evaton technologies Link SDIY User manual

Introduction

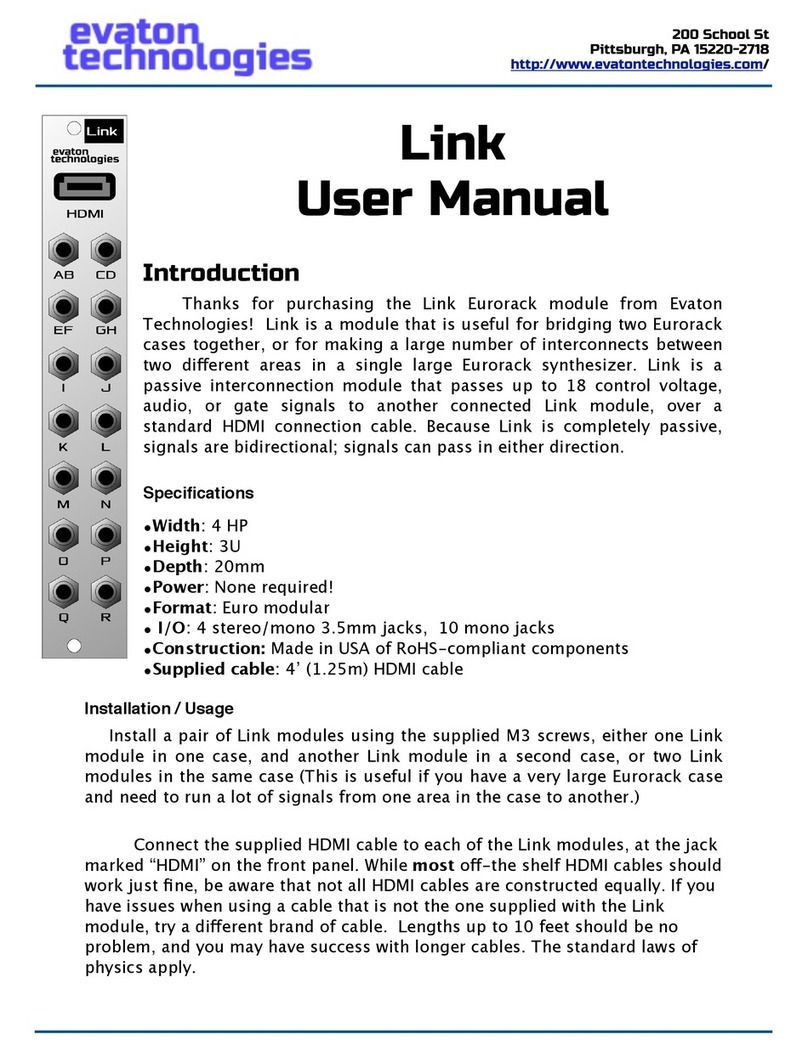

Thanks for purchasing the Link SDIY kit from Evaton Technologies! Link is a

module that is useful for bridging two Eurorack cases together, or for making a

large number of interconnects between two di!erent areas in a single large

Eurorack synthesizer. Link is a passive interconnection module that passes up

to 18 control voltage, audio, or gate signals to another connected Link module,

over a standard HDMI connection cable. Because Link is completely passive,

signals are bidirectional; signals can pass in either direction.

Skill Level

The Link SDIY kit requires basic soldering skills to complete. While all of the

surface-mount components come pre-installed, all remaining components are

standard thru-hole components. These instructions assume you already know

how to solder.

Precautions

Soldering irons are HOT! Be careful not to touch the business end of your

soldering iron at any time. Also note that components that have been soldered

will remain hot for a few moments. If you need to hold something to solder it, it

is recommended NOT to use your fingers. Wear long pants and long sleeves to

avoid solder splash from burning exposed skin.

Tools Required

A few basic electronic assembly tools are needed to complete the assembly

of the circuit board.

Soldering iron. Minimum 25 watt pencil iron; preferred temperature-

controlled, but not necessary.

Link SDIY

Assembly Manual

Revision A

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

Small wire cutter

Electronic solder. 60/40 lead/tin or 63/37 lead/tin, or lead-free. Use

rosin-core solder. Do NOT use acid-core (plumbing) solder! Small-diameter

1

solder is preferred (0.039”)

Pair of needle nose pliers for bending leads and holding components

Small bench vise or “helping hands” (optional) for holding the PCB.

8mm open-end wrench for tightening jack nuts. In a pinch, a 11/32”

wrench or pair of needle nose pliers will work. "

Acidcore music is great. Acid core solder is not.

1

Page 2

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

Kit Contents

•2 partially populated printed circuit boards (PCB)

•8x Green Stereo 3.5mm THONKiconn jacks

•20x Black Mono 3.5mm THONKiconn jacks

•2x Stainless Steel, laser-etched faceplates

•1x HDMI cable

•4x faceplate screws

Assembly Instructions

Preparation

To begin assembly, clear a space on your workbench . It helps to have good

2

lighting, and your tools located where they can be easily reached. Plug in your

soldering iron and let it come up to temperature. It helps to have a dampened

sponge nearby, to wipe the solder tip on to keep it clean . Place the bare circuit

3

board in the middle of your work area, with the white silkscreen legend facing

you.

The next few paragraphs will go step-by-step through the process of

assembling the circuit board. You may wish to check these steps o!as you go,

to keep track of your place.

Note that the instructions listed here are for building one Link module.

Repeat the instructions again to build the second module of the pair.

Also note that, while your PCB will have the HDMI connector pre-soldered,

the photos in this assembly document show that connector not installed, to

make it easier to see the components you will be soldering.

Hey, that’s my first step. My bench is always a complete mess!

2

Actually, those nifty brass-wool sponges work even better. Wish I had figured that out 30 years ago...

3

Page 3

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

____ Green Thonkiconn Stereo Jacks

J1 thru J4 are stereo

3.5mm jacks. Insert the jack

into the holes on the PCB

carefully; pay attention to

the orientation. The single

external leg on the jack

points towards the HDMI

connector on the board.

For now, only solder the

middle of pin of the jack.

We’ll go back and solder the

other two pins later.

Install all four green jacks

as shown, and solder only

the center pin.

Page 4

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

____ Black Thonkiconn Mono Jacks

J5 thru J14 are mono 3.5mm jacks. Just like the green stereo jacks, insert the

jacks carefully, making sure the external leg is facing the HDMI end of the

board. Solder just the middle pin for now. "

Page 5

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

____ Align the faceplate

Place the faceplate onto the jacks as shown. Now you can see why we only

soldered one pin of each jack. If there is a jack that isn’t lining up perfectly,

melt the solder on the center pin of that jack and reposition the jack while the

solder is melted, so that it lines up better. Check all the jacks, and make sure

the holes in the faceplate line up with all the jacks. Once you are done, remove

the faceplate temporarily.

____ Solder All Remaining Pins

Now that you are sure all the jacks are aligned properly, solder the

remaining pins on all the jacks. Make sure you don’t miss any; and you may

even want to go back and check your original solder joints when done.

Page 6

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

___ Assemble the Faceplate

Put the faceplate back onto

the jacks on the module, and finger-

tighten a nut onto each jack. Once

all the jacks are finger-tightened,

use an 8mm or 11/32” wrench or

socket to make the nuts snug.

NOTE: Be careful not to scratch

the faceplate while tightening the

nuts!

Stainless steel scratches more

easily than anodized aluminum. You

may wish to wrap your wrench or

pliers in adhesive tape before

tightening the nuts, to help avoid

scratching the faceplate. Stainless

steel was used in order to get the

correct stackup thickness needed by

the HDMI connector to allow the

HDMI plug to fully seat, and

anodized aluminum was not

available in that thickness.

Page 7

200 School St

Pittsburgh, PA 15220-2718

http://www.evatontechnologies.com/

___ Assemble the other module

Repeat the above instructions to assemble the second Link module. Follow

the instructions in the user manual on how to install and use your Link

modules!

Congratulations!

With some skill and a little luck, you should now have a fully functioning RF

Nomad that you built yourself. Congratulations!

Please join the Evaton Technologies user forums at:

http://www.evatontechnologies.com/apps/forums

Or, follow us on Facebook at https://www.facebook.com/evatontechnologies

And please join the mailing list: http://www.evatontechnologies.com/join

the RF Nomad FAQ at http://www.evatontechnologies.com/rf-nomad

Warranty

Regretfully, because this is a DIY project, Evaton Technologies cannot

warrant the finished project, but please do contact

DIY kit, and Russ will try to help you out.

Page 8

Table of contents

Other evaton technologies Control Unit manuals

Popular Control Unit manuals by other brands

TP-Link

TP-Link TL-SM321A installation guide

LOVATO ELECTRIC

LOVATO ELECTRIC DCTL Series instruction manual

Fracarro

Fracarro MOD-WL16 operating instructions

joucomatic

joucomatic ASCO 343 Series Installation

Inficon

Inficon VGC501 operating manual

DROPSA

DROPSA nano Progressive USER OPERATION AND MAINTENANCE MANUAL

Mitsubishi Electric

Mitsubishi Electric PAC-AH125 installation manual

Elektrogas

Elektrogas EVRM-NA manual

Landis+Gyr

Landis+Gyr S4e UtiliNet user manual

IBM

IBM BladeCenter 4-Port installation guide

Festo

Festo ZSB-1/8 operating instructions

Bristan

Bristan N2 SHCDIV G Installation instructions and user guide