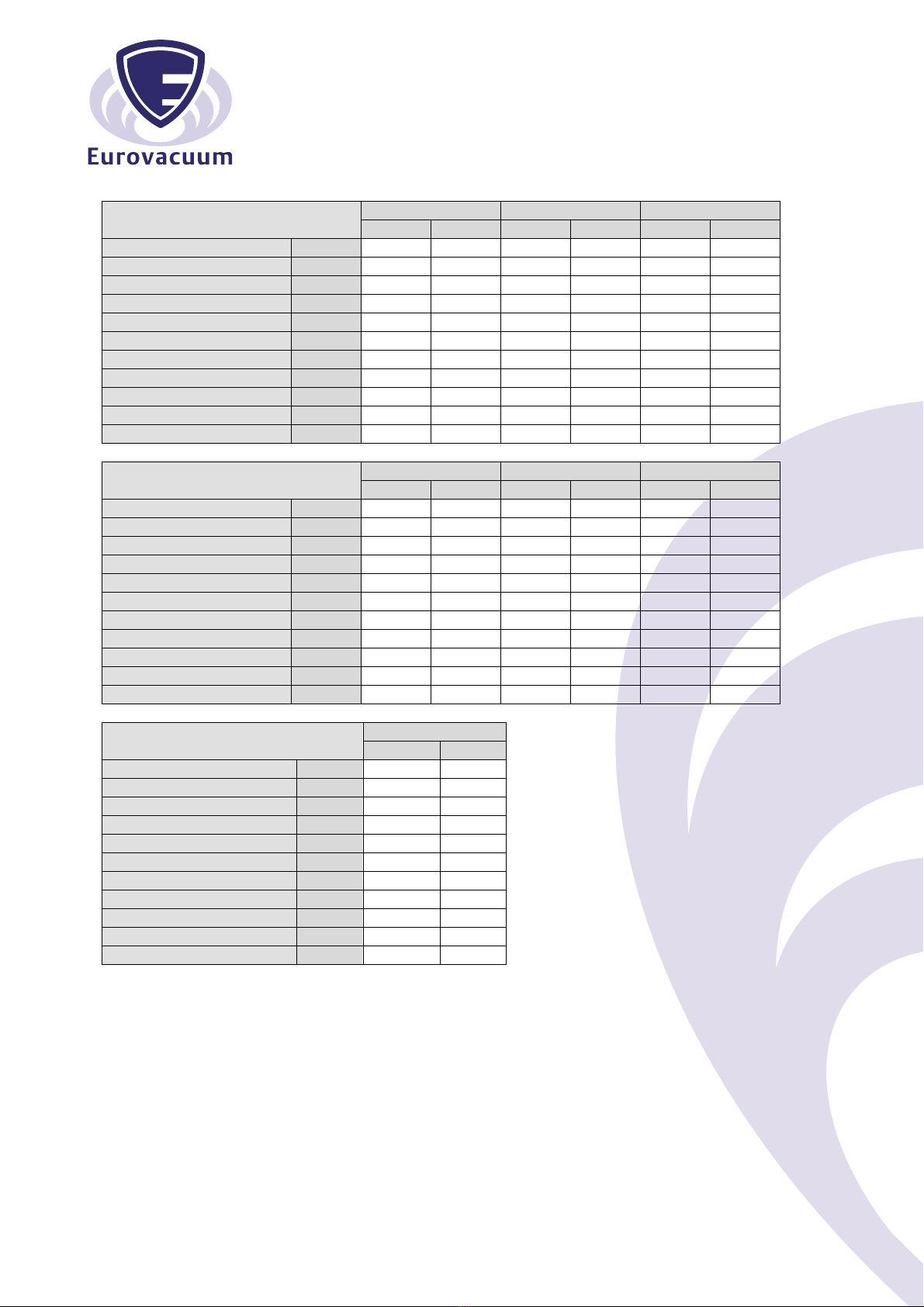

Technical Data EV-0100F EV-0160G EV-0175F

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Nominal displacement

m

3

/h

100

120

160

1

92

175

210

Ultimate pressure N type

mbar

0,

1

0,

1

0,

1

0,

1

0,

1

0,

1

Motor power

phase

k

W

2,2

,0

,7

,7

5,5

5,5

Nominal speed

rpm

1450

1740

1450

1740

1450

1740

Noise level

dB(A)

65

68

7

2

7

5

74

77

Operating temperatu

re

°C

85

85

85

85

85

85

Oil capacity

ltr

2,

7

2,

7

7

,0

7,0

7,0

7,0

Weight

kg

75

75

124

124

164

164

Admissible ambient temp

.

°C

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

Connection Inlet

G(BSP)

1¼”

1¼”

2”

2”

2”

2”

Outlet

G(BSP)

1¼”

1¼”

2

”

2

”

2”

2”

Technical Data EV-0215G EV-0250F EV-0300F

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Nominal displacement

m

3

/h

215

258

250

00

00

60

Ultimate pressure

mbar

0,

1

0,

1

0,

1

0,

1

0,

1

0,

1

Motor powe

r

kW

5,5

5,5

5

,5

7,5

7,5

9,2

Nominal speed

rpm

1450

1740

1450

1740

1450

1740

Noise level

dB(A)

74

77

74

77

75

78

Operating temper

ature

°C

85

85

85

85

85

85

Oil capacity

ltr

7

,0

7

,0

7,0

7,0

7,0

7,0

Weight

kg

145

145

184

184

188

188

Admissible ambient

temp.

°C

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

Connection Inlet

G(BSP)

2”

2”

2”

2”

2”

2”

Outlet

G(BSP)

2

”

2

”

2”

2”

2”

2”

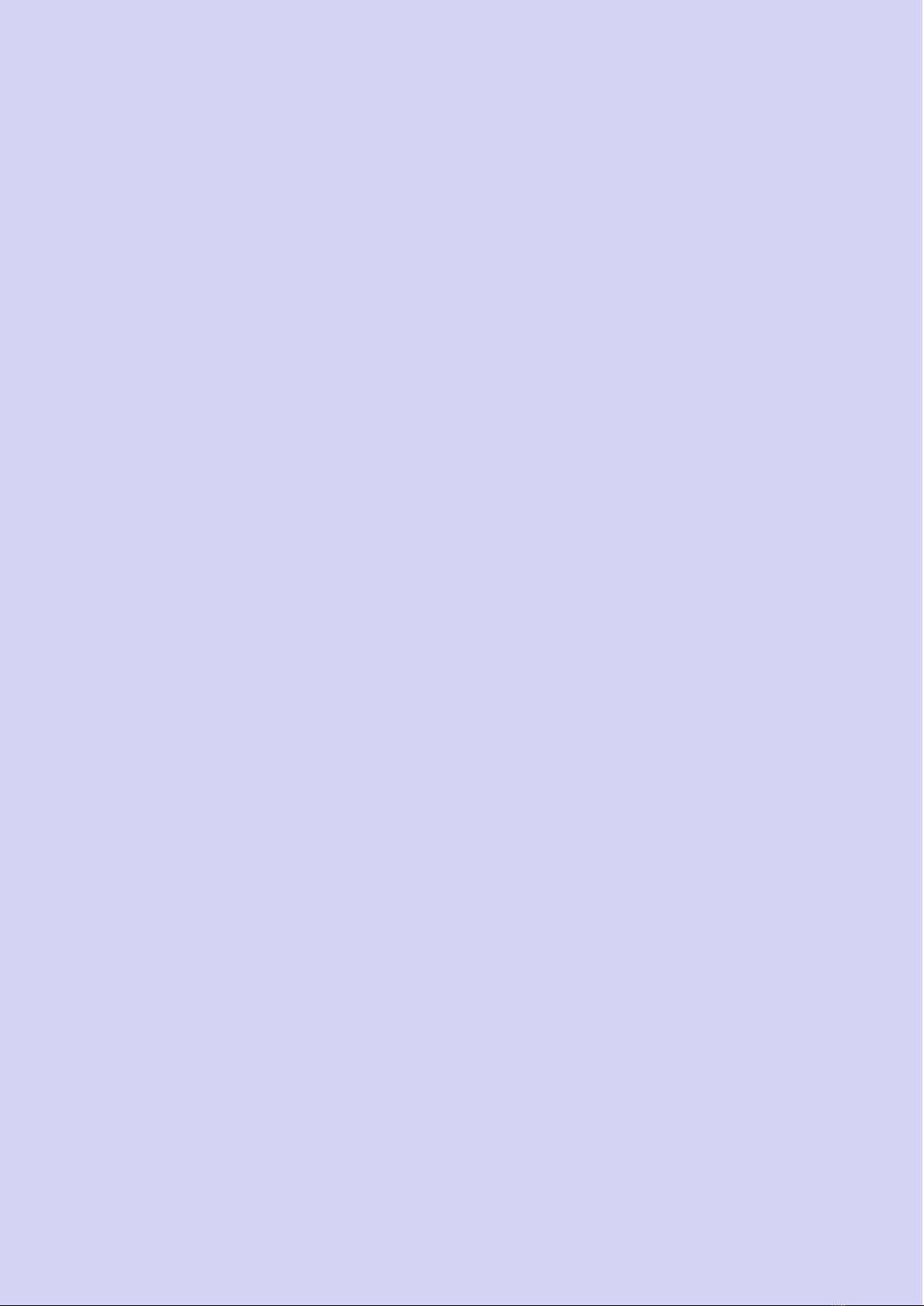

Technical Data EV-0450F EV-0500F EV-0630F

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Nominal displ

acement

m

3

/h

42

0

505

50

0

6

0

0

6

60

780

Ultimate pressure

mbar

0,

1

0,

1

0,

1

0,

1

0,

1

0,

1

Motor power

kW

11,25

15,0

1

1,25

15,0

15,0

18,5

Nominal speed

rpm

980

1160

980

1160

980

1160

N

oise level

dB(A)

7

6

7

8

77

7

9

77

79

Operating temperature

°C

80

80

8

2

8

2

80

80

Oil capacity

ltr

19

19

19

19

19

19

Weight

kg

491

5

04

5

1

5

44

582

70

Admissible ambient temp.

°C

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

10 to 40

Connection Inlet

G(BSP)

”

”

”

”

”

”

Outlet

G(BSP)

”

”

”

”

”

”

Technical Data EV-0750F

50 Hz 60 Hz

Nominal displ

acement

m

3

/h

75

0

-

Ultimate pressure

mbar

0,

1

-

Motor power

kW

1

8,5

-

Nominal speed

rpm

1500

-

N

oise level

dB(A)

7

9

-

Operating temperature

°C

8

5

-

Oil capacity

ltr

19

-

Weight

kg

5

5

-

Admissible ambient temp.

°C

10 to 40

-

Connection Inlet

G(BSP)

”

-

Outlet

G(BSP)

”

-

Eurovacuum Head office Tel. +31-(0)854890993

Einsteinstraat 58 [email protected]

2811EP Reeuwijk http://www.eurovacuum.eu

The Netherlands

This manual suits for next models

16

Table of contents

Other Eurovacuum Water Pump manuals