EUTHANEX SmartBox M1TSFF2C-FM User manual

Auto CO2System

Models M1TSFF2C-FM

4/21/2020

877-559-0159 Toll Free Euthanex Corp. / E-Z Systems Inc.

610-559-0159 Phone P.O. Box 3544

610-821-3061 Fax Palmer, PA 18043

www.euthanex.com [email protected]m

2

TABLE OF CONTENTS

Disclaimer ____________________________________ 3

System Overview _______________________________ 4

Saftey________________________________________ 5

System Setup __________________________________ 6

Operating the System ___________________________ 13

Changing Operating Specifications _________________ 20

Troubleshooting _______________________________ 30

EMC / EMI.

This equipment has been tested and found to

comply with the limits for a Class A Equipment,

pursuant to part 15 of the FCC rules.

IEC 61326-1:2005 / EZ 61326-1:2006

3

DISCLAIMER

THIS MANUAL MUST BE READ BEFORE SETTING UP AND OPERATING THE AUTO CO2

SYSTEM. The user should be thoroughly familiar with the contents of this manual prior to using the

system with animals. Only technicians that are properly certified should operate the Auto CO2System.

The user/owner of this equipment shall have the sole responsibility for any damage or injury resulting

from operation that is not in accordance with the authorized instructions. This includes, but is not limited

to, operating the equipment outside of recommended safety levels, variation from specified operating

instructions and not following standard laboratory safety procedures when working with anesthetic

agents and volatile compressed gases.

The system and its components must only be modified or repaired by Euthanex-authorized service

technicians. Improper modification or repair may result in danger to personnel, harm or death to animals

and/or equipment damage. The user/owner of this equipment shall have the sole responsibility for any

damage or injury resulting from improper maintenance and repair that is not done by authorized

maintenance and repair personnel.

Parts that have failed, in whole or in part, exhibit excessive wear, are contaminated or are otherwise at

the end of their useful life, should not be used and should be replaced with parts supplied by Euthanex

Corporation. Tampering with the controller unit by unauthorized personnel voids all warranties and

specifications. The manufacturer assumes no responsibility for any malfunction or failure of the unit if

tampering is suspected.

4

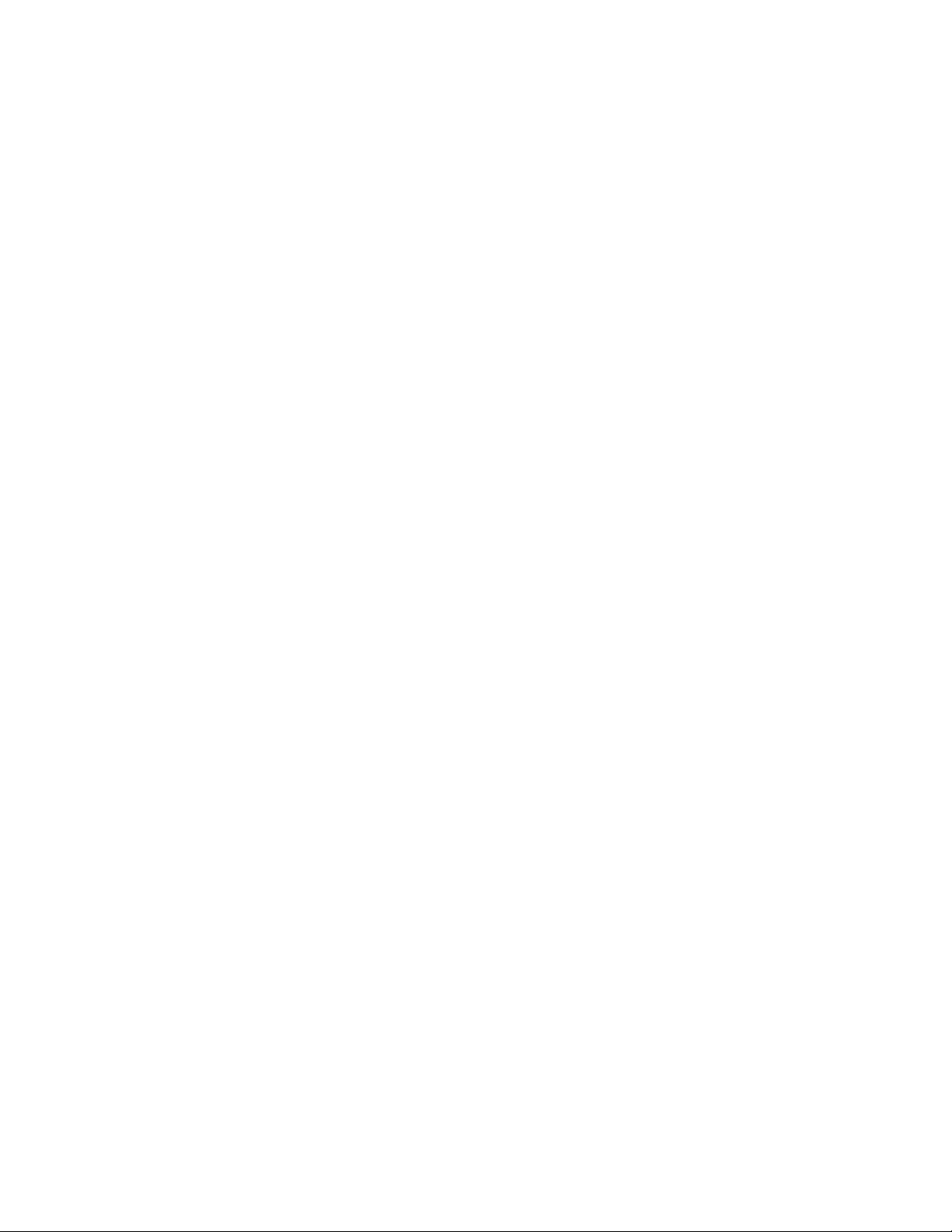

SMARTBOX FIXED FLOW SYSTEM OVERVIEW

The SmartBox Fixed Flow M1-TSFF Auto CO2System is an advanced automated euthanasia unit that

has been developed specifically for euthanizing small rodents. The system incorporates three key

components, the SmartBox Fixed Flow Controller, the M1 Chamber and the Exhaust Blower. The

system works with preset timings that assure humane and efficient levels of CO2. Gas flow rate is set at

the source (fixed flow), while the timings are controlled by the automated controller unit. The

controller does not impact the flow rate, but delivers gas at the rate that is output by the source.

The TSFF Controller operates in preset automated stages:

1) Gas Flow: Flow rate is set to conform to the AVMA guidelines for humane

euthanasia. CO2flows into the top chamber and anesthetizes the animals with minimal

stress. While the animals are anesthetized, the gas flow continues and increases the

chamber’s CO2concentration to euthanizing level.

2) Dwell Time: Gas flow shuts off and the chamber remains fully charged to assure

euthanasia of all animals.

3) Optional 2nd Gas Charge can be set for each species registered in system.

4) Evacuation Time: Onboard blower evacuates CO2out of the chamber and into the in-house

exhaust system and then shuts off after the chamber is fully purged. All gas is completely

purged from the chamber, making it safe for personnel to remove cages at the completion

of the cycle.

5

The lightning flash with an arrowhead

symbol within an equilateral triangle, is

intended to alert the user to the presence of

uninsulated "dangerous voltage" within the

product's enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to

persons.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this unit near water.

6. Do not clean by spraying liquid directly onto

unit.

7. Do not block any ventilation openings.

Install in accordance with the manufacturer's

instructions.

8. Do not install near any heat sources such

as radiators, heat registers, stoves, or other

unit that produce heat.

9. Do not defeat the safety purpose of the

polarized or grounding-type plug. A

polarized plug has two blades with one

wider than the other. A grounding type plug

has two blades and a third grounding

prong. The wide blade or the third prong

are provided for your safety. If the provided

plug does not fit into your outlet, consult an

electrician for replacement of the obsolete

outlet.

10. Protect the power cord from being walked

on or pinched particularly at plugs,

convenience receptacles, and the point

where they exit from the unit.

11. Unplug this unit during lightning

storms or when unused for long periods of

time.

12. Refer all servicing to qualified service

personnel. Servicing is required when the

unit has been damaged in any way,

such as power-supply cord or plug is

damaged, liquid has been spilled or objects

have fallen into the unit, the

unit has been exposed to rain or

moisture, does not operate normally, or has

been dropped.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the product.

Warning!

•To reduce the risk of fire or electric shock,

do not expose this unit to rain or

moisture.

•Use line cord supplied with the product.

•Be advised that different operating voltages

require the use of different types of line

cord and attachment plugs. The unit was

shipped with the requested plug. If the

installation requirements change please

contact us for the correct plug.

•This equipment should be installed near the

socket outlet and disconnection of the device

should be easily accessible.

•Do not install in a confined space.

•Do not open the unit - risk of electric shock

inside.

Caution: You are cautioned that any change or

modifications not expressly approved in this

manual could void your authority to operate

this equipment.

Service

•There are no user-serviceable parts inside.

•All service must be performed by qualified

personnel.

Voltage

100-240 v ac 50-60hz 5 amp Max (auto

select)

Pressure

175 psi max to inlet

Temp

0 to 40°C <> 10 to 85% RH (no

condensation)

SYSTEM SETUP

1) The SmartBox controller is attached to the top M1 chamber utilizing the four keyholes on the back

of the controller. Note: The chamber door must be opened to hang controller.

Align the keyholes with the four screws on the left side of the chamber. Push in and slide down to

secure. The screws may be tightened for permanent mounting.

Screw mounts on chamber side

Controller keyhole mounted

on chamber screw

7

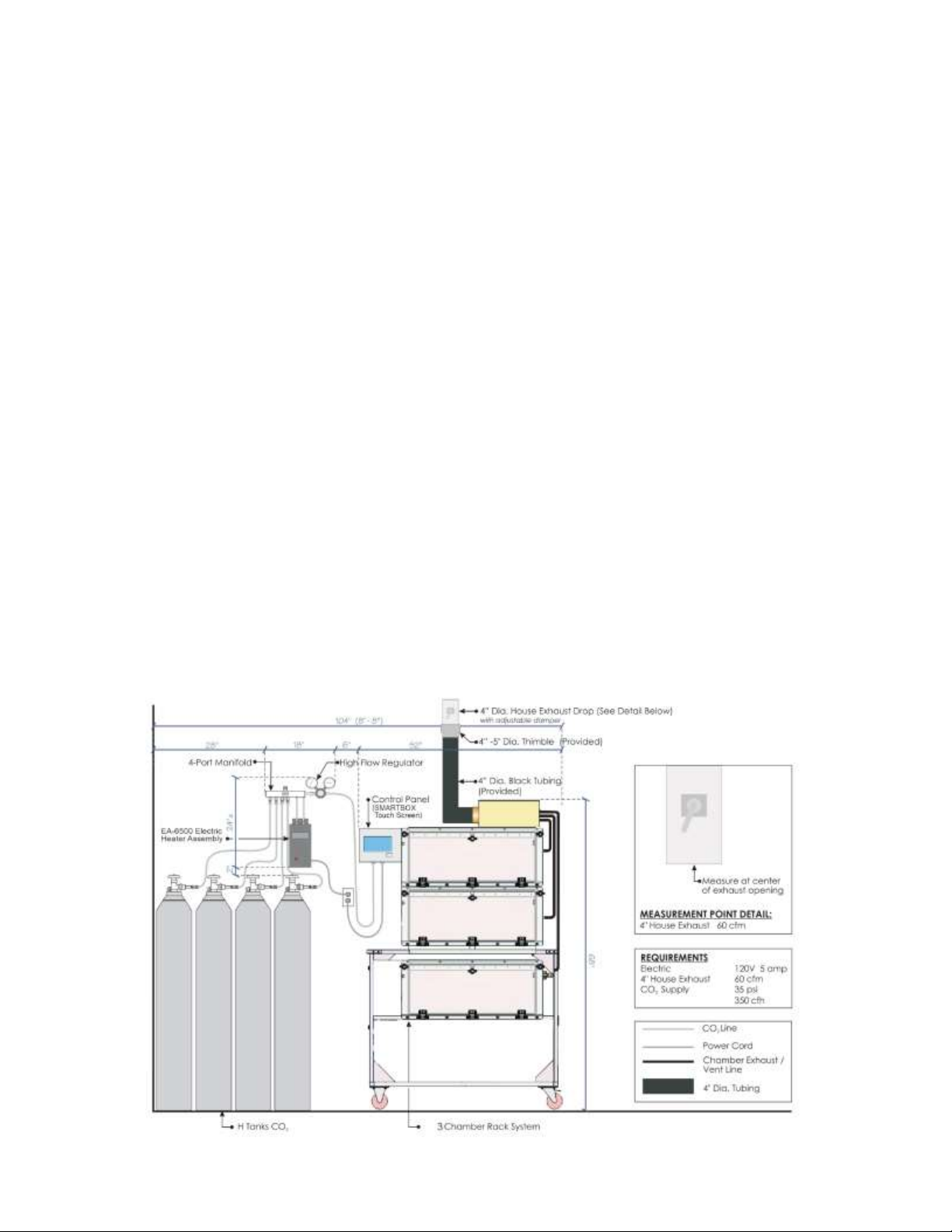

2) On the bottom of the SmartBox side control box is a brass CO2input fitting that must be connected

to the CO2supply. For Tank supply gas see step #9 and for house see step #12.

3) On the side of the M1 chamber is a brass CO2input fitting that must be connected to the CO2supply

line that is coming out of the side control box. Do this for each chamber in the system.

CO2Input Hose

CO2Input Connection

ConnCpmme.

CO2Input Fitting

8

4) TSFF-2C/3C Models Only are equipped with the ESC safety lock microswitch that allows the second

and third chamber to lock when in use. Use the four pin connector to attach to the back of the ESC.

5) Rest the exhaust blower on top of the chamber. The large 4” exhaust hose must be on left and the 1”

intake hose on the right.

6) Attach the 1” intake hose from the blower to the “CO2Out” on the right side of top chamber. The

clamp connector fastens by pulling the two clamps away from chamber. Do this for each chamber in

the system.

Connect the data cable 15 pin connector that is from the side control box to the female 15 pin

connector on the exhaust blower box next to the power

CO2Input to Exhaust Blower

CO2Output from Chamber

9

7) Attach the 4” exhaust hose from the blower to the in-house exhaust system. For facilities without

in-house exhaust, drop the exhaust hose to the floor, allowing the CO2to dissipate away from

personnel.

Euthanex also offers a flat wall plate thimble for adapting to flat return grates.

8) For hose supplied gas go to step #10

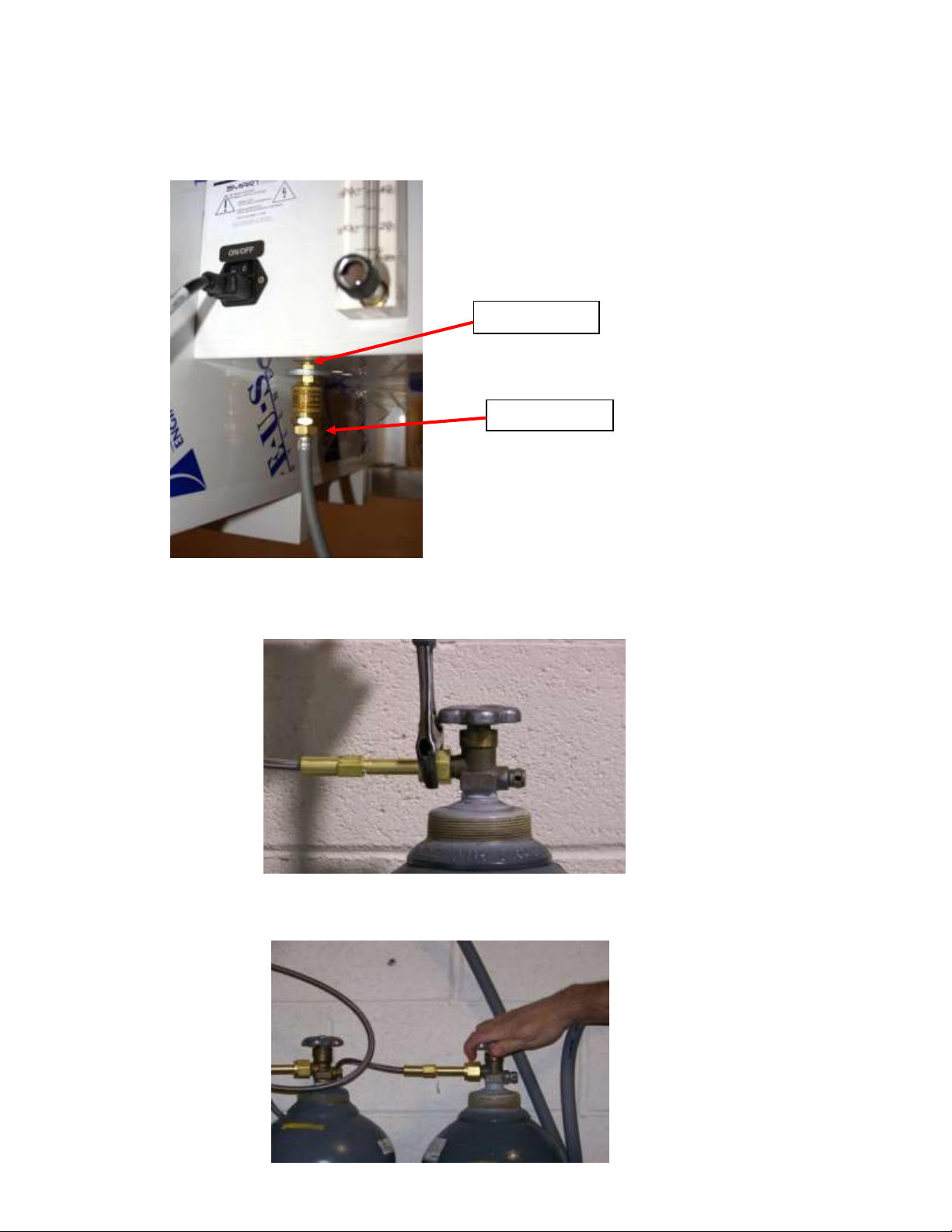

9) EA-6500 Install Instructions

The unit should be mounted above the top of the tanks as seen above. The power must be within 6 ft of

the mounting location.

Tools required: level, marker, 1/4 drill bit for concrete or drywall

Exhaust Blower

4” Exhaust

House

Damper

Thimble

10

A. Hold assembly firmly against the wall where you would like to mount your manifold.

B. Use level to ensure the manifold is level against the wall

C. Use a marker or pencil to scribe the four (4) holes, 2 located on the manifold bracket and 2

located on the regulator bracket.

D. Remove the assembly to expose scribe marks

E. Use a 1/4” drill bit (not included) and drill the four (4) holes

F. Insert the four (4) plastic anchors (included) and press firmly into the wall

G. Hold the assembly against the wall and line us the predrilled holes

H. Use a #2 screwdriver and screw the four (4) screws through the plate into the anchors

11

I. Connect the power cord. Turn on the heater and leave it on, it is thermostatically controlled.

J. Connect the hose from the regulator to the gas inlet on the side control box of your system.

K. Attach CO2 hoses to the tanks.

L. Once the tanks are connected, open the shutoffs.

CO2Input Fitting

CO2Input Hose

12

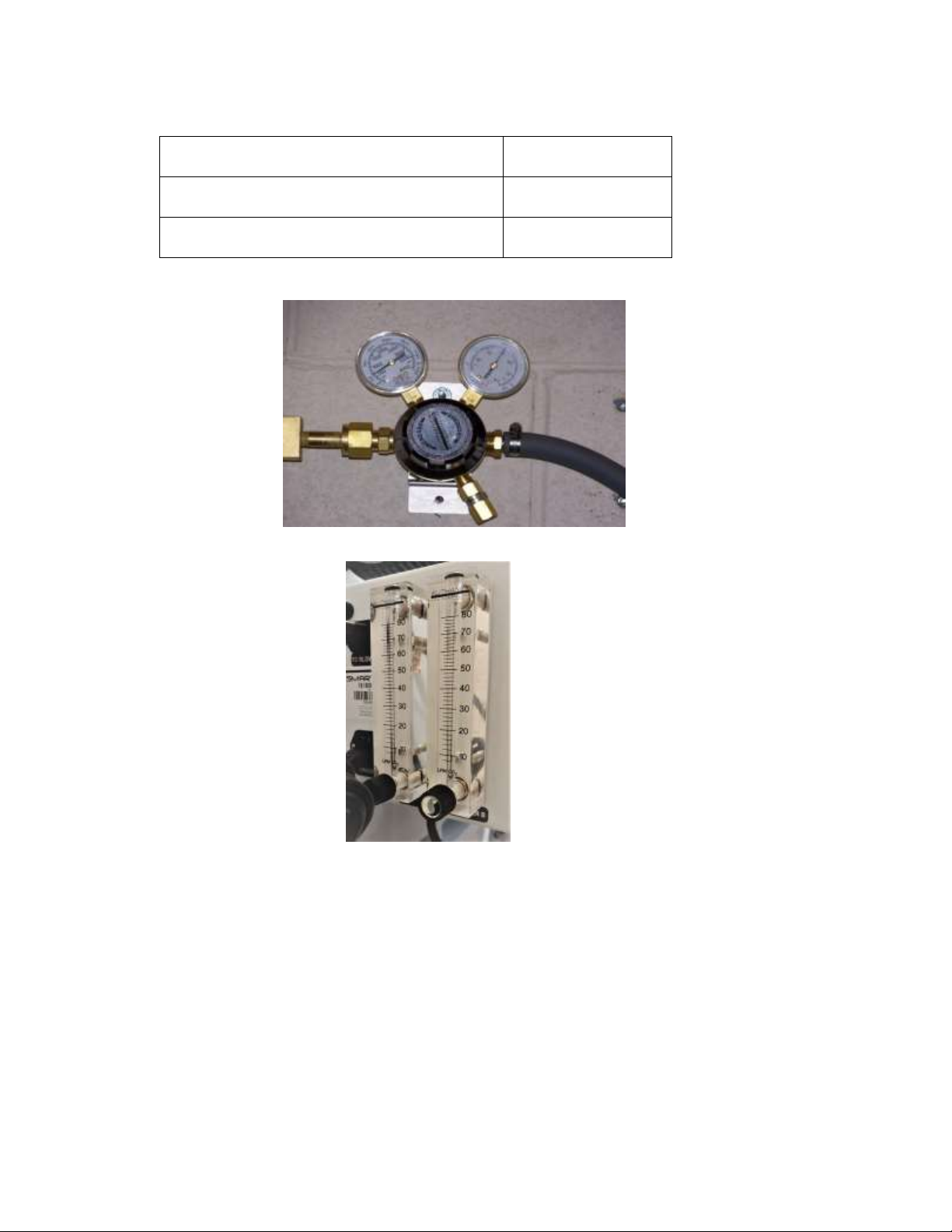

M. Adjust the regulator.

SYSTEM

SETTING

M1-TSFM-2

40 PSGI

M1-TSFM-3

40 PSGI

10) For house supplied gas connect the supplied FF-1130 hose from the barb on the house side to the

connector for gas in on the side control box as shown above.

For either methods of gas supply, gas flow is regulated using the flow meters on the back side of the

side control box. ADJUST GAS INLET RATE TO 60 LPM

13

11) Plug AC cord from SmartBox controller into AC power outlet.

12) Plug AC cord from exhaust blower into back of the SmartBox controller.

This outlet is to only be used for the EA-Blower supplied by Euthanex.

Cette sortie est à être utilisé uniquement pour l'EA-Soufflante fournies par Euthanex.

Plugging any other device into this outlet can cause electrical shock or fire.

Brancher un autre appareil sur cette prise peut provoquer un choc électrique ou un incendie.

Setup is now complete.

14

OPERATING THE SYSTEM

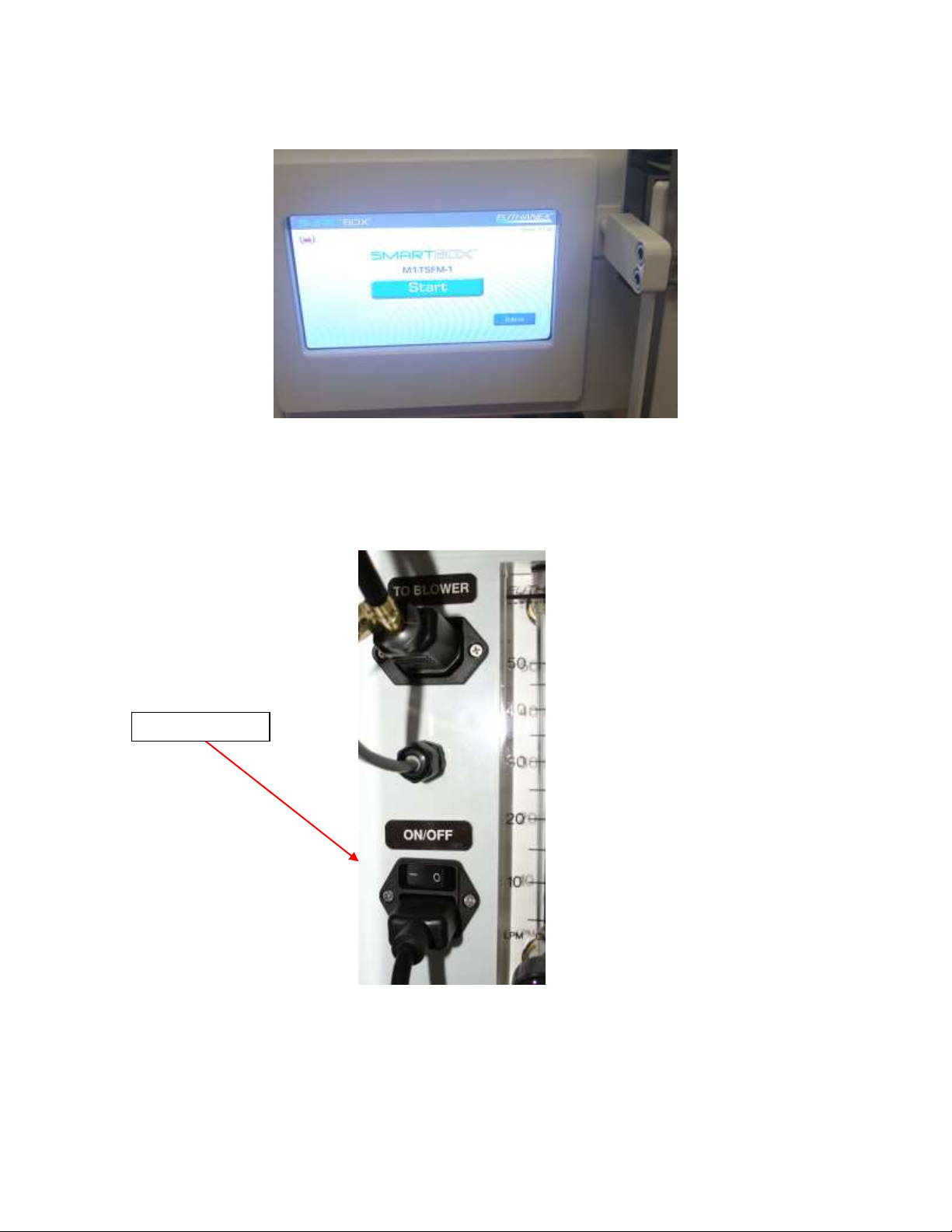

1) Press the On switch in the back of the SmartBox FF. The unit will boot and come to the home screen

ready for use. If this is the first time using the system the operating parameters must be setup prior

to running any cycles (see administrator instructions).

On/Off Switch

15

2) Turn the three knobs on the front of the M1 chamber door counterclockwise to open. Please note:

Knobs must be in a fully horizontal position in order to open.

3) The chamber(s) is now ready to be loaded. Cages with wire bar lids can be stacked in two layers. Do

not position upper layer cages directly on top of cages below. Cages must be slightly offset to allow

circulation of gas to lower level cages.

A chamber can accommodate up to 20 standard mouse cages or 3 standard rat cages. Number of

cages accommodated will vary based upon actual cage size. Do not attempt to place more cages

then will comfortably fit into the chamber.

Cages without wire bar lids require the optional “EZ-1315 Shelf Divider Panel.”

16

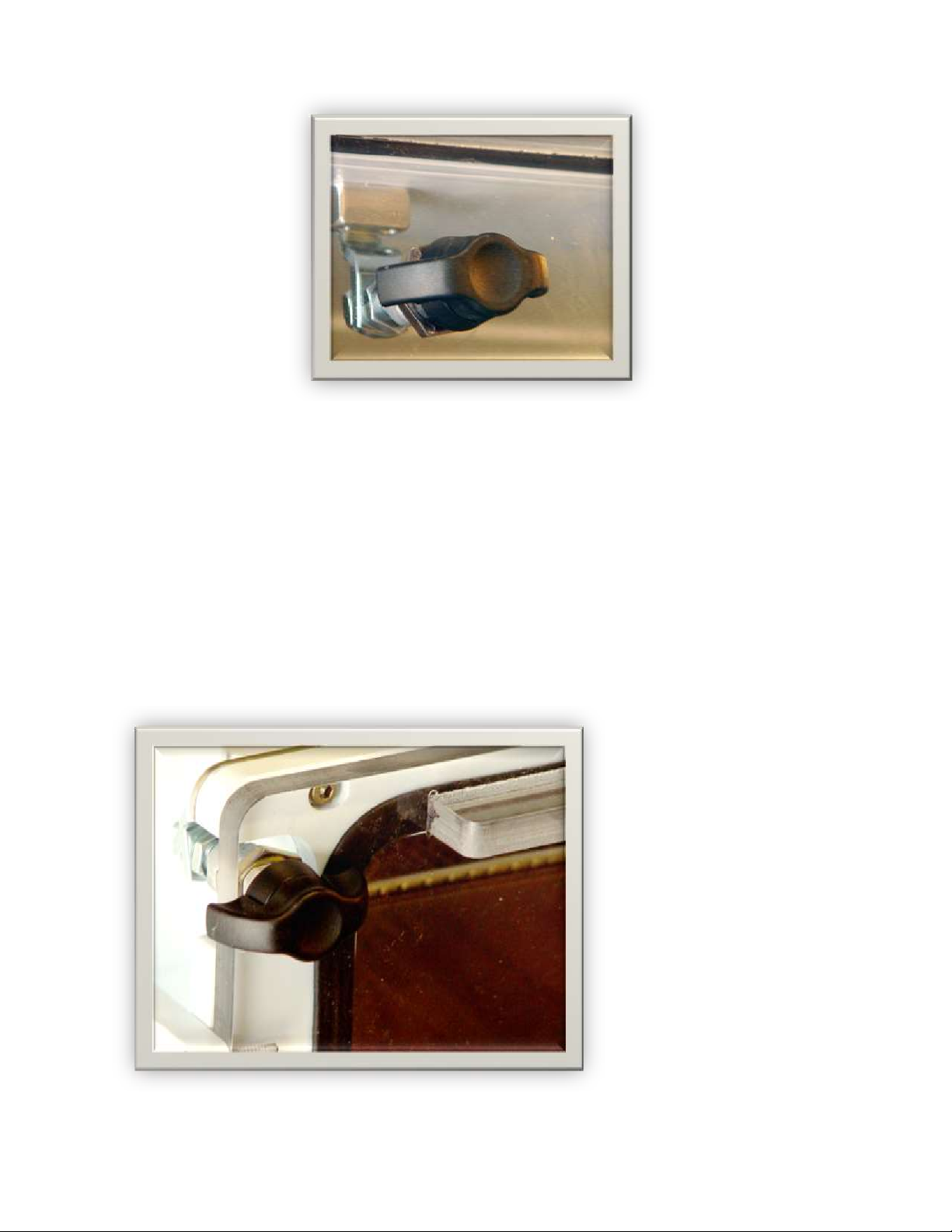

4) After the chamber is loaded, close the door and turn all three knobs fully clockwise to seal. If the

knobs are not fully turned, a slight gas leak may occur. The red “Fault” light indicates that the

door is open. It does NOT indicate that the door is not fully latched.

5) Open the gas flow from the CO2manifold by turning the regulator valve knob counterclockwise. The

left gauge should be reading 800 PSI if the tanks are full, less if it is not full tanks.

6) Open the gas flow out of the regulator by turning the control bar counterclockwise. This begins the

flow of gas to the controller. Set the regulator flow rate at 40 psgi.

CO2Tank Valve

System Pressure Gauge

Flow Gauge

17

7) From the home screen press start. Enter Password and hit “NEXT”

If the system has password turned on you will get the following screen. Enter password to move

forward.

8) Enter Password and hit “NEXT”

18

Note: The status button will show if any cycle is currently running.

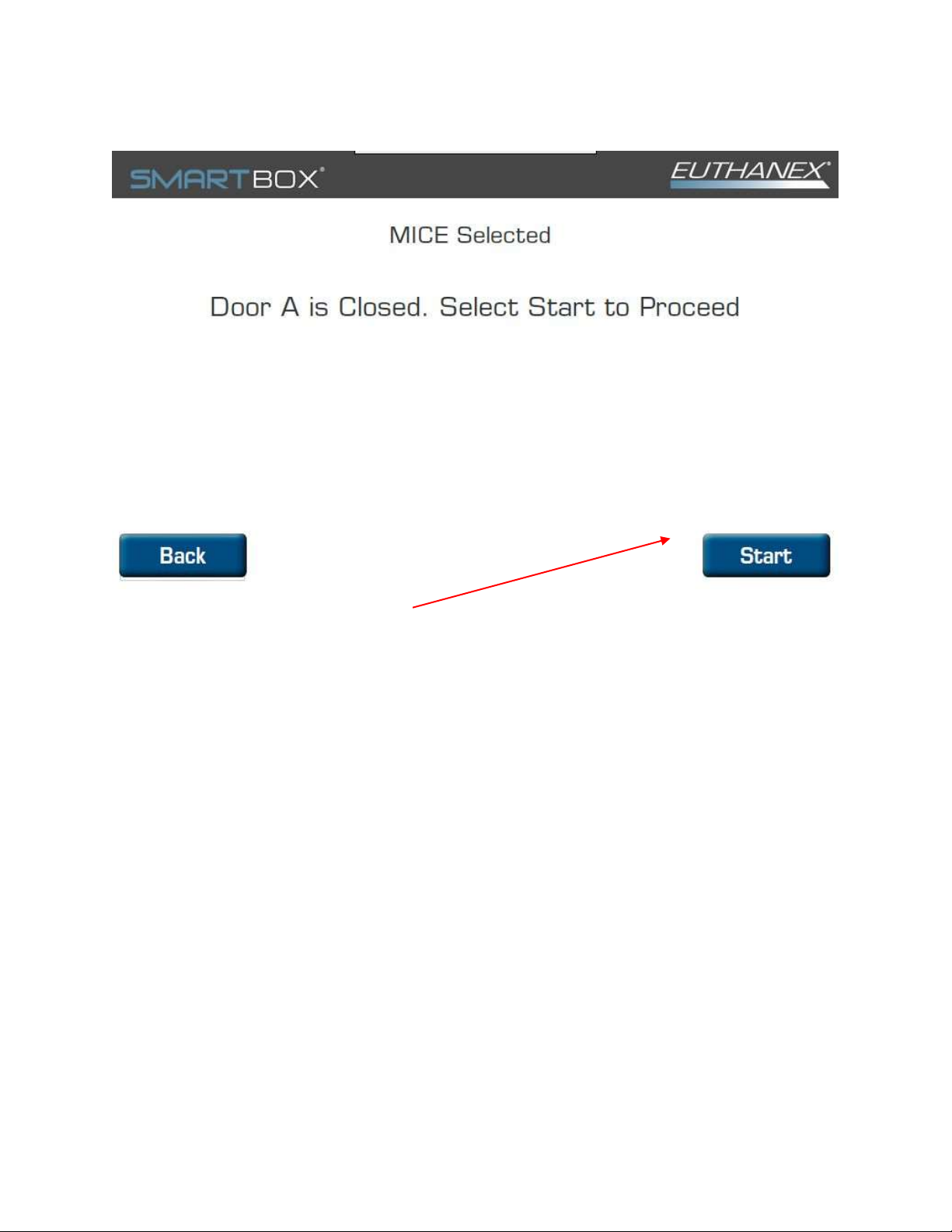

9) Select the species by touching the type you want to use, the press Next.

10) Select the chambers that will be used by touching the ones you want to use, the press Next.

19

11) If the doors are closed the above screen will appear. If the door is not shut properly you will see a

message to close the door. Press Start to begin the cycle.

12) During the first initial run, adjust the regulator flow rate to 100 CFPH. This adjustment will assure a

humane process. Animals will first be anesthetized with minimal stress and then euthanized while

asleep. Exceeding this flow rate may introduce stress to animals and result in operation outside of

AVMA guidelines. (This regulator adjustment is typically only required the first time using the

system and when a full CO2tank is first put on line.)

13) The system will cycle through three stages:

Stage 1: Gas flows through the chamber, fully charging the chamber with CO2.

Stage 2: Gas flow stops and the chamber remains fully charged with CO2.

20

Option: If programed the system will do a second charge and dwell cycle.

Stage 3: Exhaust blower turns on and purges the chamber, fully evacuating CO2.

14) After the blower automatically switches off, the animals may be safely removed from the chamber.

15) The red emergency “STOP” button may be pressed at any time to stop the euthanasia cycle. A

password may be required to engage the stop (admin setting).

The above screen will appear to allow the selection of chambers to stop. Touch the text of the ones you

want. Press "OK". Gas will immediately stop flowing and the unit will purge.

Table of contents

Other EUTHANEX Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Stark

Stark 75140 Owner's manual and safety instructions

SMC Networks

SMC Networks VR2110 Operation manual

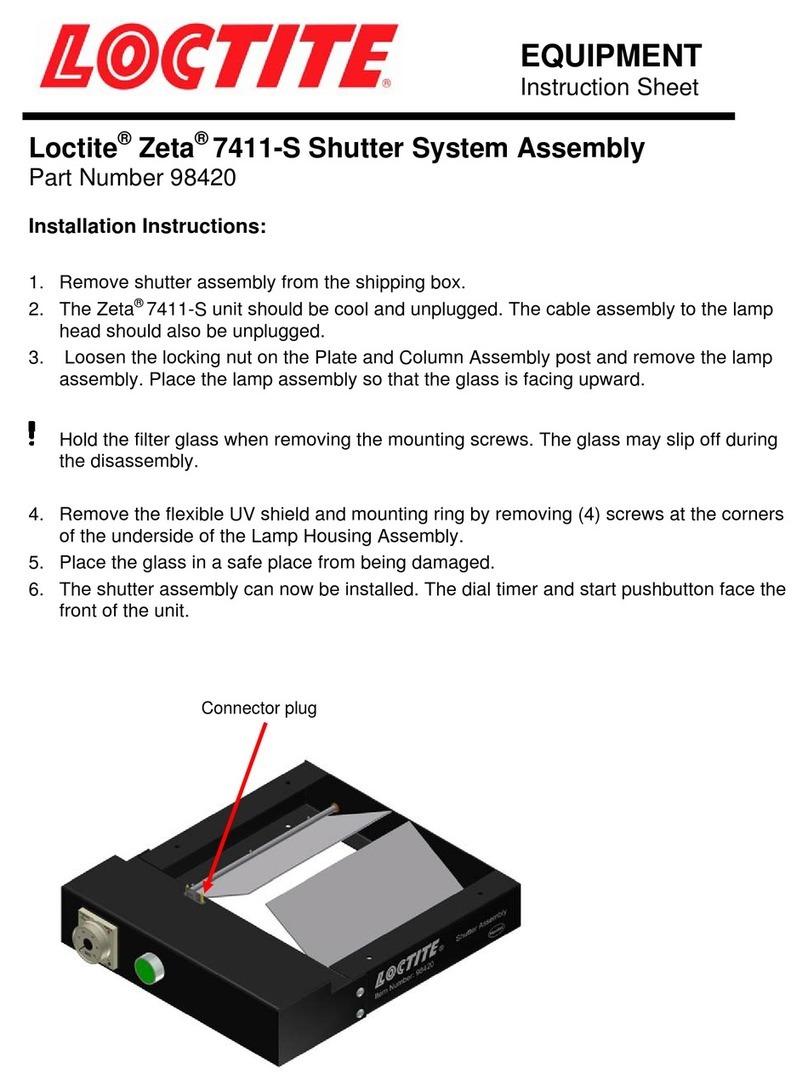

Loctite

Loctite Zeta 7411-S instruction sheet

Schrempp electronic

Schrempp electronic MG-2-T2-TRIO IOL M8 manual

AeroFlow

AeroFlow AF82-2012 installation manual

Plymovent

Plymovent MDB-2/HV Installation and user manual