Everlasting LoStagionatore STG ALL 700 INOX S ADV Instructions for use

Instruction and maintenance manualInstruction and maintenance manual

Rev.11-08

ALL-IN-ONEALL-IN-ONE

EVERTOUCHEVERTOUCH

LoStagionatore

SINCE 1956

Chapter 1 GENERAL RULES AND WARNINGS

1.1 Tests and warranty

1.2 Introduction

1.3 Product description

1.4 General safety regulations

1.5 Client’s responsibilities

1.6 Service requests

1.7 Instructions for spare parts orders

Chapter 2 SPECIFICATIONS

2.1 Dimensions

2.2 Product configurations

2.3 Power output and absorbed power

2.4 Noise level

2.5 Materials and refrigerants

Chapter 3 INSTALLATION

3.1 Transport and handling

3.2 Positioning

3.3 Wiring and electrical connection

3.4 Set-up operations

3.5 Reinstallation

3.6 Dismantling and disposal

Chapter 4 OPERATION

4.1 Applications and intended use

4.2 Safety and accident prevention

4.3 Safety data plates and guards

4.4 Operating limits

Chapter 5 ORDINARY AND PLANNED MAINTENANCE

5.1 Basic safety regulations

5.2 Cleaning operations

5.3 Periodic checks

5.4 Precautionary measures after long disuse

5.5 Preventive maintenance

Chapter 6 EXTRAORDINARY MAINTENANCE AND REPAIRS

Chapter 7 DIAGNOSTICS

Chapter 8 LO STAGIONATORE DESCRIPTION

Chapter 9 OPERATION

9.1 Installation

9.2 First Start-up

9.3 Locked Home Screen

9.4 Unlocked home Screen

Chapter 10 RECIPES

10.1 Recipe Screen

10.2 Start of Existing Recipe

10.3 Creation of New Recipe

10.4 Change and following Saving of Existing Recipe

10.5 Deleting of a Recipe

10.6 Running Recipe

INDEX

Pag. 01

Pag. 01

Pag. 01

Pag. 02

Pag. 02

Pag. 02

Pag. 02

Pag. 03

Pag. 03

Pag. 03

Pag. 03

Pag. 03

Pag. 03

Pag. 03

Pag. 04

Pag. 04

Pag. 04

Pag. 05

Pag. 05

Pag. 06

Pag. 06

Pag. 06

Pag. 06

Pag. 07

Pag. 07

Pag. 07

Pag. 08

Pag. 08

Pag. 08

Pag. 09

Pag. 09

Pag. 09

Pag. 09

Pag. 10

Pag. 11

Pag. 13

Pag. 13

Pag. 13

Pag. 13

Pag. 16

Pag. 19

Pag. 20

Pag. 29

Pag. 30

Pag. 32

Pag. 34

Pag. 35

Chapter 11 SHORTCUTS

11.1 Start_stop

11.2 Defrost

11.3 Air exchange

11.4 Rotation (optional)

11.5 Alarms

11.6 Probes

11.7 Sterilization (optional)

Chapter 12 SETUP

12.1 Date and time

12.2 Language

12.3 Connections

12.3.1 Transfers

12.3.2 Info

12.3.3 Firmware Update

12.3.4 Reboot

12.4 Parameters

Capitolo 13 SERVICE

13.1 Password access to the parameters menu

13.2 Seasoning Parameters

13.3 Alarm diagnostics

13.4 Replacement of U.V. Lamp

Pag. 39

Pag. 39

Pag. 40

Pag. 41

Pag. 41

Pag. 42

Pag. 44

Pag. 46

Pag. 47

Pag. 48

Pag. 48

Pag. 49

Pag. 49

Pag. 51

Pag. 51

Pag. 51

Pag. 51

Pag. 53

Pag. 53

Pag. 54

Pag. 56

Pag. 57

1

STAGIONATORE

Section 1: GENERAL INSTRUCTIONS

1.1 TESTING AND GUARANTEE

The appliance is tested in our works in compliance with established regulations and then shipped

ready for use.

The guarantee is valid for a full 12 months from the date of delivery of the appliance and it covers

the repair or replacement of any defective parts, with the exception of electrical and electronic

components.

Manifest defects or differences with respect to the client’s order must be communicated to the ma-

nufacturer within ve days from the receipt of the goods or they will not be covered by the guaran-

tee terms.

Any hidden or other defects must be communicated to the manufacturer within ve days from the

time that they are discovered and, in any event, within the maximum guarantee term of 12 months.

The purchaser shall be entitled only to request repair or replacement of the goods. The purchaser

is not entitled to claim compensation for direct or indirect damages of any whatsoever nature. In

any case, the right of reparation or replacement of materials will have to be exercised within the

warranty maximum time limit of 12 months from delivery date.

Repairs or replacement of defective materials will be carried out at the manufacturer’s works;

material returned to the manufacturer must be shipped carriage paid and will be returned to the

purchaser carriage forward.

1.2 INTRODUCTION

This manual has been prepared with the scope of supplying all the instructions required for the

correct use of the appliance and to maintain it in optimal condition. It also contains important user

safety information.

The following professional roles are explained in order to dene the responsibilities of each:

Installer: a qualied technician who positions the appliance and places it in service it in accordan-

ce with the instructions in this manual.

User: the person who, after reading this manual carefully, operates the appliance in accordance

with the intended use specied in this manual.

Users’ responsibilities:

- to ensure that food products are conserved at suitable temperatures and not exceeding the per-

mitted period of time

- to be aware of the regulations governing the conservation of food and to observe any whatsoever

hygiene indications that may be applicable.

The user is obliged to read the manual attentively and refer to the information in the manual at all

times.

Particular attention must be paid to the contents of heading 1.5 General Safety Warnings.

Routine Maintenance Technician: qualied technician able to perform routine maintenance of

the appliance by following the instructions in this manual (see section 5).

Special Maintenance Technician: qualied technician, authorized by the manufacturer to perform

extraordinary maintenance of the appliance (see section 6).

2

STAGIONATORE

The symbol appears at certain points in the manual to draw the reader’s attention to important

safety information.

The manufacturer declines any whatsoever responsibility in the case of improper use of the ap-

pliance deviating from the reasonably construed intended use, and for all operations carried out

that are not in compliance with the instructions laid down in the manual.

This manual must be conserved in a place that is accessible and known to all operators (installer,

user, routine maintenance technician, special maintenance technician).

This manual must not be reproduced or divulged, in whole or in part, using any whatsoever means

or in any whatsoever form.

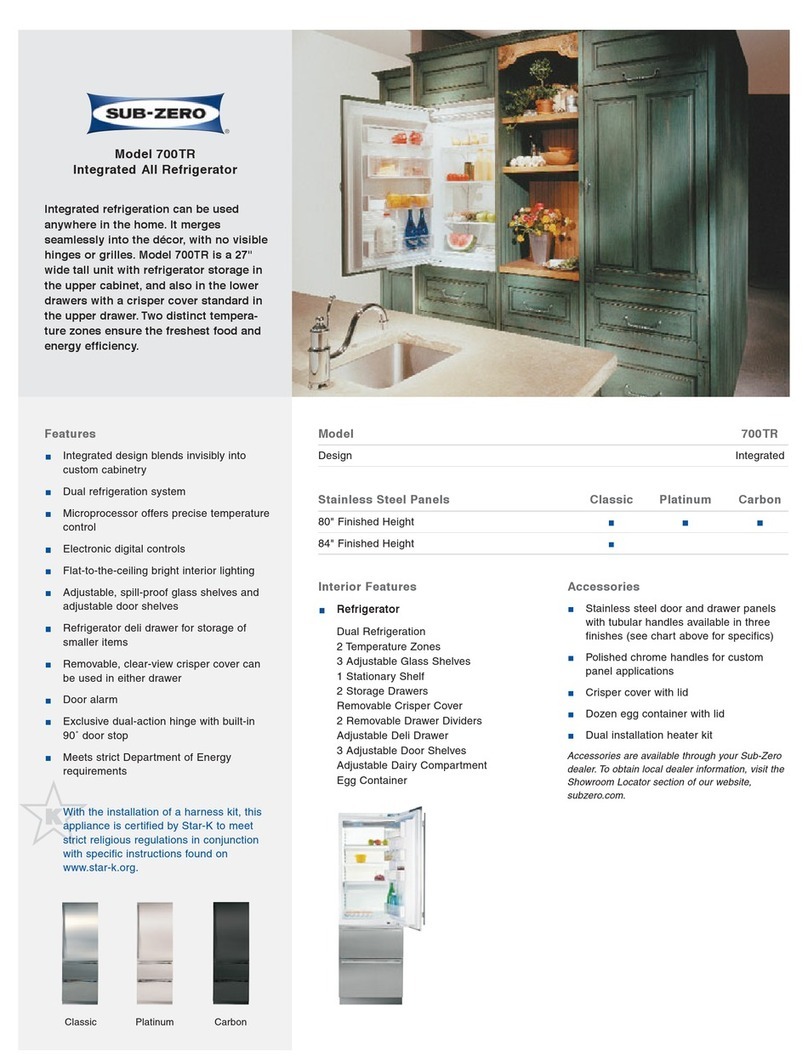

1.3 PRODUCT DESCRIPTION

The appliance comprises a modular single body with panelling in various materials and insulation

in expanded polyurethane foam, density 42 kg/cu.m.The appliance instruments are located on the

front panel which closes the front of the motor unit, inside which the condenser unit and electrical

wiring can be housed. The refrigerator interior is tted with suitable supports for wire shelves (grids)

and/or other accessories. The doors are tted with an automatic return device and magnetic seal

elements. During the design and construction stage all measures have been adopted to implement

total safety including radiused interior corners, funnel-shaped base panel to convey condensate to

exterior, no rough surfaces, xed guards protecting moving or potentially dangerous parts.

1.4 GENERAL SAFETY REGULATIONS

Read this manual carefully and follow the prescriptions contained herein.

The user assumes full responsibility in the case of operations carried out without observing the

instructions in the manual.

Primary general safety regulations:

- do not touch the unit with wet hands and/or feet

- do not use the appliance with bare feet

- do not insert screwdrivers or other pointed objects between guards or moving parts of the appliance

- do not pull the power cord to disconnect the appliance from the electrical mains

- make sure that the appliance is not used by children or unsuitably qualied persons

- before performing any cleaning or maintenance on the appliance disconnect it from the electrical

mains by switching of

the main switch and extracting the plug

- in the case of faults or malfunctions, switch off the appliance and do not attempt to repair it

yourself. All service and repair operations must be performed exclusively by suitably qualied au-

thorized technicians.

1.5 CLIENT’S RESPONSIBILITIES

The customer is required to:

- execute the electrical and hydraulic connection of the appliance

- prepare the place of installation

- provide consumable materials for cleaning

- perform routine maintenance

- Provide adequate protection for pipes and cables external to the appliance.

In the case of power failures or malfunctions do not open the doors and drawers in order to main-

tain uniform temperature inside the unit. If the problem persists for more than a few hours, move

the food contents to a more suitable place.

3

STAGIONATORE

1.6 CLIENT SERVICE REQUESTS

For all technical problems and any requests for technical service, refer exclusively to your local dealer.

1.7 ORDERING SPARE PARTS

Spare parts orders must be made by consulting the relative spare parts catalogue which gives the

correct description of the part, the part reference code and the serial number of your appliance.

Consult your dealer.

Section 2: SPECIFICATIONS

2.1 DIMENSIONS

The overall dimensions of the units having cardboard, wooden crate and wooden box packing are

reported in TABLE 1.

2.2 PRODUCT CONFIGURATION

The appliance is designed solely for the preservation of food products (see heading 4.1).

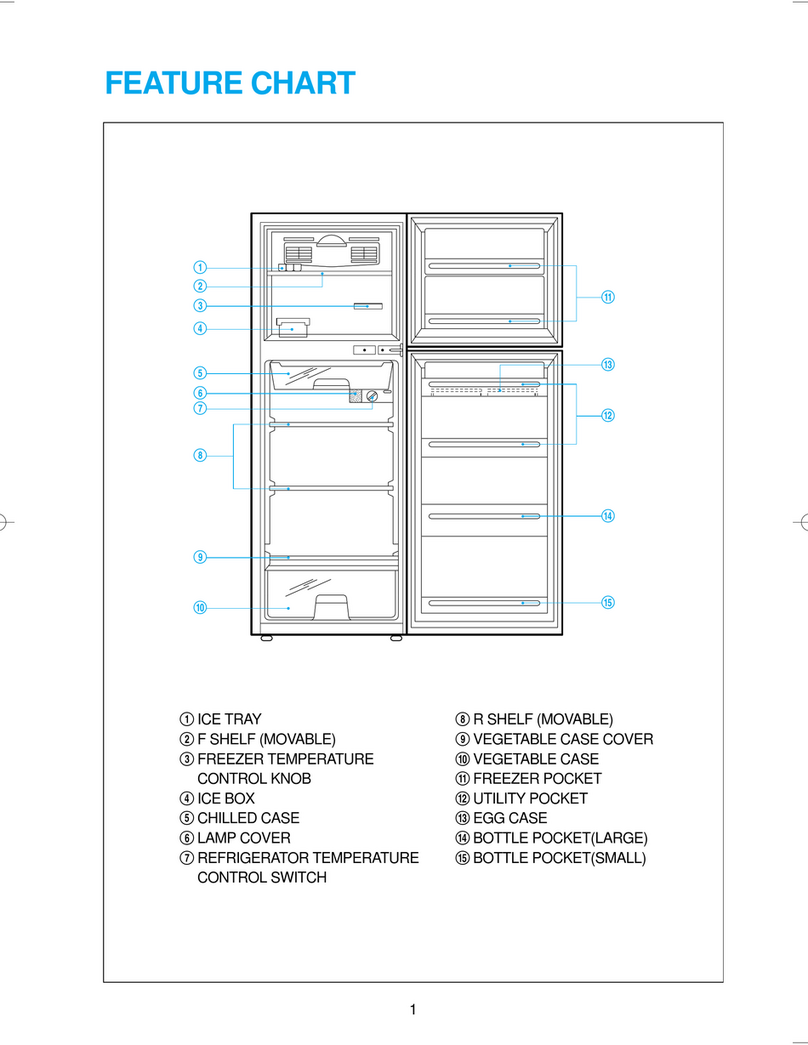

The products must be stored in observance of the load limits shown in the table and in gure 1 in

order to ensure efcient air circulation inside the appliance (g.1).

PL

H

Type Load limits mm

Model L H P

700-1500 530 1500 650

g.1 Model Kg

700 S 100

700 C / F 150C / 100F

1500 S 200

1500 C / F 300C / 200F

2.3 POWER OUTPUT AND ABSORBED POWER

Technical data for power output and absorbed power are in the enclosed TABLE 1.

2.4 NOISE LEVEL

The noise level of the appliance is below 70 dB (A).

2.5 MATERIALS AND REFRIGERANTS

Materials in contact or potentially in contact with food products are in compliance with the relevant

directives. The appliance is designed and built so that food contact parts can be cleaned before

each use. The refrigerants utilized (R404A,) comply with established regulations, see TABLE 1.

4

STAGIONATORE

Section 3: INSTALLATION

3.1 TRANSPORT AND HANDLING

The appliance must be transported and handled exclusively in a vertical position, in observan-

ce of the instructions printed on the packing.

This precaution is necessary to avoid contamination of the refrigerant circuit with compressor lube oil

with resulting valve and heat exchanger coil failure and problems starting the electric motor.

The manufacturer accepts no responsibility for problems due to transport executed in conditions

other than those specied above.

The accessories supplied with the appliance (runners, wire shelves, basins, trays) are supplied in

separate packs shipped inside or separately from the unit.

The appliance is secured to a wooden base by means of plastic ties (g.2) and wrapped in

polyethylene or packed in a carton, cage or crate.

Refer to heading 3.6 for information on correct disposal of packing material.

The appliance must be handled using a fork lift truck or a pallet truck with suitable forks (fork

length at least equal to 2/3 length of unit).

Sizes and masses of packed units are reported in TABLE 1

Maximum permissible stacking and the position of the centre of gravity are shown on the

information label on the packing.

3.2 POSITIONING

Incorrect positioning can cause damage to the appliance and generate hazardous conditions for

personnel. The installer must therefore observe the following general regulations:

- make sure you maintain a minimum of 3 cm from the walls

- the room must be well ventilated

- keep well away from sources of heat

- avoid direct sunlight

Specic positioning procedures

- remove packing material (polyethylene, cardboard box, crate, cage)

Polyethylene is potentially dangerous to children

- remove accessories from inside the unit.

Removing the wooden base: tilt the unit sideways and cut the plastic ties (g.2) lift and remove the

base.

fig.2 fig.3 fig.4

use gloves when handling wooden packing materials and the wooden base to protect the han-

ds from splinters

5

STAGIONATORE

- position the appliance with the help of a spirit level. Adjust the leveling feet on the metal base of

the unit if necessary (g.3)

- remove the protective PVC lm from the external surfaces of the unit

- position the shelf runners in the holes in the uprights (g.4)

- insert the food shelves in the runners

- insert the condensate collection tray in the relevant runners located beneath the unit

3.3 WIRING AND ELECTRIC / WATER CONNECTION

The electrical plant and electrical hook-up operations must be

performed by a qualied electrician

For safety reasons adhere to the following indications:

- check that the electrical plant is suitably sized for the absor-

bed power of the unit

- if the electrical socket and the plug on the appliance power

cord are incompatible, change the plug with a suitable compo-

nent, ensuring the replacement part is of the approved type

- do not use reductions or multi-way adapters (g.5)

It is important to connect the appliance correctly to an efcient earth system executed in com-

pliance with the relevant legislation.

Connection to the water supply

network:

All the Seasonig cabinets need to

be connected to the water supply

network to absolve the humidity

functions.The connection

to the water supply network

must be execute according to

manufacturer’s instructions and

to professional qualied personal.

The ¾ thumb connection to the

water supply network is placed in

the engine compartment, at 200

cm high from the ground. This

cabinet need to be exclusively

connected to cold water, not

distilled and demineralized. The

working pressure needs to be

between 0,1 to 0,3 MPA.

It is advisable to install a tap to

stop the water ow in case of

maintenance.

If water is a little bit tough is

recommended to install a water

softener. Any possible solid

particles, sands for example, can

be removed installing a mechanic lter that it must be periodically checked and clean.

3.4 SET-UP OPERATIONS

To avoid errors and accidents, perform a series of checks for possible damage sustained du-

ring transport, installation and hook-up operations before starting up the unit.

fig.5

6

STAGIONATORE

Preliminary Checks

-check the condition of the power cord (no cuts or chafng)

-check that the feet, door hinges and shelf supports are stable

-check the condition of internal and external components (pipelines, heat exchanger elements,

fans, electrical components, etc.); check also that all parts are rmly xed into position

-check that the door seals and drawers are not damaged (broken or scratched) and that the doors

close and are sealed properly

The user must also observe the following instructions to obtain the best operation from the ap-

pliance:

Indications for Optimal Duty

- do not block the motor compartment air vents

- make sure doors are kept closed

- keep the defrost water drain outlet clear

- limit the frequency and duration of opening; each time the door is opened the internal temperatu-

re will alter

- perform routine maintenance regularly (see section 5).

3.5 RE-INSTALLATION

Observe the following procedure:

- switch off the appliance from the main switch

- disconnect the power cord from the electrical outlet

- handle the appliance in accordance with the instructions in heading 3.1

- follow the instructions in headings 3.2 and 3.3 for positioning and hook-ups in the new location

3.6 SCRAPPING AND DISPOSAL

Scrapping and disposal of the appliance must be carried out in full observance of established legi-

slation in your country.

Section 4: OPERATION

4.1 APPLICATIONS AND INTENDED USE

4.1.1 Intended Use and Permitted Use

The appliance is designed and built for refrigerating, preserving and storing food products on com-

mercial premises.

4.1.2 Improper and Unauthorized Use

1) treatment of products that require constant monitoring with indications in the case of temperatu-

re changes or interruption of refrigeration. For example:

- medicinal products

- blood and plasma

- thermo-sensitive chemical reactants

2) use in places subject to explosive atmosphere

7

STAGIONATORE

All uses except authorized uses of the appliance shall be construed as “improper use” for which

the manufacturer declines all responsibility.

4.2 SAFETY AND ACCIDENT PREVENTION

The appliance embodies various features designed to assure the safety and protect the health of

the user. The following list describes the protections adopted against mechanical risks:

- stability: the appliance is designed and built so that even with the shelves fully extracted in the

intended conditions of operation it will remain stable so that it can be used with no risk of tipping,

falling or sudden movement

- surfaces, edges, corners: accessible parts of the appliance have no sharp corners, sharp ed-

ges or rough surfaces that could cause injury

- moving parts: moving parts of the unit are designed, built and congured to avoid risk. Moving

parts are protected by xed guards to prevent accidental contact that could result in injury

Measures adopted for protection against additional risks:

- electrical power: the appliance is designed, built and tted out with the aim of preventing

the risk of electric shock in compliance with established safety legislation

- noise: the appliance is designed and built to reduce risks related to the emission of airborne

noise to a minimum

4.3 SAFETY DATAPLATES AND GUARDS

It is strictly forbidden (g.6):

- to tamper with or remove the evaporator cover that protects the user from the risk of cutting on

the heat exchanger ns

- to remove the dataplate xed to the inside edge of the motor housing

showing technical specications (1) and earth connection warning (2)

- to remove the dataplates on the evaporator unit cover near the elec-

trical wiring inside the motor housing which warn the user to disconnect

electrical power before working on appliance (3)

- to remove the dataplate xed inside the motor compartment indicating

earthing (4)

- to remove the data tag xed to the power cord showing the type of po-

wer supply (5)

The manufacturer declines all responsibility for safety of the appliance if

the above recommendations are not observed.

4.4 OPERATING LIMITS

The appliance is designed and built to work in ambient temperatures Max. 38°C. If the ambient

conditions are different it will not be possible to achieve the performance levels specied by the

manufacturer.

The standard power supply must be 230V +/- 10% 50Hz.

1

2

3

4

5

fig.6

8

STAGIONATORE

Section 5: ROUTINE AND PROGRAMMED MAINTENANCE

The information in this section regards the user, or other non-specialized personnel, and the routi-

ne maintenance technician.

5.1 BASIC SAFETY REGULATIONS

We summarize the safety regulations already shown in heading 1.5 to ensure that the user or

maintenance technician can perform the work in conditions of total safety:

- do not touch the unit with wet hands and/or feet

- do not use the appliance with bare feet

- do not insert screwdrivers or other pointed objects between guards or moving parts of the appliance

- do not pull the power cord to disconnect the appliance from the electrical mains

- before performing any cleaning or maintenance on the appliance disconnect it from the electrical

mains by switching of the main switch and extracting the plug

5.1.1 Prohibited: Removal of Guards and Safety Devices

It is strictly forbidden to remove guards or safety devices when performing routine maintenance

work. The manufacturer disclaims all liability that may arise if this regulation is not observed.

5.1.2 Indications on Emergency Measures in Case of Fire

- disconnect the appliance from the electrical power socket or switch off the master switch on the

electrical mains line

- do not use water to douse res

- use Co2 extinguishers

5.2 CLEANING THE REFRIGERATOR

The unit is designed to preserve food products so it is important to keep it clean for reasons of

hygiene and health. The appliance is thoroughly cleaned in our factory before delivery. We recom-

mend, however, that you clean the interior of the appliance before use. Before cleaning the ap-

pliance make sure the power cord is disconnected.

5.2.1 Cleaning the Interior and Exterior of the Appliance

- cleaning products: water and non-abrasive neutral detergent. DO NOT USE SOLVENT OR THINNERS

- cleaning method: use a cloth or sponge soaked in a suitable cleaning product to clean the interior

and exterior parts of the cabinet

- sanitation: do not use substances that could alter the taste and smell of stored food

- rinsing: use a cloth or sponge soaked un clean water. DO NOT USE WATER JETS

- frequency: once a week or at different intervals in accordance with the type of food product con-

served.

5.2.2 Cleaning the Condenser

The condenser will work less efciently if it is obstructed with

foreign material so it must be cleaned once a month. Before

cleaning the condenser switch off the appliance, disconnect the

power cord and proceed as follows:

Top-mounted unit

:-for units with xed upper front panel, use

a safe step ladder for direct access to the condenser located at

the top of the appliance. Use an air jet or a dry brush and,

A

L

C

O

O

L

fig.7

9

STAGIONATORE

working with up and down movements (g.7), remove any dust or uff that has deposited on the

heat exchanger ns. In case of greasy deposits, use a brush soaked in benzene or alcohol. For

units with overturning upper front panel, unscrew the xing screw and turn the upper panel on the

top hinges. Proceed then with the cleaning as for the models with xed upper panel. Start the ap-

pliance after cleaning.

During this operation use the following personal safety measures: safety glasses, respirator

mask, chemical resistant gloves (benzine - alcohol).

5.3 PERIODIC CHECKS

The following areas of the appliance or component assemblies require periodic checking:

- condition and efciency of the door sealing elements

- condition of hinges and correct xing of the doors

- condition of electrical cables and electrical parts

5.4 PRECAUTIONARY MEASURES FOR PROLONGED DISUSE

If the appliance is to remain unused for more than 15 days proceed as follows:

- switch off the appliance and disconnect it from the electrical supply

- clean the interior of the cabinet, shelves, trays, runners and supports, paying special attention to

critical areas such as articulations and magnetic sealing strips in accordance with the indications

in heading 5.2.

- leave doors slightly open to prevent accumulation of residual humidity

5.5 PREVENTIVE MAINTENANCE

5.5.1 Start-up after Prolonged Disuse

Before starting the appliance after prolonged disuse perform preventive maintenance. Clean the

unit thoroughly as described in heading 5.2.

5.5.2 Checking Warning and Control Devices

Check the correct running of the controls according to what is reported in the“Instruction and

Maintenance Manual” enclosed. We recommend you to take out a service or maintenance con-

tract with your dealer covering:

- cleaning of the condenser

- keeping a check on the refrigerant charge

- checking complete cycle operation

- electrical safety

Section 6: SPECIAL MAINTENANCE AND REPAIRS

All maintenance work not described in the previous sections must be considered “Special Mainte-

nance”.

Special maintenance interventions and repairs are to be performed exclusively by specialized

technicians authorized by the manufacturer.

The manufacturer declines all liability in the case of work performed by the user or unauthorized

persons, or if non-original spare parts are tted to the appliance.

10

STAGIONATORE

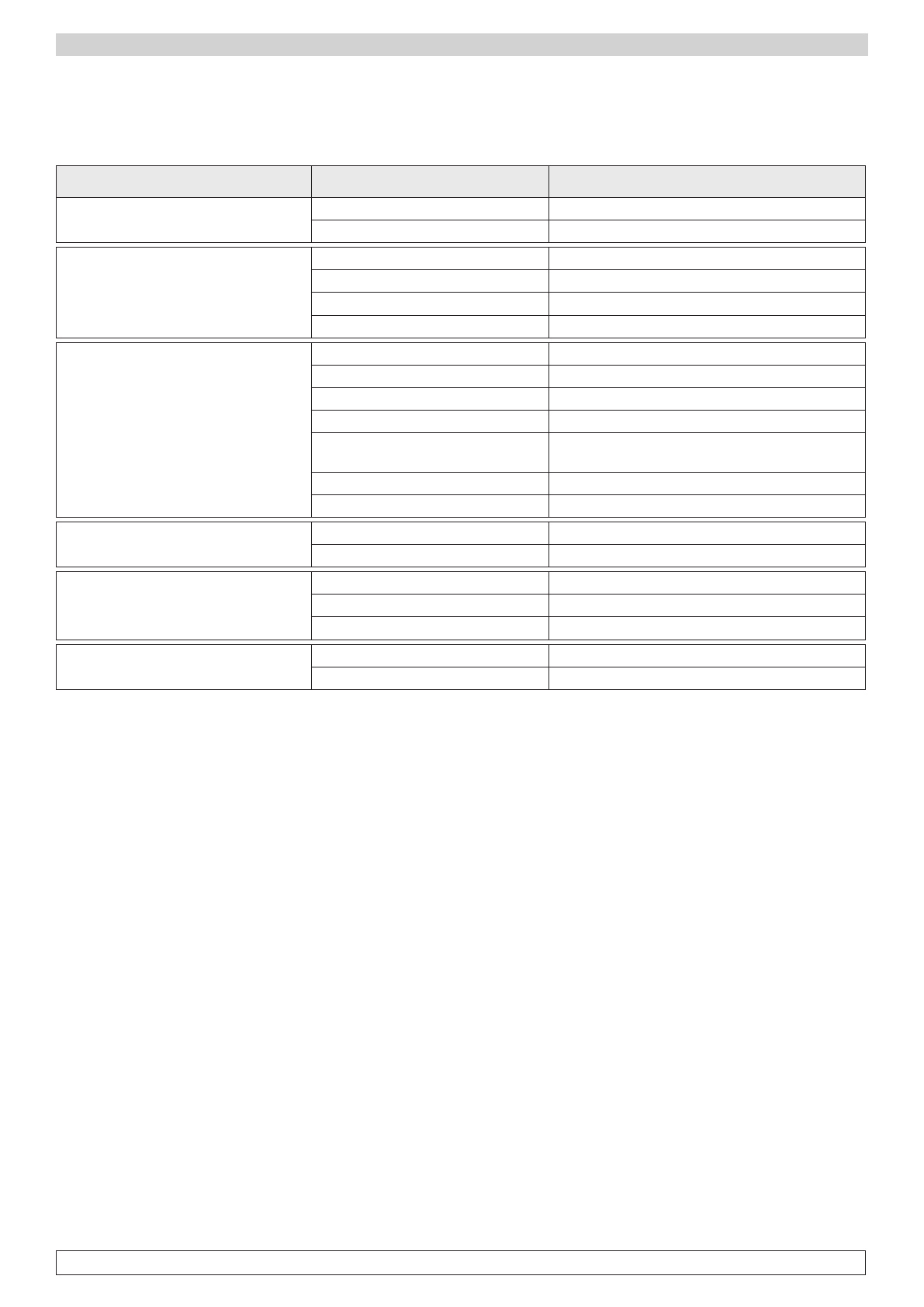

Section 7: DIAGNOSTIC

In case these problems arise, please follow the instructions stated in the following chart:

PROBLEM POSSIBLE CAUSE SOLUTION

Appliance does not switch on power failure check plug, socket, fuses, electrical line

other contact technical service

Refrigeration unit does not start set temperature has been reached set new temperature

defrosting cycle is in progress

wait for cycle to end, then switch off and on again

control panel breakdown contact technical service

other contact technical service

Refrigeration unit runs constantly,

but does not reach set temperature

room is too hot provide better ventilation

condenser is dirty clean the condenser

refrigerant needs to be recharged contact technical service

condensing fan is not running contact technical service

inefficient door seals check seals / how goods are placed inside the

cabinet

evaporator is coated with ide manual defrosting

other contact technical service

Refrigeration unit dos not stop at

set temperature

control panel breakdown contact technical service

temperature probe breakdown contact technical service

Ice block on the evaporator

improper use see section 3.4

defrost resistance breakdown contact technical service

defrost probe breakdown contact technical service

Water or ice deposits in the drip tray obstructed drain clean the drain and the drain outlet

refrigerated counter is not levelled check levelling

11

STAGIONATORE

Section 8: SEASONING CABINET

Seasoning cabinet has been designed to recreate the necessary and optimal temperature and hu-

midity conditions to season salami, cheese or meat, regardless of external weather conditions.

For instance, seasoning salami consists in giving a product a set time for resting in suitable climate

conditions, so that it can reach the best outcome in terms of organoleptic qualities, aroma and taste

in the shortest time possible.

Products must be hanged on special supports placed inside the Seasoning cabinet, so that air can

flow freely and that salami are not touching one the other.

It is also advisable to season products having the same size and type, to ensure the best result.

The Seasoning cycle can be divided into 3 main steps:

1) STEWING/DRIPPING

It lasts just a few hours: the diffusion of the aroma inside the meat is facilitated, therefore activating

the natural fermentation process and the loss of water due to gravity.

2) DRYING

It takes about six days. During this phase, the product loses a huge quantity of water. Such loss

should be as uniform as possible, alternating work and rest phases, in order to keep the gut elastic

and therefore let the water contained inside the meat reach the external part of the salami.

3) SEASONING

The duration of this phase depends on the type of product. The right regulation of humidity helps

proliferating a natural enzymatic phenomena called “good mould”, favouring the complete maturation

of the product, and capable of guaranteeing its storage and healthiness.

The EVERtouch controller manages temperature and humidity in seasoning and storage environments.

It is equipped with a 7’’ TFT display with capacitive touch screen combined with a highly-advanced

software and an extremely user-friendly interface.

As a whole, the system allows for controlling the following features: temperature (hot / cold) and

humidity (humidification / dehumidification), defrosting (electric), recoveries, dripping, air exchange

either programmed or automatic, activation of internal air recirculation for destratification and product

oxygenation.

12

STAGIONATORE

Main features:

- 7’’TFT display with high resolution (800x480 WVGA), LED backlighting and capacitive touch screen.

- Devices: USB 2.0.

- Acoustic signals.

- High quality design and icons.

- Touch screen interface with gestures, for an even more intuitive control.

- Clock and calendar (RTC).

- Multilingual.

- Software updating from USB.

- Alarm history combined with popup warning messages.

- Advanced HACCP function with detailed memory of temperature / humidity alarms triggered.

- 150 completely customizable programs can be stored on the device.

- Possibility of exporting and importing programs and parameters on USB.

- Automatic management of 20 phases for each program.

- Manual or automatic functioning with execution of the selected program.

- Diagram of the program in execution with possibility of displaying its progression (completed

phases, phases in progress and phases yet to be executed) and of representing the set values and

all remaining times.

- Temperature adjustment range: -2°C/+30°C; humidity adjustment range: 0-100 R.H.%.

- Possibility of excluding heat and humidity for managing cell-only storage with the activation of defrost cycles.

- CANBUS connection.

13

STAGIONATORE

Chapter 9: Installation and first startup

9.1 Installation

Before starting the refrigerating cabinet, it is necessary to check that all connections have been

carried out as per chapter 3.3.

9.2 First start

Once the refrigerating cabinet is connected to the power supply, the machine will begin the startup.

The display will show the uploading screen of the system software for some seconds, and then the

splash screen (fig. 8) will be displayed.

fig.8

When started, Lo Stagionatore is in STOP condition with Refrigerator as loaded recipe.

9.3 Locked Home Screen

Locked Home Screen (fig.9) is a mere visualization screen that allows increasing the safety of the

current process and avoiding accidental parameter/setting changes

fig.9

14

STAGIONATORE

ATTENTION: to change LANGUAGE or DATE and TIME, refer to paragraphs 12.1 - 12.2

It can be divided into 4 areas:

- AREA 1: The current date and time are displayed; to change the visualization format see paragraph 12.4

The name of the currently running recipe is displayed on the right.

- AREA 2: The main information about the running recipe is displayed in this area:

TEMPERATURE: The internal temperature of Lo Stagionatore is displayed in big type in the rectangle

on the left. In the underlying rectangle, Set T indicates the set-up temperature in the current phase

of the recipe.

HUMIDITY: The internal relative humidity of Lo Stagionatore is displayed in big type in the rectangle

on the right. In the underlying rectangle, Set RH indicates the set-up humidity in the current phase

of the recipe.

TIME: In the middle of AREA 2, a circular crown composed of various wedges highlights the time

progress status of the running phase. With the passing of time, the wedges become green, and when

all the wedges are highlighted, the recipe phase is completed and next phase starts. In numerical

terms, the value displayed in the middle of the crown represents the remaining time to the end of the

running phase and it can be stated in Day, Hours, Minutes.

The number of the running phase (each recipe can be composed of different phases), its name and

the remaining time to phase change are displayed inside the crown.

fig.10

The example (fig.10) indicates that the first phase ( Dry-Aging 1) of the two total phases composing

the recipe is running, and that 1 day is left to the beginning of phase 2.

15

STAGIONATORE

- AREA 3: The icons related to the statuses of the digital outputs of Lo Stagionatore are displayed:

1- Air Exchange

2 - Recovery

3 - Humidification

4 - Cooling

5 - Lighting

6 - Alarm

7 - Ventilation

8 - Warming

9 - Defrost

10 - Sterilization

11 - Cold Cuts Rotation

The output status can either be ACTIVE if it is green-coloured or NOT ACTIVE if it is white-coloured.

The last two icons on the right (sterilization and rotation) can be grey-coloured if the purchased Lo

Stagionatore model does not respectively include the germicide UV Lamp and the Cold Cuts Whirligig

rotation system.

- AREA 4: > slide to unlock

Sliding on the writing allows the unlocking of the device to access the Unlocked Home Screen

16

STAGIONATORE

9.4 Unlocked Home Screen

fig.12

The Unlocked Home Screen is an active screen, i.e. has clickable keys, unlike the Locked Home

Screen.

It can be divided in 4 areas (fig.12):

- AREA 1: It displays the current date and time; to change the visualization format see paragraph 12.1.

The name of the currently running recipe is displayed on the right.

- AREA 2: The main information about the running recipe is displayed in this area:

TEMPERATURE: The internal temperature of Lo Stagionatore is displayed in big type in the rectangle

on the left. In the underlying rectangle, Set T indicates the set temperature in the current phase of

the recipe.

HUMIDITY: The internal relative humidity of Lo Stagionatore is displayed in big type in the rectangle

on the right. In the underlying rectangle, Set RH indicates the set humidity in the current phase of

the recipe.

17

STAGIONATORE

Unlike the Locked Home Screen, the SET T and SET RH keys are clickable and allow for a quick

change of temperature and relative humidity Set Points of the running phase.

Click on the keys until fully green-coloured. (fig.13)

fig.13

The upper box will respectively display the TEMPERATURE and HUMIDITY Set Points of the running

phase; to change the values, click on the + or - keys and confirm by clicking on the SET T or ST RH

keys until fully green-coloured. (fig.14)

fig.14

The abovementioned change procedure only affects the running recipes, and it does not overwrite

the corresponding recipe that is saved in the archive.

TIME: In the middle of AREA 2, a circular crown composed of various wedges highlights the time

progress status of the running phase. With the passing of time, the wedges become green, and when

all the wedges are highlighted, the recipe phase is completed and next phase starts.

This manual suits for next models

7

Table of contents

Other Everlasting Refrigerator manuals

Everlasting

Everlasting CHOCOLATE GREEN User manual

Everlasting

Everlasting MULTILAB User manual

Everlasting

Everlasting PROFESSIONAL TRAY 05 P User manual

Everlasting

Everlasting STAGIONATOR Instructions for use

Everlasting

Everlasting BAKING CAB FL Series User manual

Everlasting

Everlasting Pastry BN 1 Installation instructions

Everlasting

Everlasting LoStagionatore MEAT Series User manual

Everlasting

Everlasting BCE2020 User manual

Everlasting

Everlasting 700 INOX Instructions for use

Everlasting

Everlasting TNV Series User manual