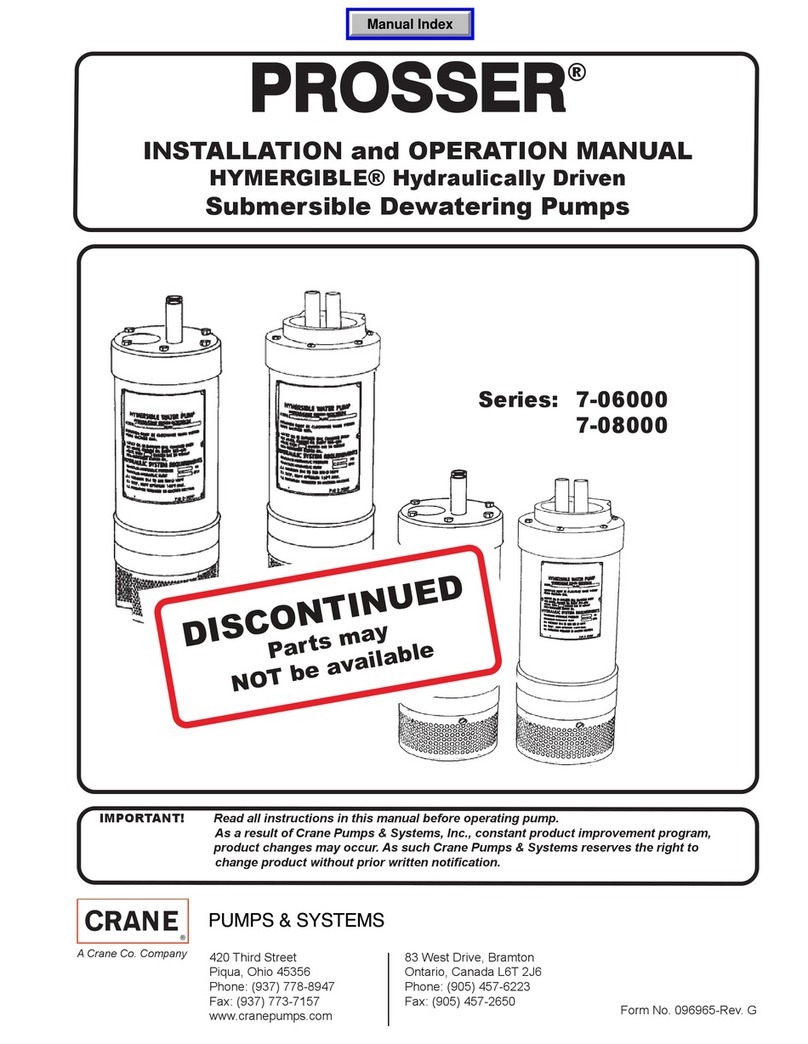

Everflo EFHP-2000 User manual

EFHP-2000

Owner’s Manual

Instructions for Assembly, Testing, Operation, Servicing, and Storage

12V Plunger Pump: For use with non-potable liquids such as water-based

agricultural pesticides and other liquids**

WARNING

READ and UNDERSTAND the Owner’s Manual completely before using this pump.

Assemble, test, and use only in accordance with the Owner’s Manual instructions.

READ and FOLLOW chemical safety instructions. Pesticides are hazardous chemicals.

KNOW emergency procedures BEFORE handling chemicals. Pump leaks, bodily chemical

contact, poisoning, and spills require immediate response.

AVOID inhaling, ingesting, or coming into contact with any chemicals.

WEAR personal protective gear when operating, cleaning, and servicing the pump.

KEEP pump and spray materials away from children and pets. Pesticides are especially

toxic to them.

DO NOT TURN ON POWER to pump until ready to spray in order to avoid unintentional

spray release.

ALWAYS keep a fire extinguisher rated “ABC” nearby.

Improper use of the pump or handling of chemicals could result in serious injury or

illness to the operator or nearby persons/animals, or could cause damage to the

environment.

** This pump is recommended for use in spraying non-flammable liquids such as pesticides, water

for plants/trees or dust control, or water-based non-flammable sealants or stains for outdoor wood

surfaces. This pump should not be used to transfer any product intended for human consumption.

WE RECOMMEND THAT THE PUMP NOT BE USED FOR OTHER PURPOSES ONCE IT HAS

BEEN USED FOR SPRAYING PESTICIDES. Any chemical will leave some residual in the pump,

even after the pump has been properly cleaned. These residual chemicals can have unexpected

effects on future uses. For example, spraying water or other liquids that are contaminated with

residual pesticide may result in unforeseen hazards to plant or animal life. This pump should not be

used by people with reduced physical, sensory or mental capabilities or lack of experience and

knowledge.

Any Questions, Comments, Problems, or Parts Orders

Call Everflo Product Support 1-800-864-1649

ITEM NUMBER: EFHP-2000

SERIAL NUMBER: __________

Hazard Signal Word Definitions

2

Table of Contents

3

Intended Use ........................................................................................................................................ 4

Summary of Important Safety Information...................................................................................... 5

During Assembly

During Operation

General Chemical Safety

Chemical Applicator Safety

Chemical Accident Procedures

Warning Label Location...................................................................................................................... 7

Unpacking ............................................................................................................................................. 8

Assembly................................................................................................................................................ 9

Installation

Step One: Mounting...................................................................................................................... 13

Step Two: Plumbing...................................................................................................................... 13

Step Three: Connect pump to vehicle battery............................................................................... 14

Step Four: Check and test completed assembly ........................................................................... 15

Operation

Important Safety Information - Operation.............................................................................. 16

General Chemical Safety

Chemical Applicator Safety

Chemical Accident Procedures

Preparing the Pump for Each Use............................................................................................. 20

Using the Pump

Step One: Assess wind conditions and clear work area........................................................ 21

Step Two: Operate the pump................................................................................................. 21

Step Three: Clean pump and decontaminate after use .......................................................... 23

Storage................................................................................................................................................. 25

Preparing for storage

Removing from storage

Troubleshooting.................................................................................................................................. 26

Specifications....................................................................................................................................... 28

Accessories........................................................................................................................................... 29

Parts Breakdown – Exploded View.................................................................................................. 30

Limited Warranty .............................................................................................................................. 31

Intended Use

4

The pump is intended for use in spraying agricultural pesticides and other non-flammable

liquids.

SPRAYING PESTICIDES:

Pesticides are hazardous chemicals that must be handled with caution as directed

throughout this manual and on the pesticide label. Pesticides are regulated by the United

States Environmental Protection Agency (EPA) and defined as:

Any substance or mixture of substances intended for preventing, destroying, repelling, or

mitigating any pest. Though often misunderstood to refer only to insecticides, the term

pesticide is a comprehensive term that applies to insecticides, herbicides, fungicides, and

various other substances used to control pests.

The pump is intended for use in spraying pesticides in liquid form only. The pump is

NOT intended for use in spraying pesticides in dry or aerosolized form, or for use with

fumigants.

SPRAYING OTHER LIQUIDS:

In addition to spraying pesticides, this pump may be used to spray other non-flammable

liquids. Example uses include: watering plants/trees or spraying water for dust control,

or applying water-based, non-flammable sealant or stain to outdoor wood surfaces.

However, WE RECOMMEND THAT THE PUMP NOT BE USED FOR OTHER

PURPOSES ONCE IT HAS ALREADY BEEN USED FOR SPRAYING

PESTICIDES. Any chemical will leave some residual in the pump, even after the pump

has been properly cleaned. These residual chemicals can have unexpected effects on

future uses. For example, spraying water or other liquids that are contaminated with

residual pesticide may result in unforeseen hazards to plant or animal life.

Contact Everflo Product Support at 1-800-864-1649 for any questions about

the appropriate use of the pump and/or optional accessories.

Summary of Important Information

5

WARNING

Read and understand this owner’s manual completely before using the pump. Read each

chemical label’s instructions before handling the chemical.

Improper use of the pump or handling of chemicals could result in serious injury or illness

for the operator or nearby persons/animals, or cause damage to the environment.

LISTED BELOW is a summary of safety information of particular importance. See individual

sections of this owner’s manual for more details.

------------------------------------ DURING ASSEMBLY-------------------------------

EXERCISE CAUTION when attaching remote switch to battery terminals. Follow the steps

listed in the Assembly section of this manual in exact sequence when connecting the pump to battery

terminals. Caution must be exercised to avoid contact with battery acid and to prevent sparking.

CHECK and TEST completed assembly as directed in this manual. Serious injury could result from

chemical leaks if pump is improperly assembled.

DO NOT MODIFY pump design.

------------------------------------DURING OPERATION------------------------------

General Chemical Safety

READ and FOLLOW each chemical label’s instructions and warnings.

AVOID inhaling, ingesting, or coming into contact with any chemicals.

KNOW applicable licensing and regulatory requirements for the chemical you plan to use.

KNOW emergency procedures before handling chemicals. Carefully review “Chemical Accident

Procedures” listed below and later in this manual. Also see First Aid instructions on the chemical

label.

WEAR protective clothing, eye protection, and chemical resistant gloves when operating the

pump. Wear additional protective gear, such as facemask or apron, as recommended on the chemical

label.

EXERCISE EXTRA CAUTION around children and pets. Pesticides are especially toxic to them.

Keep pump and spray materials away from them at all times.

DO NOT MIX OR POUR chemicals in an enclosed, unventilated area

DO NOT USE flammable or corrosive chemicals in the pump.

FLUSH the pump before switching chemicals in order to prevent dangerous chemical interactions.

STORE pesticides in a correctly labeled container and in a secure location.

MONITOR the health of operators frequently exposed to pesticides, as recommended by the

chemical label or local/federal regulations.

Chemical Application Safety

Before Spraying

INSPECT and PREPARE pump before each use as directed in this manual.

DO NOT TURN ON POWER to pump until ready to spray in order to avoid unintentional spray

release.

DO NOT SPRAY when wind speed exceeds 4 MPH in order to minimize spray drift.

CLEAR work area of people/ pets and POST warning notices to restrict access for the period

recommended on chemical label.

KEEP pump and spray materials away from children/pets. Pesticides can be especially toxic to

children and animals.

DO NOT ALLOW anyone younger than 16 to operate the pump since pesticides are especially

toxic to children.

During Spraying

DO NOT OVER-APPLY pesticide. Apply at rate recommended by chemical manufacturer. Excess

pesticide can be dangerous to humans/animals, damage desirable plants, and contaminate soil and

water sources.

Summary of Important Information

6

DO NOT EAT, DRINK, SMOKE, RUB YOUR EYES, or TOUCH YOUR BARE SKIN while

handling chemicals and spraying.

NEVER POINT A SPRAY GUN at people or animals.

EXERCISE EXTRA CAUTION when spraying near areas accessible to children and pets.

CLEAN up spills immediately per instructions on the chemical label.

TURN OFF power to pump, and RELIEVE system pressure before leaving pump unattended.

SEE Troubleshooting section of this manual before attempting any repairs. Wear personal

protective equipment and follow safety instructions.

After Spraying

CLEAN pump immediately after use according to the directions provided in this manual.

DECONTAMINATE yourself after you are done spraying and have cleaned the pump. Wash all

exposed areas of the body with soap and water, and remove and launder clothing.

DISPOSE OF or STORE remaining chemicals in secure storage with correctly marked

container.

Chemical accident procedures

Immediate response is necessary in the event of pump leaks, bodily chemical contact, poisoning, or

spills. See instructions below:

Pump leak If the pump develops a leak, immediately stop spraying. Turn off power to the

pump and follow directions below, as applicable.

Bodily

chemical

contact

Personal contamination can occur when chemicals splash, spill, or spray

directly onto a person.

1. Immediately follow First Aid instructions on chemical label.

General procedures can include:

a) Eyes – immediately flush with water.

b) Skin – wash all contaminated skin surfaces with soap and water.

c) Clothing – remove contaminated clothing. Dispose of heavily

contaminated clothing per chemical label instructions.

2. Seek medical advice if instructed on the label or the victim experiences

symptoms of harmful effects. Bring the chemical label for reference.

Poisoning by

ingestion or

inhalation

In case of poisoning from ingestion or inhalation:

If the victim has collapsed or is not breathing, call 911. Otherwise:

1. If you are the victim, immediately seek assistance from nearby personnel

because you may become incapacitated.

2. Immediately follow first aid instructions on chemical label.

3. Call a poison control center for further advice. In the U.S., call 1-800-222-

1222. Have the chemical label available for reference.

Chemical

spills Chemical spills must be quickly contained and properly cleaned up.

Refer to the chemical label for any specific clean-up instructions.

General procedures include:

1. Controlling the spill by stopping the source of the spill.

2. Containing the spill so that it does not spread and get into water sources.

3. Cleaning up the spill immediately.

4. Seeking additional advice from:

- Chemical manufacturer. See chemical label for contact information.

- State pesticide regulatory agency. In the U.S., call the National Pesticide

Info. Ctr. at 800-858-7378 for assistance in contacting your state’s agency.

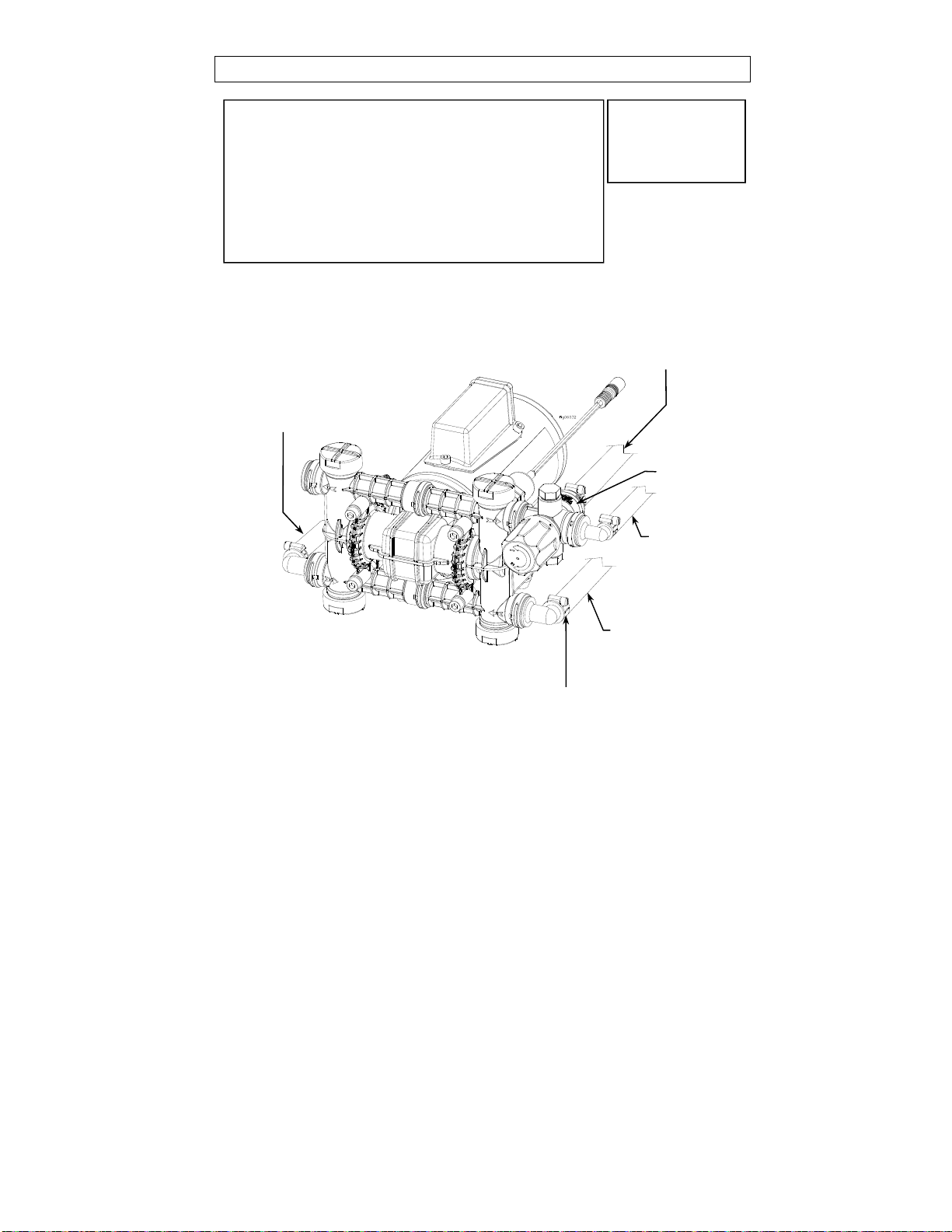

Warning Label Location

7

Always make sure safety labels are in place and in good condition. If a safety label is missing or

not legible, order new labels or unsafe operation could result.

To order replacement safety labels, call Everflo Product Support at 1-800-864-1649.

Part# Description

796106 EFHP2000 Pump Label

793288 Pump Warning Label

DO NOT PUMP FLAMMABLE FLUIDS. DO NOT USE PUMP IN AN EXPLOSIVE

ENVIRONMENT. READ AND UNDERSTAND THE OWNER’S MANUAL COMPLETELY

BEFORE USING. RELIEVE SYSTEM PRESSURE BEFORE PERFORMING MAINTENANCE.

WARNING

Unpacking

8

Closely inspect all contents in the shipping carton.

If you have missing or damaged components, please contact Everflo Product Support at

1-800-864-1649

Plunger Pump

P/N EFHP2000

Regulator Assembly

Regulator: EF-792943

Quick Connect x 1/2” Hose barb (1)

P/N EF-QC-A12

*(1) Pre-installed on Regulator

Quick Connect Plug (2)

P/N EF-789160

*(1) Pre-installed on Pump

Quick Connect x 3/8” Elbow (1)

P/N EF-QC-EL38

*(1) Pre-installed on Regulator

Quick Connect x 1/2” Elbow (2)

P/N EF-QC-EL12

¼” MNPT Plug (2)

P/N F14

*(1) Pre-installed on Regulator

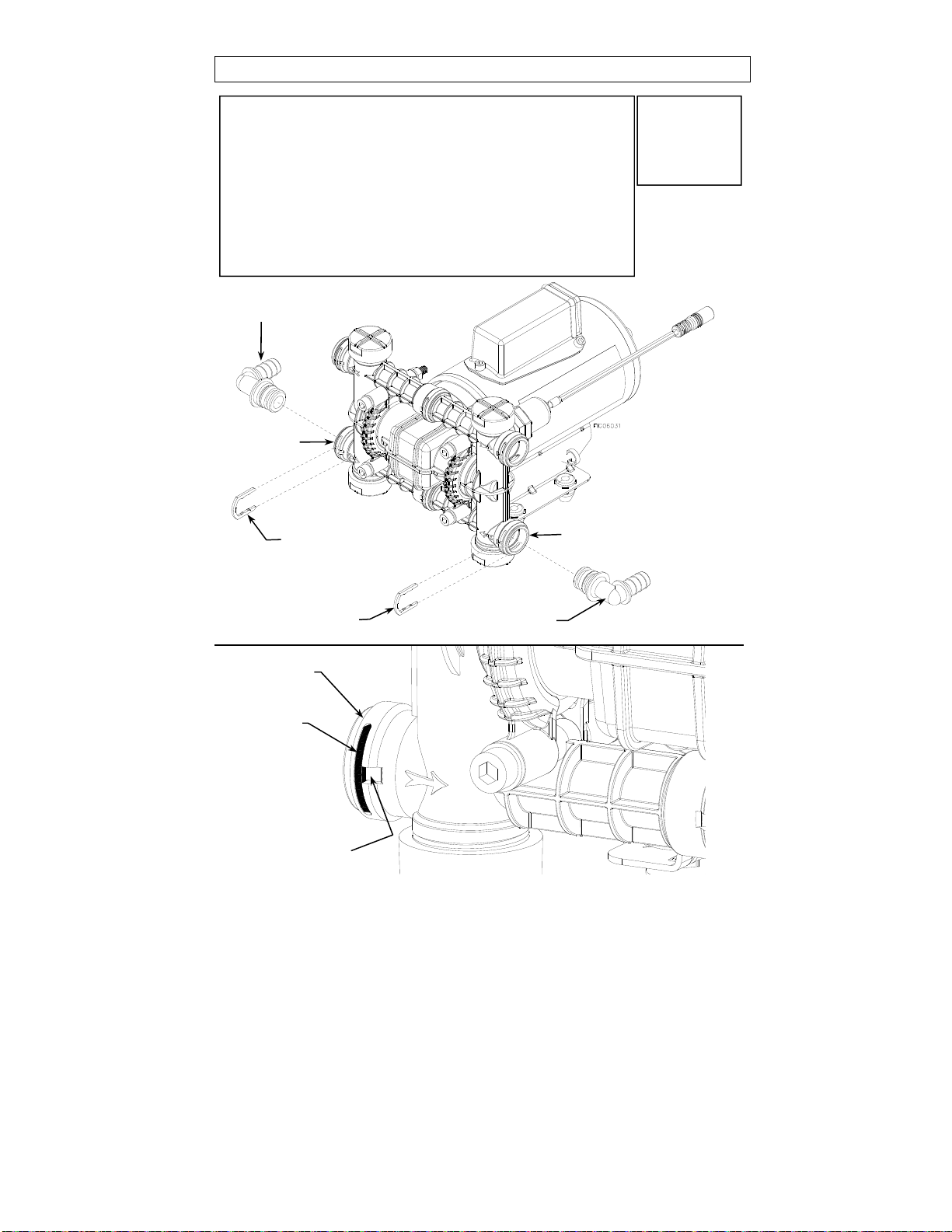

Assembly

9

Step 1 – Inlet Fitting Installation

Install (1) QC x 1/2” HB elbow fitting into the pump inlet port on the

bottom left side of the pump manifold.

Install (1) QC x 1/2” HB elbow fitting into the pump inlet port on the

bottom right side of the manifold.

oUse a flat blade screwdriver to remove QC clip from the pump before

installing fitting. Snap QC clip back into pump after fitting is inserted.

Note: The pump is configured for installing (2) QC x 1/2” HB elbow fittings

into the pump inlet ports on the bottom of the manifold. If preferred to

use only one pump inlet port, there is an extra QC plug in the manual

bag that can be installed to plug the desired port.

Tools Needed

Flat blade

screwdriver

Pump inle

t

QC x 1/2” Elbow

Inlet fitting

QC Clip

QC x 1/2” Elbow

Inlet fitting

Pump inle

t

QC Clip

QC Clip

Pump port

Insert screw-

driver here to

remove QC clip

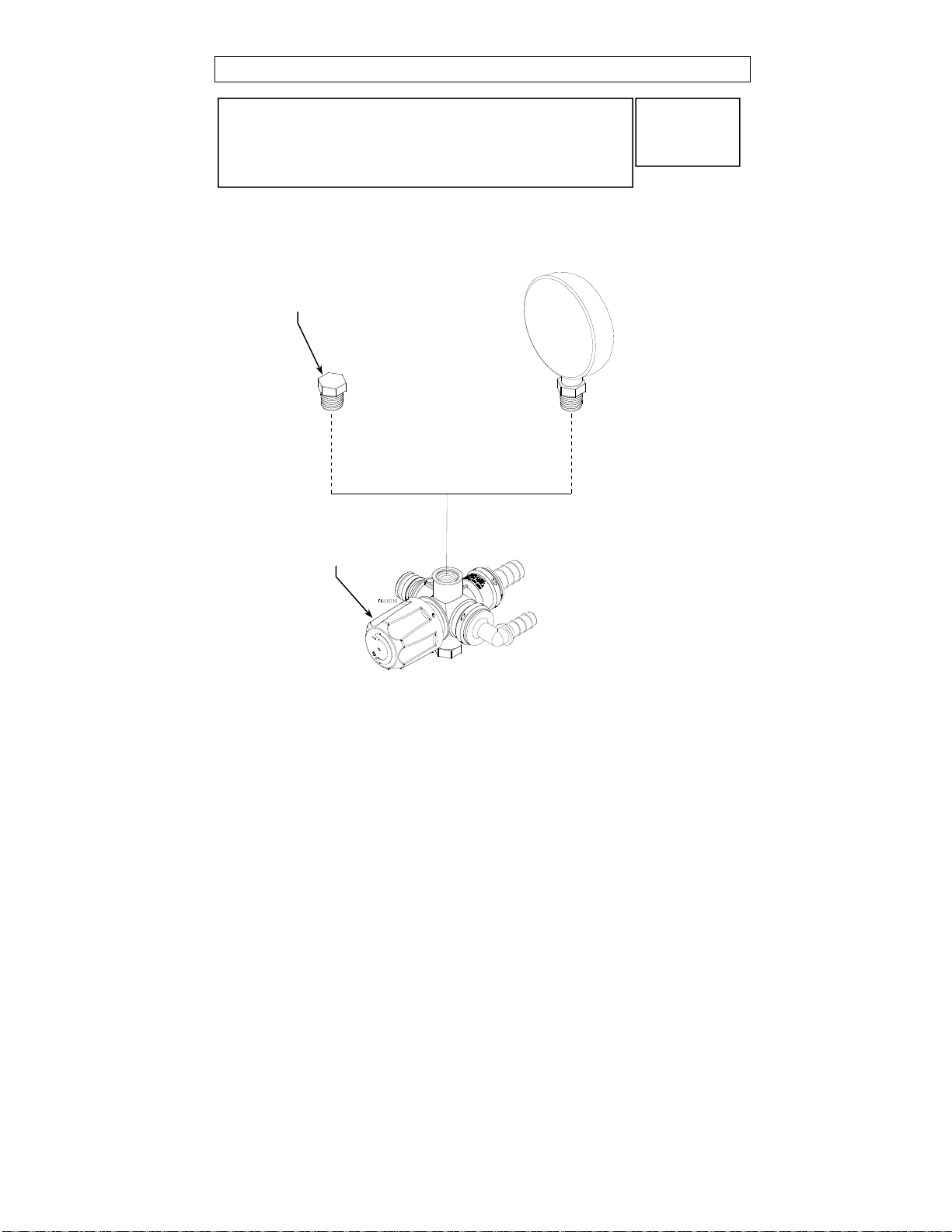

Assembly

10

Step 2 – Plug or Optional Gauge Installation

Install either the 1/4” MNPT Plug or Optional Gauge into the 1/4” FNPT

port on the regulator.

oUse a wrench to thread the plug or gauge into the regulator port.

Tools Needed

Wrench

Regulator assembly

1/4” MNPT Plug Optional Gauge:

P/N 2141GXB300

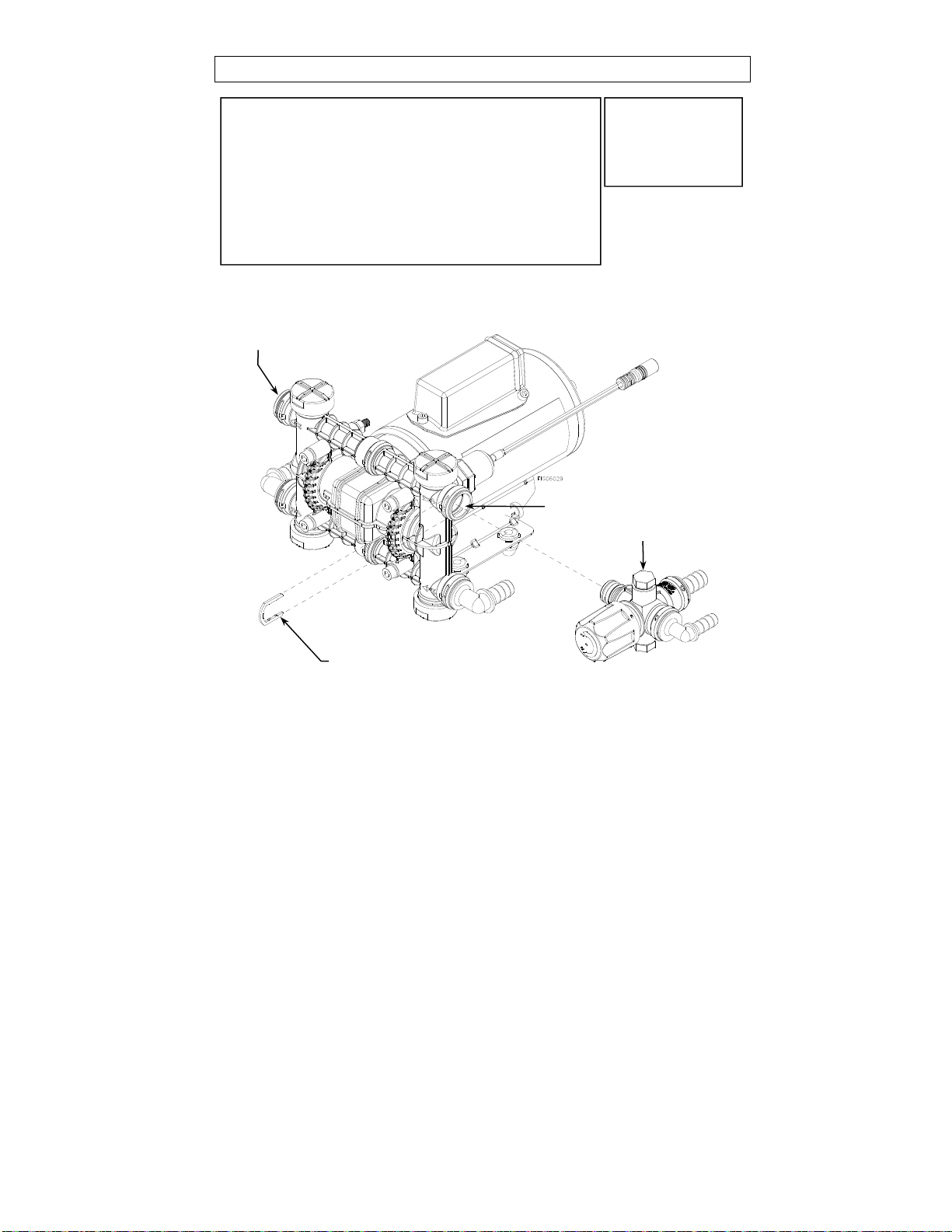

Assembly

11

Step 3 – Regulator Installation

Install the regulator into outlet port at the top right side of the

pump manifold.

oUse flat blade screwdriver to remove QC clip from the

pump before installing fitting. Snap QC clip back into

pump after fitting is inserted.

Note: The pump is configured for installing the regulator in the

right side of the manifold. If the left side is preferred, the QC

plug must first be moved from the left side outlet port to the

right side outlet port.

Tools Needed

Flat blade

screwdriver

QC Clip

Regulator assembly

Outlet port

QC Plug

Assembly

12

Step 4 – Connect Inlet, Outlet, and Bypass Hoses

Use a hose clamp (not provided) and connect a flexible hose (not

provided) to the regulator’s bypass port. The hose should return

to the pump’s water supply. See the Operation section of the

manual for detailed information about the regulator’s bypass

function.

Use hose clamps (not provided) and connect flexible hoses (not

provided) to the pump’s inlet and outlet ports. See the

Installation section of the manual for more detailed plumbing

requirements.

Tools Needed

Flat blade

screwdriver

1/2” Inlet hose

(from water supply)

1/2” Inlet hose

(from water supply)

3/8” Outlet hose

1/2” Bypass hose

(return to water supply)

* Hoses and Hose Clamps are not provided

Regulator

bypass port

Hose clamp

Installation

13

Step One: Mounting

This Everflo pump performs best with a flooded inlet. (The pump’s inlet should be located

below the supply water level.) If the pump must be placed above the water supply, suction

lift is not to exceed two feet (0.6m).

CAUTION

NEVER operate the pump dry. Catastrophic failure will occur. All plunger pumps require

liquid to lubricate the seals and keep them from overheating.

The pump should be located in an area that is dry and provides adequate ventilation.

The pump must be mounted in a horizontal position.

Secure the rubber feet with #10 (M5) fasteners. DO NOT compress the feet, doing so will

reduce their ability to isolate vibration/noise. (Note: fasteners are not included.)

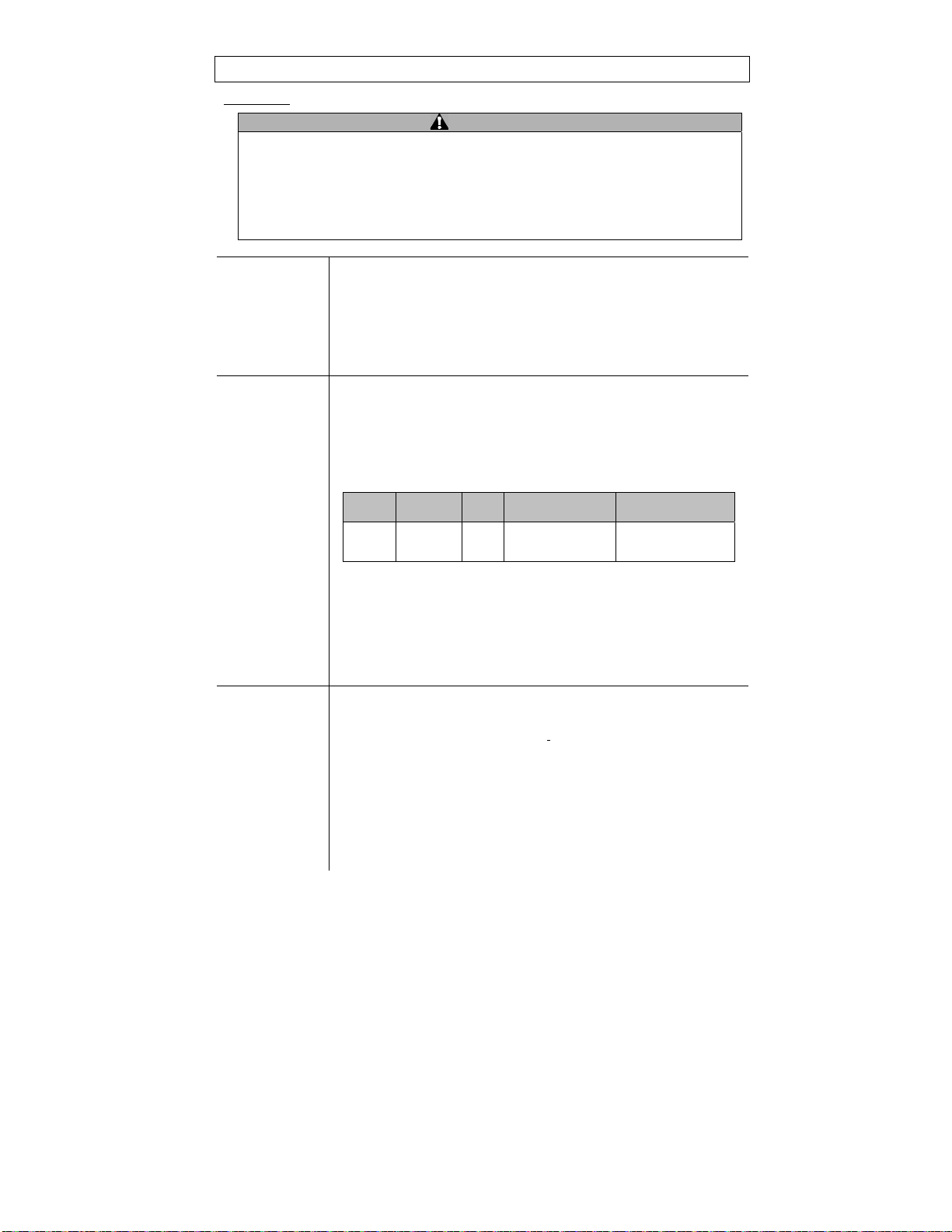

Step Two: Plumbing

See table below for port size and recommended hose sizes.

oUse Everflo quick connect fittings to connect flexible high pressure tubing.

oMaximum pump operating pressure is 200psi (13.8bar). Outlet hose working

pressure must be rated appropriately.

oA pressure regulator is included with the pump and must be used.

Pump

Model Minimum inlet

hose size

Minimum

outlet hose

size

Outlet hose

working

pressure

(minimum)

Bypass hose

diameter

EFHP-2000 1/2" (13mm)

Inside diameter 3/8" (9.5mm)

Inside diameter 200psi (13.8bar) 1/2” (13mm)

NOTE: Everflo does not recommend the use of metal fittings or rigid pipe to plumb the inlet/outlet

ports. Standard plastic threaded fittings are available by calling Everflo Product Support at 1-

800-864-1649.

Tubing should be compatible with the spraying fluid. At least 18"[450mm] length is

suggested to minimize stress on the fitting/ports and reduce noise. Allow for the shortest

possible tubing route and avoid sharp bends that may kink over time.

Installation of a 50-mesh strainer is required to prevent foreign debris from entering the

system. Failures due to foreign debris are not covered under the warranty.

NOTE: Restrictions on the inlet may cause a loss in performance and shorten pump life. Inlet pressure

must not exceed 30 psi [2.1 bar]

If a check valve is installed in the plumbing, it must have a cracking pressure of no more

than 1 psi [.07 bar].

CAUTION

DO NOT locate the motor near low temperature plastics or combustible material. The surface

temperature of the motor may exceed 250°F [121°C].

CAUTION

Sealers and Teflon tape may act as lubricant causing cracked housings or stripped threads due to

over tightening. Care should be used when applying sealers; it may enter the pump inhibiting

valve action, causing no prime or no shut-off. Failures due to foreign debris are not covered

under the warranty.

Installation (continued)

14

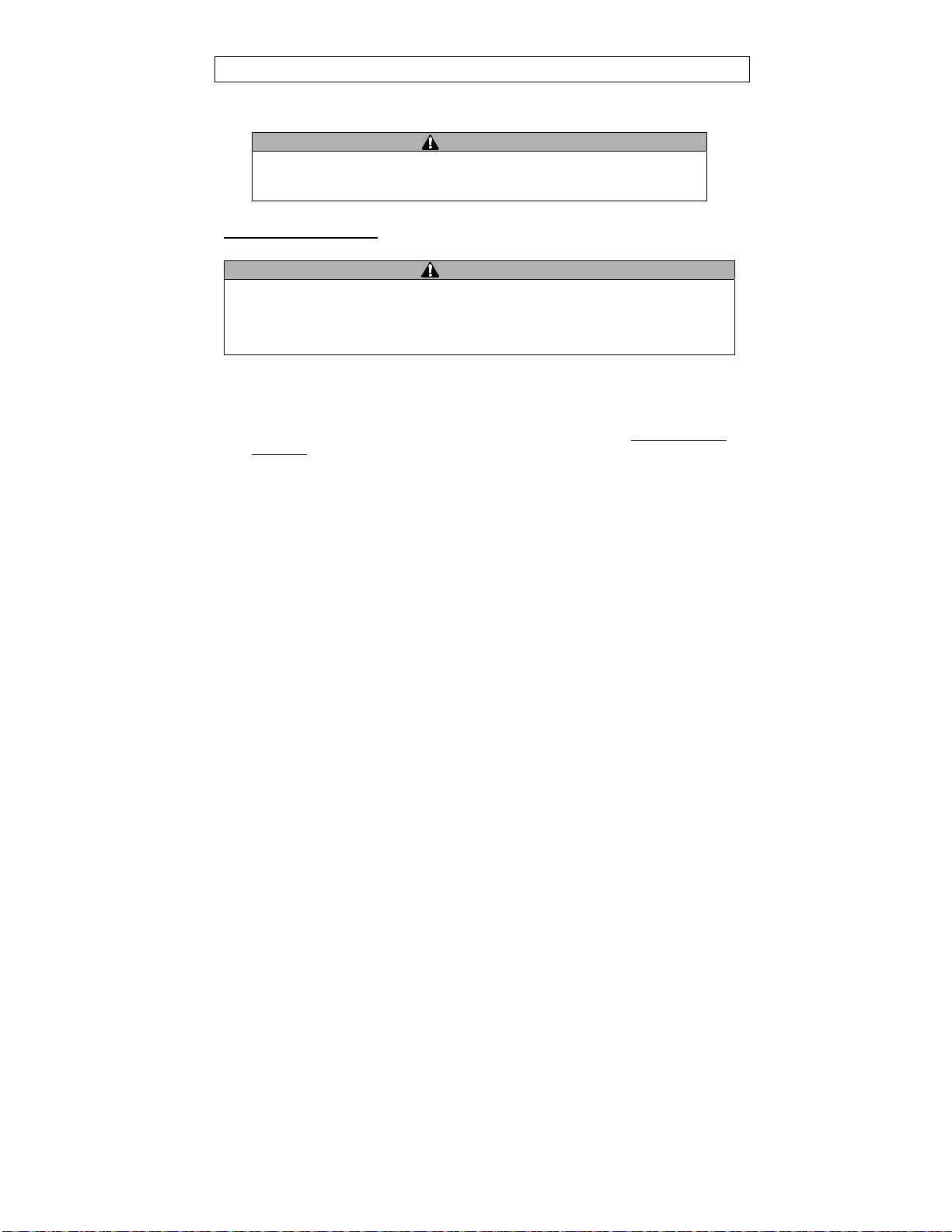

Step Three: Connect pump to battery or 12V supply

WARNING

Batteries are hazardous because they contain caustic acid, can emit explosive gases, and can

cause electric shock.

Caution must be exercised when making connections to a battery to avoid shock and contact with

the acid, and to prevent any sparking that could lead to an explosion.

ALWAYS follow the safety instructions and steps listed below in exact sequence when

connecting the pump to the battery terminals.

1. Preparatory

safety

Preparatory safety steps:

ALWAYS use eye protection

NEVER smoke or work near sparks or other sources of ignition.

NEVER touch both battery terminals at the same time or with any

non-insulated tools.

If battery acid contacts skin or clothing, flush immediately with water

and neutralize with baking soda.

2. Electrical

requirements The pump should be on a dedicated (individual) circuit, controlled

with a double pole switch (UL/CSA certified) rated at or above the

fuse ampere indicated by the pump motor label. Depending on

distance of the power source from the pump and ampere load on the

circuit, wire may need to be heavier than indicated by the chart.

The pump is protected with a fuse. Use an approved wire of the size

specified or heavier.

Voltage Model Fuse

(amp) Wire Leads Wire Size

(Stranded MTW)

12 VDC EFHP-2000 20.0 RED (positive +)

BLACK (negative -) #12 AWG (4.0mm2)

(or heavier)

Note: Use #10 AWG (5.0mm2) for wire lengths over 12 feet (3.6m). Do not

exceed 25 feet (7.6m) of total wire length.

A remote switch is included for temporarily shutting off the pump’s operation.

Call Everflo Product Support at 1-800-864-1649 to order replacement remote

switch Everflo Item #EF-794292.

3. Connect pump

to battery

Connect the pump to a 12V DC battery using the following procedure:

a) Disconnect the vehicle battery ground wire.

b) Connect the pump clamp with the red wire to the positive (+) terminal

of the battery.

c) Connect the pump clamp with the black wire to the negative (-)

terminal of the battery.

d) Reconnect the vehicle battery ground wire.

Note: Skip steps (a) and (d) if battery is not in a vehicle.

WARNING: Always connect in this sequence to avoid possible shock.

Installation (continued)

15

4. Disconnect

after use AFTE

R

EACH USE, disconnect power to the pump using the following

procedure:

a) Disconnect the vehicle battery ground wire.

b) Disconnect the pump clamp with black wire from the negative (-)

terminal of the battery.

c) Disconnect the pump clamp with red wire from the positive (+)

terminal of the battery.

d) Reconnect the vehicle battery ground wire.

Note: Skip steps (a) and (d) if battery is not in a vehicle.

WARNING: Always disconnect in this sequence to avoid possible shock.

NOTE: It is important to disconnect power to the pump when not in use for

safety reasons. ALWAYS verify that the power has been disconnected

before adding chemicals or servicing.

Step Four: Check and test completed assembly.

WARNING

Check and test completed assembly

Serious injury could result from chemical leaks if pump is improperly assembled or the design

of the pump is modified.

Follow the steps below to ensure the pump is properly assembled. Never modify the pump

design.

1. Check

assembly Check assembly to assure the pump is properly assembled and in safe

working condition:

2. Before

starting the

pump

a) Test the system for leaks with water

b) Ensure water supply is adequate. Do not run dry.

c) Check inlet strainer for debris.

d) Verify hoses are in good condition and all connections are tight.

Operation – Important Safety Information

16

Now that you have completed and tested your assembly, there is some important safety and health

information you need to know with regard to handling and spraying chemicals.

WARNING

Carefully read and make sure you understand the following safety information before

using the pump.

General Chemical Safety:

WARNING

Pesticides are hazardous chemicals.

Heed the warnings below and follow all instructions carefully.

Improper handling of chemicals can result in serious injury or illness, or cause damage to the

environment.

Chemical label. ALWAYS READ and FOLLOW all chemical label instructions.

Licensing/regulation. Refer to any applicable licensing restrictions or state/federal regulations

with regard to the application of the particular chemical you plan to use.

Emergency procedures. Before handling chemicals, carefully review the “Chemical Accident

Procedures” listed later in this section, as well as the “Statement of Practical Treatment” on the

chemical label.

Inhalation/contact. ALWAYS take precautions to avoid inhaling or coming into contact with

the chemical.

Personal protective equipment. ALWAYS wear protective clothing, eye protection, and

chemical-resistant gloves when operating and cleaning the pump. Wear additional protective

gear (such as facemask or apron) as recommended on the chemical label.

Children/pets. Pesticides can be especially toxic to children and animals. ALWAYS exercise

extra caution around children. Keep pump and all spray materials away from children and

animals.

Ventilation. ALWAYS ensure there is adequate ventilation when mixing, pouring, or spraying.

Flammables. NEVER use any flammable chemicals in the pump.

Corrosives. DO NOT use corrosive chemicals in the pump. They can weaken the pump and its

parts, resulting in leaks. Check with the chemical manufacturer to ensure chemical is

compatible with all components of the pump.

Chemical interaction. ALWAYS flush the pump before switching chemicals. Different

chemicals may interact dangerously with each other.

Chemical storage. ALWAYS store pesticides in a properly labeled container and in a secure

location per the manufacturer’s recommendations.

Health monitoring. Monitor the health of operators who are frequently exposed to pesticides,

as recommended by the chemical label or local/federal regulations.

Operation – Important Safety Information (continued)

17

Chemical Application Safety:

WARNING

Caution must be used when spraying chemicals to avoid unsafe exposure to humans and the

environment.

Heed the warnings below and follow all instructions carefully.

Before Spraying

Pump prep. ALWAYS inspect and prepare the pump before use according to the directions

provided in this manual.

Keep pump off. Do not turn on power to the pump until ready to spray in order to avoid

unintentional spray release.

Wind speed. NEVER spray when wind speed exceeds 4 MPH in order to minimize spray drift.

Clear area/post. ALWAYS keep the work area clear of people and pets. POST warning

notices to restrict access by the public for the period recommended on chemical label.

Operator age. You must be 16 years of age or older to operate this pump. Pesticides are

especially toxic to children.

During Spraying

Over-application. DO NOT over-apply pesticide. Apply at a rate recommended by chemical

manufacturer. Excess pesticide can be dangerous to humans, damage desirable plants, and

contaminate soil and water sources.

Children/pets. ALWAYS exercise extra caution when spraying near areas accessible to

children and pets.

Eating/smoking. DO NOT eat, drink, smoke, rub your eyes, or touch any part of your bare skin

while handling chemicals and spraying.

Heat/flames. DO NOT spray near open flames or sources of heat.

Spills. ALWAYS clean up spills immediately per instructions on the chemical label.

Unattended. ALWAYS turn off power to pump, and relieve system pressure before leaving

pump unattended.

Troubleshooting. ALWAYS refer to the safety instructions in the Troubleshooting Section

before attempting any repairs.

After Spraying

Clean pump. ALWAYS clean the pump immediately after use according to the directions

provided in this manual.

Decontaminate. ALWAYS decontaminate yourself immediately after you are finished

spraying and handling chemicals. Wash all exposed areas of the body with soap and water and

remove and launder clothing.

Chemical disposal/storage. ALWAYS dispose of or store remaining chemicals properly as

recommended on the chemical label.

Operation – Important Safety Information (continued)

18

Chemical accident procedures:

WARNING

Before you use the pump, review the following information with regard to handling

accidents.

Chemical spills, pump leaks, personal contamination, and poisoning are accident situations

which you may encounter.

All require an immediate response – See instructions below.

Pump leak In the event that the pump develops a leak while spraying chemicals, you

must immediately stop spraying.

Turn off power to the pump and follow the directions below, as

applicable.

Bodily chemical

contact Personal contamination can occur when chemicals splash, spill, or spray

directly onto a person.

1. Follow the emergency first aid instructions on the chemical label listed in

the “First Aid” or “Statements of Practical Treatment” section.

General procedures include:

a) Eyes – immediately flush with water or follow other directions as

specified on the chemical label.

b) Skin – immediately wash all contaminated skin surfaces with soap

and water, or follow directions as specified on the chemical label.

c) Clothing – remove contaminated clothing immediately. Dispose of

heavily contaminated clothing per the instructions on the chemical

label for safe chemical/container disposal.

2. Seek medical advice if instructed on the label, or if the victim experiences

symptoms of harmful effects such as burning, swelling, nausea, chest

pain, difficulty breathing, dizziness or confusion. When seeking medical

advice, be sure to bring the chemical product label.

Poisoning by

ingestion or

inhalation

In case of poisoning from ingestion or inhalation:

IF THE VICTIM HAS COLLAPSED OR IS NOT BREATHING, CALL

911. Otherwise:

1. If you are the victim, immediately seek assistance from nearby personnel

because you may become incapacitated.

2. Follow the emergency first aid instructions on the chemical label in the

“First Aid” or “Statement of Practical Treatment” section.

3. Call a poison control center for further advice. In the U.S., call 1-800-

222-1222 to be automatically linked to the nearest certified poison

control center. Have the chemical label available for reference.

Chemical spills Chemical spills must be quickly contained and properly cleaned up.

Refer to the chemical label for any specific clean-up instructions with regard

to the chemical spilled.

Operation – Important Safety Information (continued)

19

General procedures include:

1. Control the spill by stopping the source of the spill. If the source of the

spill is a container leak, place the leaking container in a larger, watertight

container. Keep unprotected people away from the spill site.

2. Contain the spill so that it does not spread and get into water sources.

Use a shovel or other tool to make a dike around the spill with soil, sod,

or absorbent material.

3. Clean up the spill immediately -- Absorbent materials like ground

corncobs or pet litter should be spread on the spill area to soak up the

pesticide. The contaminated material should then shoveled into a leak-

proof container. Do not flush the spill area with water until you receive

advice as directed below.

4. Seek additional advice from the chemical manufacturer and your state’s

pesticide regulatory agency regarding decontamination of the spill site:

- Chemical manufacturer. The chemical label provides contact

information for the chemical manufacturer.

- State pesticide regulatory agency. In the U.S., call the National

Pesticide Information Center at 1-800-858-7378 for assistance in

determining how to contact your state’s pesticide regulatory

agency.

Operation – Preparing the Pump for Each Use

20

If the pump has been used previously, it must be prepared BEFORE EACH SUBSEQUENT USE.

WARNING

Read instructions below carefully for inspecting and preparing the pump.

Damaged or clogged equipment could result in leaks or uncontrolled spray.

Leaks could result in injury to the operator or bystanders from chemical exposure, or cause

damage to the environment.

Important safety rules:

Power off. Make sure all power is OFF before cleaning, inspecting, or servicing the pump.

Guards / shields. Make sure all guards and shields are replaced after servicing the pump.

Replacement parts. If a part needs replacement, only use parts that meet the manufacturer’s

specifications. Replacement parts that do not meet specifications may result in a safety

hazard or poor operation of the sprayer.

1. Ensure clean

system Ensure the pump has been thoroughly flushed and drained of all

residual chemicals from prior uses.

2. Inspect &

repair Inspect and test the sprayer thoroughly:

a) Inspect hoses/ lines for exposed mesh and holes. Replace all worn

or damaged hoses/ lines.

b) Inspect fittings for cracks and leaks. Replace all damaged fittings

with original Everflo parts.

c) Partially fill system with plain water and spray to test for leaks.

Repair as needed.

IMPORTANT: After any repair work has been done, ALWAYS test for

leaks with water one final time before using.

Be certain the pump materials will be compatible with the chemical being pumped. Everflo pumps are

intended for intermittent or continuous duty when the proper operating criteria are met. If unsure of the

chemical compatibility with the Everflo pump components or the motor’s intended design, please call

Everflo Product Support at 1-800-864-1649 for assistance.

Table of contents

Other Everflo Water Pump manuals

Popular Water Pump manuals by other brands

Crane

Crane PROSSER HYMERGIBLE 7-06000 Series Installation and operation manual

Moog

Moog Enteralite Infinity Field guide

Reefe

Reefe RainPro RM5000 Installation Guide & Owners Information

Lincoln

Lincoln QUICKLUB 203 owner's manual

AL-KO

AL-KO HW 4000 FCS manual

KSB

KSB Amarex N S 32-160 Installation & operating manual