EverSewn sparrow 15 Series Operating instructions

Repair Manual

sparrow 15 series

1

CONTENTS

1.

Products specification .......................................................................................2

2. Outlook .....................................................................................................................3

3. Names of

principal

parts ..........................................................................................4

4.

Removing methods

of

externalparts

4.1 Face plate..........................................................................................................5

4.2 Free arm cover ..................................................................................................5

4.3 Base plate..........................................................................................................5

4.4 Back cover.........................................................................................................5

4.5 Front cover ........................................................................................................6

5.

Adjusting methods

of each

part

5.1 Symbol instructions ...........................................................................................7

5.2 Play of arm shaft................................................................................................7

5.3 Play of arm shaft worm and pattern cam...........................................................8

5.4 Drop middle point of needle...............................................................................8

5.5 Height of presser foot ........................................................................................9

5.6 Needle flow at maximum zigzag width ............................................................10

5.7 Drop middle point of needle.............................................................................11

5.8 Needle position of zigzag ................................................................................12

5.9 Height of needle bar........................................................................................13

5.10 Automatic needle threader adjustment............................................................14

5.11 Distance-needle-hook......................................................................................15

5.12 Timing of needle and hook ..............................................................................16

5.13 Distance adjustment between shuttle driver shaft gear complete and

lower shaft gear complete ...............................................................................17

5.14 Play between shuttle driver shaft gear and lower shaft gear...........................18

5.15 Feed cam position adjustment.........................................................................19

5.16 Feed lifting rock cam position adjustment .......................................................19

5.17 Feed-dog height ..............................................................................................20

5.18 Position of the feed-dog in relation to the needle plate (front to back) ............21

5.19 Position of feed-dog in relation to the needle plate (left to right) .....................22

5.20 Upper thread tension adjustment ....................................................................23

5.21 Lower thread tension adjustment ....................................................................24

5.22 Motor belt tension............................................................................................25

5.23 Reverse patterns .............................................................................................26

5.24 Forward and reverse stitching in buttonhole sewing (feeding pitch of

reverse and forward stitching is not even).......................................................27

5.25 Buttonhole upper and lower stitching problem ................................................28

5.26 Bobbin winding problem ..................................................................................29

6.

Circuit

diagram

........................................................................................................30

A

TTENTION

Be sure to observe the following, as they may well become causes for fire,

electric-shock, injuries, and damage to parts.

- Be sure to unplug power source before engaged in disassembly, installation,

adjustment.

- In case of installing please pay special care to clamp electrical cords, etc., scars

to sheath, mis-circuit, etc.

- Be sure to use regular standard part in replacing.

2

1. Products specification

TYPE

ITEM

KX0L

sew&go 1

sew&go 3

sew&go 5

Machine style

Free arm

Size of machine (mm) L x W x H

398 x 169 x 298.5 mm

Weight (kg)

6 (only machine)

Max rotation speed (rpm)

750±50 rpm

Rated voltage

North America AC 120V Europe AC 230V

Motor power

North America 70W Europe 70W

Motor type

AC Option (Auto type)

Needle position

Center and left position

Zigzag out-breaking device

Multiple-player cams conversion type

Hook system

Semi rotary hook

Thread take up lever

Slit type

Presser foot lift

Two-steps type

Needle threader

Manually

Auto type

Auto type

Needle plate

Screw fixing type

Upper thread tension adjust device

Top of upper plate inclusive turning knob

Bobbin winder

Self releasing with automatic stop

Reverse

Press down type

Kinds of stitches

9

17

23

Dials

2

2

3

Stitch length adjust device

Dial type

Max. length of stitch (mm)

4.0 ~ 4.5mm

Max. width of zigzag (mm)

4.6 ~ 5.0mm

Face plate upper plate

Plastic

Sewing table

Coupled with accessories / Spare parts box

LED Lamp

Inclusive within face plate

Speed control device

Controller

Power supply switch

Pulsating, two steps

Protective cover

Option

Nos. of accessories

Option

3

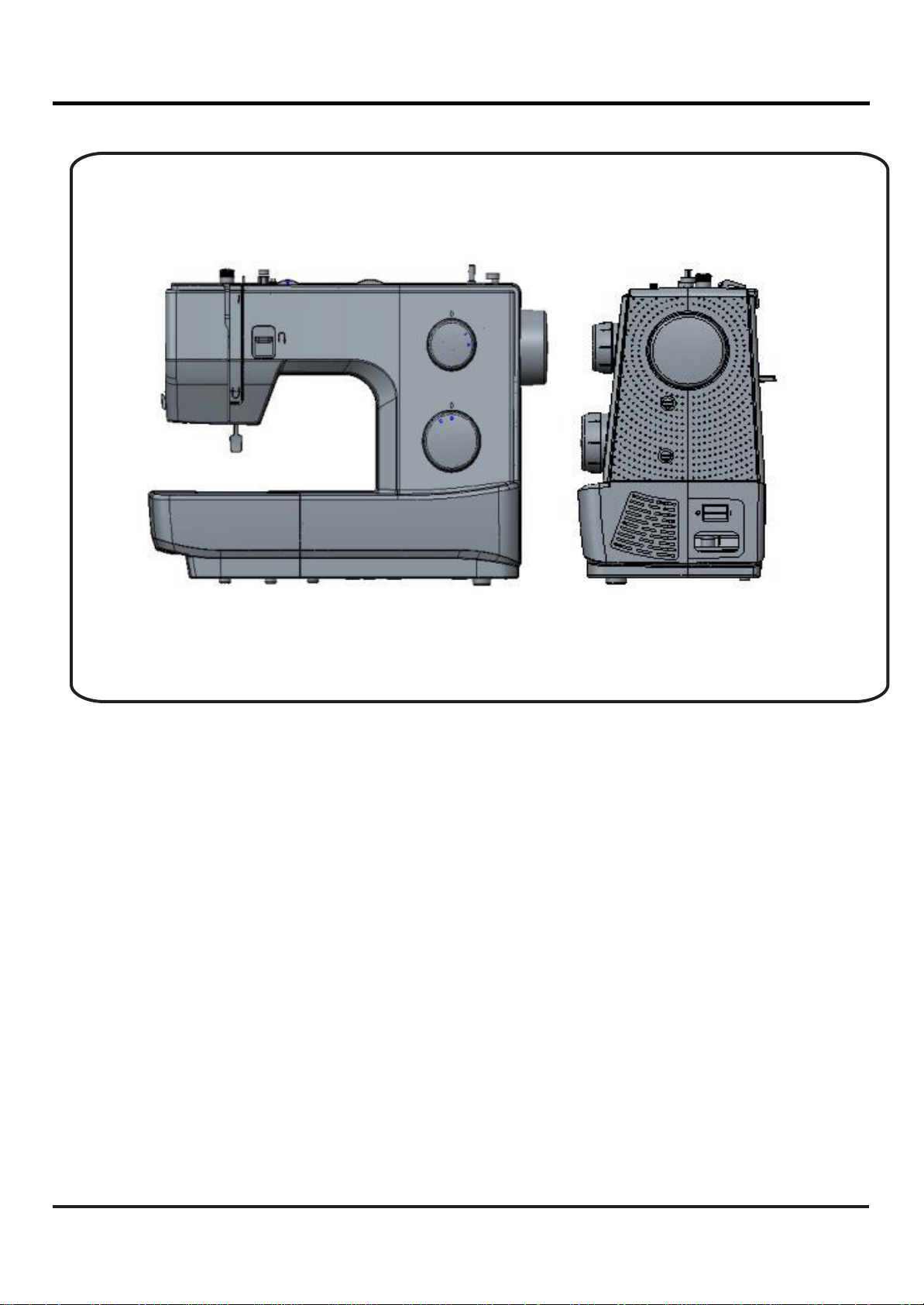

2.

Out

Look

4

3. Names of principal parts

1. Thread tension dial

2. Thread take-up lever

3. Presser foot pressure adjustment

4. Thread cutter

5. Presser foot

6. Needle plate

7. Sewing table and accessory box

8. Reverse sewing lever

9. Bobbin wider stopper

10.Stitch width dial (for sew&go 5)

11.Stitch length dial

12.Pattern selector dial

13.One step buttonhole lever

(for sew&go 5)

14.Automatic threader (optional)

15. Horizontal spool pin

16. Bobbin winder spindle

17. Hole for second spool pin

18. Handwheel

19. Power switch

20. Main plug socket

21. Bobbin thread guide

22. Upper thread guide

23. Face plate

24. Handle

25. Presser foot lifter

26. Foot control

27. Power cord

5

4. Removing methods of external parts

4-1 Face

plate

Remove the screw (a) and the face plate. ①

Face

plate

a

1

4-2 Free arm

cover

Remove the screw (b) and the free arm cover.

②

4-3 Base

plate

- Lay down machine. Remove 4 screws (c,

d,e,f).

- Remove the base plate. ③

c

d

Base

plate

e

f

3

4-4 Back

cover

- Remove the face plate, cap, free arm cover,

and base plate first.

- Lift spool rod and remove 4 screws (g,h,i,j).

- Loosen screw (k) about 3mm.

- Remove the back cover. ④

g

h

j

l

Back cover

k

4

a

b

c

f

d

i

j

k

e

g

h

①

②

③

6

4-5 Front

cover

- Loosen screw (l) about 3mm.

m

5

- Remove the screw (m) which deeply inside

the machine.

n

6

-Remove the pattern selector dial.

- Remove the front cover following direction of

arrow. ⑤

Pattern selector

dial

Front

cover

7

l

m

Selector dial

Selector dial

⑤

7

5. Adjusting methods of each part

5-1 Symbol

instructions

Noise occur while the machine is

running. Skip-over stitching, needle breakage,

and problems associated with needle.

Delivery of cloth to be in disorder and

insufficient, problems associated with

delivery amount.

Stitch tightening problem.

BH right and left stitching is not even,

incorrect length and problems

associated with buttonhole sewing.

Bobbin winding problem.

5-2 Play of arm

shaft

1) Remove the face plate, free arm cover,

base plate, back cover, front cover and

loosen screws (a, b) of arm shaft collar

(A). (1)

2) Pull hand wheel backward.

b

B

A

3) Push arm shaft collar (A) to left tightly

against arm shaft bushing (B). Then

fasten and secure screws (a, b). (1)

4) Be sure proper distance between arm a

shaft collar and arm shaft bushing. (2)

5) Be sure arm shaft operates smoothly 1

after adjustment.

6) Arm shaft collar and arm shaft bushing

being too tightly closed might cause

insufficient operation of arm shaft.

7) Follow steps 1, 2, 3 in order to re-adjust.

B

b

A

a

2

1

8

5-3 Play of arm shaft worm

and

pattern

cam

1) Remove the face plate, free arm cover,

base plate, back cover, front cover and

loosen screw (a) of arm shaft worm.

2) Push arm shaft worm (A) to right to

mesh with gear of pattern cam (B). Then B

A

fasten screw.

3) Confirm proper tightness by checking a

pattern cam gear's movement.

4) The insufficient tightness could be re-

adjusted by following steps 1, 2.

5) Re-confirm needle flow after above

adjustment is necessary.

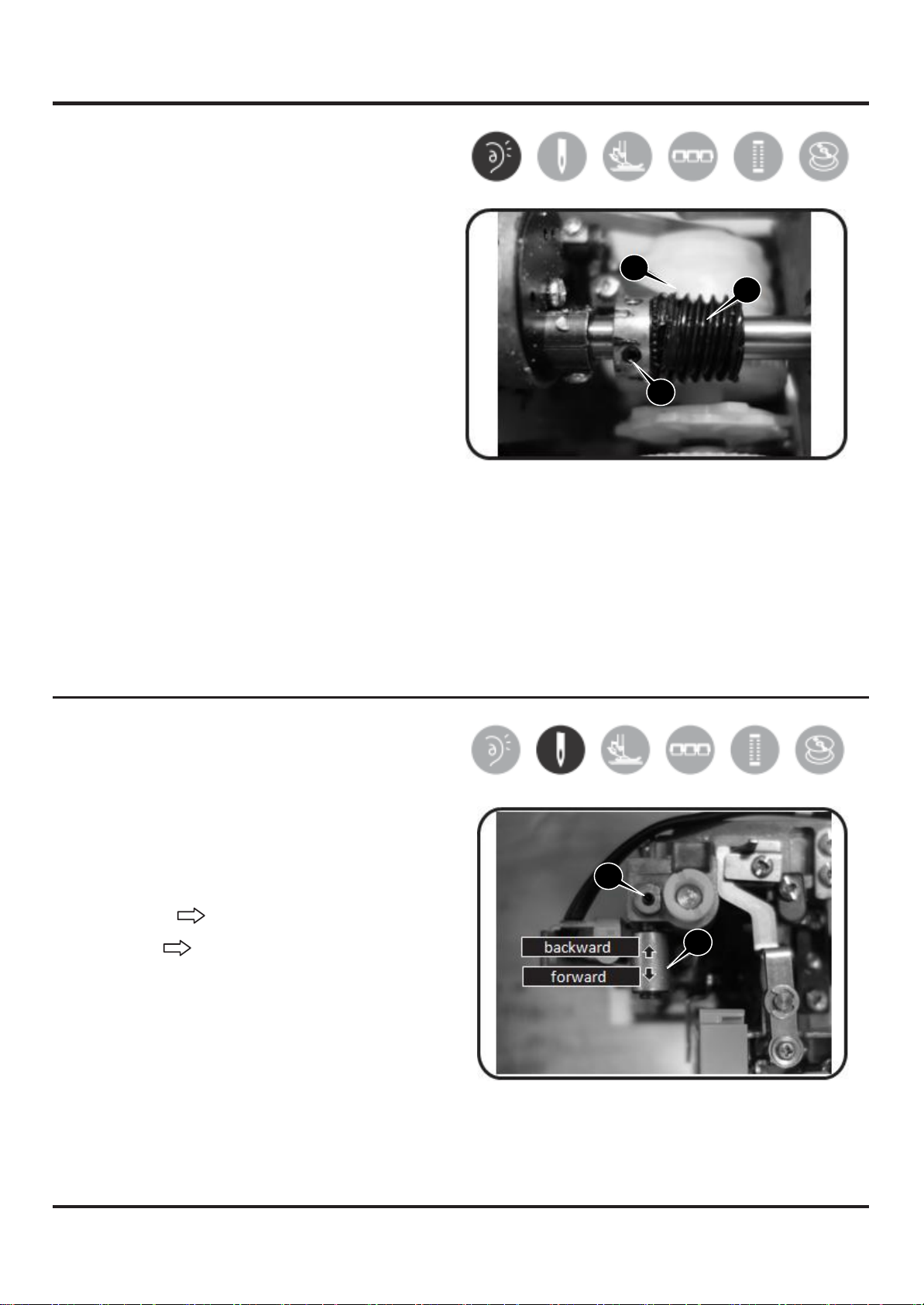

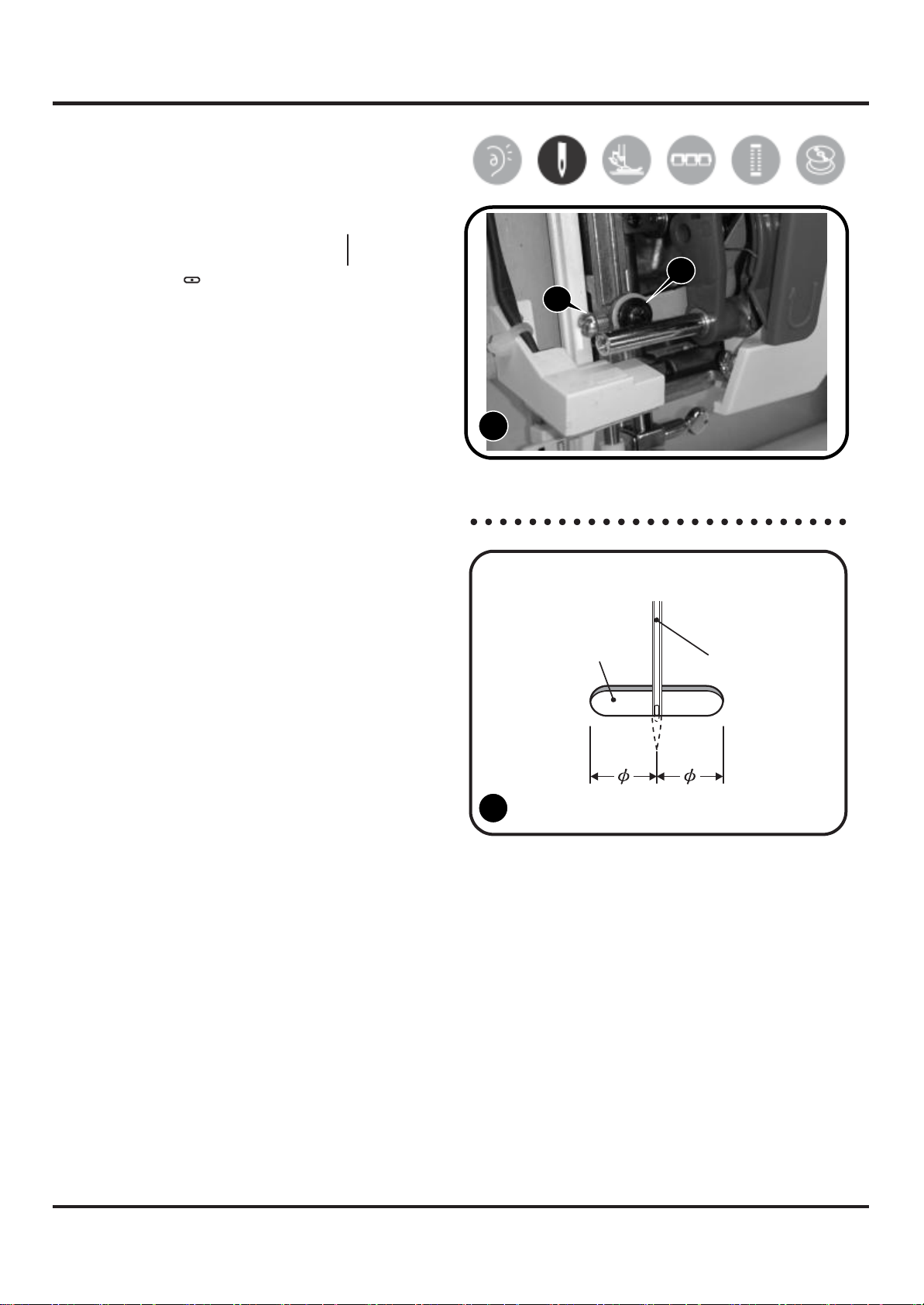

5-4 Drop middle point of

needle

1) Remove the face plate.

2) Loosen screw (a) of needle bar

supporter. (A)

3) Turn needle bar supporter (A) forward /

backward to adjust needle.

Backward to move needle forward

Forward to move needle backward

4) Set needle position above center of

needle plate and fasten screw (a).

a

backward

A

forward

a

B

A

a

A

9

5-5 Height of presser

foot

1) Remove the face plate and lift up

presser bar lifter lever (A). (1)

2) Loosen screw (a) of presser bar bracket

with the hexagon screwdriver (3mm). (1)

3) Place gauge (B) (6.0 - 6.2mm) on top of

needle plate. (2)

A

a

4) Lift up presser bar lifter lever so bottom

of presser foot and top surface of gauge

would meet.

5) Secure tightly screw (a). 1

6) The correct setting of gauge should be

6.0 - 6.2mm.

B

2

A

a

B

2

1

10

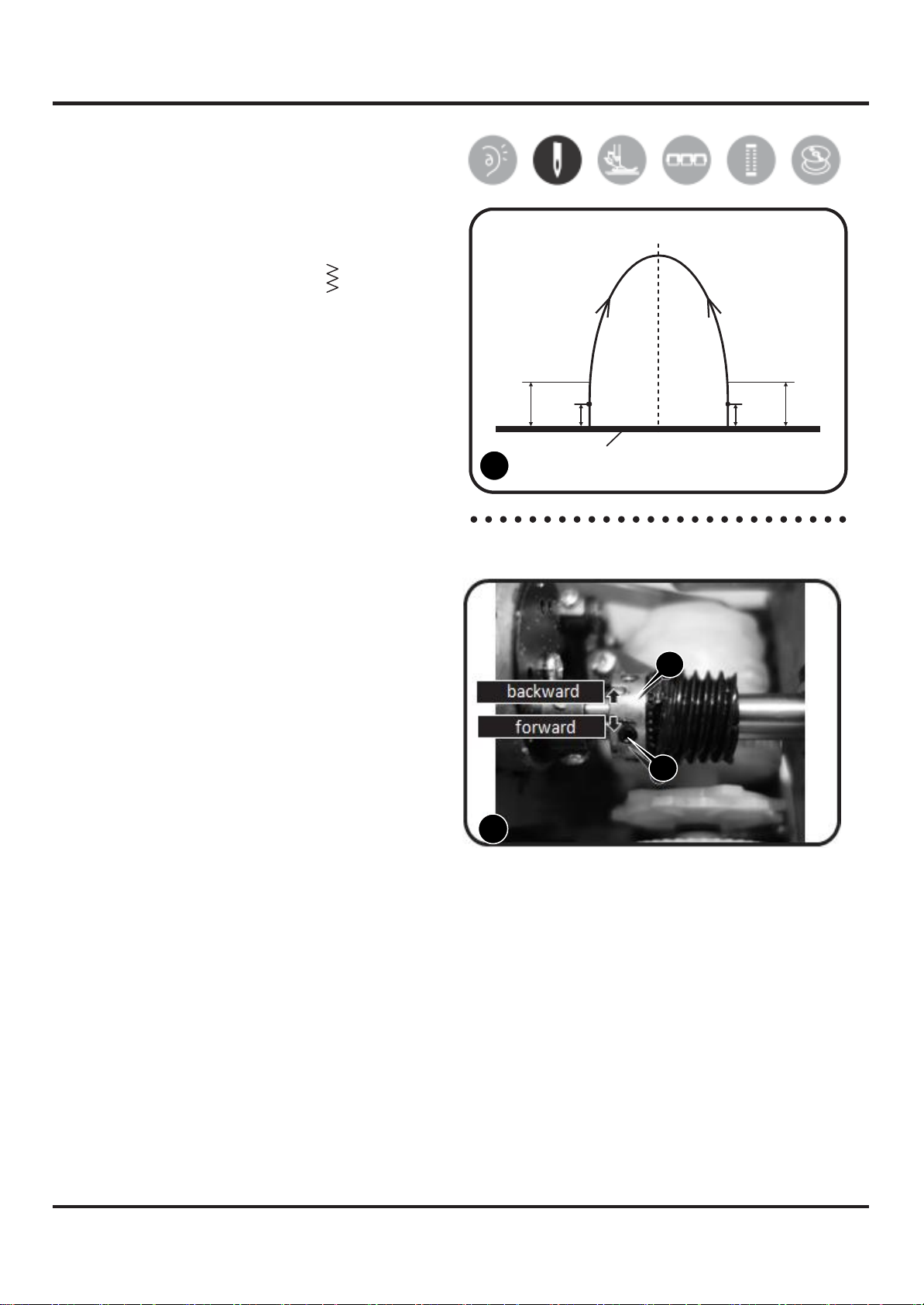

5-6 Needle flow at maximum z

igzag

width

1) Remove the face plate, free arm cover,

base plate, back cover and front cover.

2) Set pattern selector dial to " ".

3) Set needle bar at its lowest point when it

swings to left. Turn hand wheel to move

the needle bar upward. The vertical

distance in which the needle point goes

up at the left position from the top of the

needle plate should be 3 - 5mm. (1)

5mm

3mm

3mm

5mm

4) If needle flow is less than 3mm, loosen

arm shaft worm screw (a) and turn arm

shaft worm (A) toward back. (2)

5) If needle flow is more than 6mm, turn

arm shaft worm (A) toward front. (2)

6) After adjustment. Secure tightly arm

shaft worm screw.

Needle

plate

1

a

7) To be sure arm shaft operate smoothly

after adjustment.

8) Otherwise, gearing match of arm shaft

worm gear and pattern cam gear could

be too big. To correct this problem,

follow adjustment 5-3. (P.S. Re-

adjustment of needle flow is necessary

after adjustment)

A

backward

forward

A

a

2

1

11

5-7 Drop middle point of

needle

1) Remove the face plate, free arm cover,

base plate and back cover first.

2) Set pattern selector dial to " ", stitch

width dial " " (for 3-dial model).

3) Loosen screw (a), than adjust screw unit

(b). (1)

4) clockwise needle moves left a

counter-clockwise needle moves right

b

Make sure needle drops on middle of 1

needle hole. (2)

5) Tighten srew (a).

Needle

hole

Needle

2

b

a

2

2

1

12

5-8 Needle

position

of

zigzag

1) Remove the face plate.

2) Set pattern selector dial to " ".

(maximum zigzag width)

3) Loosen nut (a) of the screw(b). (1)

4) Adjust needle by turning

clockwise / counter-clockwise. screw(b) a

b

5) Make sure needle drops on left / right of

needle hole with even distance to the

edge of needle hole. (2)

6) After adjusting, re-tighten nut (a). 1

Needle

Needle

hole

2

a

b

2

1

13

5-9 Height of needle

bar

1) Remove the face plate and free arm

cover.

2) Remove shuttle hook.

3) Place the gauge of diameter 23mm into

the center of the hook. (1).

4) Set needle at its lowest point,stop at

the position whan point of the needle

across the edge of the gauge. (1)

5) Loosen screw (a). (2)

6) Adjust height of needle by moving

needle bar (B) upward / downward.(2)

7) The correct setting of gauge should be

23mm.

8) After adjusting, re-tighten screw (a). a

B

2

a

B

2

1

14

5-10

Automatic

needle

t

h

reader

adjustment

1) Check the threader hook.

If it is damaged, change new one.

If it is inclined, adjust the threader hook

properly.

Needle

2) If the threader hook can not enter needle

hole freely, please adjust the threader

stopper. (1)

0.1mm

Threader

hook

3) Adjust the stopper: (2)

- Remove face plate and turn hand wheel

to raise needle bar to its highest position.

- Loosen screw (a) of the threader stopper 1

(A).

Threader

hook

- Move the stopper (A) upward and the

threader hook will become higher.

Move the stopper (A) downward and the

threader hook will become lower.

- Adjust the stopper to the proper position

A

for entering needle hole freely. a

- Fasten the screw (a).

2

A

a

2

1

15

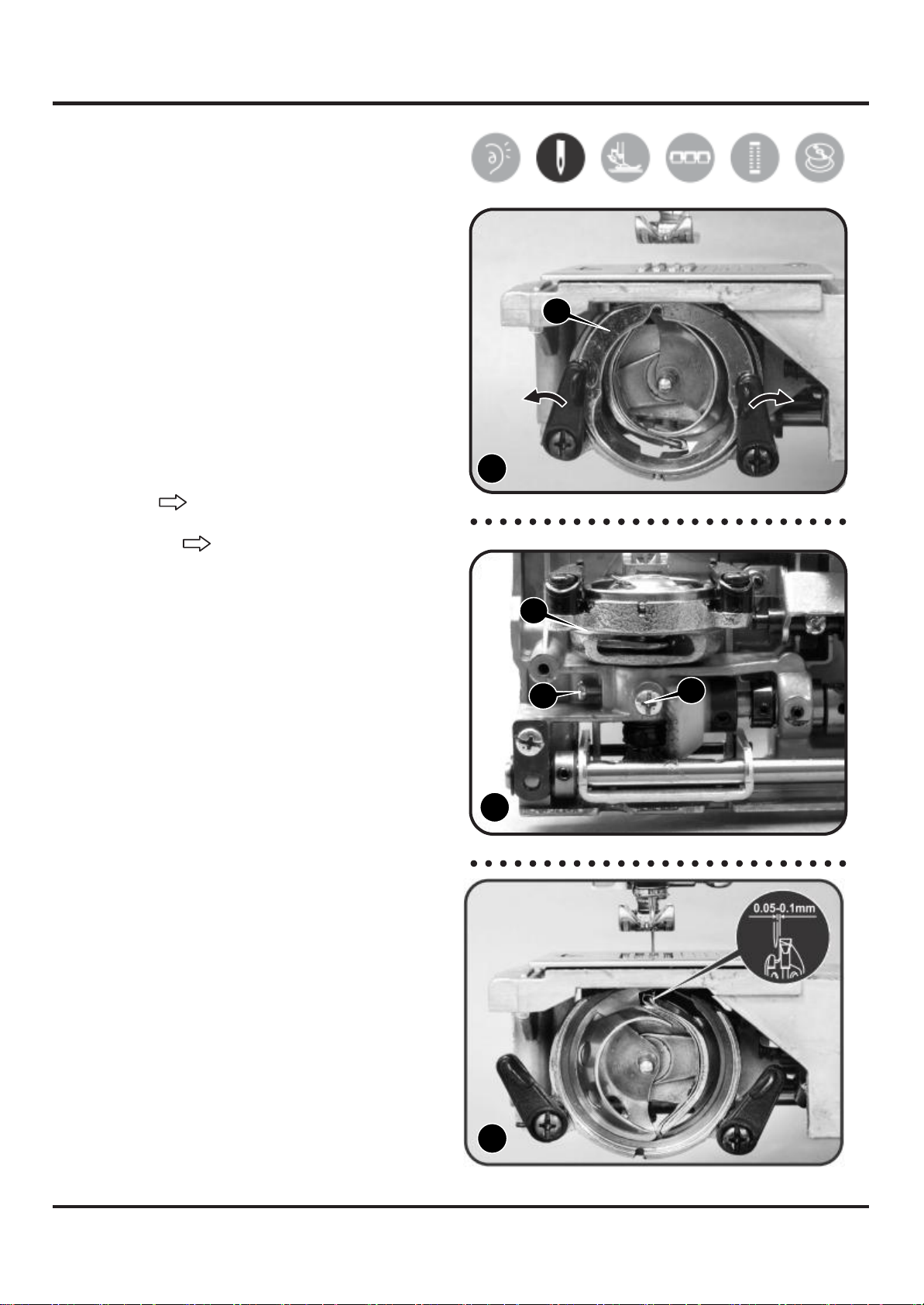

5-11

Distance-needle-hook

1) Remove the free arm cover.

2) Remove shuttle hook holder (A). (1)

3) Set needle at its lowest point when it

swings to right, stop at the position

when point of the needle and shuttle

A

hook will agree with.

4) Loosen screws (a, b) of open shuttle

race. (2)

5) Move shuttle race (B) upward/downward

to adjust movement. (2) 1

Upward tighten the distance

Downward lengthen the distance

6) Make sure space between needle and

tip of hook to be 0.05-0.1mm. (3)

B

7) After adjustment, re-tighten screws.

8) Re-assemble back shuttle hook holder. a

b

2

0.05-0.1mm

3

A

a

B

b

3

2

1

16

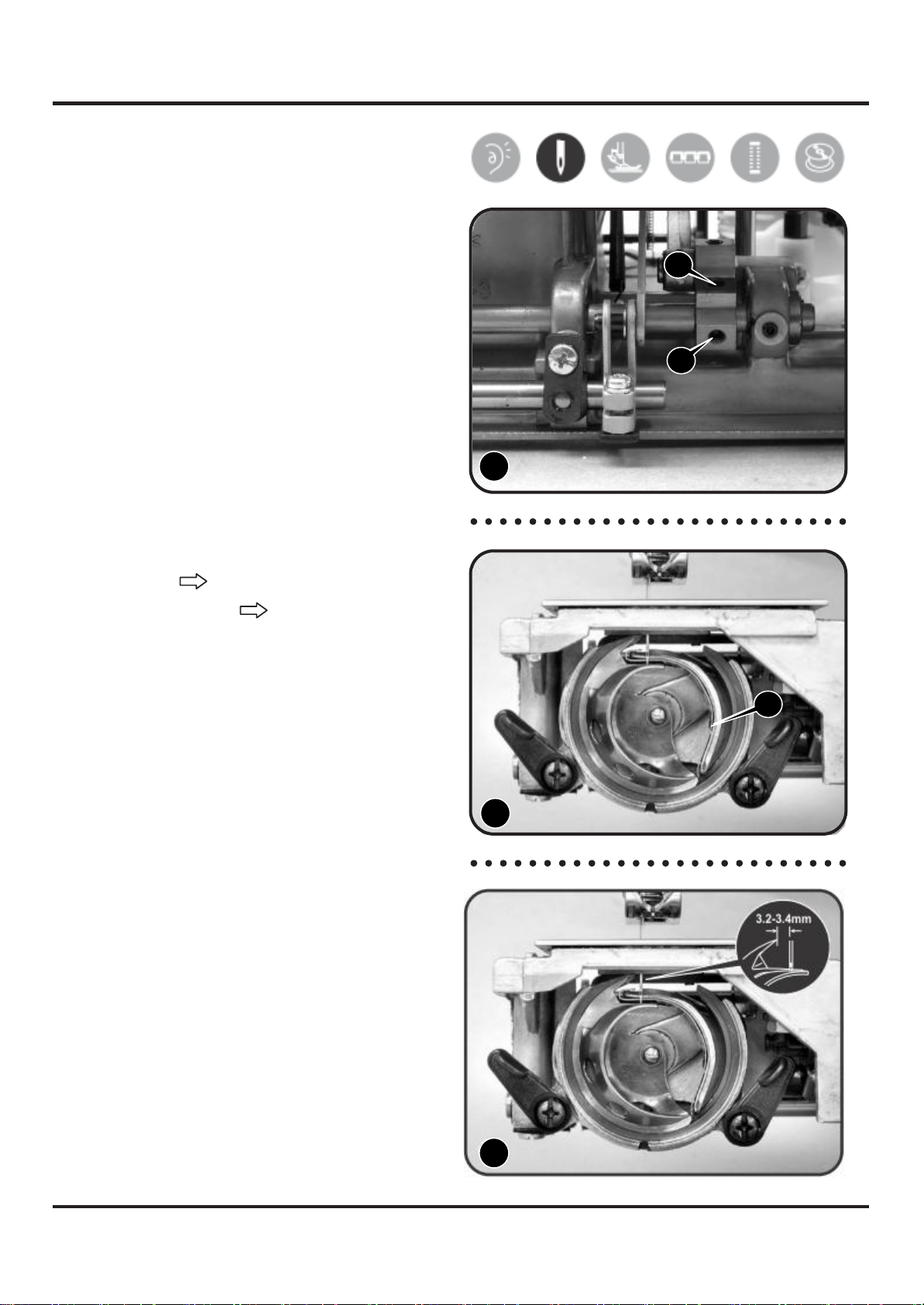

5-12 Timing of needle and

hook

1) Remove

plate. the free arm cover and base

2) Remove shuttle hook holder.

3) Set needle bar at its highest point and

b

loosen screw (a) of crank connecting

rod crank. (1)

4) Set needle bar at its lowest point when it

swings to left. a

5) Loosen another screw (b) of crank

connecting rod crank. (1)

6) Turn shuttle driver (A) to adjust timing of

needle and hook. (2) 1

7) Tighten two screws of crank connecting

rod crank when clearance between

point of hook and upper part of needle

eye is 3.2 - 3.4mm. (3)

Clockwise timing is smaller

Counterclockwise timing is bigger.

8) Re-assemble shuttle hook holder.

A

2

3.2-3.4mm

3

b

a

A

1

2

3

17

5-13 Distance

adjustment between

shuttle driver shaft

g

ear

complete and lower

s

haft

gear

complete

1) Remove free arm cover. Proceed to

loosen screw (a) and push feed lifting

rock cam (A) to right. (1)

A

2) Push lower shaft gear (B) to left tightly

against shuttle driver shaft gear

complete (C). (2) a

3) Push feed lifting rock cam (A) back

toward left and secure it tightly. 1

4) Avoid over-tightening shuttle driver shaft

gear complete and lower shaft gear

complete. If gearing match to be big,

then the torque will be bigger causing

shaking.

B

C

2

A

a

B

C

2

1

18

5-14 Play between shuttle

driver

shaft gear and lower

shaft

gear

1) Remove the face plate, free arm cover,

base plate, back cover and loosen

screws (a, b) of shuttle driver shaft gear

(A). (1)

A

2) Remove shuttle driver shaft gear (A). (1) a

b

3) Turn needle to its lowest point and when

rear end of shuttle driver shaft comes

across descending needle. In this

position face cut-facing side of shuttle

driver shaft to front. (2) 1

4) Re-assemble back shuttle driver shaft

gear, align shuttle driver shaft gear and

lower shaft gear (B) to mesh with each

other at one point (second teeth location)

(3).

5) Re-tighten screws of shuttle driver shaft

gear. Tighten first screw positioned at

cut-facing side of shuttle driver shaft.

6) Insert shuttle hook and check timing.

7) Re-assemble back shuttle driver shaft.

2

B

B

Keep two

teeth

unmeshed

Align to

mesh

with each

other

3 in this

point

A

a

b

B

B

3

2

1

19

5-15 Feed cam

position

adjustment

Problems associated with delivery amount,

stitch unbalance and needle breakage, make

the following adjustments:

1) Remove the face plate, free arm cover,

base plate, back cover and front cover.

2) Loosen screw (a) of feed cam at arm A a

shaft position. Make sure hair line

marking on feed cam (A) match

correctly with marking of arm shaft (B).

B

5-16 Feed

lifting

rock cam

position

adjustment

Problems associated with delivery amount,

stitch unbalance and needle breakage, make

the following adjustments:

1) Lift needle to its highest position.

B

2) Loosen screw (a) and make sure hair

line marking on feed lifting rock cam (A)

A

match correctly with marking of feed

lifting rock crank (B). (1) a

2

B

A

a

B

A

a

1

This manual suits for next models

3

Table of contents

Other EverSewn Sewing Machine manuals

EverSewn

EverSewn Hero User manual

EverSewn

EverSewn Maker 200 User manual

EverSewn

EverSewn CH04AX Operating instructions

EverSewn

EverSewn Sparrow QE User manual

EverSewn

EverSewn sparrow 15 User manual

EverSewn

EverSewn Sparrow X User manual

EverSewn

EverSewn Celine User manual

EverSewn

EverSewn sparrow 20 User manual