EverSewn Sparrow QE User manual

1

INSTRUCTION MANUAL

This sewing machine is intended for household use.

IMPORTANT SAFETY INSTRUCTIONS

When using a sewing machine, basic safety precautions should always be followed, including the following.

Read all instructions before using.

DANGER - To reduce the risk of electric shock:

Never leave unattended when plugged in. Always unplug this machine from the electric outlet immediately after

using and before cleaning.

WARNING-

To reduce the risk of burns, re, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

2. Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use out doors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn the power switch to the o position (symbol O), then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep ngers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deect the needle causing it to break.

14. Switch the sewing machine o (symbol O) when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot.

15. Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other user servicing adjustments mentioned in the instruction manual.

16. Handle the foot controller with care and avoid dropping it on the oor. Be sure not to place anything on top of it.

17. Use only the handle to lift and move the machine.

18. Do not expose the machine or machine plastic case to sunlight directly. Also, do not keep it in a very warm or

damp place.

19. The Appliance is not intended for use by young children or inrm persons without supervision.

20. Young children should be supervised to ensure that they do not play with the appliance.

SAVE THESE INSTRUCTIONS

Servicing should be performed by an authorized service representative.

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

2

CONTENTS

STARTING TO SEW...................................................23

A. START AND END OF SEAM ................................... 23

B. REVERSE STITCHING ........................................... 24

C. AUTO TACK, AUTO TACK & CUT........................... 24

D. TURNING CORNERS ............................................. 25

E. SEWING HEAVY FABRIC ....................................... 25

F. SEWING OVER OVERLAPPED AREAS................. 26

G. THREAD CUTTER .................................................. 26

H.

IF YOU WANT TO DRAW UP THE BOBBIN THREAD

... 26

STRAIGHT STITCH SEWING....................................27

ELASTIC STITCH SEWING.......................................28

ZIGZAG STITCH SEWING.........................................29

HAND LOOK QUILTING STITCH...............................29

MULTI-STITCH ZIGZAG ............................................30

A. MENDING................................................................ 30

B. ELASTIC BAND SEWING ....................................... 30

APPLIQUE..................................................................30

OVERCASTING-OVERLOCKING..............................31

A. USING THE OVERCASTING FOOT ....................... 31

B. USING THE REGULAR FOOT................................ 31

BLIND HEM STITCHING............................................32

BUTTONHOLE SEWING ...........................................33

AUTOMATIC BAR-TACK............................................35

INSERTING ZIPPERS

(CENTERED INSERTION /

LAPPED INSERTION)

........................................ 36

A. CENTERED INSERTION ........................................ 36

B. LAPPED INSERTION .............................................. 37

SCALLOP STITCH.....................................................38

A. SCALLOP HEM ....................................................... 38

B. SCALLOP EDGING ................................................. 38

PATCH WORK............................................................39

DECORATIVE STITCHES..........................................39

PIN TUCK...................................................................40

FREE ARM SEWING..................................................40

MAINTENANCE .........................................................41

A. BOBBIN HOLDER ................................................... 41

B. HOOK RACE AND FEED DOG ............................... 41

MESSAGE..................................................................42

HELPFUL HINTS........................................................43

SETTING OF LCD, LED LIGHT, and BEEP...............44

MAIN PARTS................................................................3

EXTENSION TABLE.....................................................5

ACCESSORIES............................................................5

CONNECTING THE MACHINE....................................6

FOOT CONTROLLER..................................................6

FUNCTION OF EACH PART........................................7

A. START/STOP BUTTON............................................. 7

B. REVERSE BUTTON.................................................. 7

C. NEEDLE UP-DOWN/SLOW BUTTON ...................... 7

D. THREAD CUTTER BUTTON..................................... 7

E. SPEED CONTROL BUTTON .................................... 7

F. PRESSER FOOT LIFTER ......................................... 8

G. DROP FEED LEVER ................................................. 8

H. PRESSURE REGULATOR........................................ 8

HOW TO USE THE NEEDLE PLATE FOR STRAIGHT

STITCH.........................................................................9

KNEE LIFTER LEVER................................................10

DUST COVER............................................................10

TO SELECT A PATTERN / ADJUST A PATTERN .....11

A. TO SELECT A BASIC PATTERN............................. 11

B. TO SELECT OTHER PATTERN .............................. 12

C. TACK/CUT BUTTON ............................................... 13

D. ADJUSTING THE STITCH WIDTH AND LENGTH... 13

E. NEEDLE POSITION CONTROL.............................. 13

F. TENSION BUTTON ................................................. 13

G. STITCH PATTERN................................................... 14

THREAD TENSION....................................................15

BOBBIN SETTING .....................................................16

A. REMOVING THE BOBBIN ...................................... 16

B. WINDING THE BOBBIN .......................................... 16

C. INSERTING THE BOBBIN....................................... 17

THREADING THE MACHINE.....................................18

A. PREPARING TO THREAD MACHINE..................... 18

B. SETTING SPOOL OF THREAD ON SPOOL PIN.... 18

C. THREADING THE UPPER THREAD ...................... 19

D. THREADING THE NEEDLE EYE............................ 20

CHANGING THE PRESSER FOOT...........................21

A. CHANGING THE PRESSER FOOT ........................ 21

B. REMOVING THE PRESSER FOOT HOLDER ........ 21

FABRIC, THREAD AND NEEDLE TABLE..................22

INSERTING THE NEEDLE ........................................22

3

PatternTension

Width/

Length

Tack/

Cut

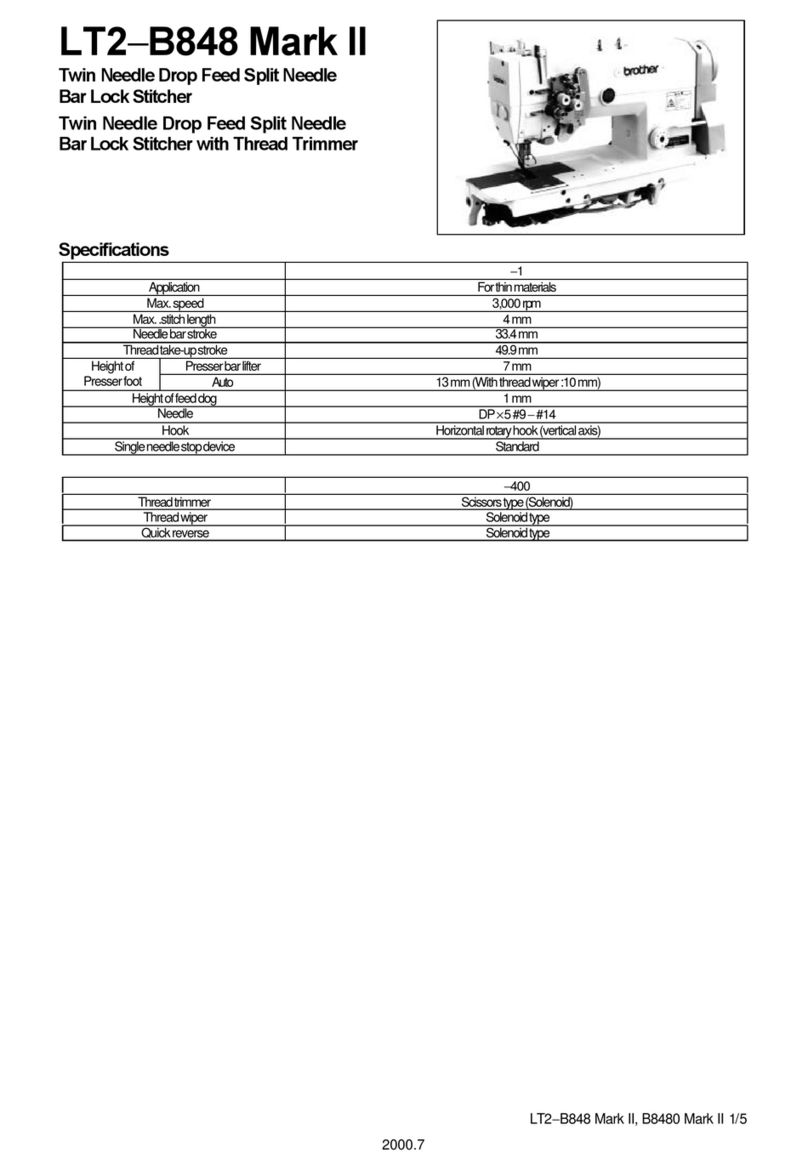

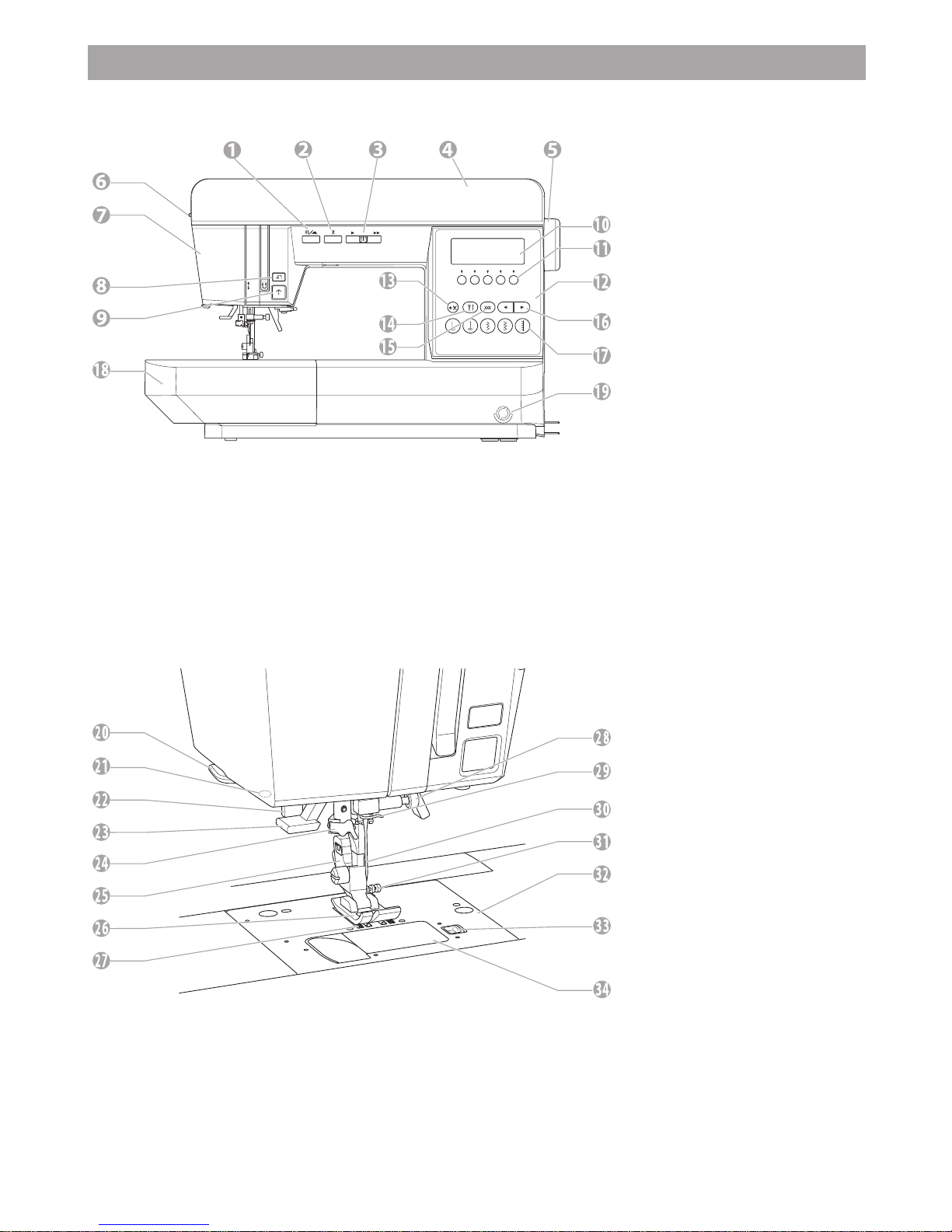

MAIN PARTS

1. Needle Up-Down/Slow

Button

2. Thread Cutter Button

3. Speed Control Button

4. Top Cover

5. Hand Wheel

6. Pressure Regulator

7. Light Cover

8. Reverse Button

9. Start/Stop Button

10. LCD

11. Function Buttons

12. Control Panel

13. Tack/Cut Button

14. Width/Length Button

15. Tension Button

16. Pattern Buttons

17. Basic Stitch Buttons

18. Extension Table

19. Knee Lifter Lever Socket

20. Thread Cutter

21. Hole for Loupe (Option)

22. Buttonhole Lever

23. Needle Threader Lever

24. Needle Threader

25. Presser Foot Holder

26. Presser Foot

27. Fabric Feed Dogs

28. Needle Clamp Screw

29. Needle Bar Thread Guide

30. Needle

31. Lock Button

32. Needle Plate

33. Bobbin Cover Latch

34. Bobbin Cover

4

REAR VIEW

35. Inside of Top Cover*

36. Pattern Chart

37. Bobbin Winder Thread

Guide

38. Thread Guide

39. Thread Guide

40. Thread Take-up lever

(Inside)

41. Thread Tension Regulator

(Inside)

42. Spool Cap

43. Spool Pin

44. Felt Washer

45. Bobbin Winder Thread

Guide

46. Thread Cutter

47. Bobbin Winder Stop

48. Bobbin Winder Spindle

49. Handle

50. Thread Cutter

51. Presser Foot Lifter

52. Power Switch

53. Terminal Box

54. Foot Controller Jack

55. Foot Controller

56. Power Line Cord

57. Drop Feed Lever

* To open the top cover, lift up

the front of cover.

* The Drop Feed Lever is

only accessible after the

extension table is removed.

5

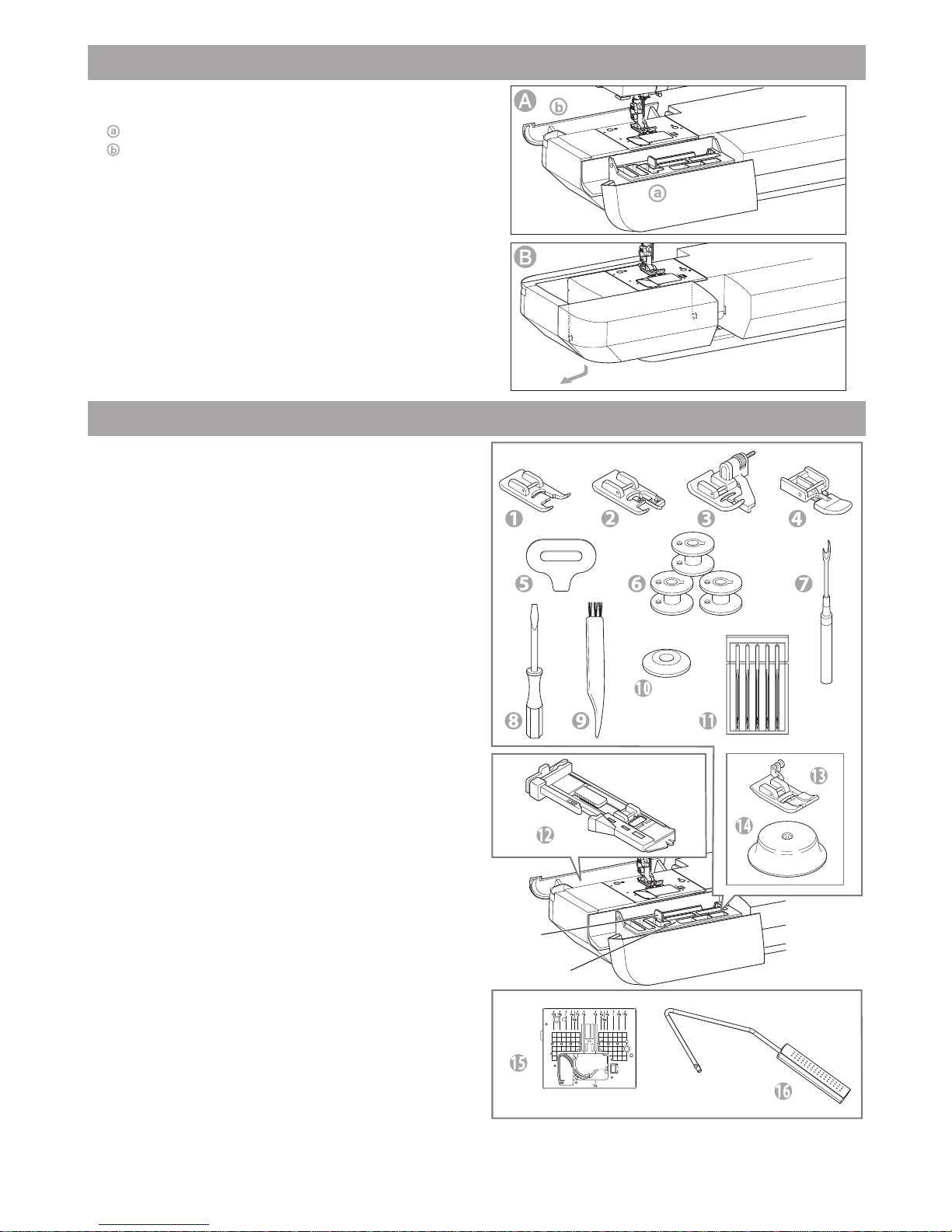

EXTENSION TABLE

A. OPENING THE ACCESSORY CASE

Grasp the front/rear case and pull outwards.

: Front Case

: Rear Case

B. REMOVING THE EXTENSION TABLE

Hook your nger to the left bottom side of extension

table and slide it to the left. To attach, insert to the

right.

1. Satin Foot (B)

2. Overcasting Foot (C)

3. Blind Foot (D)

4. Zipper Foot (E)

5. Driver for Needle Plate

6. 4 Bobbins (1 is in the machine)

7. Seam Ripper

On the accessory tray (Front case)

In the rear accessory case

Under the accessory tray (Front case)

Lift up the tray by holding the tab. There is a

compartment underneath.

On the machine when delivered

Provided on the top of styrofoam when

delivered

Accessories are provided in the accessory case.

8. Screw Driver

9. Brush

10. Small Spool Cap

11. Needle Pack

12. Buttonhole Foot

13. Regular Foot (A)

14. Spool Cap Tab

Tray

ACCESSORIES

15. Needle Plate for Straight Stitch

16. Knee Lifter Lever

BC D E

A

6

DANGER: To reduce the risk of electric

shock.

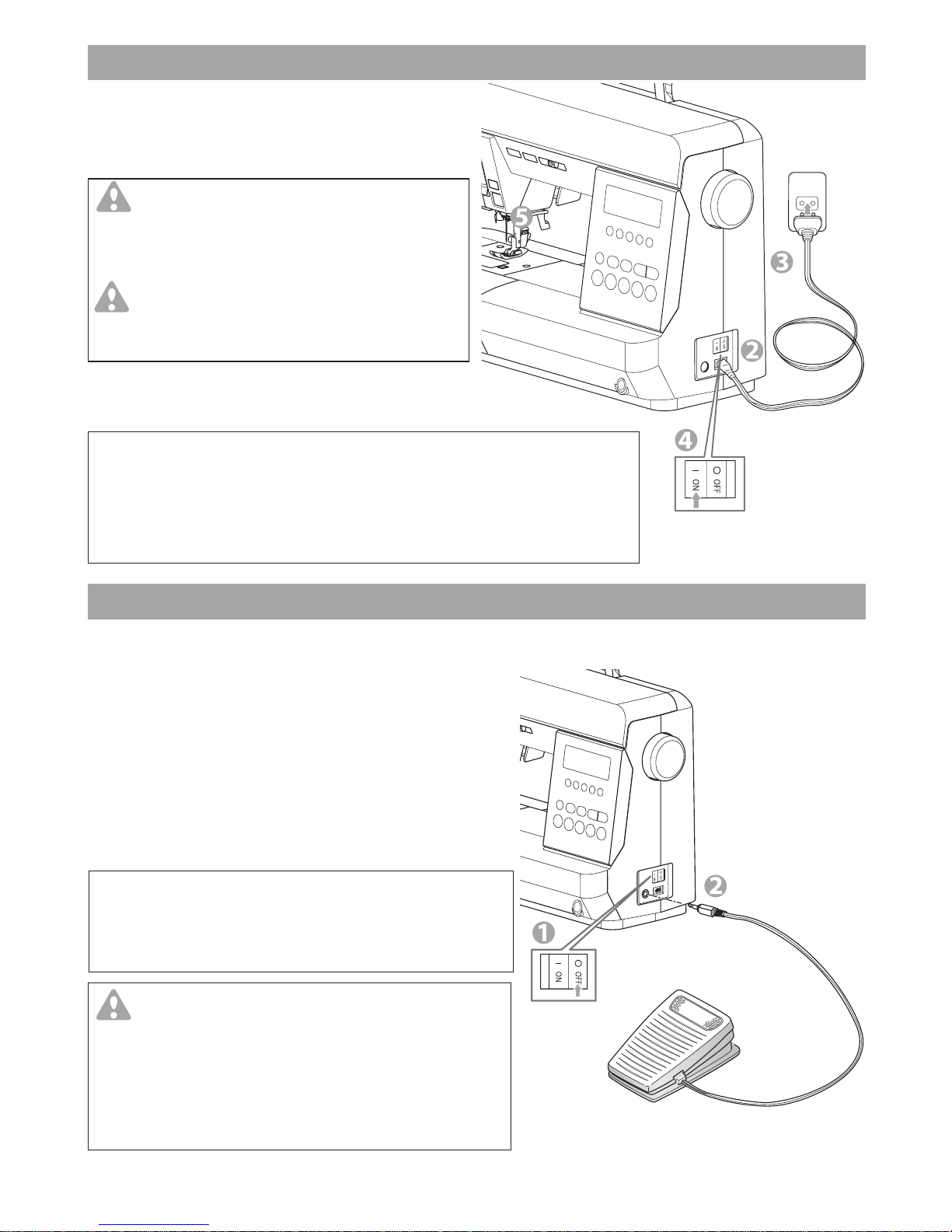

CONNECTING THE MACHINE

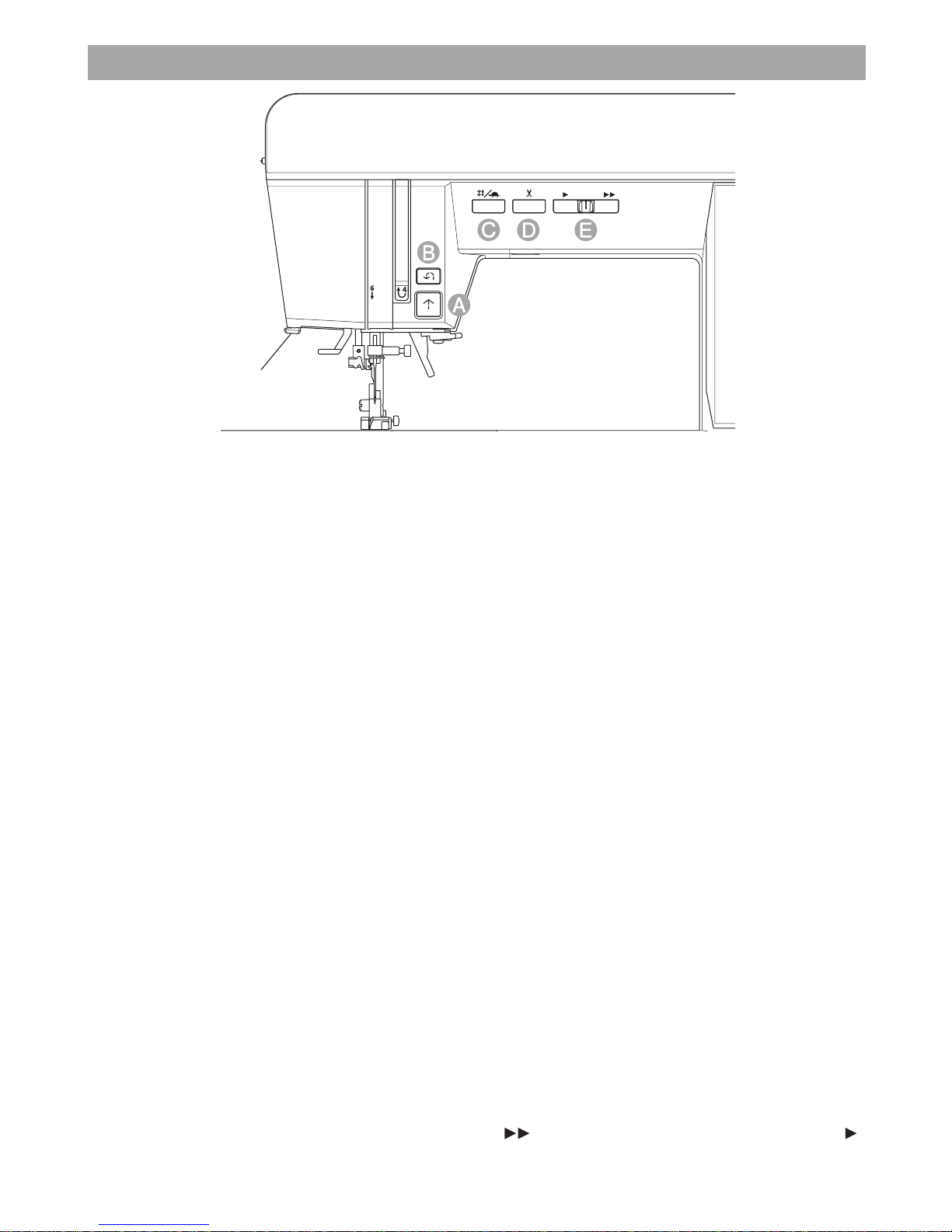

Use of foot controller will permit control of start, stop and

speed with your foot.

When the foot controller is connected, start/stop button will

be deactivated. (See page 7)

1. Turn o the power switch. (Symbol O)

2. Push foot controller plug into the jack on machine.

3. Place foot controller at your feet.

4. Turn on the power switch.

5. A lamp will light up when switch is turned on.

6. The harder you press the foot controller, the faster the

machine will sew. The machine will stop when foot

controller is released.

WARNING: To reduce the risk of burns, re,

electric shock, or injury to persons.

Tap Function

When you press and release the foot controller quickly, the

needle position will be changed.

NOTE: Needle stop position will not be changed.

1. Place machine on stable table.

2. Connect the power line cord to the machine by

inserting the 2-hole plug into the terminal box.

3. Connect the power line plug to the electric outlet.

4. Turn on the power switch.

5. A lamp will light up when switch is turned on.

6. To disconnect, turn the power switch to the o

position (Symbol O), then remove plug from outlet.

FOR UNITED STATES AND CANADA USERS:

POLARIZED PLUG INFORMATION

This sewing machine has a polarized plug (one blade wider than the other). To

reduce the risk of electric shock, this plug is intended to t in a polarized outlet

only one way. If the plug does not t fully in the outlet, reverse the plug. If it still

does not t, contact a qualied electrician to install the proper outlet. Do not

modify the plug in any way.

Never leave unattended when plugged in. Always

unplug this machine from the electric outlet

immediately after using and before maintenance.

WARNING: To reduce the risk of burns,

re, electric shock, or injury to persons.

Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

FOOT CONTROLLER

1. Turn o the power when connecting the foot controller to

the machine.

2. Handle the foot controller with care and avoid dropping it

on the oor. Be sure not to place anything on top of it.

3. Use only foot controller provided with this machine. (Type

C-9001 manufactured by CHIEN HUNG TAIWAN Ltd))

7

PatternTension

Width/

Length

Tack/

Cut

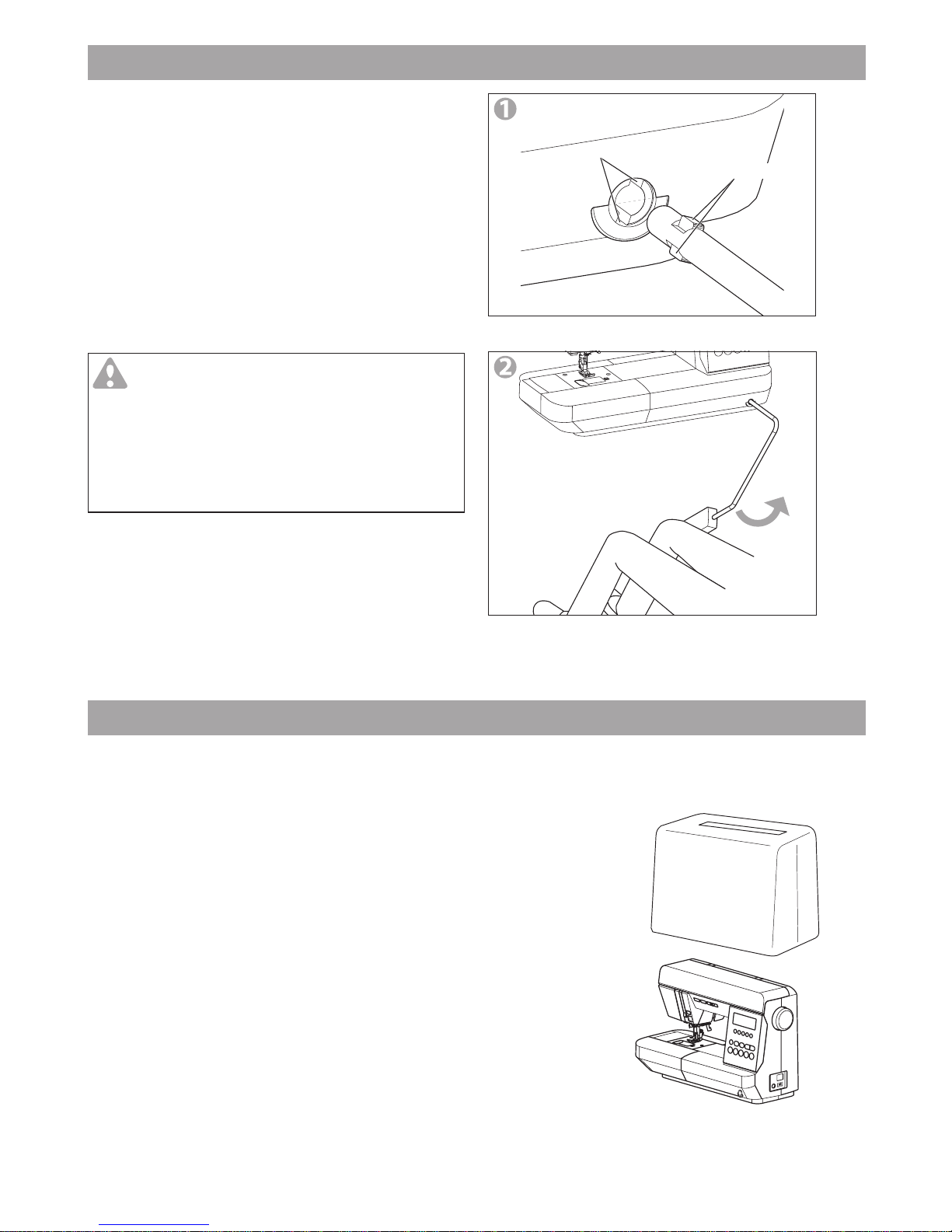

FUNCTION OF EACH PART

A. START/STOP BUTTON

The machine will start running when start/stop button is pressed and will stop when pressed the second time. The

machine will rotate slowly at start of sewing.

MONITOR LAMP

Green Light “ON”: Ready to sew or to wind bobbin.

Red Light “ON”: Presser foot is not in down position or buttonhole lever is not lowered.

If the red light is on, the machine will not start even when start/stop button is pressed.

If upper thread is not threaded, machine will stop after a few turns. (Upper thread sensor)

NOTE:

When the foot controller is connected, start/stop button will be deactivated.

B. REVERSE BUTTON

The machine will continue to sew in reverse at low speed while this button is pressed and stop when this button is

released.

NOTE:

When the foot controller is connected and the pedal is pressed, machine will sew in reverse while this button is

pressed. When released, machine will sew forward.

C. NEEDLE UP-DOWN/SLOW BUTTON

While NOT sewing, needle STOP position will be changed up or down by pressing this button.

While sewing, by pressing this button, machine will sew in slow speed. Pressing this button again, the speed will

return.

D. THREAD CUTTER BUTTON

Press this button after sewing to cut the upper and lower bobbin threads.

The machine will cut both threads automatically.

CAUTION:

* Do not press this button when there is no fabric in the machine or if there is no need to cut the threads. The thread

may tangle, resulting in damage.

* Do not use this button when cutting thread thicker than #30, nylon thread or other speciality threads. In this case,

use the thread cutter. See page 26.

E. SPEED CONTROL BUTTON

The machine will sew faster when the button is slid to the right ( ), and sew slower when button is slid to the left ( ).

NOTE:

When the foot controller is connected, the speed control is automatically set to the maximum speed.

Thread Cutter

8

G.DROP FEED LEVER

NOTE:

The Drop Feed Lever is only accessible after the

extension table is removed.

The fabric feed dogs project up through the needle

plate, directly below the presser foot. Their function

is to move the fabric being sewn. The drop feed lever

controls the fabric feed dogs.

For ordinary sewing, move the lever to the right. This

raises feed dogs to their highest position. For most

sewing, the lever should be in this position.

For darning or free motion embroidery or whenever

fabric is to be moved by hand, move the lever to the left

to lower the fabric feed dogs.

F. PRESSER FOOT LIFTER

The presser foot is lifted up or down by this lever.

NOTE:

Machine will not start when the presser foot is lifted.

(Except for bobbin winding)

H. PRESSURE REGULATOR

The correct pressure allows fabrics to feed properly

while sewing. The setting of the presser foot pressure

is determined mainly by the weight of the fabric being

sewn.

For lightweight fabrics such as sheers, batiste, voile,

etc, the pressure is decreased. For heavyweight fabrics

like denim or canvas, the pressure in increased.

To increase the pressure, turn dial to 5. (○○○○○)

To decrease the pressure, turn dial to 1. (○)

For most fabrics, turn dial to 3. (○○○)

Fabric

feed

dogs

Front

Back

9

HOW TO USE THE NEEDLE PLATE FOR STRAIGHT STITCH

When sewing light-weight fabric you can get beautiful

straight stitches without puckering by using the

needle plate for straight stitch. This is because the

needle plate for straight stitch has a smaller needle

hole than the regular needle plate.

Remove the regular needle plate and attach the

needle plate for straight stitch.

Regular Needle Plate

(On the machine when delivered)

PatternTension

Width/

Length

Tack/

Cut

CHANGING THE NEEDLE PLATE

SEWING

CAUTION: To prevent accidents.

Disconnect the power when changing the needle

plate.

Select the straight stitch center needle position (No. 2,

4, 30).

CAUTION: To prevent accidents.

Select stitch numbers 2, 4 and 30 only while using

the needle plate for straight stitch. Do not move the

needle position from center (3.5).

Otherwise, needle hit the needle plate and break.

1. Remove the extension table, the needle, the

presser foot and the holder. Remove the bobbin

cover and bobbin. Remove the screws holding

the regular needle plate.

: Driver for needle plate

2. Remove the regular needle plate by lifting up the

right side of the plate.

3. Place the needle plate for straight stitch inserting

the hook ( ) and holes ( ) into the machine.

Retighten the screws.

4. Replace the bobbin and the bobbin cover, the

presser foot and holder.

Replace the needle and extension table.

Needle Plate for Straight Stitch

10

KNEE LIFTER LEVER

Convexes

Slits

By attaching the knee lifter lever to the machine, you

can lift or down the presser foot by your knee.

1. Insert the knee lifter lever into the socket of machine

so that the convexes of the lever t into the slits of

the socket.

2. Press the lever to the right to lift up the foot.

Release the lever to lower the foot.

CAUTION: To prevent the accidents.

- Insert the knee lifter lever all the way into the socket.

If it is not inserted correctly, it may come o during

use.

- DO NOT TOUCH THE KNEE LIFTER LEVER

WHILE SEWING. Needle may break or sewing may

jam.

Cover the machine with dust cover when it is not in use.

DUST COVER

11

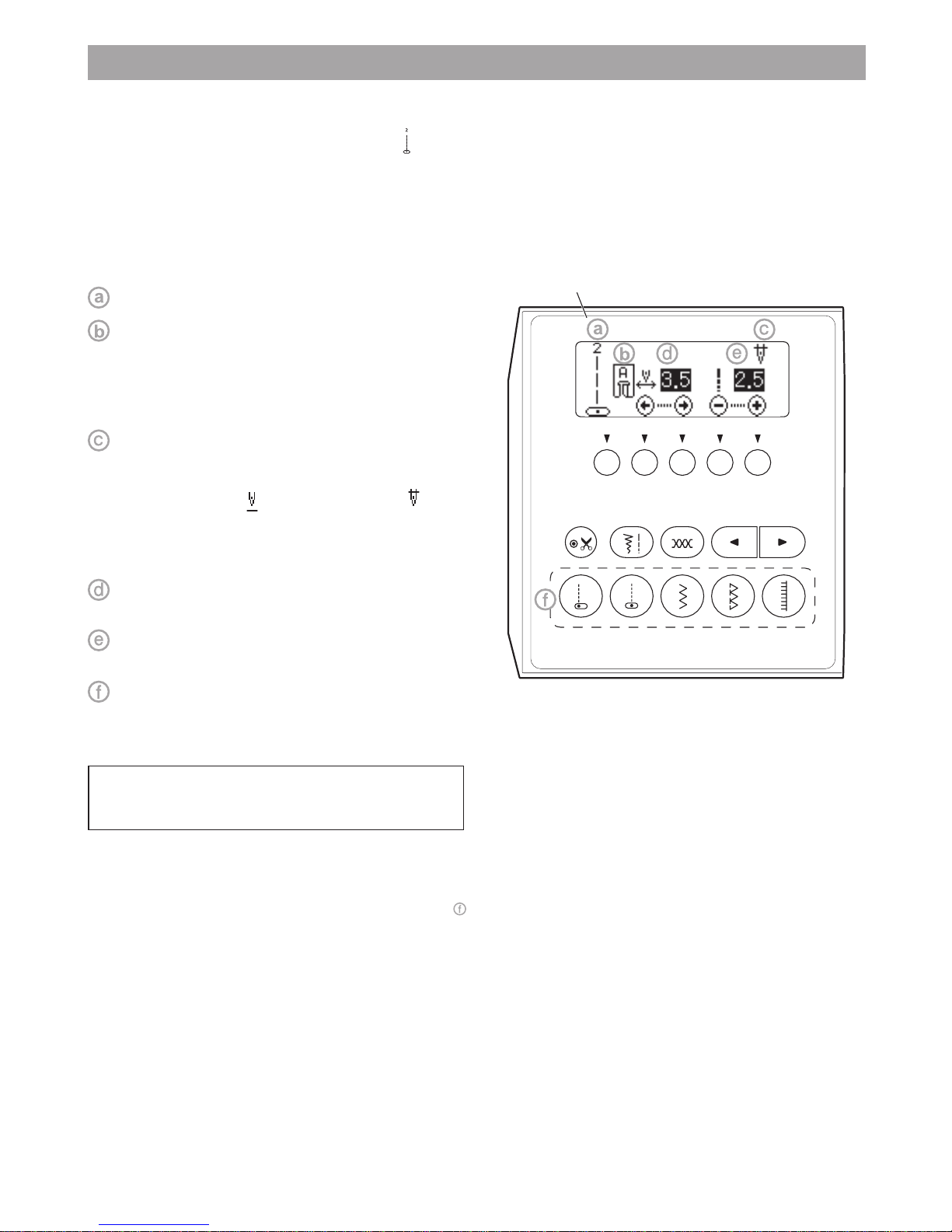

This machine has 70 patterns.

(See the pattern chart located inside of the top cover.)

When you turn on the machine, straight stitch ( ) will be

selected and indicated on the LCD.

When you select a pattern, the following are indicated

on the LCD:

You can select basic stitch by touching these buttons ( )

directly. Selected stitch will be indicated in the screen.

NOTE:

Please do not press the buttons strongly.

The buttons in the control panel react by lightly touching

with the ngertip.

NOTE:

If the LCD can not be seen well, you can adjust the

brightness. (See page 44)

PatternTension

Width/

Length

Tack/

Cut

Control Panel

Pattern Number and Stitch Pattern

TO SELECT A PATTERN / ADJUST A PATTERN

A. TO SELECT A BASIC PATTERN

Suitable Presser Foot

The presser foot indicated on the LED is suggested

for use for normal sewing.

You can use other presser feet according to the

purpose of sewing described in this manual.

Needle Stop Position

Indicates needle stop position by selecting needle

up/down button.

Up position: Down position:

When you turn on the machine, needle stop position

is set to down position.

Stitch Width/Needle Position

Stitch Length

Basic Stitch Buttons

See page 13.

See page 13.

See the next topic "TO SELECT A BASIC

PATTERN".

12

Tension

Width/

Length

Tack/

Cut Pattern

Tension

Width/

Length

Tack/

Cut Pattern

Tension

Width/

Length

Tack/

Cut Pattern

Tension

Width/

Length

Tack/

Cut Pattern

NextPrevious

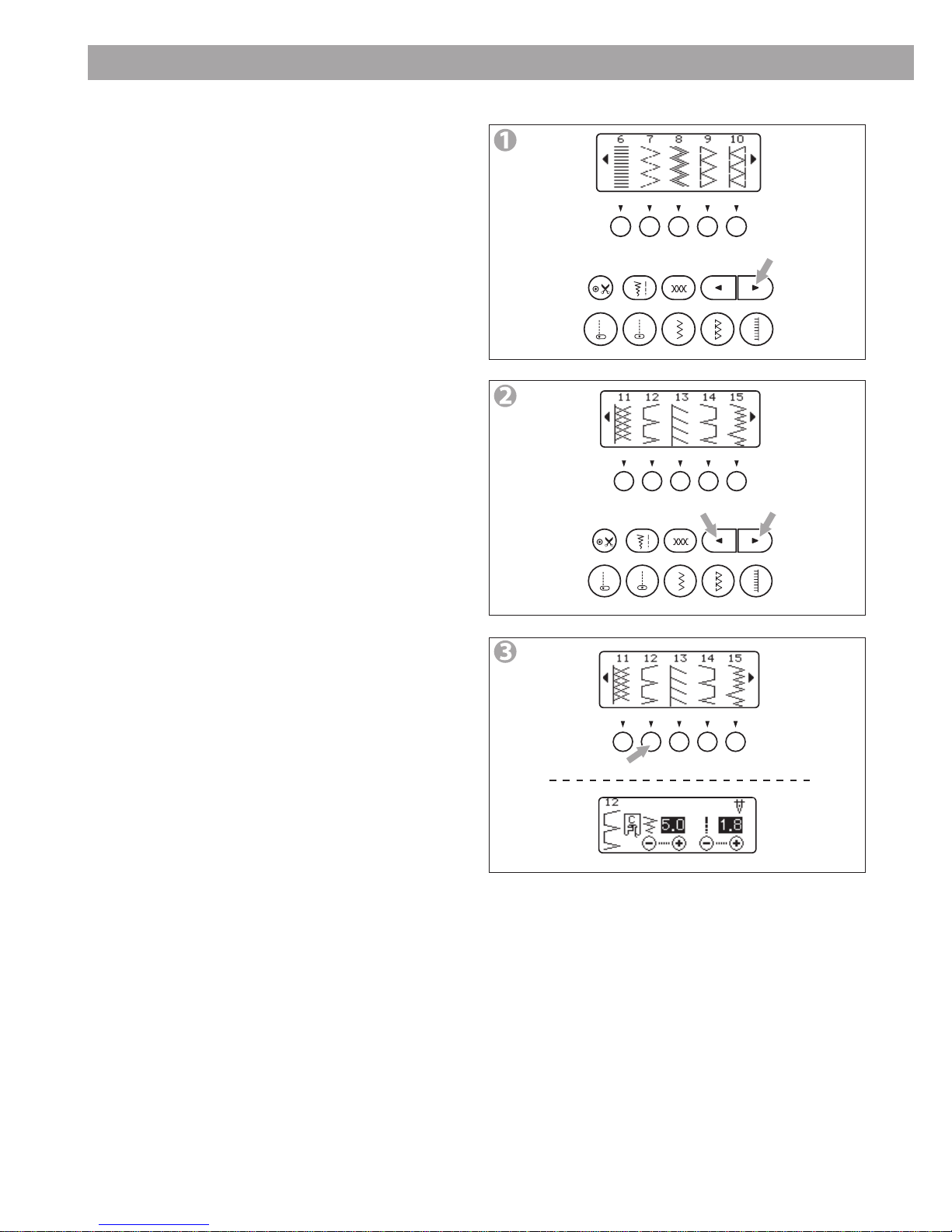

1. Touch the right or left pattern button.

The 5 patterns including currently selected will be

displayed on the LCD.

2. By touching the left pattern button, the previous 5

patterns will be displayed.

By touching the right pattern button, the next 5

patterns will be displayed.

Touch these buttons until the pattern which you want

to sew will appear.

3. Touch the function button under the pattern you

want to sew.

The LCD screen will indicate the stitch width/needle

position and stitch length of the selected pattern.

B. TO SELECT OTHER PATTERN

13

You can sew tack stitch at the beginning and end of the

stitch by touching the tack/cut button. Also, you can cut

threads automatically after end tacking. See page 24.

Touching the width/length button, the display changes

as illustration (D).

When you select a pattern, stitch width and length are

set for suitable width and length automatically and

indicated on the screen. You can adjust them manually.

If the screen is indicating the thread tension, touch the

width/length button to indicate them.

To narrow the stitch width, touch the function button (a).

To widen the stitch width, touch the function button (b).

To shorten the stitch length, touch the function button (c).

To lengthen the stitch length, touch the function button (d).

* Preset stitch width and length are indicated as a

highlighted number.

* The beep sounds at the maximum or minimum value.

(The maximum or minimum value is dierent by each pattern. When

stitch width or length is not appeared, its pattern cannot change these

settings.)

When straight stitch patterns (1, 2, 4, 30) have been

selected, stitch width buttons change to adjust the

needle position.

To move the needle to the left, touch the function button

(e).

To move the needle to the right, touch the function

button (f).

Touching the tension button, the display changes as

illustration (F).

The thread is automatically setup to a suitable thread

tension. When you touch this button you can adjust it

manually. See page 15.

Number 0 - 3.5 - 7.0

Position Left Center Right

PatternTension

Width/

Length

Tack/

Cut

PatternTension

Width/

Length

Tack/

Cut

PatternTension

Width/

Length

Tack/

Cut

Stitch Width

Stitch Length

PatternTension

Width/

Length

Tack/

Cut

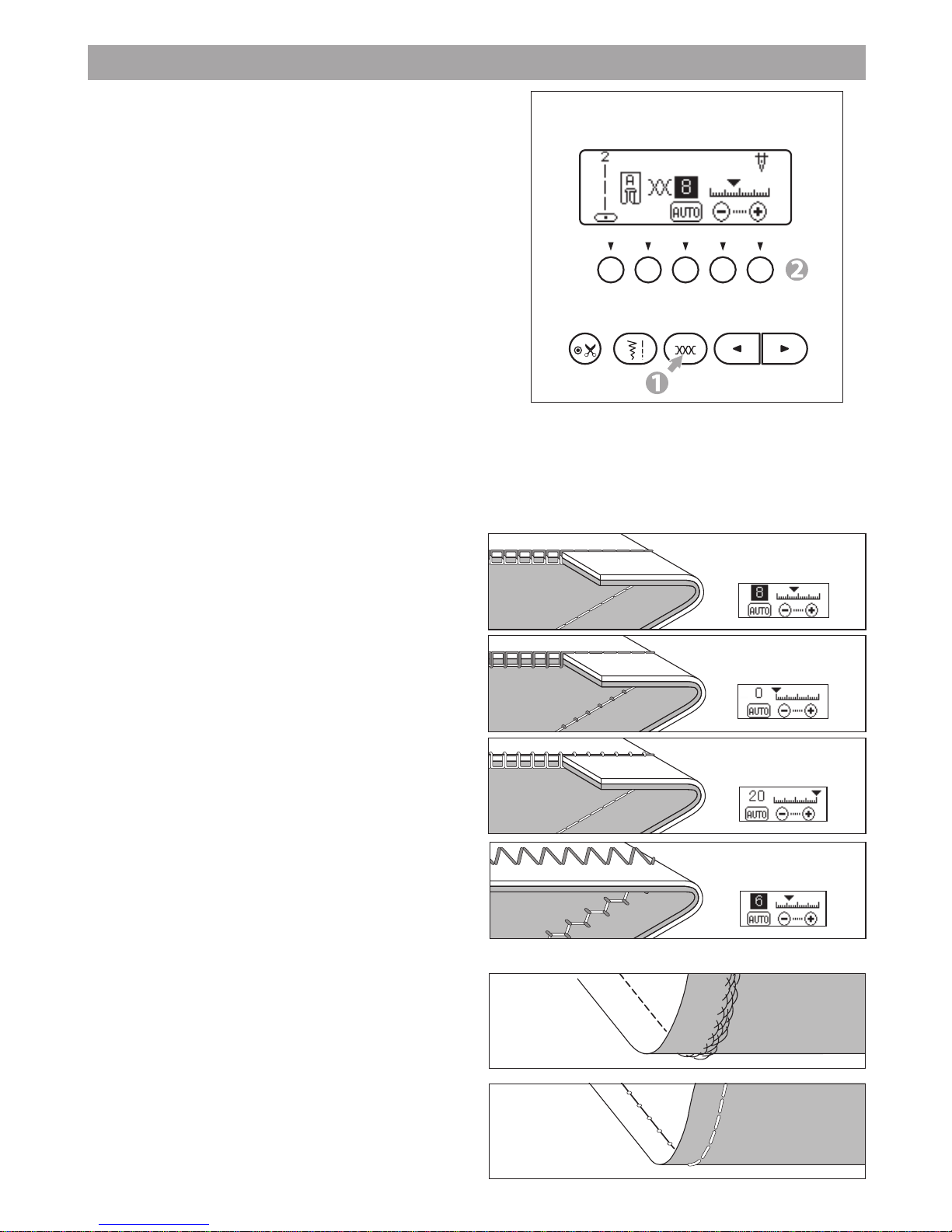

C. TACK/CUT BUTTON

D. ADJUSTING THE STITCH WIDTH AND

LENGTH

E. NEEDLE POSITION CONTROL

F. TENSION BUTTON

-+

-+

f

e

d

c

b

a

14

* Highlighted pattern numbers indicate the

basic stitch patterns.

G.STITCH PATTERN

15

This machine adjusts the thread tension automatically

when you select a pattern.

However, you can change the thread tension as follows.

1. Touch the thread tension button.

The state of thread tension is displayed with

numerical value and scale. (Thread tension screen)

2. Change the thread tension with function buttons:

• To return to default tension, touch the function

button (a).

• To weaker the tension, touch the function button (b).

• To stronger the tension, touch the function button (c).

* Preset tension number is highlighted.

* You can start sewing on this thread tension screen as

it is.

* When you reselect a pattern, tension will return to

default.

Thread tension except for straight stitch

When sewing stitches other than straight stitch, thread

tension is automatically adjusted to be weaker than

when sewing a straight stitch.

This will cause upper needle thread to appear on the

bottom side of fabric, resulting in better stitching.

Helpful Hints

If your sewing appears as shown on the right, (stitches

on the top side of fabric are good but bottom side tends

to look like a towel), it could be that the upper thread

is not threaded correctly. Refer to page 18 for correct

threading.

* Also, if the bobbin thread comes out on the front side of the fabric

even though the thread tension is set to the automatic setting value,

the way of setting bobbin is wrong. Refer to page 17 and set the

bobbin correctly.

PatternTension

Width/

Length

Tack/

Cut

Preset thread tension

Upper and bobbin thread will lock appromaximately in

the middle of fabric.

When thread tension is decreased.

Upper thread will appear on the bottom side of fabric.

When thread tension is increased.

Bobbin thread will appear on the top side of fabric.

THREAD TENSION

b

ac

Thread Tension Guide

16

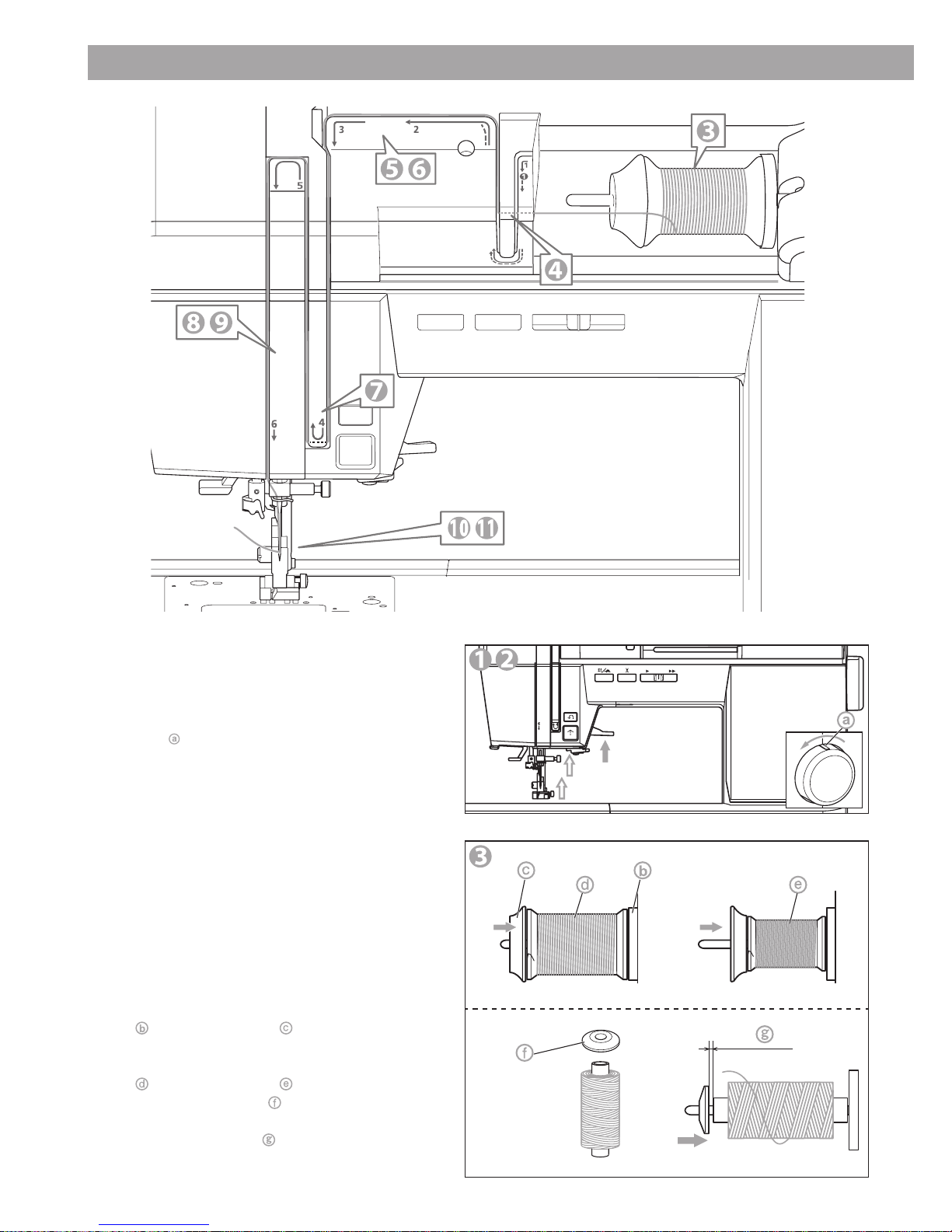

B. WINDING THE BOBBIN

1. Open the top cover.

2. Place the bobbin on the bobbin winder spindle

so that the groove ( ) on the bobbin ts to the

spring ( ) on the spindle.

Push bobbin to the right to engage bobbin winder.

(LCD will indicate the bobbin winder mode.)

3. Set the felt washer ( ) to the right side of spool.

Set the spool of thread on spool pin so that the

thread unrolls from the front of the spool.

Set the spool cap ( ) on spool pin as far as it will

go.

Reverse spool cap direction according to the size

of spool.

: Large Spool : Small Spool

Use the small spool cap ( ) when you use cross

wound thread. Leave small opening between cap

and spool as illustrated ( ) for smooth thread

feeding.

4. Hold thread in both hands and hook thread to

the guide from rear opening.

Bring thread frontward and pass through the

thread guide from right to left.

5. Bring thread backward and pass through the

thread guide ( ) from left to right.

6. Bring thread to the right and pass thread through

the thread guide from rear side. Pass thread

under tension disc in counter clockwise direction.

A. REMOVING THE BOBBIN

11.5 mm

Actual Size

NOTE:

Use the bobbin dedicated to this model.

BOBBIN SETTING

1. Raise the presser foot lifter.

2. Pull the bobbin cover latch to the right and

remove the bobbin cover.

3. Lift up the bobbin from the machine.

17

PatternTension

Width/

Length

Tack/

Cut

C. INSERTING THE BOBBIN

1. Place bobbin into bobbin holder ( ) with the

thread unwinding counter clockwise.

2. Draw thread into notch ( ) with holding the

bobbin.

3. Pull thread along the groove from up to down.

Pull thread to the right to cut the thread ( ).

4. Replace the bobbin cover. Set the left tabs ( )

into the holes in needle plate and push the right

side of bobbin cover down until it clicks into

place.

7. Hold the thread by your left hand and wind the

thread to the bobbin 4-5 times clockwise.

8. Hook the thread under the front wing of the

bobbin winder thread guide ( ) from left to right

and cut the thread.

9. Start the machine by pressing the start/stop

button or pressing the foot controller pedal.

The bobbin winding will stop automatically when

bobbin is full. (Release the pedal.)

10. Push the bobbin and spindle to the left.

Remove the bobbin from the spindle. Hook

thread to the thread cutter ( ) from left-back to

right-front.

NOTE:

This machine can start to sew without drawing

up the bobbin thread.

If you want to draw up the bobbin thread, see

page 26.

CAUTION: To prevent accidents.

Turn o the power before carrying out the below

operation.

18

THREADING THE MACHINE

A. PREPARING TO THREAD MACHINE

B. SETTING SPOOL OF THREAD ON SPOOL

PIN

1. Raise the presser foot lifter.

2. Raise the needle to its highest position by turning

the hand wheel toward you.

The mark ( ) of hand wheel comes to the top.

(Keep this position until needle eye threading.)

3. Open the top cover and set spool as below.

- Pull up the left end of spool pin.

- Set the spool of thread on spool pin so that the

thread unrolls from the front of the spool.

- Set the spool cap on spool pin as far as it will go. (See

illustration.)

: Felt Washer : Spool Cap

Reverse spool cap direction according to the size

of spool.

: Large Spool : Small Spool

Use the small spool cap ( ) when you use cross

wound thread. Leave small opening between cap

and spool as illustrated ( ) for smooth thread

feeding.

Table of contents

Other EverSewn Sewing Machine manuals

EverSewn

EverSewn sparrow 15 Series Operating instructions

EverSewn

EverSewn Hero User manual

EverSewn

EverSewn Celine User manual

EverSewn

EverSewn Maker 200 User manual

EverSewn

EverSewn sparrow 20 User manual

EverSewn

EverSewn CH04AX Operating instructions

EverSewn

EverSewn sparrow 15 User manual

EverSewn

EverSewn Sparrow X User manual