X-TEND HOPPER – X130

31025 R0 3

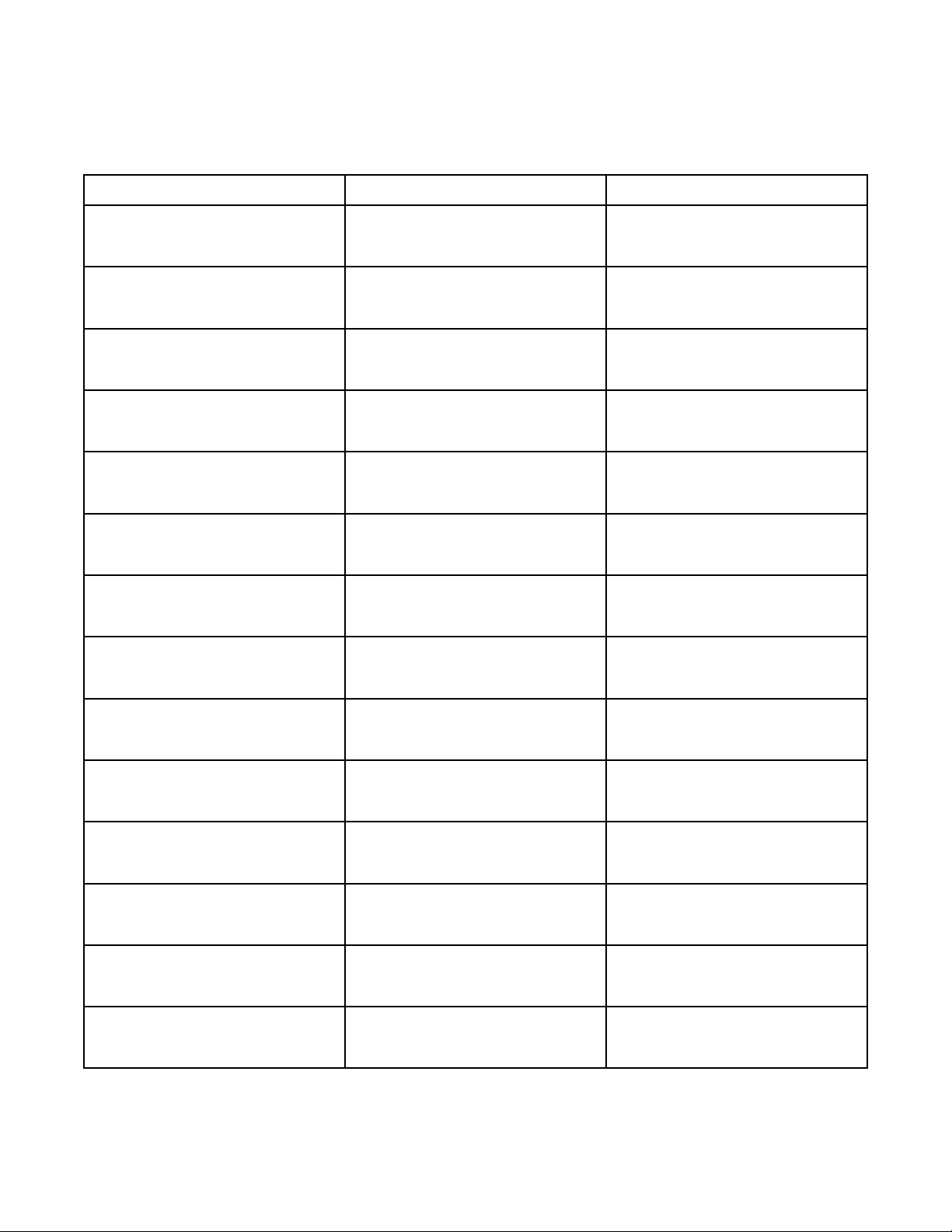

CONTENTS

1. Introduction ............................................................................................................................................ 5

1.1. Serial Number Location............................................................................................................ 5

2. Safety....................................................................................................................................................... 6

2.1. Safety Alert Symbol and Signal Words..................................................................................... 6

2.2. General Safety .......................................................................................................................... 6

2.3. Additional Safety Information.................................................................................................. 7

2.4. Rotating Flighting Safety .......................................................................................................... 7

2.5. Rotating Parts Safety................................................................................................................ 7

2.6. Guards Safety ........................................................................................................................... 7

2.7. Hydraulic Winch Safety ............................................................................................................ 8

2.8. Work Area Safety ..................................................................................................................... 8

2.9. Drives and Lockout Safety...................................................................................................... 10

2.9.1 Hydraulic Power Safety ............................................................................................ 10

2.10. Personal Protective Equipment............................................................................................ 11

2.11. Safety Equipment ................................................................................................................. 11

2.12. Safety Decals ........................................................................................................................ 13

2.12.1 Decal Installation/Replacement............................................................................. 13

2.12.2 Safety Decal Locations and Details ........................................................................ 13

3. Features................................................................................................................................................. 19

4. Assembly ............................................................................................................................................... 20

4.1. Assembly Safety ..................................................................................................................... 20

4.2. General Assembly................................................................................................................... 20

4.3. Verify Auger Assembly ........................................................................................................... 21

4.3.1 Install the X-Tend Hopper Lift Arm ......................................................................... 21

4.3.2 Replace the Short Truss Brace ................................................................................. 22

4.3.3 Install the Hydraulic Winch ...................................................................................... 23

5. Operation .............................................................................................................................................. 26

5.1. Operation Safety .................................................................................................................... 26

5.2. Transport Preparation ............................................................................................................ 26

5.3. Operator Controls .................................................................................................................. 28

5.4. Start-Up and Break-In............................................................................................................. 29

5.4.1 Prior to First Use....................................................................................................... 29

5.4.2 After First Use........................................................................................................... 30

5.5. X-Tend Hopper Operation...................................................................................................... 30

6. Maintenance ......................................................................................................................................... 32

6.1. Maintenance Safety ............................................................................................................... 32

6.2. Lubricate the Equipment........................................................................................................ 32

6.3. Service Interval ....................................................................................................................... 33

6.3.1 Weekly Service ......................................................................................................... 33

6.3.2 Semi-Annual Service................................................................................................. 34

6.3.3 Annual Service.......................................................................................................... 35

6.4. Adjusting the Hopper Drive Chain Tension............................................................................ 35

6.5. Adjusting the Wheel Drive Chain Tension ............................................................................. 37

6.6. Swing Auger Chain Tension.................................................................................................... 38

7. Troubleshooting.................................................................................................................................... 39