HIOS JUKUREN BLG-BC2 series User manual

Brushless Screwdriver®

with built-in Screw Counter and Pulse System

“JUKUREN” BLG-BC2 series

Operation Manual

(August 2018)

<Note>

BLG-BC2 I/O Cable set is optional (P/N: BLG-BC2-3010).

Contents

・BLG-BC2 I/O Cable

・Application software (Including the instruction manual)

・Communication specifications

HIOS Inc.

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan 270-2223

TEL: +81-47-392-2001FAX: +81-47-392-7778

NO.ET-A011-BC2 18A

- 1 -

Thank you for your purchasing HIOS “JUKUREN” BLG-BC2 Screwdriver.

■Pulse System

The pulse system is a mechanism using an electric signal (pulse) that occurs during motor revolutions.

By installing several fasteners into the assembly the driver learns the numbers of motor revolutions

required to correctly tighten the fasteners to the desired torque. The driver then establishes the minimum to

maximum revolutions for process acceptance and displays the result of screw tightening with the LED green

and red lights on the unit.

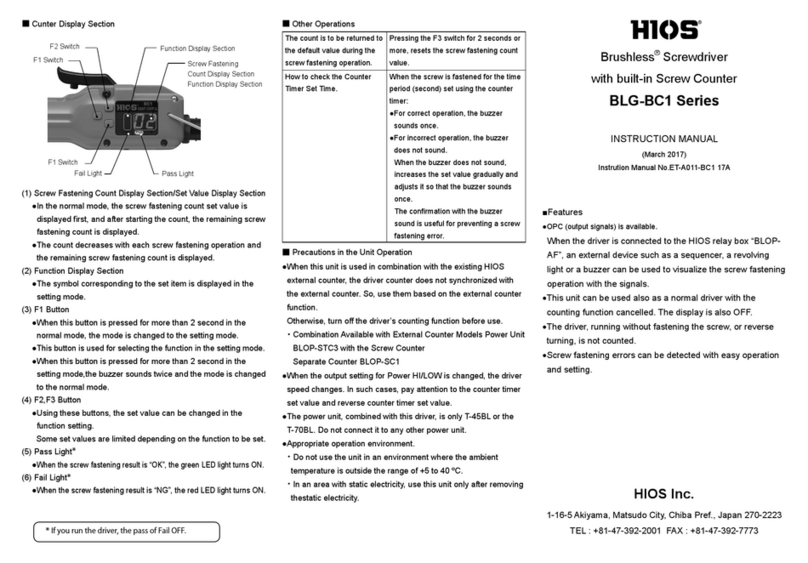

■Button and display descriptions

1. Screw Count Display Section/Set Value Display Section

●The screw fastening count set value is displayed when the counter function is On. After starting the count,

the remaining screw fastening count is displayed.

●The count decreases with each screw fastening operation and the remaining screw fastening count is

displayed.

2. Function display section

●The symbol corresponding to the function is displayed in the setup mode. (See page 3.)

3. F1 Button

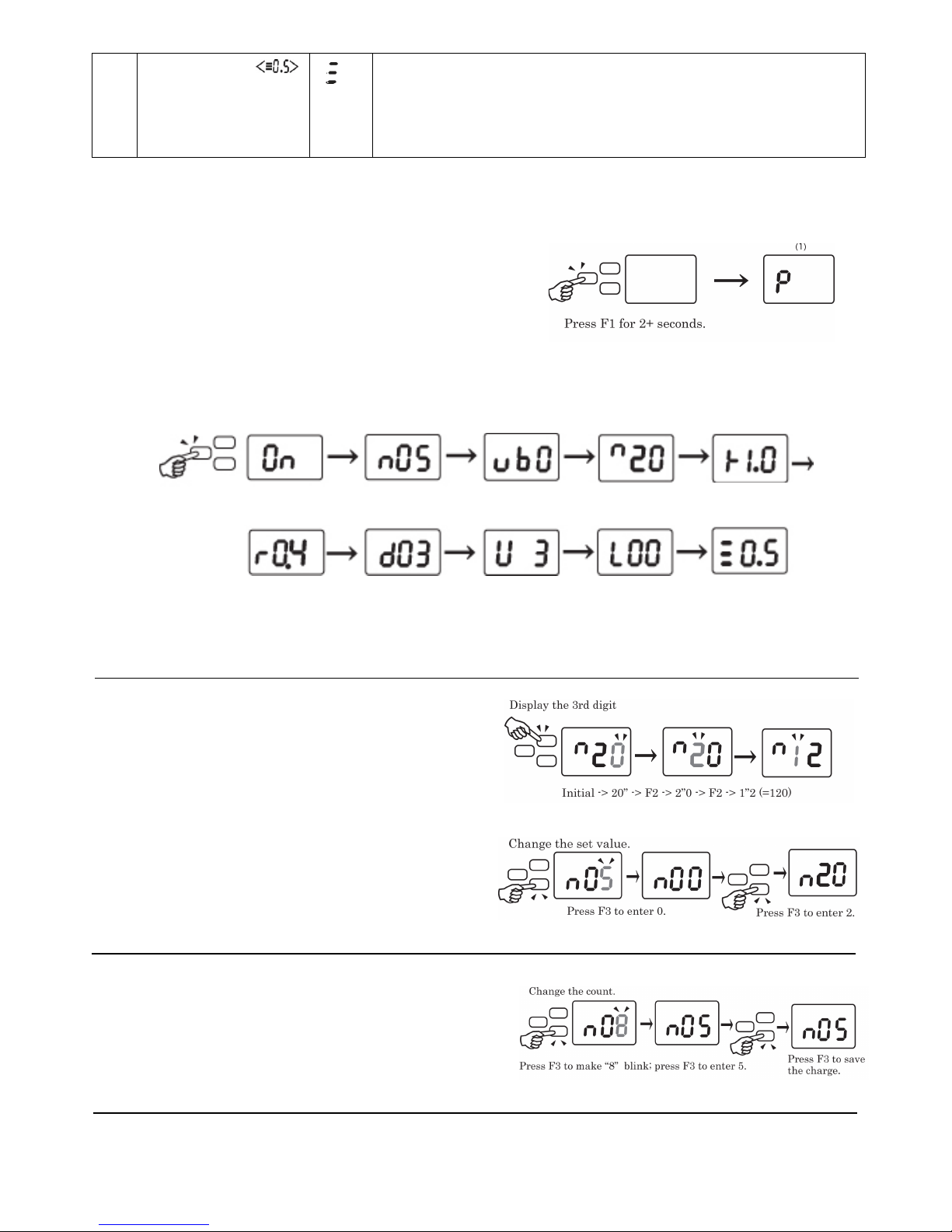

●Press and hold the F1 button until the “P” then the “On” is displayed

●Continue to press the F1 button to scroll through the setup functions

●Press and hold the F1 button until the buzzer sounds twice to save the change.

4. F2 and F3 Buttons

●Using these buttons, the set value can be changed in the setup functions.

Some set values are limited depending on the function that is being set.

●Press and hold the F2 button until「r0」is displayed and the Pass/Fail lights blink.

5. Pass Light*

●When the screw fastening is done properly, the green LED light turns on.

6. Fail Light*

●When the screw fastening is done improperly, the red LED light turns on.

* The Pass or Fail light turns off, when the lever switch is turned on.

- 2 -

■Direct Teaching

(Note)

Before Direct Teaching, fasten 1 or 2 screws to adjust the start position. (must-do)

1.

F2

Button →Press and hold until “r 0” is displayed and Fail/Pass lights blink.

2. Start Direct Teaching.

Fasten 3 or more of the same screws into the same joint.

Direct teaching needs to be done using screws, parts and a method of pick up which will be used

in your production.

3. F3 Button

→Press to select the acceptable range of Pass/Fail criteria.

It is displayed in the order of ±0%, ±5%, ±10%,±15%, ±20%.

4. F1 Button → Press to confirm the reference values of Pass/Fail including the acceptable range.

Example >

Assuming the reference values including the acceptable range are from 90 to 120,

the Pass range is from 91 to 119.

(Note)

In order to complete Direct Teaching, make sure to work through all the steps (1-4) .

5. F2 Button → Press and hold until the buzzer sounds twice to complete Direct Teaching.

6. All set!

■

List of setup functions

Fail Pass

Control Unit

Display:

No. of motor revolutions is displayed and either Pass/Fail light gets on.

・The No. of motor revolutions is displayed up to triple digits.

・The No. of revolutions can be displayed up to 999.

F1 Button, F2 Button, F3 Button:

These are used for each setup.

3rd, 2nd, 1st digit

- 3 -

Dis-

play

Mode (default)

Symbol

Description

(1)

Counter

On: When selected, the counter function is available.

OFF:

When selected, it is used as a normal driver.

On/OFF

(2)

Count

The screw fastening count value is set.

・

Setting range: 1 to 99

(3)

Min. revolutions*

The minimum numbers of motor revolutions .

・

Display range: 000

-

999,

・

Setting range : 000

-

999

* Hundreds place is not displayed.

Fx. Min. no. is “110” but only “10” is displayed on the screen.

Max. revolutions*

The maximum numbers of motor revolutions

・

Display range: 000

-

999,

・

Setting range : 000

-

999

* Hundreds place is not displayed.

Fx. Max. no. is “120” but only “20” is displayed on the screen.

Refer to “3. Value Setting for Each setup functions” on page 4 for details.

If the detected pulse is smaller than the minimum or larger than the maximum,

the red LED light (Fail) turns on.

If the detected pulse is larger than the minimum and smaller than the maximum,

the green LED light (Pass) turns on.

(4)

Work Reset Timer

The buzzer sound time period after the work is completed is set.

・Setting range: 0.0-3.9 seconds

Note: Set it based on the Reverse Count Timer set value.

(5)

Reverse Count Timer

The time period until the Reverse Count is performed is set.

Set the Work Reset Timer operation time based on the time period up to

when the Reverse Count is performed.

・

Setting range: 0.1

-

1.0 second

(Note) It is available when the “Reverse Count Enable” has been set in the

System setting.

(6)

System Setting

Each buzzers and Reverse Count Enable/Disable is set up.

The Setting is performed with a combination of the tenth digit and single unit

digit.

●2nd digit

0: Buzzers Enable / Reverse Count Enable

1: Buzzers Enable / Reverse Count Disable

2: Buzzers Disable / Reverse Count Enable

3: Buzzers Disable / Reverse Count Disable

●1st Digit

2: Driver shut off (Torque Up) buzzer Disable

3: Driver shut off (Torque Up) buzzer Enable

(7)

Over Time

This sets whether or not the Over Time/Short Time error is detected.

Short Time

0: Neither of motor revolutions is detected.

1: Only the minimum no. is detected.

2: Only the maximum no. is detected.

3: Both are detected.

(8)

Total no. of

The total No. of the driver shut off is displayed.

the driver shut off

This counts all the driver shut off regardless of whether the Count is On/OFF.

How to read the values:

2nd digit:×1 million cycles

1st digit:

×

100,000 cycles

- 4 -

(9)

No Error Time

for double fastening

No error time can be set with three bars + values in order to avoid unnecessary

errors during double fastening.

・

This setting is enable only when fastening is done properly.

・Display range: 0.0-9.9 ・Setting range: 0.0-9.9 sec

■Screw Counter

1. Changing to the Setup Mode:

Press and hold the F1 Button until “P” then the

“On” is displayed.

2. Setting Mode:

Pressing the F1 button allows you to scroll through each setup functions.

Refer to “List of setup functions” on page 3 for the changing and setting any functions.

Note: The no. of motor revolutions is displayed up to triple digits.

3. Value Setting for Each setup functions:

●Verify the hundreds (3rd) digit.

Press the F2 Button to change the figure position

for setting.

●Change the value.

Pressing the F3 button increases the value one by one.

Press and hold the F1 button until the buzzer sounds

twice to save the change.

4. Change cycle count.

Press F1 Button for more than 2 sec. to increment to

display number. Follow the procedure described in

3 above.

The count can be set between 1 and 99.

(Count )

(

Pulse/ Min

)(

Pulse/ Max

)

(Work Reset Timer)

(Reverse Count Timer)

(System)

(Over Time/

(Total No. of the

(No Error Time for

Short Time) driver shut off) double fastening)

(1) (2) (3)

※

(3)

※(

4

)

(5) (6) (7)

(8)

(

9

)

(Count)

(Min. revolutions)

(Max. revolutions)

(Work Reset Timer)

- 5 -

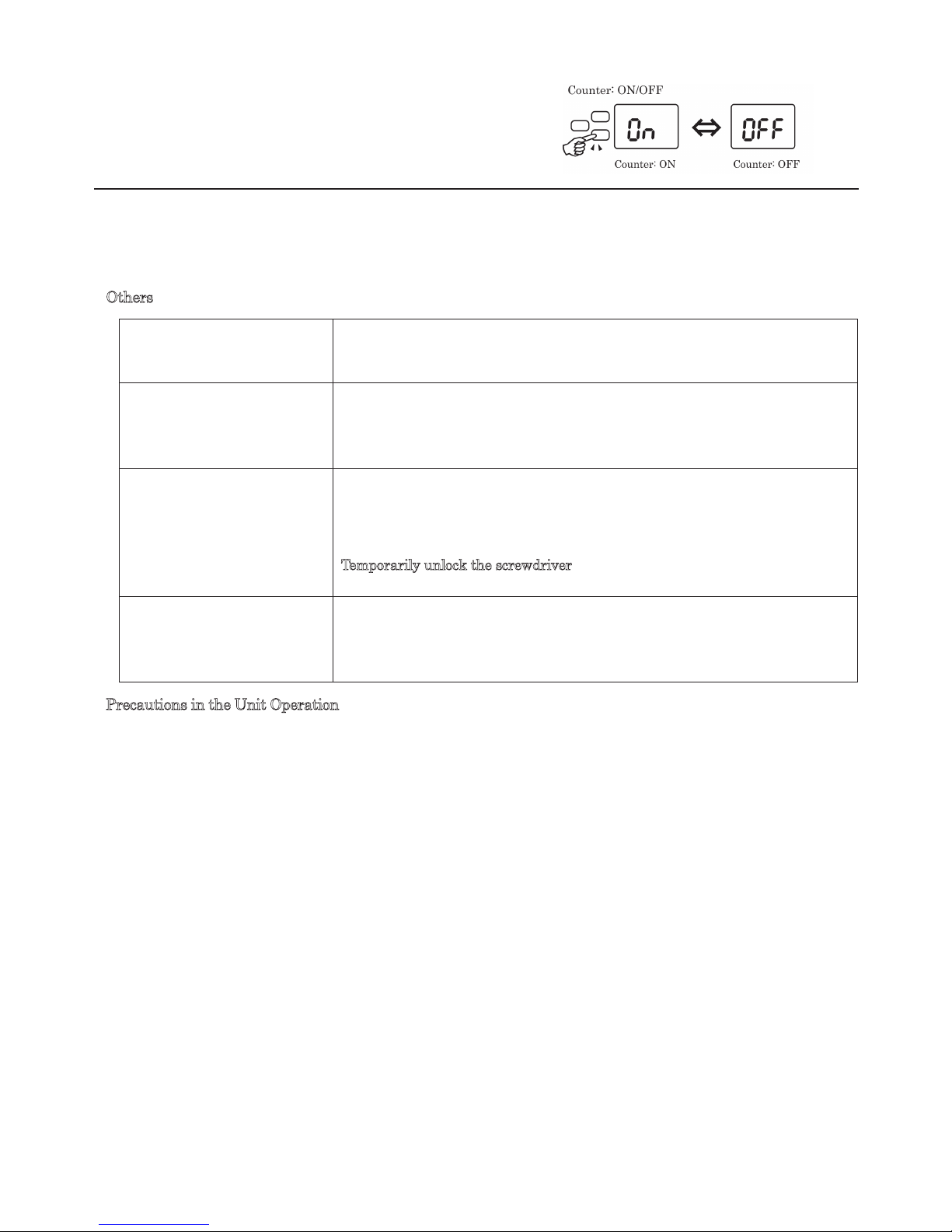

5. Turn the count ON/OFF

Press F1 Button for more than 2 sec. to turn the counter

ON/OFF

(Note) The way of setting the functions is common except how to set the counter ON/OFF.

■Others

■Precautions in the Unit Operation

●When this unit is used in combination with the existing HIOS external counter, the driver counter does not

synchronized with the external counter. So, use them based on the external counter function.

Otherwise, turn off the driver’s counting function before use.

・Combination Available with External Counter Models Power Unit

BLOP-STC3 with the Screw Counter

Separate Counter BLOP-SC1

●Appropriate operation environment.

・Do not use the unit in an environment where the ambient temperature is outside the range of +5 to 40 ºC.

・In an area with static electricity, use this unit only after removing the static electricity.

The count is to be returned to

the default value during the

screw fastening operation.

Pressing the F3 button for 2 seconds or more, resets the screw fastening count

value.

If you fasten a screw after the

driver turns counterclockwise:

There may be some difference in results of motor revolutions after the driver

turns counterclockwise as the start position may have changed.

In this case, the start position needs to be reset by fastening a screw before

starting actual fastening again in order to avoid errors.

"

---

" is shown on the

display.

Once the cumulative usage count exceeds 1 million, "

---

" blinks on the

display and the screwdriver is locked.

In such case, overhaul or maintenance is required. Please contact your dealer

or HIOS.

Temporarily unlock the screwdriver

Press and hold F2 and F3 buttons at the same time.

To see the version of

screwdriver.

Press and hold F1 button

→

Press F3 button (deactivate screw-counter)

→

Press and hold F1.

The current version will be displayed following the "HIOS" text.

Activate screw-counter if necessary.

Other manuals for JUKUREN BLG-BC2 series

1

Table of contents

Other HIOS Power Screwdriver manuals

HIOS

HIOS CL-9000NL User manual

HIOS

HIOS BL-2000 User manual

HIOS

HIOS BLG Series User manual

HIOS

HIOS BLG-BC1 Series User manual

HIOS

HIOS CL-2000 Installation manual

HIOS

HIOS BLF-2000 User manual

HIOS

HIOS VZH-1820 User manual

HIOS

HIOS BLG-7000BC2-GT-S User manual

HIOS

HIOS CL-9000 User manual

HIOS

HIOS DCD-40L User manual