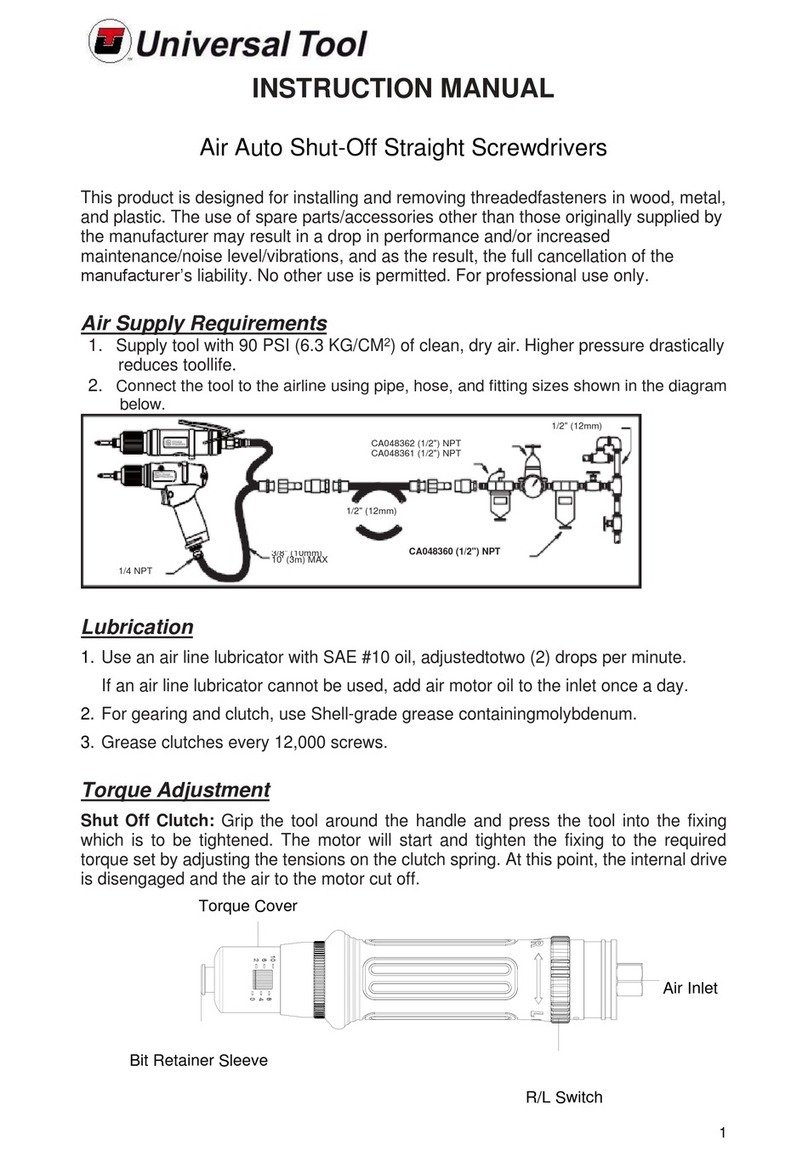

Operating

Select the correct screwdriver bit or fastener driver to suit the screw or

fastener to be tightened or loosened. Insert appropriate drive bit.

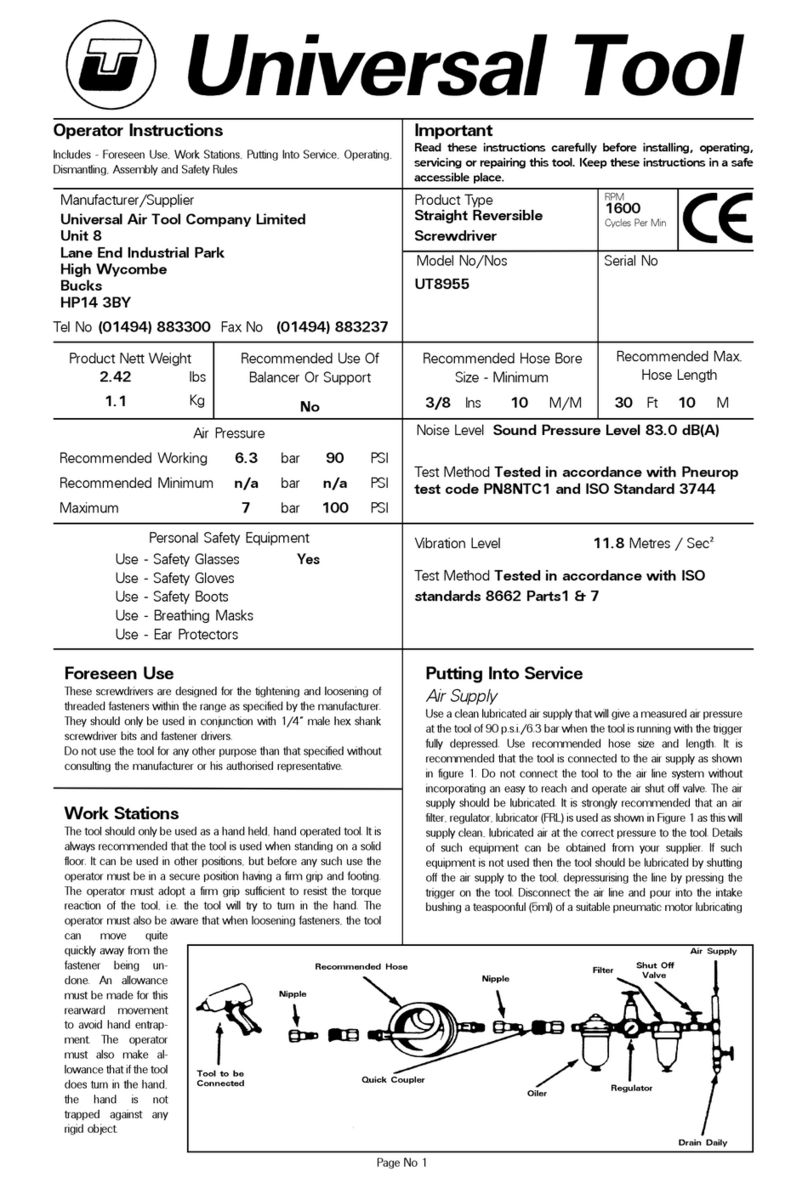

This model has an adjustable clutch so that the torque applied to the

fastener can be adjusted to give the required tightness within the torque

range of the tool. To set the tool to give a particular torque output, turn

the torque ring (55) to the right to increase the torque output or to the

left to decrease the torque output. This screwdriver has a push to start

system which eliminates the use of a throttle lever; the air motor will

automatically stop when the screwdriver reaches the pre-set torque

If the fastener is not sufficiently tightened or cannot be loosened then

the tool in adjustable clutch mode has insufficient capacity. Select a

more powerful tool.

The person setting up the tool must be aware of this torque reaction at

high setting levels of the clutch and that the tool will try to turn against

the hand. All that is required is a firm grip.

The only thing that will affect the output is a change in the air supply

pressure. The output can be increased up to the use of the maximum

allowed supply pressure and decreased with a reduction in supply

pressure until the tool fails to operate.

It must also be understood that even if the clutch is set to slip it may not

do so if the supply air pressure falls below the pressure at which the

clutch was set. It is therefore strongly recommended that a pressure

control valve is used. Information as to suitable equipment can be

obtained from your supplier.

When using the tool keep the screwdriver bit pressed firmly into the

screw head to avoid cam out and screw head damage.

Dismantling & Assembly Instructions

Disconnect from air supply.

Grip the tool in a vice fitted with soft jaws Take off rear housing (61).

Remove C ring (59) take off bit slide sleeve (58) spring (46) torque ring

(55) regulation washer (54) and needle pins (53) Unscrew clutch

housing (52) left hand thread and remove anvil bushing (50) washer

(49) torque spring (48) spring (46) and slide base (47) When removing

anvil (44) take care not to lose ball (45).

Take off C ring (43) and remove ball race (42) ball (39) end clutch (40)

centre clutch (38) ball (39) rear clutch (36) pilot pin (35) ball (34) and

retainer (33).

Take off front housing (32) then remove internal gear (31) remove

second gear cage (29) and take off second plant gear (28) and second

main gear (27) then remove first gear cage (26) and take off first plant

gear (25).

Pull out air motor from pistol housing (1) tap end of rotor and remove

front plate (20) and remove bearing (21) take off cylinder (16) and

remove rotor blades (18) then tap off end plate (15) and remove

bearing (14) Pull out valve (11) and o-ring (10).

To remove the valve assembly first take off button (9) and remove lock

pin (8) then pull out valveassembly (7-1, 7, 4, 5, 3, and 6) thenunscrew

the cap screw (67) and remove (66, 65, 64, 63 and the operating rod

(62). Too remove the reverse switch take out set screw (12) and pull off

switch (13). Removing the silencers:- unscrew second silencer (74)

and pull out first silencer (70).

Reassembly

Clean all components and examine for wear and tear. Look in particular

for wear and cuts on O-rings, wear on rotor blades, gears and clutch

components.

Coat all parts with pneumatic tool lubrication oil, one preferably

containing a rust inhibitor and grease all bearings, gears and clutch

parts with a molybdenum or lithium based general purpose grease.

Before reassembling the motor, make sure that the faces of end plate

(15) & (20) that abut cylinder (16) are flat and free from burs. If

necessary lap on a flat fine grade of abrasive paper. Reassemble in the

reverse order.

When refitting the complete motor assembly to the pistol housing (1)

first make sure that the motor assembly is clamped tightly together and

that the rotor spins freely. Reassemble in the reverse order, reset the

clutch as required and set the correct air pressure.

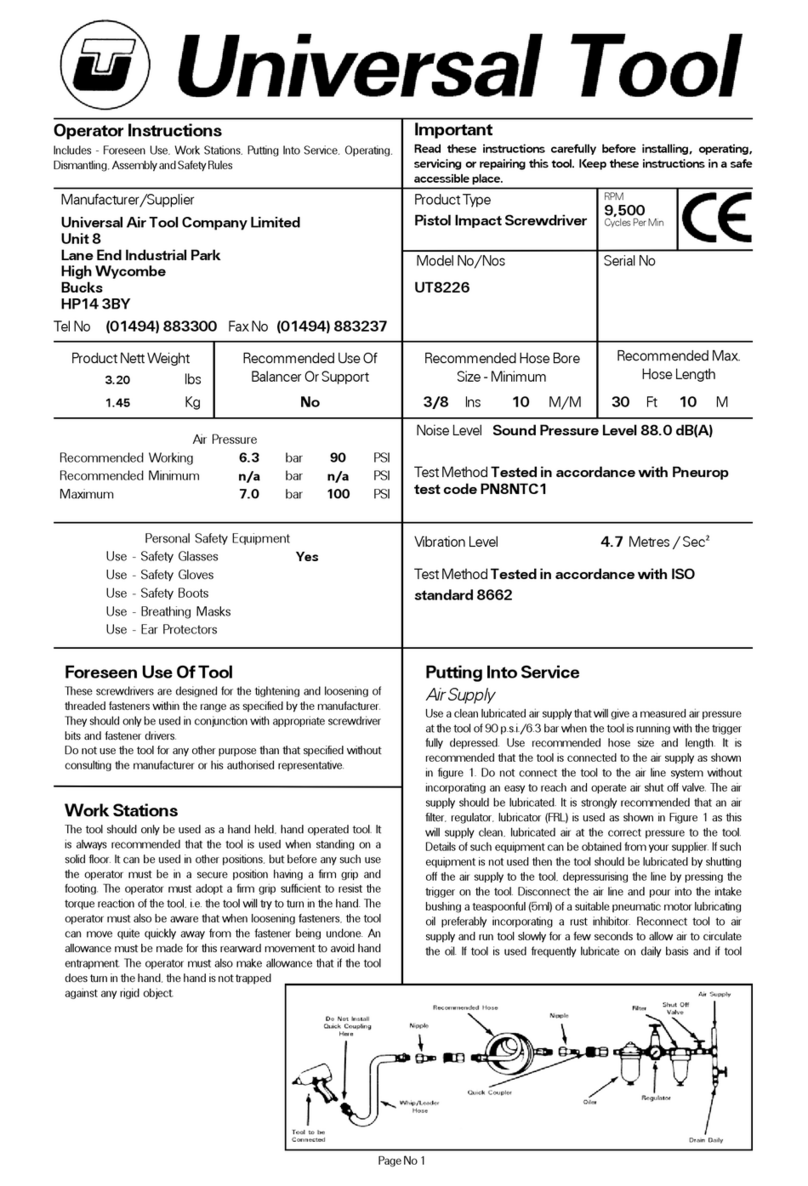

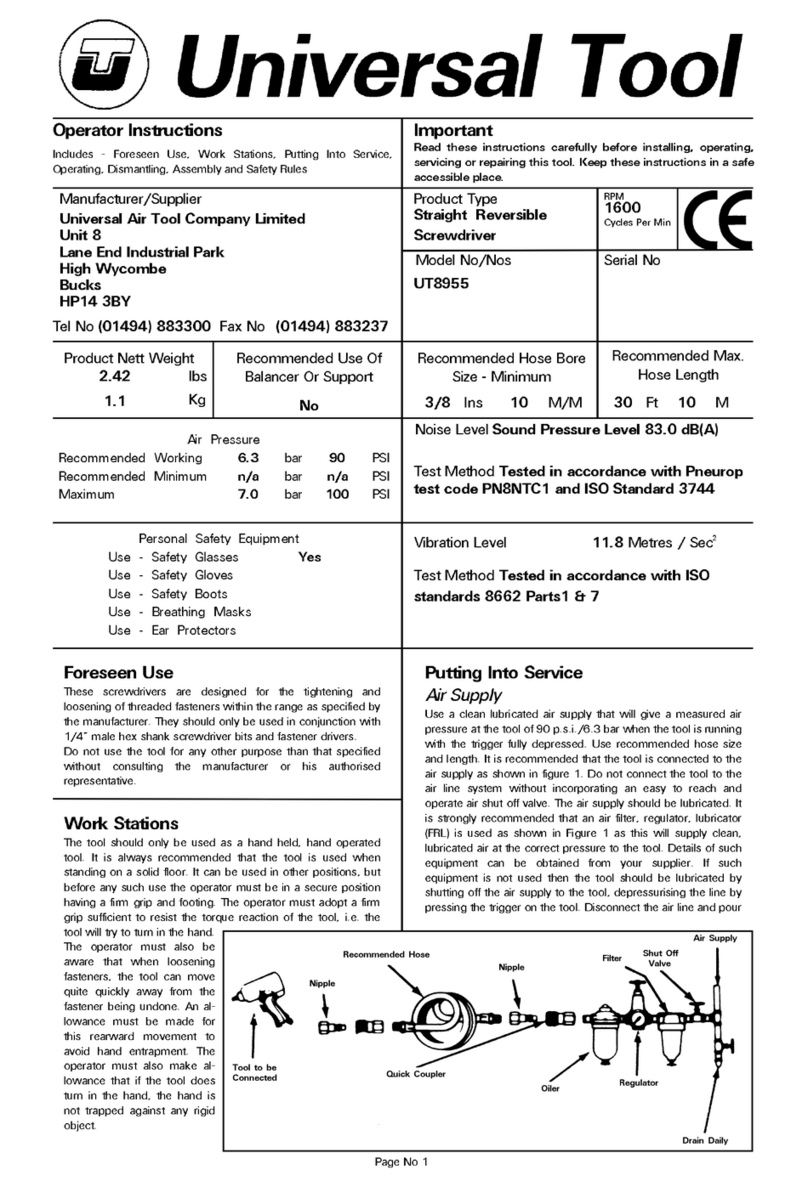

(5ml) of a suitable pneumatic motor lubricating oil preferably

incorporating a rust inhibitor. Reconnect tool to air supply and run tool

slowly for a few seconds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or lose power.

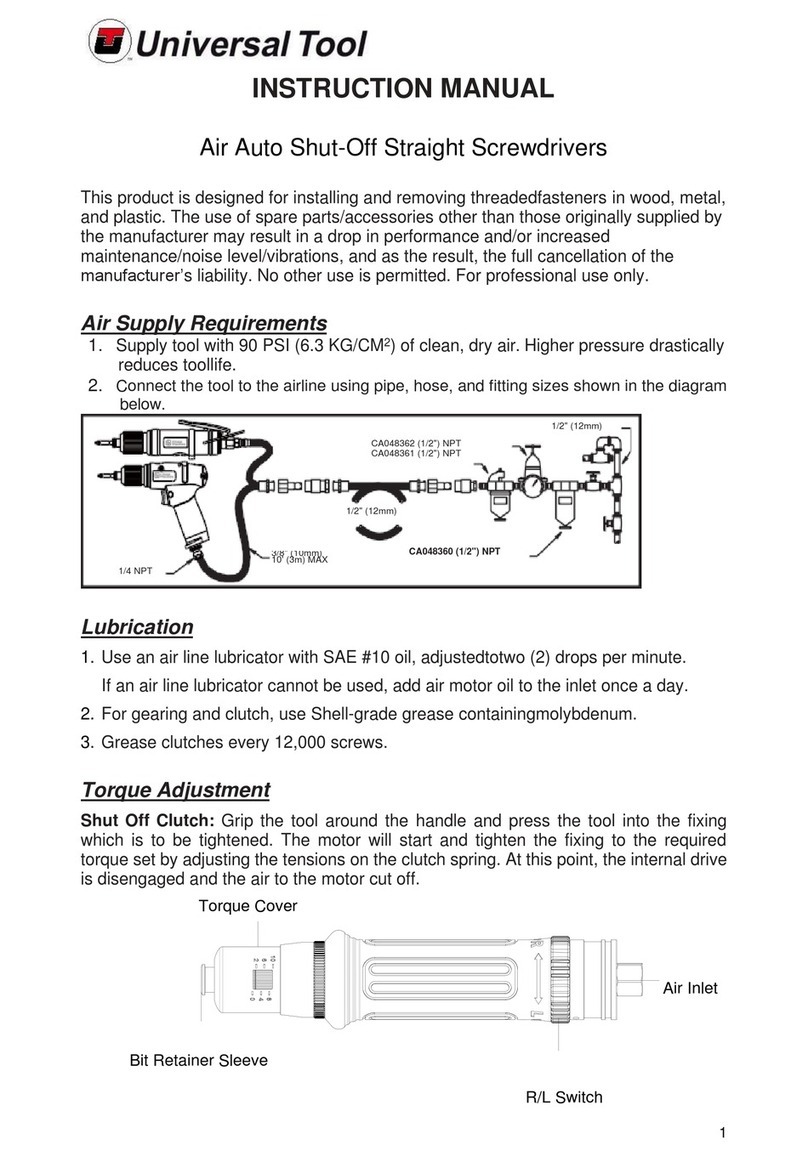

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of 100

p.s.i./7.0 bar.

Page No 2

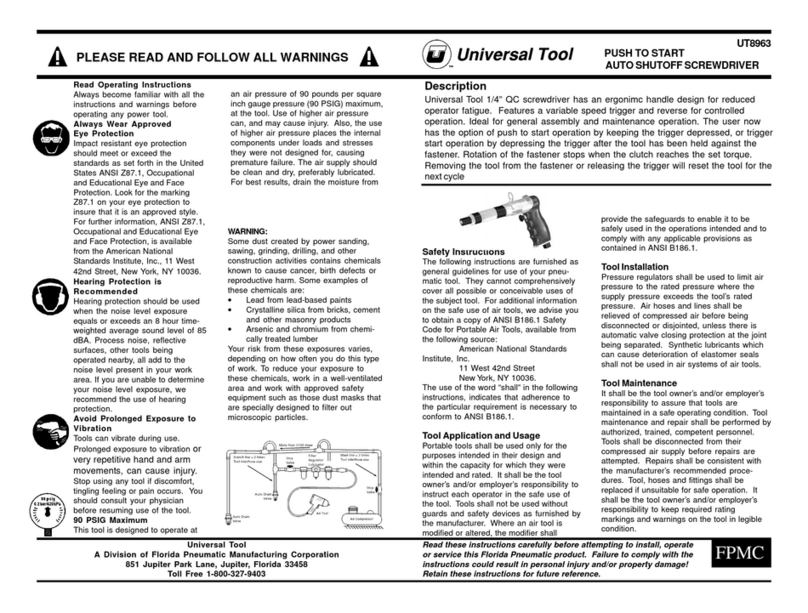

Safety Rules For A Screwdriver

1) Read all the instructions before using this tool. All operators must be

fully trained in its use and aware of these safety rules.

2) Do not exceed the maximum working air pressure.

3) Use personal safety equipment.

4) Use only compressed air at the recommended conditions.

5) If the tool appears to malfunction remove from use immediately and

arrange for service and repair.

6) If the tool is used with a balancer or other support device ensure that

it is fixed securely.

7) Always keep hands away from the working attachment fitted to the

tool.

8) The tool is not electrically insulated. Never use the tool if there is any

chance of it coming into contact with live electricity.

9) Always when using the tool adopt a firm footing and/or position and

grip the tool firmly to be able to counteract any forces or reaction forces

that may be generated whilst using the tool.

10) Use only correct spare parts. Do not improvise or make temporary

repairs.

11) Do not lock, tape, wire, etc. the on/off valve in the run position. The

trigger/lever etc. must always be free to return to the 'off' position when

it is released.

12) Always shut off the air supply to the tool, and depress the

trigger/lever etc. to exhaust air from the feed hose before fitting,

adjusting or removing the working attachment.

13) Check hose and fittings regularly for wear. Replace if necessary. Do

not carry the tool by its hose and ensure the hand is remote from the

on/off control when carrying the tool with the air supply connected.

14) Take care against entanglement of moving parts of the tool with

clothing, ties, hair, cleaning rags, etc. This will cause the body to be

drawn towards the tool and can be very dangerous.

15) It is expected that users will adopt safe working practices and

observe all relevant legal requirements when installing, using or

maintaining the tool.

16) Do not install the tool unless an easily accessible and easily operable

on/off valve is incorporated in the air supply.

17) Take care that the tool exhaust air does not cause a problem or

blows on another person.

18) Never lay a tool down unless the working attachment has stopped

moving.

19) Always ensure that the reverse button is in the selected position

before starting the tool.

20) Do not use bits or sockets with excessive wear to the input and

output drives. Make sure the bit, socket, extension is firmly fixed to the

tool.

21) When loosening fasteners first ensure that there is sufficient

clearance behind the tool to avoid hand entrapment. The tool will move

away from the threaded joint as the nut/bolt is loosened and rides up

the thread moving the tool with it.