Everlasting BCE2020 User manual

1

ENGLISH

BLAST CHILLERS / SHOCK FREEZERS

PROFESSIONAL TRAY

Use and maintenance manual

Rev.11-20 Matricola / Serial number

2

ENGLISH

Thank you for choosing this product.

Please read the warnings contained in this manual carefully, as they provide important information

regarding safe operation and maintenance.

Make sure to keep this manual for any future reference by the various operators.

In some parts of the manual, the symbol appears, indicating an important warning that must be

observed for safety purposes.

CHAPTER 1 BOUNDARY CHARACTERISTICS OF OPERATION

The blast chiller has been designed and built to operate in optimal conditions at temperatures of

up to +43°C, with adequate air circulation. In places with characteristics that are different from the

requirements, the stated performance cannot be guaranteed.

Standard power voltage for models PROFESSIONAL TRAY 05 - 07 is 230V/50Hz; for models

PROFESSIONAL TRAY 10 - 15 - 20 is 400V/3N-Ph/50 Hz or the one indicated on CE label.

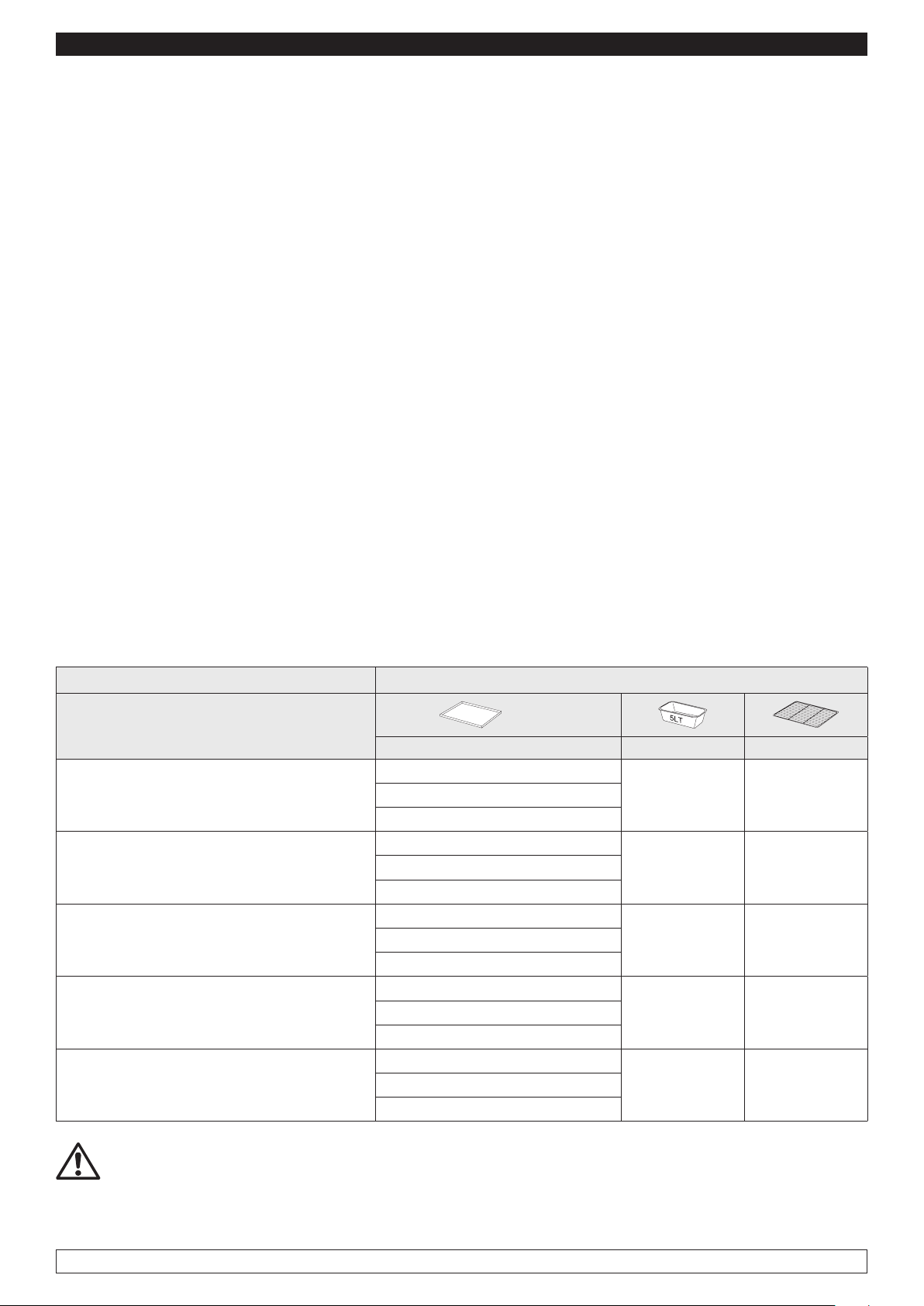

The following table shows the cooling and/or freezing capacity in kg.

Model Blast chilling Kg.

+90°C / +3°C Rapid freezing Kg.

+90°C / -18°C

PROFESSIONAL TRAY 05 P 20 14

PROFESSIONAL TRAY 07 P 25 18

PROFESSIONAL TRAY 10 P 35 25

PROFESSIONAL TRAY 15 P 55 40

PROFESSIONAL TRAY 20 P 75 55

N.B.: the times and quantities in kg above are valid for products with a maximum thickness of 4 cm.

Maximum time: Positive chilling: 90 min, Freezing: 240 min

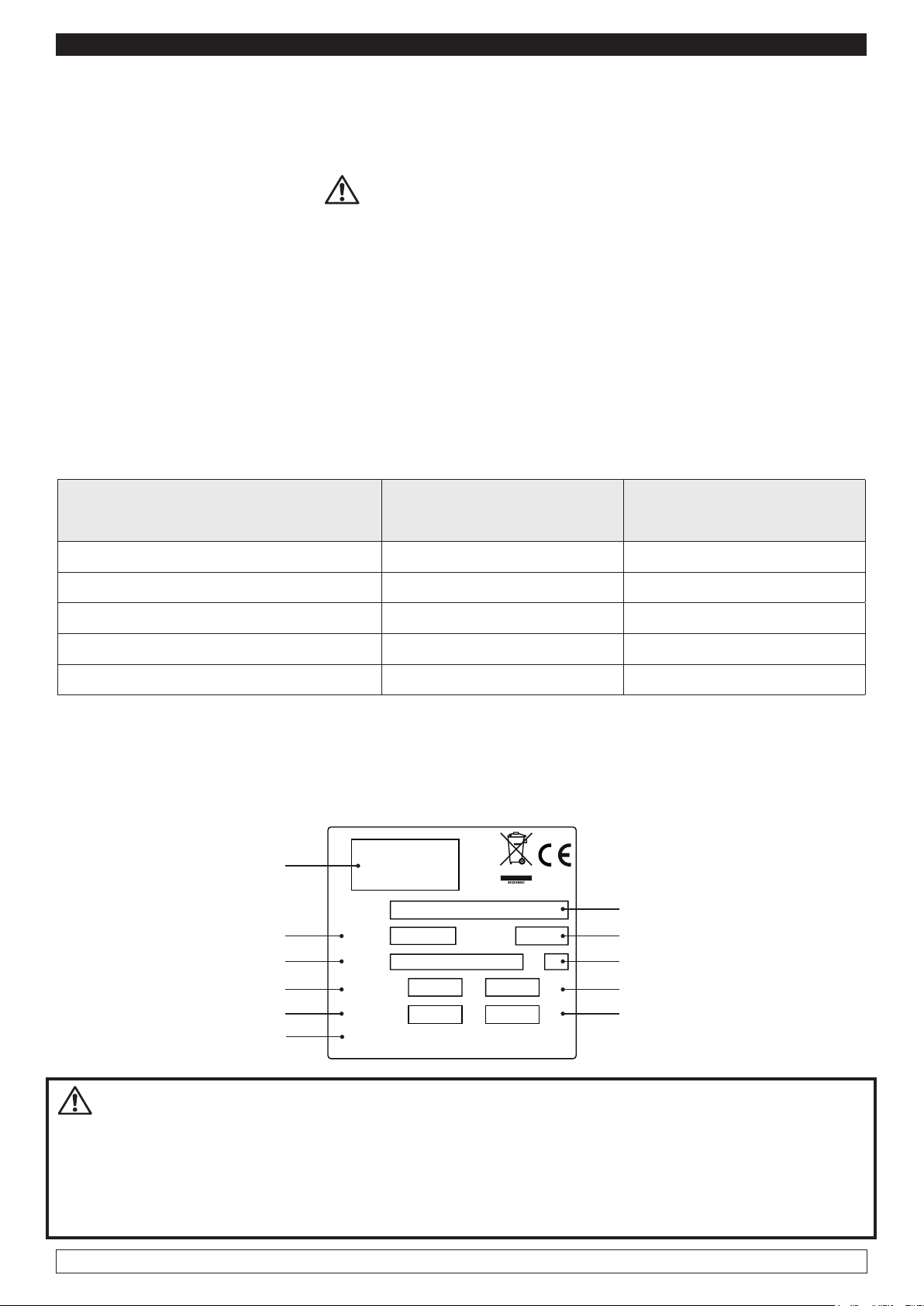

The technical features of blast chillers PROFESSIONAL TRAY 05 - 07 - 10 - 15 - 20 are listed on

the CE label placed on the rear side of the body.

AKw

Kg

CL.

Matricola

Ser. Number

Modello

Model

Cod.Art

Code

Tensione

Tension

Assorbimento

Absorption

Gas

Gaz

IP20, CLASS 1

Model

Registration Number

Climate class

Electrical power

Quantity of coolant

Manufacturing Company

Code article

Operating voltage

Power consumption

Type of coolant

Degree of protection

ATTENTION: any request for intervention, technical support and spare part must refer to the

SERIAL NUMBER on the CE label, on the manual cover or on the compressor motor.The producer

declinesanyresponsibilityforanyimproperornotreasonablyforeseenusageoftheblastchillerandfor

anyoperationcarriedoutbyneglectingtheindicationslistedonthemanual.Themanufacturerdeclines

any liability for improper use of the blast chiller, as well as use that could not have been reasonably

foreseen, and for all operations performed on it that disregard the instructions in the manual.

3

ENGLISH

The main general safety standards are listed below:

- Do not use or place electrical devices inside the refrigerated compartments if they are not of the

type recommended by the manufacturer

- Do not touch the blast chiller with damp or wet hands or feet

- Do not use the blast chiller barefoot

- Do not insert screwdrivers or other objects between the guards or moving parts

- Do not pull the power cord to unplug the blast chiller from the electricity network

- The blast chiller is not intended to be used by persons (including children) with physical or mental

problems, or lack of experience and knowledge, unless they are controlled or instructed in using the

unit by a person responsible for their safety. Children must be supervised to ensure that they do not

play with the appliance.

- Before carrying out any cleaning or maintenance, disconnect the blast chiller from the mains power

supply by turning off the main switch and pulling the plug

- In the event of failure and/or malfunction of the blast chiller, turn it off and to refrain from any attempt

to repair or intervene directly. It is necessary to exclusively contact a qualified technician.

Blast chiller model PROFESSIONAL TRAY is composed of a modular single body insulated with

expanded polyurethane with 42 kg/m3 density, internally covered in Stainless Steel AISI 304 and

externally by different materials.

In the design and construction, all measures have been adopted to

ensure a blast chiller that complies with safety and hygiene requirements, such as: rounded inte-

rior corners, deep drawing with drain on the outside for the condensate liquids, no rough surfaces,

fixed guards on moving or dangerous parts. The products must be stored in observance of the

load limits given in the table, in order to ensure an efficient circulation of air inside the blast chiller.

Load capacity BLAST CHILLERS PROFESSIONAL TRAY

PROFESSIONAL TRAY Capacity

Mod. GN 1/1

Nr° Nr° Nr°

PROF. TRAY

05 5Passo 70 mm. 6 26 Passo 52,5 mm.

9Passo 35 mm.

PROF. TRAY

07 7Passo 70 mm. 9 39 Passo 52,5 mm.

13 Passo 35 mm.

PROF. TRAY

10 10 Passo 70 mm. 12 413 Passo 52,5 mm.

19 Passo 35 mm.

PROF. TRAY

15 15 Passo 70 mm. 18 620 Passo 52,5 mm.

30 Passo 35 mm.

PROF. TRAY 20

21 Passo 70 mm. 24 827 Passo 52,5 mm.

41 Passo 35 mm.

The installation must be performed exclusively by a qualified technician

4

ENGLISH

1.1 It is prohibited to remove the guards and safety devices

t is absolutely forbidden to remove safety guards.

The manufacturer disclaims any liability for accidents due to failure to comply with this obligation.

1.2 Information on emergency operations in the event of fire

- disconnect the Blast chiller from the power source or cut off the power supply

- do not use water jets

- use dry chemical or CO2 extinguishers

CHAPTER 2 CLEANING THE REFRIGERATOR

Since the blast chiller will be used to store food, cleaning is necessary for hygiene and health

protection purposes. The cleaning of the blast chiller has already been carried out at the factory. It

is suggested, however, to carry out an additional cleaning of the internal parts before use, making

sure that the power cord is unplugged.

2.1 Cleaning the interior and exterior cabinet

For this purpose the following are indicated

- the cleaning products: water and mild, non-abrasive detergents. DO NOT USE SOLVENTS AND

THINNERS

- methods for cleaning: wash the interior and exterior parts with warm water and mild soap or with a

cloth or sponge with suitable products

- disinfection: avoid substances that can alter the organoleptic characteristics of the food

- rinsing: cloth or sponge soaked in warm water. DO NOT USE WATER JETS

- frequency: weekly is recommended, the user can set different frequencies depending on the type

of food being stored.

REMARK: Clean frequently the door seals.

Some preserved products could release some enzymes that could damage the seals causing its

quick deterioration. For the cleaning, use only specific products for this purposes, available also on

request on our sales network.

2.2 Cleaning the condenser

The efficiency of Blast chillers is compromised by condenser / remote condensing unit obstruction;

therefore, it is necessary to clean it monthly. Before carrying out this operation, turn off the Blast chiller

/ remote condensing unit, disconnect the power cable and proceed as follows:

Motor at the bottom – open the front control box by unscrewing the specific screws and by turning it

on the lower hinges.

Motor at the top- for models with non-flippable fixed front, use a safe stepladder and directly access

the condenser, placed on the upper part of the Blast chiller.

Remotecondensingunit–accordingtothemodel,removethecondenserprotectionasperinstructions

on the supplied unit manual.

Remove dust and lint from the wings by vertical movements with the help of an air jet or a dry brush.

In case of oily deposits, use a brush imbibed with specific detergents. For models with flippable fronts,

unscrew the block screw and turn the front by the top hinges; proceed then with cleaning as for models

with fixed front. After completing the operation, restart the Blast chiller. Evaporators installed above

the appliances are cartaphoresis-treated to reduce corrosion problems.

5

ENGLISH

During this operation, use the following personal protective equipment: goggles, respiratory

protection mask, chemically resistant gloves (gasoline-alcohol).

CHAPTER 3 PERIODIC CHECKS TO BE CARRIED OUT

The following are the points or units of the blast chiller that require periodic checks:

- integrity and efficiency of door seals

- integrity of the grilles in contact with food

- integrity of the fixing hinges of the doors

- integrity of the power cord of the blast chiller

3.1 PRECAUTIONS IN CASE OF LONG PERIODS OF INACTIVITY

A long period of inactivity is defined as a stoppage of more than 15 days.

It is necessary to proceed as follows:

- switch off the blast chiller and disconnect it from the power supply

- carry out a thorough cleaning of the interior cabinet, shelves, trays, guides and supports, paying

special attention to critical points such as the joints and magnetic gaskets, as indicated in Chapter 2.

- leave the door partly open to prevent air stagnation and residual humidity

CHAPTER 4 PREVENTIVE MAINTENANCE

4.1 Restarting after a long period of inactivity

Restarting after long inactivity is an event that requires preventive maintenance.

It is necessary to perform a thorough cleaning as described in chapter 2.

4.2 Control of the warning and control devices

We recommend that you contact your dealer for a service or maintenance contract that includes:

- cleaning of the condenser

- verification of the coolant load

- remote condensing unit condenser cleaning

- verification of the full cycle operation

- electrical safety

CHAPTER 5 EXTRAORDINARY MAINTENANCE AND REPAIR

All maintenance activities that have not been described in previous chapters are considered

“Extraordinary Maintenance.” Extraordinary maintenance and repair are tasks reserved exclusively

to the specialist personnel authorized by the manufacturer.

No liability is accepted for actions carried out by the user, by unauthorized personnel, or with the use

of non-original replacement parts.

6

ENGLISH

CHAPTER 6 TROUBLESHOOTING

Problems may occur, in the blast chiller, identified as shown in the table:

TROUBLE DESCRIPTION POSSIBLE CAUSES HOW TO REPAIR IT

the blast chiller does not turn on no power supply check the plug, socket, fuses, line

other contact technical support

the refrigeration unit does not start the set temperature has been reached set new temperature

defrosting in progress wait until the end of cycle / turn power off

and on again

control panel failed contact technical support

other contact technical support

the refrigeration unit runs conti-

nuously but does not reach the set

temperature

location is too hot aerate more

condenser is dirty clean the condenser

insufficient coolant contact technical support

stop the condenser fan contact technical support

insufficient sealing of doors check the seals / provision of goods

evaporator completely frosted manual defrosting

other contact technical support

the refrigeration unit does not stop at

the set temperature command panel failed contact technical support

temperature sensor ceiling failed contact technical support

block of ice on the evaporator misuse see chapter 1.

defrost heater fault contact technical support

defrost probe damaged contact technical support

accumulation of water or ice in the

drip tray drain clogged clean the pipette and the drain

blast chiller is not level check levelling

CHAPTER 7 INSTRUCTIONS FOR REQUESTING ASSISTANCE

For any technical problem and for intervention, assistance and spare-part requests it is necessary

to exclusively revert to one’s dealer, providing the code and the serial number indicated on the

specification label attached to the appliance.

CHAPTER 8 SAFETY AND ACCIDENT PREVENTION

The blast chiller has been built with suitable measures to ensure the safety and health of the user.

The following are the measures taken to protect against mechanical risks:

-stability:Theblastchiller,even with thegrilles removed, hasbeen designed andbuiltin suchaway

thatunderthe intendedoperating conditions,its stabilityissuitable foruse withoutriskofoverturning,

falling or unexpected movement

- surfaces, edges, corners: the accessible parts of the blast chiller are, within the limits allowed by

their functions, free of sharp angles and sharp edges, as well as rough surfaces likely to cause injury

- moving parts: were designed, constructed and arranged to avoid risks. Certain parts are equipped

with fixed guards so as to prevent risks of contact which may result in injury

7

ENGLISH

The following are the measures taken to protect against other risks:

- electricity: The blast chiller has been designed, built and equipped so as to prevent risks from

electricity, in accordance with the specific legislation in force

- noise: The blast chiller has been designed and built in such a way that risks resulting from the

emission of airborne noise are reduced to the minimum level

8.1 safety devices adopted

It is absolutely forbidden (Fig. 2):

- tamper with or remove the condensing unit cover casing

- to tamper with or remove the evaporator housing casing that protects the user against the risk of

being cut by the evaporator fins and the movement of the internal fan

- remove the labels specifiyng the technical features and the warnings for ground connection of the

condensing unit

- remove the labels applied at the inner edge of the engine compartment, showing the technical

specifications (1) and the instructions for grounding (2)

remove the condesing unit label warning to cut off the power supply before operating on the appliance

- remove the label applied on the evaporator guard and near the electrical wiring inside the engine

compartment, which warns the user to turn off the power supply before working on the unit (3)

- to remove the labels applied inside the engine compartment, indicating grounding (4)

- to remove the label applied on the power cord, indicating the type of power supply (5)

The manufacturer declines any responsibility for the safety of the blast chiller if this were to happen.

1

2

3

4

5423

1

2

3

Fig.2

8.2 Indications for optimal operation

- do not obstruct the motor-compartment air intakes (place at minimum 50 cm from ceiling)

- do not block the air vents of the engine compartment

- place the foodstuffs on the appropriate shelves or containers. Do not place them directly on the

bottom, or leaning against the walls, doors or fixed guards

- close the doors carefully

- always keep uncluttered the defrosting water drain hole placed on the bottom

- always keep the defrost water drain hole clear of obstructions

- limit, to the extent possible, the frequency and duration of door opening. Each opening causes a

change in the internal temperature

- perform periodically current maintenance (see chapter 3)

8

ENGLISH

CORRECT LOAD THE BLAST CHILLER

AVOID overloading the blast chiller beyond the set limits shown in the table

NO OK

Donotplacethetraystooclosetoeachothersoastoavoidunevenaircirculationinsidetheblastchiller

NO OK

Do not place the trays too far away from the evaporator

NO OK

Donotconcentratethetraysinoneareaoftheblastchillerincasetheloadisnotcomplete;distribute

its height evenly NO OK

In case of interruption or failure of the power supply circuit, prevent the opening of the doors in order

to maintain a uniform temperature inside the blast chiller.

If the problem persists longer than a few hours it is recommended to move the product to a suitable

place.

9

ENGLISH

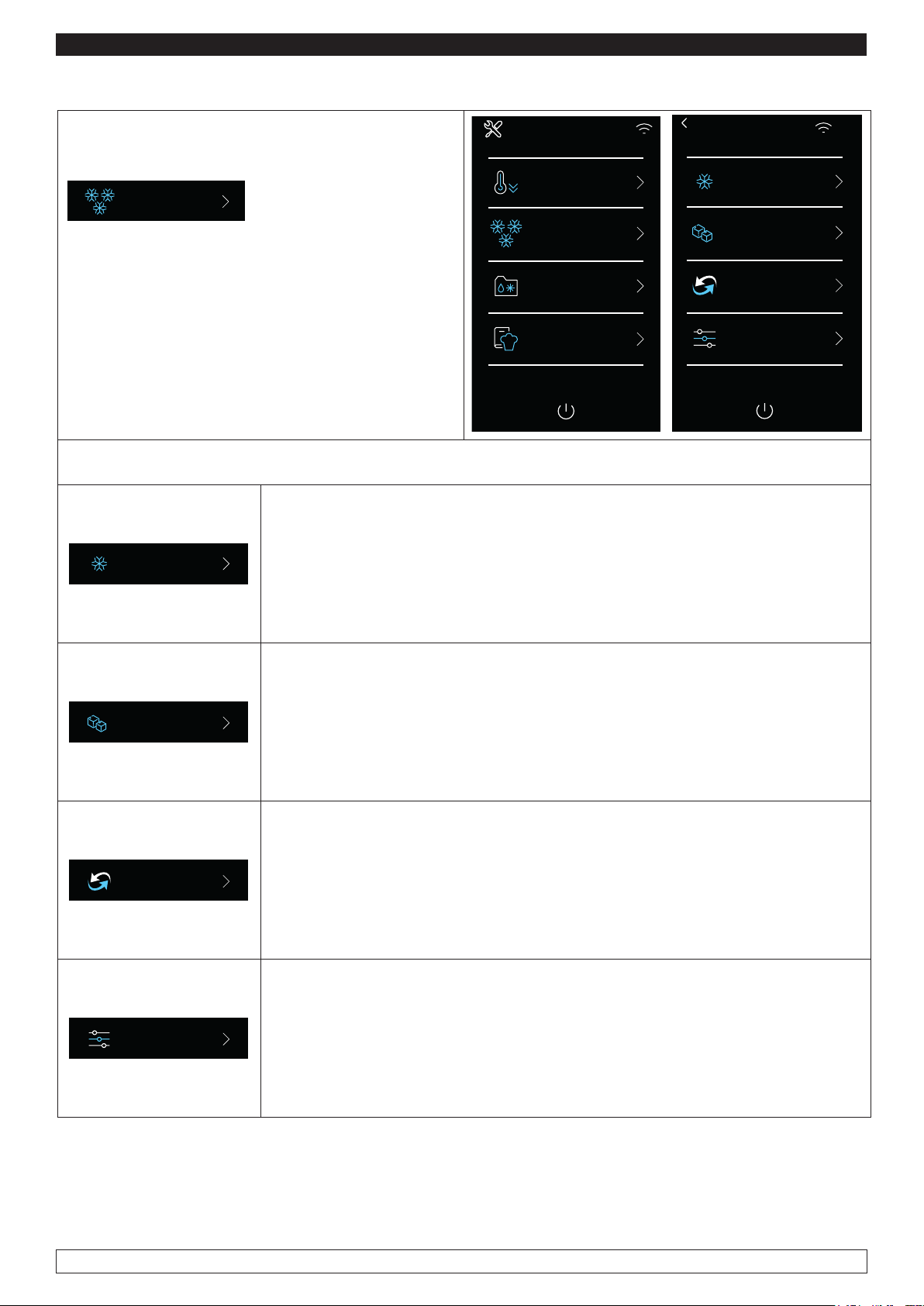

CHAPTER 9 CONTROLS

9.1 Control panel description:

the Blast chiller control panel is a digital thermoregulator with 5-inch capacitive touch-screen graphic

display.

HOME screen

The available operation statuses are:

- OFF control panel is off

- STAND-BY control panel is powered and turned off

- ON control panel is powered, turned on and waits for an operation cycle to start

- RUN control panel is powered, turned on and an operation cycle is running.

In case of power interruption during “STAND-BY” or “ON” status, when power will be restored the

control panel will resume the current status before the interruption.

In case of power interruption during “RUN” status, when power will be restore the Blast chiller will

operate as follows:

- if blast-chilling or shock-freezing was running, the cycle will be restored by taking into consideration

the duration of the power shortage;

- if STORAGE was running, the cycle will continue with the same settings;

- if LEAVENING or SLOW COOKING was running, the cycle will be resumed from the poit where it

was interrupted.

10

ENGLISH

9.2 INSTRUCTIONS FOR USE

9.2.1 Start-up

Before starting up the Blast chiller, make sure that electrical connections have been carried

out as indicated on chapter 14.

Plug in the Blast chiller; the display will turn

on and will show the status it was in before

unplugging it, i.e.:

On/stand-by screen: push on the central area to

go to HOME screen;

- directly on HOME screen , displaying the

operation menus.

ON/STAND-BY

PRESS TO START

11:38

11:38 11:38

SCROLL TO UNLOCK

13:35

HACCP

15:50 10/04/2019

15:50 10/04/2019

Start

Stop

01 / 20

CYCLE DURATION

25 °C

High temperature

11:38

Alarm list

Needle Probe

HOME

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

If the duration of the power shortage has caused a clock error, it will be necessary to reset real dat

and time (Chapter 10)

- Push the central key on the On/stand-by

screen to turn on the control panel: HOME

screen will be displayed.

- Push the key at the bottom of the HOME

screen to turn off the control panel.

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

PRESS TO START

11:38

11:38 11:38

SCROLL TO UNLOCK

13:35

HACCP

15:50 10/04/2019

15:50 10/04/2019

Start

Stop

01 / 20

CYCLE DURATION

25 °C

High temperature

11:38

Alarm list

Needle Probe

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

9.2.2 Silencing the buzzer

Push any key while the buzzer rings.

11

ENGLISH

9.2.3 Open door warning

- The following warning is displayed when the door is opened

- Push any area on the display to remove the visualization.

PRESS TO START

11:38

11:38

11:38

SCROLL TO UNLOCK

13:35

HACCP

15:50 10/04/2019

15:50 10/04/2019

Start

Stop

01 / 20

CYCLE DURATION

25 °C

High temperature

11:38

Alarm list

Needle Probe

9.3 OPERATION

The appliance can manage the following operation cycles:

- Temperature-based blast chilling and storage

- Temperature-based hard blast chilling and storage

- Time-based blast chilling and storage

- Time-based hard blast chilling and storage

- Temperature-based shock freezing and storage

- Temperature-based soft shock freezing and storage

- Time-based shock freezing and storage

- Time-based soft shock freezing and storage

- Multitimer continuous cycle

- Precooling

- Sanification

- Thawing (optional)

- Defrosting

- Ice-cream hardening

- Chocolate

- Drying

- Sterilisation (optional)

ThefollowingadditionalfunctionsareavailableonmodelsMULTIFUNCTIONALPROFESSIONALTRAY:

- Retarding-Proofing

- Slow cooking

12

ENGLISH

9.3.1 OPERATION MODE selection

Choose the operation mode by selecting the corresponding key on the HOME screen.

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

Allows selecting a chamber precooling cycle

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

Allows activating Blast chiller mode

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

Allows activating special cycle mode

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

Allows selecting recipe model, where prestored recipes are available

The icon appears in case of running alarms.

HACCP Push to visualize the archive of alarms detected during operation;

13

ENGLISH

9.3.2 BLAST-CHILLING / SHOCK-FREEZING cycle selection

- Push the key on the HOME screen to select a

BLAST-CHILLING or SHOCK-FREEZING cycle

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

HACCP

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

5°C

Slow Cooking

Proofing

Blast Chiller

Thawing

HACCP

Conservation

11:38

HACCP

11:38

Slow Cooking

Proofing

Thawing

Conservation

Cookbook

SPECIAL CYCLES

11:38

BLAST CHILLER

PRE-COOLING

COOKBOOK

PRE-COOLING

5°C

START

-10°C -6°C

STOP

XX

PRE-COOLING PRE-COOLING

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Holding

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOK

CONTINUOUS

FREEZING

CHILLING

MANUAL

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOK SLOW COOKING

AND HOLD

Red Meat

It will be possible to select one of the following functions:

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

BLAST CHILLING: allows selecting a standard blast chilling cycle

with its specic presets. It is possible to select the HARD mode on the

same screen: in this case, blast chilling is composed of two phases with

different setpoints.

At the end of blast chilling, the corresponding storage phase is carried

out with specic septoints according to the selected blast-chilling type.

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

SHOCK FREEZING: allows selecting a standard shock freezing cycle

with its specic presets. It is possible to select the SOFT mode on the

same screen: in this case, shock freezing is composed of two phases

with different setpoints.

At the end of shock freezing, the corresponding storage phase is carried

out with specic septoints according to the selected shock-freezing type.

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

CONTINUOUS CYCLE: allows selecting and endless blasti-chilling/

shock-freezing cycle with the possibility of inserting various operation

timers.

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

MANUAL CYCLE (CUSTOMIZED): Push the key to start the procedure

to set a customized cycle. It is possible to create up to 4 phases in

this cycle. Once all phases are set, the cycle can be started or the set

program can be saved inside the recipe list.

14

ENGLISH

- BLAST CHILLING/SHOCK FREEZING AND STORAGE

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

Push on these areas to respectively go to a BLAST-CHILLING or

SHOCK-FREEZING cycle: the following screen with active “core probe”

key is displayed.

NOTE: if the core probe is present and not in error, the default cycle is

always TEMPERATURE-BASED.

- Push the key to go to a TIME-BASED CYCLE: the core probe

key will deactivate and the TIME key will activate.

13:35

CHILLING

0 °C

3 °C

--- min

HARD

-20 °C

15 °C

HARD

2 °C

60 min

HARD

13:35

CHILLING

HARD

HARD

HARD

HARD

CONS

CONS

HARD

The selected cycle will propose the preset settings for that cycle

- Push the

13:35

FREEZING

-45 °C

-18 °C

--- min

SOFT

-40 °C

15 °C

5

SOFT

2 °C

SOFT SOFT

SOFT

CONS

CONS

SOFT

SOFT

key to asdjust the preset settings within the allowed

ranges.

- Push the

13:35

FREEZING

-45 °C

-18 °C

--- min

SOFT

-40 °C

15 °C

5

SOFT

2 °C

SOFT SOFT

SOFT

CONS

CONS

SOFT

SOFT

key to activate the EXPERT MODE and adjust all

setpoints of the various non-visible phases foreseen for the selected

cycle.

13:35

FREEZING

-45 °C

-18 °C

--- min

SOFT

-40 °C

15 °C

5

SOFT

2 °C

SOFT SOFT

SOFT

CONS

CONS

SOFT

SOFT

- Once all settings are completed, push to end the phase: a

summary screen with data regarding the set cycle will be displayed, as

shown here below.

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

Push the

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

key to save the set program, or

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

to start the cycle.

15

ENGLISH

If the cycle is TEMPERATURE-BASED, a test to check the correct insertion of core probe inside

the product will be carried out. If the test is not passed, the cycle automatically becomes TIMED-

BASED: the buzzer rings and the running alarm symbol will be displayed.

- During the execution of the cycle, the main

setpoints will be displayed.

Push the key to visualize the temperature

trend chart with 5-minute sampling, except

when cycle is resumend after a power shortage

and after the start of a storage phase.

it is possible to stop the cycle at any one time

by pushing the STOP key.

-15 °C

8 °C

13:35

3/3 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

1/3115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120 160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

1/3 115 minIN PROGRESS...

HARD

-40°C

-18°C

SOFT

HARD

SOFT

HARD

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

1/3 115 minIN PROGRESS...

STOP

STOP STOP

-15 °C

8 °C

13:35

3/3 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

1/

31

15 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120 160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

1/3 115 minIN PROGRESS...

HARD

-40°C

-18°C

SOFT

HARD

SOFT

HARD

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

1/3 115 minIN PROGRESS...

SKIP

STOP STOP

STOP

- Once the BLAST CHILLING/SHOCK

FREEZING cycle has ended (either the core

probe temperature has been reached or the

time has ended), the buzzer rings and the

STORAGE phase begins, after carrying out the

DEFROSTING phase

- The STORAGE phase is endless and only

ends if the STOP key is pushed

-15 °C

8 °C

13:35

3/3 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

1/3115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120 160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

1/3 115 minIN PROGRESS...

HARD

-40°C

-18°C

SOFT

HARD

SOFT

HARD

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

1/3 115 minIN PROGRESS...

SKIP

STOP

STOP

STOP

- COMBINED cycle with SLOW COOKING (MULTIFUNCTIONAL models)

- If available on the appliance, it is possible to add a a SLOW

COOKING or SLOW COOKING + CONSERVATION phase after blast

chilling or shock freezing during the setting of a MANUAL BLAST

CHILLING/SHOCK FREEZING CYCLE

- In the lower part of the screen, two specic areas allow you to add a

possible SLOW COOKING

13:35

CHILLING

0 °C

3 °C

--- min

HARD

SLOW COOKING

SLOW COOKING

AND HOLD

phase or a SLOW COOKING AND

HOLD phase

13:35

CHILLING

0 °C

3 °C

--- min

HARD

SLOW COOKING

SLOW COOKING

AND HOLD

If SLOW COOING is selected at the end of the phase, the

appliance will stop and remain in STAND-BY; if SLOW COOKING +

CONSERVATION is selected at the end of the cycle, the appliance will

continue operating with CONSERVATION phase and its adjustment

preset. CONSERVATION phase is endless and only ends after pushing

the STOP key for 5 seconds.

13:35

CHILLING

0 °C

3 °C

--- min

HARD

SLOW COOKING SLOW COOKING

AND HOLD

16

ENGLISH

Presets for SLOW COOKING or slow COOKING + CONSERVATION

are as per standard cycles.

SLOW COOKING = 80°C Chamber 60°C Core Probe

CONSERVATION: 60°C Chamber

It will be possible to adjust the value of each phase also during the

setting of a manual cycle.

- Here below a setting as example:

HARD BLAST CHILLING + SLOW COOKING + CONSERVATION

Push the SKIP

START

Fase 1

-20 °C

12 °C

--- min

Fase 2

-2 °C

3 °C

--- min

Fase 3

3 °C

--- °C

--- min

Mantenimento

50 °C

45 %

--- min

Lenta Cottura

80 °C

80 %

230 min

-15 °C

8 °C

--- min

FASE 1

-15 °C

8 °C

--- min

LENTA COTTURA

CONTINUO

SURGELAZIONE

ABBATTIMENTO

MANUALE

HACCP

13:35

LENTA COTTURA

E MANTENIMENTO

FASE 1

LENTA COTTURA LENTA COTTURA

E MANTENIMENTO

Carni Rosse

SKIP key to end the running phase and go to the next

one START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

SKIP

- HARD BLAST CHILLING/SHOCK FREEZING - SOFT BLAST CHILLING and STORAGE CYCLE

It is possible to select a hard blast chilling/ soft shock freezing by pushing

13:35

CHILLING

0 °C

3 °C

--- min

HARD

-20 °C

15 °C

HARD

2 °C

60 min

HARD

13:35

CHILLING

HARD

HARD

HARD

HARD

CONS

CONS

HARD

or

13:35

FREEZING

-45 °C

-18 °C

--- min

SOFT

-40 °C

15 °C

5

SOFT

2 °C

SOFT

SOFT

SOFT

CONS

CONS

SOFT

SOFT

. on

the blast chilling /shock freezing setting screen. Before selecting this mode, make sure to set the

type of desired cycle (TIME-BASED or TEMPERATURE-BASED).

This cycle is composed of two chilling phases with different setpoints and of a subsequent

STORAGE phase.

- a first “hard” phase for blast chilling and “soft” for shock freezing, with unmodifiable setpoints

defined by relative parameters;

- a second chilling phase BLAST-CHILLING/SHOCK-FREEZING

- a third STORAGE phase with adjustable setpoints.

At the end of a phase, the controller automatically starts next phase.

The end of the first two phases is signalled by the buzzer ringing.

Also for this cycle it is possible to select the TIME-BASED mode: in this case, the passage to the

next phases is determined by the elapsing of the set time.

17

ENGLISH

- CONTINUOUS cycle

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

Push the key to select a CONTINUOUS CYCLE, to be started only by

mode:

- TIME-BASED

After selecting the cycle, a screen on which to set chamber

temperature, fan speed, end-cycle storage duration and temperature

values appears.

MULTITIMER

CONSERVATION

1

3

2

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN PROGRESS...

STOP

13:35

CONTINUOUS

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN PROGRESS...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN PROGRESS...

-15 °C

13:35 248 minCONSERVATION

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELECT YOUR OPTION

Save recipe

START

START

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-10 °C

CONS

-10 °C

CONS

STOP STOP STOP

CONSERVATION

13:35

Cycle is started by pushing the START key; it ends only when all timers are elapsed; after this,

the STORAGE phase begins

TIME-BASED cycle allows setting up to four MULTITIMER timers.

Cycle starts by activating only the first timer with its presets, while the

other timers are activated by pushing teh key

CONSERVAZIONE

1

3

2

13:35

CONTINUO

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN CORSO...

STOP

13:35

CONTINUO

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN CORSO...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN CORSO...

-15 °C

13:35 248 minCONSERVAZIONE

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELEZIONA LA TUA OPZIONE

Salva ricetta

START START

13:35

CONTINUO

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP STOP STOP

CONSERVAZIONE

13:35

CONSERVAZIONE

1

3

2

13:35

CONTINUO

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN CORSO...

STOP

13:35

CONTINUO

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN CORSO...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN CORSO...

-15 °C

13:35 248 minCONSERVAZIONE

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELEZIONA LA TUA OPZIONE

Salva ricetta

START START

13:35

CONTINUO

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP STOP STOP

CONSERVAZIONE

13:35

CONSERVAZIONE

1

3

2

13:35

CONTINUO

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN CORSO...

STOP

13:35

CONTINUO

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN CORSO...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN CORSO...

-15 °C

13:35 248 minCONSERVAZIONE

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELEZIONA LA TUA OPZIONE

Salva ricetta

START START

13:35

CONTINUO

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP STOP STOP

CONSERVAZIONE

13:35

and

setting a time while the cycle is already running.

When the timer is confirmed with time setting, the conutdown starts

directly.

Each timer is independent and, when elapsed, it ca be reset and

restarted.

Cycle ends only when all set timers are elapsed.

At the end of a timer countdown, the buzzer rings; a notification

appears and the value “0 min” for the respective timer is visualized in

green colour.

CONSERVATION

1

3

2

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN PROGRESS...

STOP

13:35

CONTINUOUS

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN PROGRESS...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN PROGRESS...

-15 °C

13:35 248 minCONSERVATION

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELECT YOUR OPTION

Save recipe

START START

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP

STOP STOP

CONSERVATION

13:35

18

ENGLISH

- CUSTOMIZED cycle

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

- “MANUAL CUSTOMIZED” cycle allows setting a cycle composed of

maximum 4 phases (3 CHILLING phases and 1 STORAGE phase),

and can be composed of TEMPERATURE-BASED, TIMED-BASED or

MIXED phases

On MULTIFUNCTIONAL models it is possible to set a SLOW

COOKING or SLOW COOKING + CONSERVATION phase at the end

of the cycle

PHASE 1

-15 °C

8 °C

--- min

- The “CUSTOMIZED” cycle is started by activating the first phase,

which is a core-probe phase by default.

It is possible to change the phase to TIME-BASED and set the relative

setpoints.

Push

PHASE 1

-15 °C

8 °C

--- min

to add any extra phase; push

PHASE 1

-15 °C

8 °C

--- min

to remove a phase from

the program.

Use the arrows on top to move among the various phases.

Once the desired phases are entered and the various settings are

carried out, push to confirm: a summary screen will be then

visualized.

65 °C80 °C

SOFT

79 °C 80 °C

13:35

Fase 1/2115 minIN PROGRESS...

80 % 80 %

8 m 230 m

SKIP

13:35

Fase 2/2 248 minHOLDING

46 °C 50 °C

45 % 45 %

--- m

50 °C

--- min

45 %

START

Slow cooking

80 °C

80 %

230 min

Holding

50 °C

45 %

--- min 0 °C

3 °C

--- min

HARD

HARD

HARD

HARD -20 °C

15 °C

HARD

2 °C

CONSERVATION

60 min

SLOW COOKING AND CHILLING

Slow cooking

80 °C

80 %

230 min

Hard blast chilling

-20 °C

15 °C

--- min

Soft blast chilling

0 °C

3 %

--- min

Conservation

2 °C

--- °C

--- min

79 °C 80 °C

13:35

Fase1/4115 minIN PROGRESS...

80 % 80 %

8 m 230 m

-15 °C

8 °C

13:35

Fase 4/4 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

Fase 2/4115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

Fase 2/4115 minIN PROGRESS...

HARD

-40°C

-18°C

13:35

Fase 4/4248 minCONSERVATION

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

Fase2/4115 minIN PROGRESS...

13:35

SLOW COOKING

80 °C

230 min

80 % 60 °C

CHILLING HOLDING

CHILLING HOLDING

HOLDING SLOW COOKING AND HOLD CHILLING CHILLING

HARD

HARD

HARD

START

CONSERVATION

STOP STOP SKIP STOP STOP STOP STOP

13:35

SPECIAL CYCLES

DEFROST

UV

SANITATION

HARDENING DRYING

CHOCOLATE STERILIZATION

THAWING RETARDER PROOFERS SLOW COOKING

Push START to start the cycle or

65 °C80 °C

SOFT

79 °C 80 °C

13:35

Fase 1/2115 minIN PROGRESS...

80 % 80 %

8 m 230 m

SKIP

13:35

Fase 2/2 248 minHOLDING

46 °C 50 °C

45 % 45 %

--- m

50 °C

--- min

45 %

START

Slow cooking

80 °C

80 %

230 min

Holding

50 °C

45 %

--- min 0 °C

3 °C

--- min

HARD

HARD

HARD

HARD -20 °C

15 °C

HARD

2 °C

CONSERVATION

60 min

SLOW COOKING AND CHILLING

Slow cooking

80 °C

80 %

230 min

Hard blast chilling

-20 °C

15 °C

--- min

Soft blast chilling

0 °C

3 %

--- min

Conservation

2 °C

--- °C

--- min

79 °C 80 °C

13:35

Fase1/4115 minIN PROGRESS...

80 % 80 %

8 m 230 m

-15 °C

8 °C

13:35

Fase 4/4 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

Fase 2/4115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

Fase 2/4115 minIN PROGRESS...

HARD

-40°C

-18°C

13:35

Fase 4/4248 minCONSERVATION

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

Fase2/4115 minIN PROGRESS...

13:35

SLOW COOKING

80 °C

230 min

80 % 60 °C

CHILLING HOLDING

CHILLING HOLDING

HOLDING SLOW COOKING AND HOLD CHILLING CHILLING

HARD

HARD

HARD

START

CONSERVATION

STOP STOP SKIP STOP STOP STOP STOP

13:35

SPECIAL CYCLES

DEFROST

UV

SANITATION

HARDENING DRYING

CHOCOLATE STERILIZATION

THAWING RETARDER PROOFERS SLOW COOKING

to save it into the recipe list.

19

ENGLISH

9.4 SETPOINT setting

9.4.1 CHAMBER TEMPERATURE SETPOINT setting

When a blast-chilling, shock-freezing, continuous or customized cycle is selected, the chamber

temperature, product temperature, time and fan speed presets are loaded as per parameter settings.

These values can be adjusted by users withing the defined ranges.

Push the

PHASE 1

-15 °C

8 °C

--- min

key next to the value to adjust to enable the adjustment;

the screen here below will appear and the value to be adjusted will turn

different color.

- Set the desired value using the lower bar

PHASE 1

-15 °C

8 °C

--- min

.

Once the setting is completed, push the

PHASE 1

-15 °C

8 °C

--- min

key next to the adjusted

value and return to the previous screen.

PHASE 1

-15 °C

8 °C

--- min

9.4.2 PRODUCT TEMPERATURE SETPOINT setting

Proceed as described for chamber setpoint, after pushing the

PHASE 1

-15 °C

8 °C

--- min

key regading product temperature

(i.e. the temperature detected by core probe)

PHASE 1

-15 °C

8 °C

--- min

9.4.3 CYCLE DURATION setting

Proceed as described for chamber setpoint, after pushing the

PHASE 1

-15 °C

8 °C

--- min

key regarding cycle duration.

9.4.4 FAN SPEED setting

Proceedasdescribedforchambersetpoint,afterpushingthe

PHASE 1

-15 °C

8 °C

--- min

keyregarding fanspeed.Minimum

fan speed can be set for any cycle except SLOW COOKING.

9.5 CYCLE execution

- Push the START key to start a cycle as per setttings.

If the cycle is TEMPERATURE-BASED, blast-chilling/shock-freezing

phasesendwhenthecoreprobe(orcoreprobes)reachthesettemperature.

If the cycle is TIME-BASED, blast-chilling/shock freezing phases end

when the set time(s) elapse.

The following sreen is displayed during the execution of the cycle.

Push the key to visualize probe values, input/output status and

possible running alarms.

-15 °C

8 °C

13:35

3/3 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

1/3115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120 160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

1/3 115 minIN PROGRESS...

HARD

-40°C

-18°C

SOFT

HARD

SOFT

HARD

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

1/3 115 minIN PROGRESS...

SKIP

STOP

STOP STOP

20

ENGLISH

9.6 CYCLE end

- If the TEMPERATURE-BASED blast-chilling/shock-freezing cycle ends

correctly, i.e. temperature at product core is reached within the allowed

time, STORAGE phase automatically starts and the following screen is

displayed.

if the TEMPERATURE-BASED cycle does not end within the allowed

times, the alarm icon will warn about the anomaly, but the chilling cycle

will continue anyway. -15 °C

8 °C

13:35

3/3 248 minCONSERVATION

HARD

-40°C

-18°C

13:35

1/3115 minIN PROGRESS...

HARD

set cella

T cella

Set spillone

Set cella

40

-45

60

30

-30

-15

15

45

80 120 160 200 240

set spillone

T spillone

-15 °C

8 °C

13:35

1/3 115 minIN PROGRESS...

HARD

-40°C

-18°C

SOFT

HARD

SOFT

HARD

-15 °C

8 °C

HARD

-40°C

-18°C

13:35

1/3 115 minIN PROGRESS...

SKIP

STOP

STOP

STOP

- For TEMPERATURE-BASED cycles, push the STOP , key to display

the screen allowing the functions of:

CONSERVATION

1

3

2

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN PROGRESS...

STOP

13:35

CONTINUOUS

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN PROGRESS...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN PROGRESS...

-15 °C

13:35 248 minCONSERVATION

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELECT YOUR OPTION

Save recipe

START START

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP STOP STOP

CONSERVATION

13:35

- memorization of the previously carried-out cycle.

- or push the STOP key again to return to main menu

CONSERVATION

1

3

2

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-15 °C

12 °C

8 °C

2 °C

1

2

3

13:35 95 minIN PROGRESS...

STOP

13:35

CONTINUOUS

-15 °C

--- °C

--- min

-15 °C

1

13:35 32 minIN PROGRESS...

68 min

20 min

332 min

412 min

-15 °C

168 min

20 min

332 min

412 min

13:35 32 minIN PROGRESS...

-15 °C

13:35 248 minCONSERVATION

-40°C -15 °C

STOP

13:35 248 min

-40°C

8 °C

SELECT YOUR OPTION

Save recipe

START START

13:35

CONTINUOUS

-15 °C

3 °C

--- min

-10 °C

CONS -10 °C

CONS

STOP STOP

STOP

CONSERVATION

13:35

- At the end of a TIME-BASED cycle, the blast-chilling/shock-freezing

mode starting screen will be displayed.

START

Phase 1

-20 °C

12 °C

--- min

Phase 2

-2 °C

3 °C

--- min

Phase 3

3 °C

--- °C

--- min

Conservation

50 °C

45 %

--- min

Slow Cooking

80 °C

80 %

230 min

-15 °C

8 °C

--- min

PHASE 1

-15 °C

8 °C

--- min

SLOW COOKING

CONTINUOUS

FREEZING

CHILLING

MANUAL

HACCP

13:35

SLOW COOKING

AND HOLD

PHASE 1

SLOW COOKING SLOW COOKING

AND HOLD

Red Meat

Table of contents

Other Everlasting Refrigerator manuals

Everlasting

Everlasting BAKING CAB FL Series User manual

Everlasting

Everlasting 700 INOX Instructions for use

Everlasting

Everlasting Pastry BN 1 Installation instructions

Everlasting

Everlasting PROFESSIONAL TRAY 05 P User manual

Everlasting

Everlasting STAGIONATOR Instructions for use

Everlasting

Everlasting CHOCOLATE GREEN User manual

Everlasting

Everlasting MULTILAB User manual

Everlasting

Everlasting LoStagionatore STG ALL 700 INOX S ADV Instructions for use

Everlasting

Everlasting TNV Series User manual

Everlasting

Everlasting LoStagionatore MEAT Series User manual