Eversola ES-M-Abcp Series Maintenance and service guide

Ref. : LYHT-INSTALLATION MANUAL Version : OR Updated on : 2021-06

All Rights Reserved by Eversola LuoYang Co., Ltd.

Ref. : LYHT-INSTLLATION MANUAL Version :OR Updated on : 2021-06

Eversola LuoYang Co., Ltd.

No.8, 2nd Jinye Road, Jinping Town, Yiyang County, Luoyang City,

Henan Province, 471600, P.R. China

Customer Service hot line:

+86 379 68951871(HQ)

Fax:

+86 379 68951871(HQ)

Email:

Web: www.eversola.com

Eversola Jiangsu Co., Ltd.

No.69 Kanghua Road,Economic and technological development zone,Hai‘an City,

Jiangsu Province, 226600, P.R. China

Contents

Disclaimer of Liability

Preface

Product Identification

Safety

Transportation and Handling

Installation

Maintenance

Annual Inspection

Applicable Law and Dispute Settlement

All Rights Reserved by Eversola LuoYang Co., Ltd.

Ref. : LYHT-INSTALLATION MANUAL Version :OR Updated on : 2021-06

·01·

01

01

02

02

03

05

10

11

11

·02··01·

1. Disclaimer of Liability

1. The use of this manual and installation, handling, maintenance and use of modules

are beyond Eversola’s control, and Eversola does not assume any responsibility for

loss, damage, injury or expense resulting from incorrect installation, handling, use or

maintenance.

2. Eversola assumes no responsibility for any infringement of intellectual property right

(including without limitation patent, copyright and trademark) or other rights of third

parties that may result from use of modules. No license in connection with intellectual

property right (including without limitation patent, copyright and trademark) or other

rights of Eversola, Whether expressly or impliedly, is granted to customers because of

use of modules.

3. All information stated in this manual is based on Eversola’s knowledge and

experience, but no warranty about such information (including modules

specifications) is made by Eversola, whether expressly or implied. Eversola reserves

the right to update this manual, modules specifications or relevant information

without prior notice.

2. Preface

This manual offers general installation and maintenance information of the

Photovoltaic Modules (hereinafter referred to as the Modules) of Eversola LuoYang

Co., Ltd or Eversola Jiangsu Co., Ltd (hereinafter referred to as Eversola).

Before installation, handling or maintenance, ensure that you have read and

understand this manual and use the module correctly & safely.

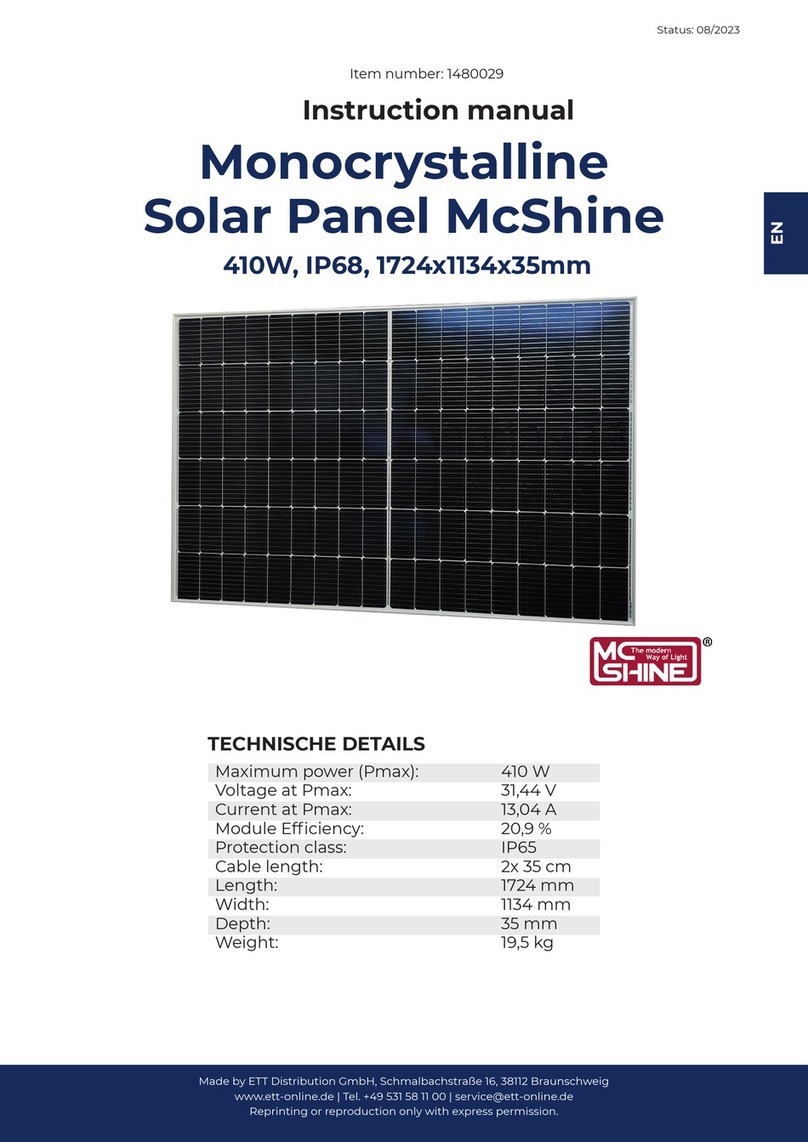

The installation manual is for all modules, the model names covered are:

A Series Module:

ESxxxM-Abcp, (xxx=390-410, 420-450, 525-555, in steps of 5W, 144 cells)

ESxxxM-Agcd, (xxx=390-410, 420-450, 525-555, in steps of 5W, 144 cells)

ESxxxM-24/Abpw, (xxx=290-345, in steps of 5W, 72 cells)

ESxxxP-24/Abpw, (xxx=290-345, in steps of 5W, 72 cells)

B Series Module:

ESxxxM-Bbcp, (xxx=325-340, 350-375, 440-460, in steps of 5W, 120 cells)

ESxxxM-Bgcd, (xxx=310-330, in steps of 5W, 120 cells)

ESxxxM-24/Bbpw, (xxx=320-325, in steps of 5W, 60 cells)

ESxxxP-24/Bbpw, (xxx=245-285, in steps of 5W, 60 cells)

Remarks

1. The“xxx”means for the module power, for detailed information please refer

to the module datasheet.

2. ES indicate Eversola, while M indicate Mono Crystalline, P indicate Poly

Crystalline.

3. Product Identification

Nameplate: Describes the product model; rated power; rated current, rated

voltage, open circuit voltage, and short circuit current. All above parameters are

measured in standard testing conditions: irradiance of 1000W/M2, AM 1.5, Module

temperature 25℃.

Other information, such as weight, size, maximum system voltage and maximum

fuse current, module application class and safety class are marked on the

nameplate as well.

Barcode: the barcode is located in the inside the glass the module, and contains

the serial number (also displayed).

Do not remove or alter any label or marking, this will void warranty.

4. Safety

ATTENTION: Danger of death from electric shock

1. Installation, trouble shooting and maintenance of solar installations present

hazards associated with electrocution, electrical arcs, burns, working from heights

and manual handling; therefore, this work must only be carried out by suitably

trained professionals with the appropriate safety equipment and procedures in

place at all times. All installation work must comply with the local codes and relevant

international electrical standards.

2. Electrical hazards must be taken in account at all times when working on or

around solar modules. Please take necessary actions to avoid possibility of electrical

injuries.

3. Mating connector pair on module and array leads must be the same brand and

type.

4. Do no strike modules or subject modules to impact with tools or objects.

5. Do not install a panel that has been damaged, glass smashed or back-sheet torn.

6. Do not touch exposed parts, cables or connectors.

7. Do not dismantle, disassemble or modify any parts of the modules and do not remove

or alter in anyway the labels or markings on modules.

8. Do not step or walk on the modules. Doing so may damage and crack parts of

modules.

9. Do not expose modules to chemicals, for instance paints, solvents, adhesives.

10. Keep the modules away from inflammable gas, hazardous chemicals or flammable

explosive items.

11. Do not artificially focus light on the module.

5. Transportation and handling

Solar Modules are glass and contain very fragile silicon wafers inside them and must be

transported and handled with utmost care. Do not strike, drop or bend a solar module.

1. Never transport other items (e.g. Inverters) on top to a solar module pack.

2. Store the modules safely in cool and dry area. The packaging is not weatherproof.

3. Leave modules in their packaging until they are to be installed, the modules must avoid

rain and sand erosion after unpacking.

4. Unpacking PV modules from the original package:

Step 1: Remove securing straps.

Step 2: Remove the pallet lid.

Step 3: Unpack the modules one by one and stack

them(surface glass side down) without removeing

the cardboard edge protector.

Step 4: Remove the cardboard edge protector from the

modules before installing.

·03· ·04·

5. Check the module for damage due to transportation before the installation.

6. Use extreme caution if stacking modules for transport of less than a pallet at a time

line up the modules with their edge protectors in place and wraps, strap and fasten

them so that they cannot move around or rattle and fall. Care must be taken with

fasteners that secure modules but do not bend or damage the modules in any way.

7. The modules should be transported in their original packaging where possible with

any free space in the box securely filled with soft packaging materials to prevent the

panels from moving around.

8. Never move modules by pulling their cables.

9. Carry the modules with both hands and with their glass surface facing the

operator when absolutely necessary (one operator available) (please see Figure 2).

Do NOT stack the modules back-sheet side down to avoid glass scratch and electric

shock risk (please see Figure 3).

10. Do not step or walk on the modules. Dong so may damage module (please see

Figure 4).

11. Do not carry wet or hot modules dropping a module from an height and impact

of falling tools may affect the electrical performance or break the module (see

Figure 4).

12. The surface oxide layer of the frame may be damaged by sharp objects, do not

destroy or scratch the frame of the modules.

13. Glass surface, back-sheet and aluminum frame are susceptible to damage that could

affect the performance or integrity of the PV module; do not damage or scratch the

surfaces, and do not spray any non-validated chemicals paints, solvents or adhesive to

any of the surfaces, including the frame. Doing so may degrade performance or cause

irreparable damage and will void any applicable warranties.

6. Installation

1. The electrical and mechanical installation must be comply with international and

local standards and principles including cable connection building codes etc.

2. The mounting structures must be designed by qualified structural engineers, and

installation design and procedures shall be consistent with the relevant local

standards.

3. Installers must be qualified and familiar with solar and electrical principles.

4. The working ambient temperature range is -40℃ to +85℃ and Relative Humidity

≤85%.

5. The modules shall be installed so as to maximize solar exposure and to minimize

shading by trees, buildings or other obstacles in the surrounding area. Generally in

the Northern hemisphere modules are ideally orientated to the south and in the

southern hemisphere modules orientated to the north.

6. Notify Eversola of any damage to product immediately. Do not use or install

damaged modules. Damaged modules may cause fire or electric shock, resulting in

property damage, fire and or death.

7. Do no disconnect or connect any cables under load, the bending cable radius of

Junction box must more than 43mm.

8. Match the polarities of cables and terminals when making the connections, failure to

do so may result in damage to the module. Keep the connector dry and clean and

do not impact external force on the connector such as heavy snow, strong wind.

9. The maximum modules of one PV string N=(The maximum system

voltage)/[(Voc)*1.25], note the Voc is the value at the lowest temperature in the

project sites.

10. Suitable over current protection devices (string fuses etc.) must be installed when

connecting 3 or more strings in parallel configuration.

11. Under normal conditions, a module may be able to produce voltage and current

higher than in standard test condition. Accordingly, when determining component

rated voltage, conductor ampacities, fuse current and size of controls connected to

the PV output, the short circuit current and open circuit voltage value marked on

this module shall be multiplied by a factor (safety factor) of 1.25.*

·06··05·

*Note:

The safety factor for component rated voltage, conductor ampacities, fuse

current and size of controls connected to the PV output is subject to the

meteorological conditions of project sites.

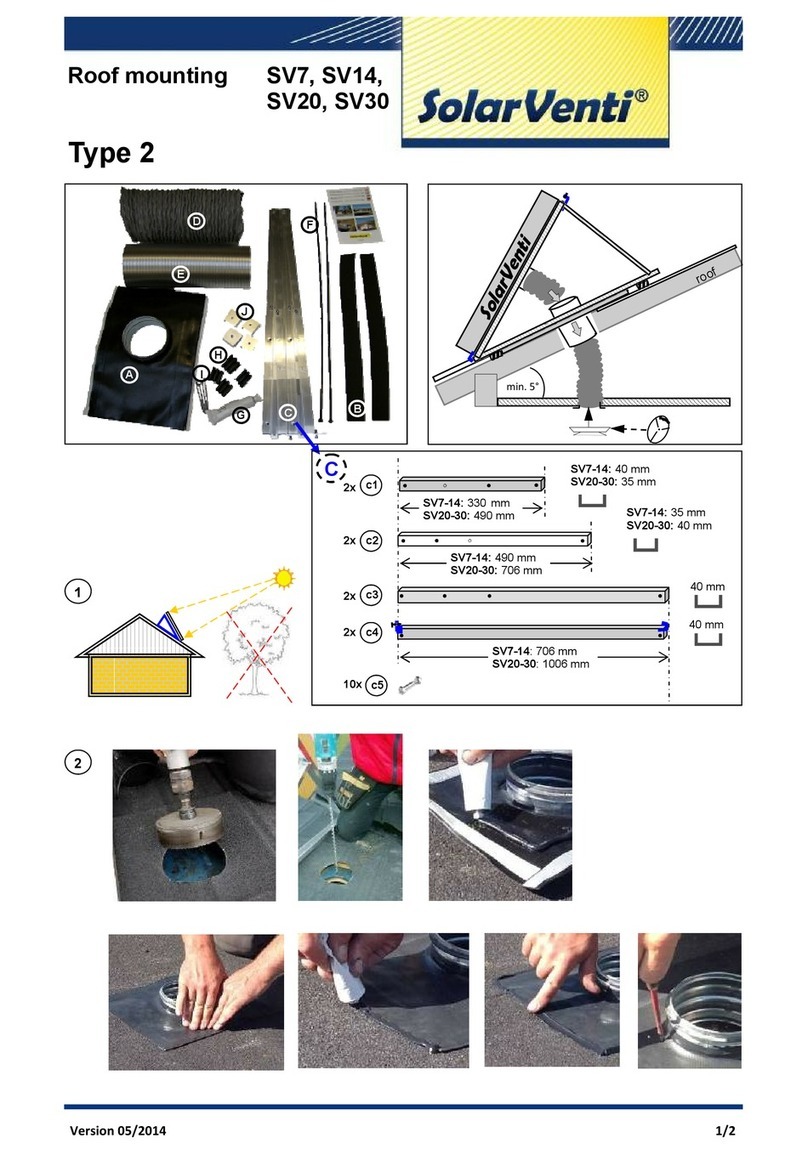

12. Select either method of fixing mentioned below depending on site conditions:

Screw-fixing system (Figure 5-a), Fixture-fixing system (Figure 5-b).

13. Installation method and location

1) Screw-fixing:

Fixing the modules on the bracket at 12 border prefabricated installation holes

(figure 6). All the fastening pieces are made of stainless steel. Installing holes A must

be fixed with bolts and customer can choose one of the installation B or C to use.

Applied torque is recommended as 7-11 N*m for M6 (diameter is 6mm) screw in

installation holes C and 14-20 N*m for M8 (diameter is 8mm) screw in installation holes

A&B.

2) Fixture-fixing:

Fix the module safely and securely on the mounting structure. The length of clamp

should be 40mm minimum. Applied torque is recommended as 7-11 N*m for

M6(diameter is 6mm) screw. The clamp are made of aluminum alloy.

For A series modules, four clamps must be used:

·08··07·

3) Inserting System:

Fix the module with U type groove or flange beam.

All available installation methods for A series modules (Figure 9)

For other series module, fix the module with the long sides (Figure 8-1) according to the

bracket locations specified and mechanical load requirement.

For other series module, fix the module with the long sides or short sides according to

the bracket design and mechanical load requirement. (Figure 10)

Fixing eight installation holes simultaneously is recommended according to the security

Considerations. When installed correctly, the modules can withstand a maximum snow

Pressure of 5400 Pa or wind pressure of 2400 Pa.

14. When installing the modules on the roof, ensure there is an appropriate mounting

structure.

·10··09·

18. It is better to use the modules with same specifications same color when

connected in series.

19. Artificially concentrated sunlight shall not be directed on the module.

20. Our modules have passed the salt mist and ammonia test (Please refer the test

report for detailed information) and can be installed in some corrosive

environments, e.g. sea side.

21. The modules should not be installed at the place which is less than 100 meters

from the seashore. If the distance of the seashore and the project site is

100~10000 meters, anti-corrosion application should be taken during the

installation and grounding processes.

15. The minimum separation between two modules shall be more than 10mm; when

installing on the roof, the recommended separation between the modules and the

roof surface is 100mm to allow for air flow around the modules. When installing on

ground mounts keep ground clearances to more than 450mm.

16. Grounding

1) Grounding method shall be consistent with the local standard and regulations. Any

grounding system/method, which is designed in accordance with relevant

international and local standards and regulations, such as UL2703, UL467,

IEC60335, NEC article 250 and section 690.V.43, etc. could be attached to the

modules.

2) In order to prevent electrochemical corrosion, material in contact with module

frames, should be properly selected and galvanic isolation provided where

necessary.

3) PID (Potential Induced Degradation) due to combined effects of high temperature,

high humidity and high voltage, is most likely to be observed in similar climates and

mounting surroundings such as India, Southeast Asia, floating designs. Expect for

equipment grounding, negative system grounding is strongly recommended as the

basic solution for PID phenomenon.

4) Grounding wire shall be the bare copper wire with simple surface treatment and no

insulation sleeve. Wire cable with cross-sectional area of 4mm2(10~12 AWG) and

ground clamp (such as Tyco, identification of product: 1954381-2) are

recommended(diagrammatic sketches are as follows).

17. When the connecting wires of the modules do not meet length requirements, a

correctly rated electrical cable that is designed and certified for long term outdoor

use along with the correct connectors can be used to extend the connections.

Match the same brand and type of module connectors to extend the connection.

The cross-sectional area for PV array wire must be no less than 4mm2, and the

connection system is IP67 rated.

7. Maintenance

1. Do not touch any live parts of the array wires, uninsulated cable and the

connector. Use the safety equipment when working on solar equipment

(insulating tool, insulating gloves etc.).

2. An opaque cloth or other non-abrasive material can be used for cover the

front of the modules to eliminate sunlight exposure and reduce the chance of

electrocution during maintenance when required.

3. Cleaning instructions

Periodic cleaning is recommended for solar modules. The cleaning process

should be done by suitably trained professionals with the appropriate safety

equipment and procedures in place at all times. When cleaning the module

surface.

a) The following rules apply:

√ To reduce cold and hot shock clean panels at low irradiance time.

√ Only use soft cloths or sponges to clean the glass surface.

√ Only use clean water as the cleaning solvent.

√ The difference between water temperature and module temperature

should be in the range of -5℃ to +10℃.

√ Water pressure should be less than 1000Pa.

b) following notes should be taken into account:

√ No other chemical should be used in cleaning process.

√ No aggressive tools or coarse cleaning materials are permitted.

√ Do not step or walk on the modules.

√ Do not strike modules or subject modules to impact with tools or objects.

√ Isolate modules during cleaning and maintenance, the modules must not

be under load.

√ Do not touch exposed cables or connectors.

√ Do not remove dust in dry way (without water).

·11·

7. Annual Inspection

1. Check if nuts, bolts of mounting structure are secure and not loose. Tighten

the loose components again, if required.

2. Check the connecting cables, grounding cables and connectors and the

performance of the ground resistance.

3. Check all electrical and mechanical connections for freedom from corrosion.

4. Check the ground resistance of metal parts such as the module frames and

the mounting structures.

9. Applicable law and dispute settlement

This “installation & Maintenance for PV modules”shall be governed by and

interpreted under the laws of Hong Kong (irrespective of its choice of law

principles). Except for the technical disputes, all disputes arising out of or in

connection with this “installation & Maintenance for PV Modules” shall,

unless amicably settled between the parties, shall be settled by arbitration in

Hong Kong under the Hong Kong international Arbitration Centre

Administered Rules in force when the Notice of Arbitration is submitted in

accordance with these rules. The language of arbitration shall be English. The

award of the Arbitrators will be final and binding upon the parties. Provided

that there is any inconsistency between the sale’s contracts to which this

“Installation & Maintenance for PV Modules” is attached, the terms and

conditions of the sales contract shall prevail.

This document constitutes part of the contract and valid automatically when

the contract is signed.

All Rights Reserved by Eversola LuoYang Co., Ltd.

Ref. : LYHT-INSTALLATION MANUAL Version :OR Updated on : 2021-06

This manual suits for next models

8

Table of contents

Popular Solar Panel manuals by other brands

Regulus

Regulus KPC1 BP Installation and operation manual

Furrion

Furrion FSFP16MW2-BL user manual

Viessmann

Viessmann Vitosol 300-TM Installation information

Viessman

Viessman VITOSOL 100-F installation instructions

Donaldson Torit

Donaldson Torit E-100 Installation and operation manual

Velux

Velux CLI + EKW Directions for use

Gasolarxy

Gasolarxy PG-GSP100W Installation guide & manual

COMFORTPOOL

COMFORTPOOL SOLAR MAT user manual

Trina Solar

Trina Solar Trinasmart Installation and safety manual

Sunforce

Sunforce 36170 manual

Kings Adventure

Kings Adventure AKSR-PN160W 04 user manual

Roger Technology

Roger Technology B71/PBX Instruction and warnings for the installer