Evinrude & Johnson E-134-A User manual

---------

--

--

--'-

-

-_.-----_

..

--

-

--

----

---.--

--

----------_.

_-_

...

--

-_.

__

..

_----

-----------

.---

.-----. _.-

._

---

--

--------_

..

------------

-----

-.--

.-

..

----

.

----.----

..

~-

..

---.-

---

---

- -

.-

--

-

---

---------

-.-----

---_

.

---

...

--

-------

-

-

--

-

----------

- . -_

...

--

.----

---_

.

_-

-

--

- -

----.

--

--------

--

-----

--

- --

----

...

_

-_

..

---_

...

_----------_

..•

- - ._.- -

--

--

_

..

_---

---

--

-

- '

..

-

...

-"

.

__

. -"

'--'-'---'-

-

----

~----

----

---------------------

--

-----

-_

.-

--

._--_._--------

------

.-

...._..- .

_-----

-

._

----

--

-

_.-

-.--

----:-::--

-

-=------

--

'--

---'--

---.

---

--

--

---

----

.

---------_

._-

-_.--_._---

-------

-.---

---

-===

~----------

-----

-

----

-

------::...=-:.:..:.-~

-- .._

-_.

---

-_.

_-

- --

-.

==~

-

~~:--===--=-~-

-

-=~---

~--:

~~

-~

:

-=~:

.

==~----=--=--=----=----

.

------

===--

-

_.

=--=-~-=-

---

---

-

---

_.---_.-

._

-- --

..

.

=-~=~-----

-

-

..

_---------

---

.--

--:-.:.~:~--.-

..

--------

---

--

--

--

.-

-----------

---

-------

--

---

~~~=--_-~

-

==-~~~=~-~:

--

~-====~~~~

-~

=

--

-

_

u-

--

--

-

---

-

--

--

-----.--

-

____

q

-

-

~

---

.-

---

--

.-

._

-

---------

------

---------

--

-_.-

--

----

---

------

--

---

--_

..

..-

---

----------_

.-

---

--=------------

-

---

--

--

--

--------

-----_

._

----_.

--

-

---

- - -

--

--:;:;--

- --.- ----

.-

--

.-

--

.---._"

_-

"-_. --

--

-

---

.

---

-------

--

-

...

==:~;~~,,;--_~_-

.

:-~

.:

~~-;:.

..

~=-'~cc~;-;.

-

:;;

..

~

...

~

~-

J;VIN

RU

DE&.

_

------

=--=~:====~-~~-

:.

~~-~

--=---

--

-=

~

:~

~~

.

-~

=-:

-

~-=---

~~

:-:--~--~

-

~-==-~-~~=-

~.

-

J0HN

sat..

I

--_._

.

_-

--

------_

..

__

._--

----

---

--

I~

...

_------._---------------_.-

_.

_-_

....

---

.'. -

--

- -

---.-

-:..

.--

-_.--

."

..

_-

...

_

._

---

--

-

--

--.-

..

--_.

---

-_._

.-

----------

--

-

..

-

·

---:.

_:_

-:..:=--=~

.

-----t-

"

1

--

.- -

------

_.

-

--. -

----

.---

-.~

_.

--

...

_--' .

-

-=

:--~

.-:---.

...

-.

-------

.

..

-

--

------ -

-

..........

._

___ ___

___

..

_.

__

._

______

.

_____

_

___

..

_

1-

-

1'~~""7

-'

--

-

---

-'-

-

------_.-

ervice

manual

35

HP MODELS:

40

HP MODELS:

50

HP MODELS:

E-134-A,

J-134

-A

E-144-A,

J-144-A

E-164-A,

J-164-A

SNOWMOBILE

DIVISION/OUTBOARD

MARINE

CORPORATION, 3031 NORTH 114th STREET,

MILWAUKEE,

WISCONSIN 53222

OUTBOARD

MARINE

CORPORATION OF

CANADA

LTD., PETERBOROUGH,

CANADA.

PART

NO.

406226

(

r

-

PAGE

Fuel

Recommendations

..................

.

iv

SECTION 1 INTRODUCTION AND

SAFETY

WARNINGS

...•.

1-1

Controls

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-

2

SECTION

2

SPECIFICATIONS

AND

SPECIAL

SERVICE

TOOLS

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Torque

Specifications.

. . . . . . . . . . . . . . . . . . .

2-2

Snowmobile

Special

Service

Tools

...........

2-3

SECTION 3

GENERAL

SNOWMOBILE INFORMATION

Two

Stroke

Cycle

Engine

Theory

...........

.

Carburetion

.........................

.

Ignition

............................

.

Lighting

System

•......................

Power

Flow

.........................

.

Primary

Drive

.....................

.

Neutral

Control

....................

.

Secondary

Drive

....................

.

SECTION

4

TROUBLE

SHOOTING

3-1

3-1

3-2

3-3

3-3

3-3

3-4

3-4

Description

..........................

4-1

Trouble

Shooting

Procedures.

. . . . . . . . . . . . . .

4-2

Starting

. . . . . . . . . . . . . . . . . . . . . . . . .

..

4- 2

Starting

-

Manual

Starter

......•........

4-3

Starting

-

Electric

Starter

..............

4-3

Running

-

Low

Speed

Only

..............

4-3

Running

-High

Speed

Only

..............

4-3

Running

-

High

and

Low

Speed.

. . . . . . . . .

..

4-4

SECTION

5

TUNE-

UP

PROCEDURES

Description

.........................

.

Factors

Affecting

Performance

............

.

Fuel

System

. . . . . . . . . . . . . . . . . . . . . . . .

Ignition

System

,

~

:

"

. . . . . . . . . . . . . . . . . .

Compression

.

~

,,~:

,

'

..................

.

New

Vehicle

Deliverf':

..................

.

Tune-

Up

Procedures

...................

.

Compression

Check

....................

.

Ignition

Timing

Check

..................

.

Carburetor

Adjustments

. . . . . . . . . . . . . . . . . .

Needle

Valves

......................

.

Linkage

...........•...............

Spark

Plugs

.........................

.

SECTION

6

FUEL

SYSTEM

5-1

5-1

5-1

5-1

5-1

5-2

5-2

5-3

5-3

5-4

5-4

5-4

5-4

Description

..............

'.'. . . . . . . . .

..

6-1

Fuel

Flow

...........................

6-1

Carburetor.

. . . . . . . . . . . . . . . . . . . . . . . .

..

6-1

Removal

and

Cleaning

.................

6-1

Disassembly,

Repair,

Reassembly

and

Installation.

'. . . . . . . . . . . . . . . . . . . . .

..

6-2

Reed

Valves

. . . . . . . . . . . . . . . . . . . . . . . .

..

6-4

Installation.

. . . . . . . . . . . . . . . . . . . . . .

..

6-5

Fuel

Pump.

. . . . . . . . . . . . . . . . . . . . . • . .

..

6-5

Removal

..........................

6-5

Cleaning,

Inspection

and

Repair

. . . . . . . . .

..

6-5

T

ABLE

OF

CONTENTS

."

ii

TABLE

OF

CONTENTS (CONT)

PAGE

SECTION 6

FUEL

SYSTEM

(CONT)

Reassembly

........................

6-5

Fuel

Primer.

. . . . . . . . . . . . . . . . . . . . . . .

..

6-5

Air

Silencer

. . . . . . . . . . . . . . . . . . . . . . . .

..

6-6

Fuel

Tank

...........................

6-6

Fuel

Line

Tie

Strap

. . . . . . . . . . . . . . . . . . .

..

6-6

SECTION 7 IGNITION

AND

ELECTRICAL

SYSTEMS

Description

.........................

.

Test

Equipment

..•.•...•...•..•........

C.D.

Ignition

System

Trouble

Shooting

........

.

Introduction

.......................

.

C.D.

Ignition

System

Do's

and

Don'ts

.......

.

Test

#1

Ignition

Coil

Output

Check

.,

......

.

Test

#2

Ignition

Safety

Stop

Switch

Check

....

.

Test

#2A

Ignition

Switch

Check

..........

.

Test

#3

Power

Pack

2S

Output

Check

......

.

Test

#4

Charge

Coil

Output

Check

........

.

Test

#5

Retard

Sensor

Coil

Input

Check

.....

.

Test

#5A

Advance

and

Retard

Sensor

Timing

Check

.....................

.

Test

#6

Advance

Sensor

Coil

Resistance

Check

..........................

.

Test

#7

Retard

Sensor

Coil

Resistance

Check

..

Test

#8

Charge

Coil

Resistance

Check

.....

.

Test

#9

Ignition

Coil

Continuity,

Power

and

Insulation

Checks

..................

.

Test

#10

Kilovolt

Check

...............

.

Lighting

System.

. . . . . . . . . . . . . . . . . . . . . . .

Trouble

Shooting

....................

.

Lighting

Coils

...•.•..•..•....•.•.•.

Lighting

Coil

Resistance

Test

..•...••.•.•

Dimmer

Switch

Test

.................

.

Brakelamp

Switch

Test

................

.

Headlamp

Test

..•.........•.........

Ignition

Timing

. . . . . . . . . . . . . . . . . . . . . . . .

Spark

Plugs

. .

.......................

.

Battery

............................

.

Description

.......................

.

Specifications

. . . . . • . . . . . . . . . . . . . . .

..

Removal

and

Installation

. . . . . . . . . . . . . . . .

Battery

Servicing

..•.................

Battery

Care

.••...............•....

Battery

Testing

...........•..........

Battery

Charging

...................

.

Slow

Charging

.....................

.

Warranty

.....•....................

Starter

System

.......................

.

Description

.......................

.

Maintenance

.......................

.

Starter

System

Testing

.......•........

Starter

Circuit

Testing

................

.

Starter

Motor

Testing

................

.

Inspection

of

Starter

Motor

. . . . . . . . . . . . . .

Headlamp

Adjustment

. . . . . . . . . . . . . . . . . . . .

7-1

7-1

7-3

7-3

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-10

7-11

7-11

7-11

7-12

7-12

7-12

7-13

7-13

7-13

7-14

7-14

7-14

7-14

7-15

7-15

7-15

7-16

7-16

7-16

7-17

7-17

7-17

7-18

7-18

7-18

7-18

7-19

7-19

7-20

7-20

7-21

)

)

-

PAGE

SECTION

8 MANUAL

STARTER

Description

..........................

8-1

Removal

and

Disassembly.

. . . . . . . . . . . . . . . . 8-1

Cleaning,

Inspection

and

Repair

. . . . . . . . . . . . . 8- 1

Reassembly

..........................

8- 2

SECTION

9 ENGINE

Description

..........................

9-1

Removal

.........................

. 9- 1

Disassembly.

. . . . . . . . . . . . . . . . . . . . . . .

..

9- 2

Assembly

...........................

9-5

Installation

of

Engine

Assembly

to

Chassis

.....

9- 10

Break-in

Period

.......................

9-

10

SECTION

10

DRIVE

TRAIN

Description

.........................

.

Transmission

Belt

Inspection

and

Replacement

..

.

Brake

.............................

.

Primary

Drive

.......................

.

Disassembly

............•••.•.......

Disassembly

of

Flywheel

from

Engine

......

.

Cleaning,

Inspection

and

Repair

...•.......

Reassembly

of

Flywheel

.•....•....•....

Primary

Drive

Reassembly

.•........

.

..

Neutral

Lockout

Adjustment

............

.

Secondary

Drive

................•.•.•..

Disassembly

.

........•.............

Servicing

Secondary

Assembly

•..•........

Cleaning

and

Inspection

...............

.

Reassembly

.....•.....•..••...•....

Chain

Case

..........•.•..............

Disassembly

......•....•....••....•

Cleaning

and

Inspection

......•.........

Reassembly

.••.••.....•.........•.•

SECTION

11

STEERING,

TRACK

AND SUSPENSION

10-1

10-1

10-2

10- 3

10-3

10- 3

10-3

10-4

10- 4

10-4

10-5

10- 5

10- 5

10- 5

10-5

10-6

10-6

10- 6

10- 6

Description

.....•.•.....•........

11- 1

Steering

Column

. . . . . . . . . . . . . • . . . • . • •

..

11- 1

Disassembly.

• • . . . . . . • . • . . . . • . • . • .

..

11-1

Reassembly

. . . . . . . . • . . • . . . . . . . . . .

..

11-1

Ski

Alignment.

• • . . • . • • . • . . . . . . . . . • . .

..

11-1

Track

and

Suspension

•............•.....

11- 2

Track

Tension

....••.......•........

11-

2

Track

Alignment.

. . . . . . . . . . . . . • . • . .

..

11- 2

Removal

of

Trucks

and

Track

. . . . • . . . • .

..

11-3

SECTION

12 LUBRICATION AND STORAGE

Engine

Lubrication

....................

.

OMC 2+4

Fuel

Conditioner

.............

.

Lubrication

Recommendations

. . . . . . . . . . . . . .

Preventive

Maintenance

..

.

...•...........

Air

Silencer

..•

.

.•....•........•....

Fuel

Filter

Screen,

Fuel

Pump

....•......

Off

Season

Storage

. . . . . . . . . . . . . . . . . . . . . .

After

Storing

-

Before

Using

............

.

12- 1

12-1

12- 3

12-4

12- 4

12- 4

12- 5

12- 5

Wiring

Diagrams

..•...•.......•.•......

At

Back

of

Manual

iii

TABLE OF CO

NTENTS

(C

ONT)

.'

"

I'

iv

~

"'J

-:-":::-

3':':':-':::/

CANADA

U.S.A.

U.S.A.

2.7025

"-

fVI

HR~

IUURIel'

22019

21246

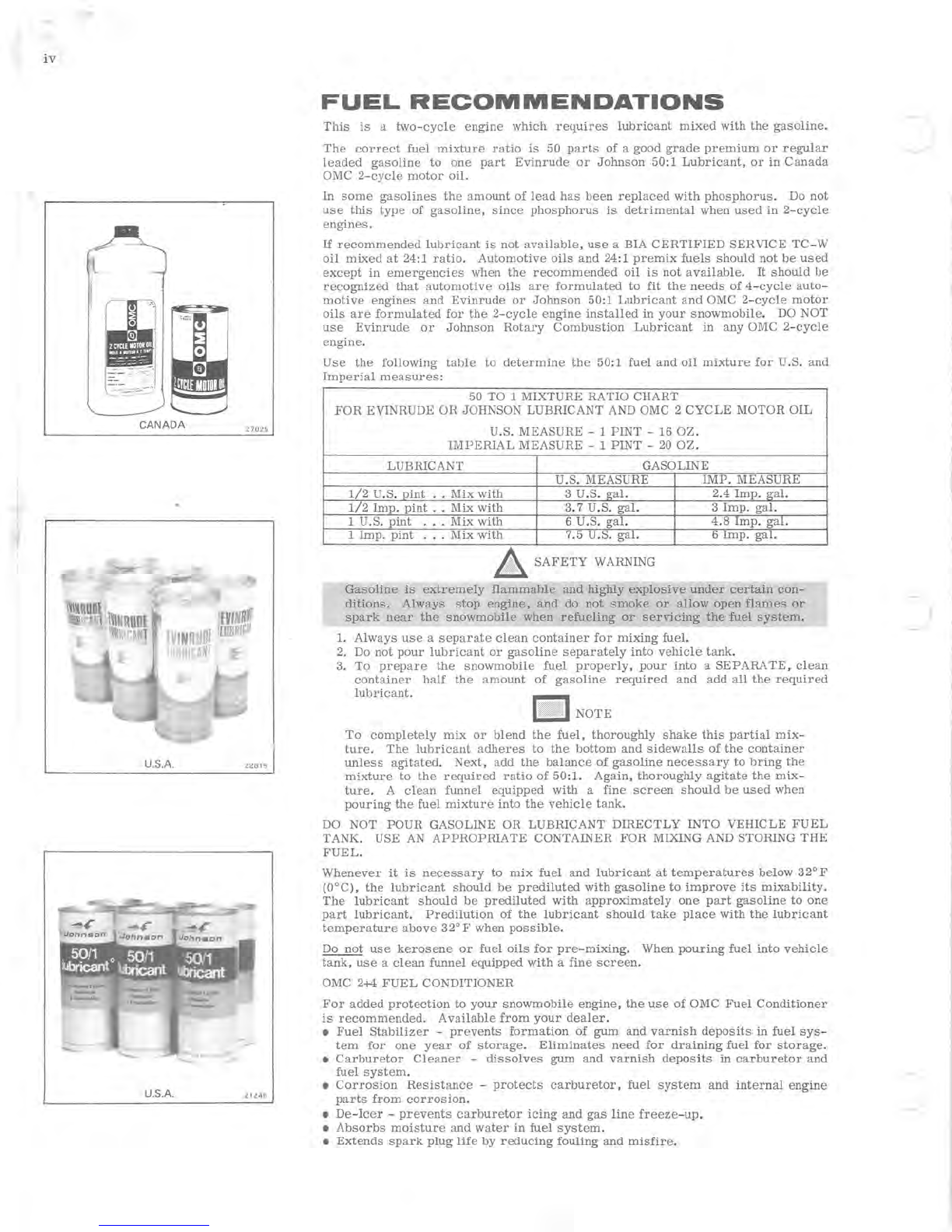

FUEL

RECOMMENDATIONS

This

is

a

two-cycle

engine

which

requires

lubricant

mixed

with

the

gasoline.

The

correct

fuel

mixture

ratio

is

50

parts

of

a good

grade

premium

or

regular

leaded

gasoline

to

one

part

Evinrude

or

Johnson

50:1

Lubricant,

or

in

Canada

OMC

2-cycle

motor

oil.

In

some

gasolines

the

amount

of

lead

has

been

replaced

with

phosphorus.

Do

not

use

this

type

of

gasoline,

since

phosphorus

is

detrimental

when

used

in

2-cycle

engines.

If

recommended

lubricant

is

not

available,

use

a BIA

CERTIFIED

SERVICE

TC-W

oil

mixed

at

24:1

ratio.

Automotive

oils

and

24:1

premix

fuels

should

not

be

used

except

in

emergencies

when

the

recommended

oil

is

not

available.

It

should

be

recognized

that

automotive

oils

are

formulated

to

fit

the

needs

of 4-

cycle

auto-

motive

engines

and

Evinrude

or

Johnson

50:1

Lubricant

and

OMC

2-cycle

motor

oils

are

formulated

for

the

2-cycle

engine

installed

in

your

snowmobile.

DO NOT

use

Evinrude

or

Johnson

Rotary

Combustion

Lubricant

in

any

OMC

2-cycle

engine.

Use

the

following

table

to

determine

the

50:1

fuel

and

oil

mixture

for

U.S.

and

Imperial

measures:

50 TO 1 MIXTURE RATIO CHART

FOR

EVINRUDE

OR

JOHNSON LUBRICANT AND OMC 2

CYCLE

MOTOR

OIL

U.S. MEASURE - 1

PINT

-16

OZ.

IMPERIAL

MEASURE - 1

PINT

-

20

OZ

.

LUBRICANT GASOLINE

U.S. MEASURE

IMP.

MEASURE

1/2

U.S.

pint

..

Mix

with

3 U.S.

gal.

2.4

Imp.

gal.

1/2

Imp.

pint

..

Mix

with

3.7 U.S.

gal.

3

Imp.

gal.

1 U.S.

pint

.. . Mix

with

6 U.S.

gal.

4.8

Imp.

gal.

1

Imp.

pint

.. .

Mix

with

7.5 U.S.

gal.

6

Imp.

gal.

&.

SAFETY

WARNING

Gasoline

is

extremely

flammable

and

highly

explosive

under

certain

con-

ditions.

Always

stop

engine,

and

do not

smoke

or

allow

open

flames

or

spark

near

the

snowmobile

when

refueling

or

servicing

the

fuel

system.

1.

Always

use

a

separate

clean

container

for

mixing

fuel.

2. Do

not

pour

lubricant

or

gasoline

separately

into

vehicle

tank.

3.

To

prepare

the

snowmobile

fuel

properly,

pour

into

a SEPARA

TE,

clean

container

half

the

amount

of

gasoline

required

and

add

all

the

required

lubricant.

U

irlll!t

UNOTE

To

completely

mix

or

blend

the

fuel,

thoroughly

shake

this

partial

mix-

ture.

The

lubricant

adheres

to

the

bottom

and

sidewalls

of

the

container

unless

agitated.

Next,

add

the

balance

of

gasoline

necessary

to

bring

the

mixture

to

the

required

ratiO

of

50:1.

Again,

thoroughly

agitate

the

mi.x-

ture.

A

clean

funnel

equipped

with

a

fine

screen

should

be

used

when

pouring

the

fuel

mixture

into

the

vehicle

tank.

DO NOT

POUR

GASOLINE

OR

LUBRICANT

DIRECTLY

INTO VEHICLE

FUEL

TANK. USE

AN

APPROPRIATE

CONTAINER

FOR

MIXING AND STORING

THE

FUEL.

Whenever

it

is

necessary

to

mix

fuel

and

lubricant

at

temperatures

below

32°F

(O°C),

the

lubricant

should

be

prediluted

with

gasoline

to

improve

its

mixability.

The

lubricant

should

be

prediluted

with

approximately

one

part

gasoline

to

one

part

lubricant.

Predilution

of

the

lubricant

should

take

place

with

the

lubricant

temperature

above

32°F

when

possible.

Do

not

use

kerosene

or

fuel

oils

for

pre-mixing.

When

pouring

fuel

into

vehicle

tank,

use

a

clean

funnel

equipped

with

a

fine

screen.

OMC 2+4

FUEL

CONDITIONER

For

added

protection

to

your

snowmobile

engine,

the

use

of

OMC

Fuel

Conditioner

is

recommended.

Available

from

your

dealer.

•

Fuel

Stabilizer

-

prevents

formation

of

gum

and

varnish

deposits

in

fuel

sys-

tem

for

one

year

of

storage.

Eliminates

need

for

draining

fuel

for

storage.

•

Carburetor

Cleaner

-

dissolves

gum

and

varnish

deposits

in

carburetor

and

fuel

system.

•

Corrosion

Resistance

-

protects

carburetor,

fuel

system

and

internal

engine

parts

from

corrosion.

•

De-Icer

-

prevents

carburetor

icing

and

gas

line

freeze-up.

•

Absorbs

moisture

and

water

in

fuel

system.

•

Extends

spark

plug

life

by

reducing

fouling

and

misfire.

1-1

SECTION

1

INTRODUCTION

AND

SAFETY

WARNINGS

The

snow

machine

has

been

designed

and

built

for

dependable, high

performance.

It

is

important

to

every

snow

machine

owner

to

be

able

to

receive

skilled

and

thorough

service

for

his

vehicle

when

necessary.

It

is

important

to

the

service

dealer

to be

able

to

offer

the type

of

skilled

service

which will

maintain

the

customer's

satisfaction.

This

manual,

together

with

the

regularly

issued

service

bulletins

and

Parts

Catalogs,

provide

the

serviceman

with

all

the

literature

necessary

to

service

this

snowmobile.

An

effort

has

been

made

to

produce

a

manual

that

will

not

only

serve

as

a

ready

reference

book

for

the

ex-

perienced

serviceman,

but

will

also

provide

more

basic

information

for

the

guidance

of

the

less

experienced

man.

The

Parts

Catalogs

contain

complete

listings

of

the

parts

required

for

replacement.

In

addition,

the

exploded

views

illustrate

the

correct

sequence

of

all

parts.

This

catalog

can

be

of

considerable

help

as

a

reference

during

disassembly

and

reassembly.

The

Table

of

Contents

on

page

i

enables

the

reader

to

locate

quickly

any

desired

section.

Section

2

lists

complete

specifications

on

the

snowmobile.

All

general

information,

including

2

cycle

engine

theory,

troubleshooting,

and

tune up

procedures,

are

given

in

Sections

3

through

5

of

this

manual.

Sections

6

through

11

provide

fully

illustrated,

de-

tailed,

step-by-step

disassembly

and

reassembly

instructions

and

ad-

justment

procedures.

Section

12

provides

lubrication

and

storage

in-

formation.

In

this

way,

the

texts

treat

each

topic

separately;

theory

and

practice

are

not

intermixed.

This

makes

it

unnecessary

for

the

experienced

serviceman

to

reread

discussions

of

theory

along with

specific

service

information.

Illustrations

placed

in

the

margins

pro-

vide

unimpeded

reading

of

explanatory

test,

and

permit

close

relation-

ship

between

illustration

and

text.

Figure

1-1

4

70

11

1-2

Read

this

manual

carefully

to

become

thoroughly

familiar

with

the

procedures

as

described,

then

keep

it

readily

available

in

the

service

shop

for

use

as

a

reference.

If

properly

used,

it

will

enable

the

ser-

viceman

to

give

better

service

to

the

snowmobile

owner,

and

thereby

build

and

maintain

a

reputation

for

reliable

service.

This

service

manual

covers

all

phases

of

servicing

the

snowmobile,

however,

new

service

situations

sometimes

arise.

If

a

service

question

does

not

appear

to

be

answered

in

this

manual,

you

are

invited

to

write

to

the

Service

Department

for

additional

help.

Always

be

sure

to

give

complete

information,

including

model

number

and

vehicle

serial

number.

All

information,

illustrations,

and

specifications

contained

in

this

literature

are

based

on

the

product

information

available

at

the

time

of

publication.

The

right

is

reserved

to

make

changes

at

any

time

without

notice.

47012

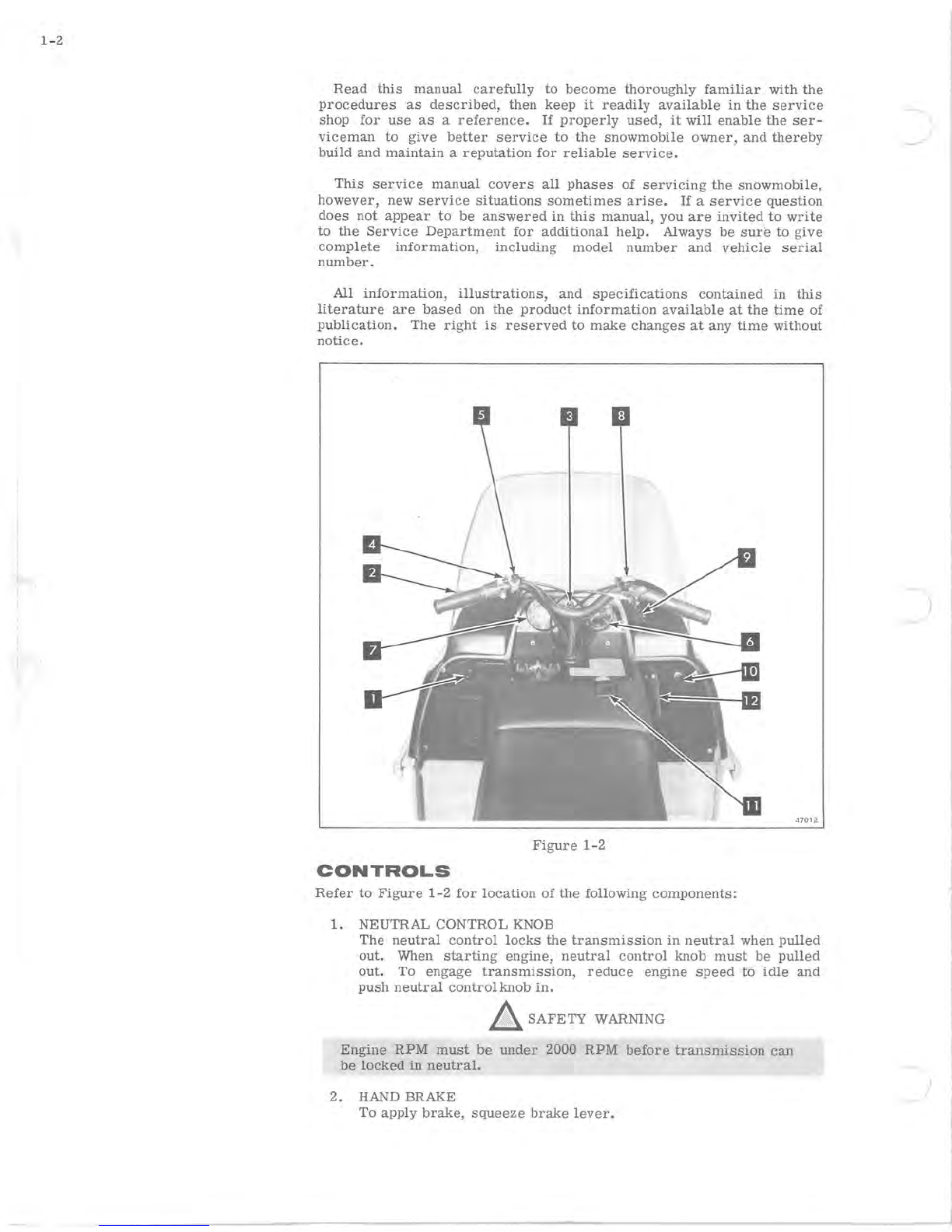

Figure

1-2

CONTROLS

Refer

to

Figure

1-2

for

location

of

the

following

components:

1. NEUTRAL CONTROL KNOB

The

neutral

control

locks

the

transmission

in

neutral

when

pulled

out.

When

starting

engine,

neutral

control

knob

must

be

pulled

out.

To

engage

transmission,

reduce

engine

speed

to

idle

and

push

neutral

control

knob

in.

A SAFETY WARNlNG

Engine

RPM

must

be

under

2000

RPM

before

transmission

can

be

locked

in

neutral.

2. HAND BRAKE

To apply

brake,

squeeze

brake

lever.

3.

IGNITION/LIGHTS SWITCH

The

key

operated

ignition

switch

has

four

positions,

'OFF,'

'RUN/

LIGHTS'

(operate

with

lights),

'RUN'

(operate

without

lights),

and

'ST

ART'

(for

use

with

accessory

electric

start).

4.

PARKING LOCK

To

apply

parking

lock,

with

brake

engaged,

flip

parking

lock

into

position.

To

release,

squeeze

brake

lever.

5.

HI

~

LOW

BEAM HEADLAMP SWITCH

The

headlamp

beam

switch

selects

either

high

beam

or

low

beam

when

ignition

switch

is

in

the

RUN/LIGHTS

position.

6.

SPEEDOMETER/ODOMETER

The

speedometer/odometer,

which

indicates

MPH

and

miles

traveled,

is

an

accessory.

7. TACHOMETER

The

tachometer,

which

indicates

engine

RPM,

is

an

accessory.

8.

SAFETY

STOP

SWITCH

This

switch

allows

the

operator

to

stop

engine

power

instantly.

Rotate

switch

to

either

side

of "RUN"

position

to

stop

engine.

Rotate

switch

to

"RUN"

position

to

allow

restarting

of

engine.

9.

THROTTLE

The

thumb

operated

throttle

lever

is

located

on

the

right

hand

steering

bar.

Squeezing

the

throttle

increases

engine

speed

and

power

is

transmitted

to

the

track.

When

lever

is

released,

engine

returns

to

idle.

10. CHOKE C.ONTROL KNOB

The

choke

control

is

used

during

starting

and

engine

warm-up

to

enrich

the

fuel-air

mixture

to

the

engine.

Pull

to

choke.

11.

PRIMER

Pushing

the

primer

knob

manually

pumps

fuel

into

the

intake

manifold.

A

cold

engine

should

be

primed

prior

to

starting.

12.

MANUAL

STARTER

HANDLE

Snowmobile

is

started

by

pulling

the

manual

starter

handle.

&:.

SAFETY

WARNINGS

-All

operators

must

be

properly

instructed

in

the

operation

of

the

ve-

hicle.

Many

dangerous

situations

are

created

by

negligence.

-When

operating

a

snowmobile,

wear

protective

clothing

and

head-

gear

such

as

a

brightly

colored

helmet

as

well

as

padded

clothes.

DO

NOT WEAR LOOSE CLOTHING

such

as

scarves,

tassel

caps,

etc.

Such

clothing

could

get

entangled

with

the

machinery,

branches

or

other

objects

and

cause

personal

bodily

injury.

It

is

recom-

mended

that

operator

and

passenger

wear

helmets

which

meet

the

requirements

of

ANSI Z90.1 -1971

or

equivalent.

-Do

not

overload

vehicle

with

passenger.

-Keep

feet

on

running

board

at

all

times.

-

Use

headlight

for

early

morning,

evening

and

night

operation.

Use

headlight

in

heavily

wooded

areas

during

the

day.

-Do

not

operate

vehicle

on

or

around

sled,

ski,

and

toboggan

hills.

-

Do

not

operate

vehicle

at

maximum

speeds

in

other

than

a

supervised,

charted

area.

Be

certain

no one

is

behind

unit

when

making

a

fast

start,

as

ice,

stones,

etc.,

may

be

thrown

into

the

air

by

lugs

on

the

track.

1-3

1-4

-

Extra

caution should be

exercised

when

using

vehicle

on

ice.

Steering

control

is

greatly

reduced

on

ice.

Beware

of thin

ice.

Always

use

two hands

for

steering.

-When

crossing

plowed

roads,

approach

with

caution.

Do not jump

snow banks

as

you

might

find

yourself

in

the

path

of oncoming

traffic.

-

Do

not

operate

vehicle

on

bare

ground

or

gravel

as

steering

response

may

be

reduced.

-Do

not

execute

"blind

jumps."

Snow

drifts

can

hide

tree

stumps,

logs

and

excessive

drop

offs.

-

Do

not

smoke

while

operating

vehicle.

Ashes

can

be

dangerous

to

passengers

as

well

as

operator.

-Do

not

operate

vehicle

while

under

the

influence

of intoxicating

bev-

erages,

narcotics

or

other

habit

forming

drugs.

-

Never

leave

the

machine

unattended while engine

is

running.

-Remove key

from

vehicle

whenever

it

is

not

in

use.

-

Wear

goggles to

protect

the

eyes

from

lashing

tree

and

shrub

branches,

and

from

wind and

sun

glare.

Goggles should

meet

the

requirements

of

Vehicle

Equipment

Safety

Commission

regulation

VESCO -

8.

Do

not

attempt

to

perform

repairs

on

your

vehicle

while engine

is

running.

Before

servicing

any

part

of the engine

or

drive

unit:

always

dis-

connect

spark

plug

wires

to

prevent

accidental

start

of engine; and

turn

the

ignition

switch

to

"OFF"

position

to

discharge

the

high

volt-

age

capacitor.

A

charged

capacitor

could give a

severe

electrical

shock.

Never

remove

a fuel

hose

without

first

removing

the

tie

rap

clamp.

Never

attempt

to

install

a fuel

hose

with a

tie

rap

preassembled.

Always

assemble

the

tie

rap

after

the

fuel

hose

is

assembled

to

the

nipple.

Improper

assembly

could

result

in

a

leak.

All

reassembled

tie

raps

should

be

located

in

the

original

assembled

location.

~

PROHIBITED

-

Operation

on

private

property

without

owner's

permission.

Operation

of

vehicle

on public

roads,

streets

or

highways

unless

it

is

legal

to do

so.

(

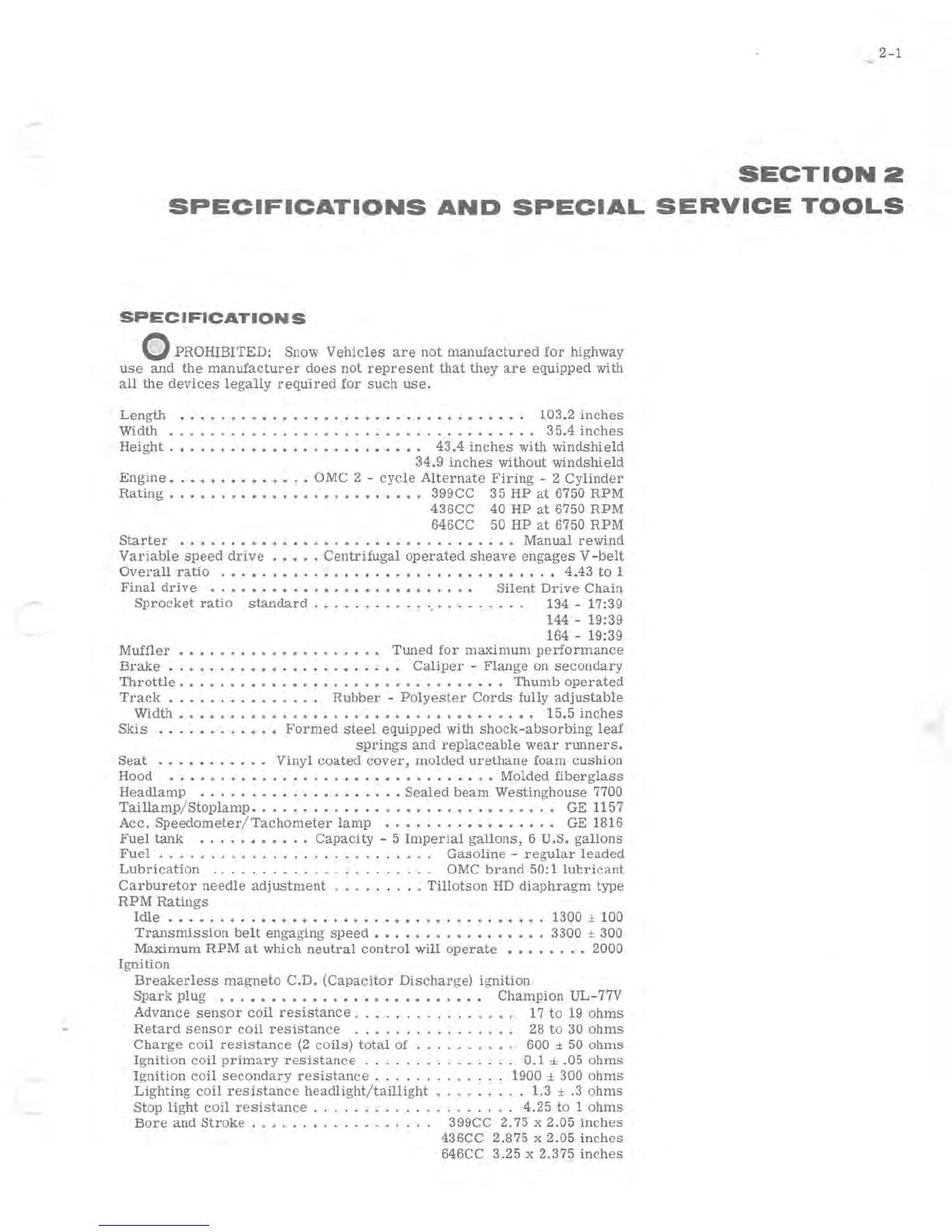

2-1

SECTION

2

SPECIFICATIONS

AND

SPECIAL

SERVICE

TOOLS

SPECIFICATION

S

o

PROHIBITED:

Snow

Vehicles

are

not

manufactured

for

highway

use

and

the

manufacturer

does

not

represent

that

they

are

equipped

with

all

the

devices

legally

required

for

such

use.

Length

•......••.••.•••.••••.•••••••••...

103.2

inches

Width

.•..........••.•.•...•.....•••••.••.

35.4

inches

Height.

• . . • • • . • • • • . • . . • • • . • • •

•.

43.4

inches

with

windshield

34.9

inches

without

windshield

Engine

•..••.•.•.••.•

OMC 2 -

cycle

Alternate

Firing

- 2

Cylinder

Rating

•.•....••.•.•....•••••.•.

399CC

35

HP

at

6750

RPM

436CC

40

HP

at

6750

RPM

646CC 50

HP

at

6750

RPM

Starter

•.••.••••••.•...•..•••..•...•.•.•

Manual

rewind

Variable

speed

drive

..••.

Centrifugal

operated

sheave

engages

V

-belt

Overall

ratio

...•..•.......•.•..•..••••••••..•

4.43

to

1

Final

drive

..•.••••.•••••••••••••...•

Silent

Drive

Chain

Sprocket

ratio

standard

••.•.......•

,.........

13'4

-17:39

144 -19:39

164 -19:39

Muffler

• • • . . . . • • . . • . . . • . .

..

Tuned

for

maximum

performance

Brake

• • • . . . . • • • • • . . • . . • . . •

•.

Caliper

-

Flange

on

secondary

Throttle.

• • • . . • • . . . • • • • . . . . • • . . . . • • . • •

..

Thumb

operated

Track

. . . • • . . . • • . . .

.•

Rubber

-

Polyester

Cords

fully

adjustable

Width.

. • • • • . • . • . . . • • • . • • • • • . . . • • • . . • . •

•.

15.5

inches

Skis

•.....•..•.•

Formed

steel

equipped

with

shock-absorbing

leaf

springs

and

replaceable

wear

runners.

Seat

.••••.•...

•

Vinyl

coated

cover,

molded

urethane

foam

cushion

Hood

..•.•...•....•.••••••••..•••••••

Molded

fiberglass

Headlamp

....••.•....•...•...

Sealed

beam

Westinghouse

7700

Taillamp

/

Stoplamp.

. . . . . • • . . • • • . . • • • . . • • . • . • . •

•.

GE 1157

Acc.

Speedometer

/

Tachometer

lamp

••.....••••••.••.

GE 1816

Fuel

tank

•....••••..

Capacity

- 5

Imperial

gallons,

6 U.S.

gallons

Fuel

. . . . . . . . . . . . . . . . . . . . . . . . .

..

Gasoline

-

regular

leaded

Lubrication

.

.....................

OMC

brand

50: 1 lul::ricant

Carburetor

needle

adjustment

.........

Tillotson

HD

diaphragm

type

RPM

Ratings

Idle

.•.....•••••••••.••..•••..••....•..•.

1300 ± 100

Transmission

belt

engaging

speed

••••.•...•••.••••

3300 ± 300

Maximum

RPM

at

which

neutral

control

will

operate

.•••.•..

2000

Ignition

Breakerless

magneto

C.D.

(Capacitor

Discharge)

ignition

Spark

plug

••.•••••••••••••••••••••••

Champion

UL-77V

Advance

sensor

coil

resistance.

. . . . . . . . . . . . .

..

17

to

19

ohms

Retard

sensor

coil

resistance

...

........

.....

28

to

30

ohms

Charge

coil

resistance

(2

coils)

total

of . . . . . . . .

..

600 ± 50

ohms

Ignition

coil

primary

resistance

. . . . . . . . . . . . .

..

0.1

± .05

ohms

Ignition

coil

secondary

resistance.

. . . . . . . . . . . . 1900 ± 300

ohms

Lighting

coil

resistance

headlight/taillight

.........

1.3 ± .3

ohms

Stop

light

coil

resistance

...................

'

4.25

to

1

ohms

Bore

and

Stroke.

. . . . . . . . . . . . . . .

..

399CC

2.75

x

2.05

inches

436CC 2.875 x

2.05

inches

646CC

3.25

x 2.375

inches

2-2

Piston

displa

c

ement

35

HP

399CC

.................

24.35

cu.

in.

40

HP

436CC

.............

.. ..

26.62

cu. in.

50

HP

646CC

.................

39.40

cu

in.

Cylinder

compression

........................

100

to

120

psi

End

gap.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

.007 -.017

Specifications

and

features

may

be

changed

at

any

time

without

noti

ce

and

without

obligation

towards

vehicles

previously

ma

nufacturer.

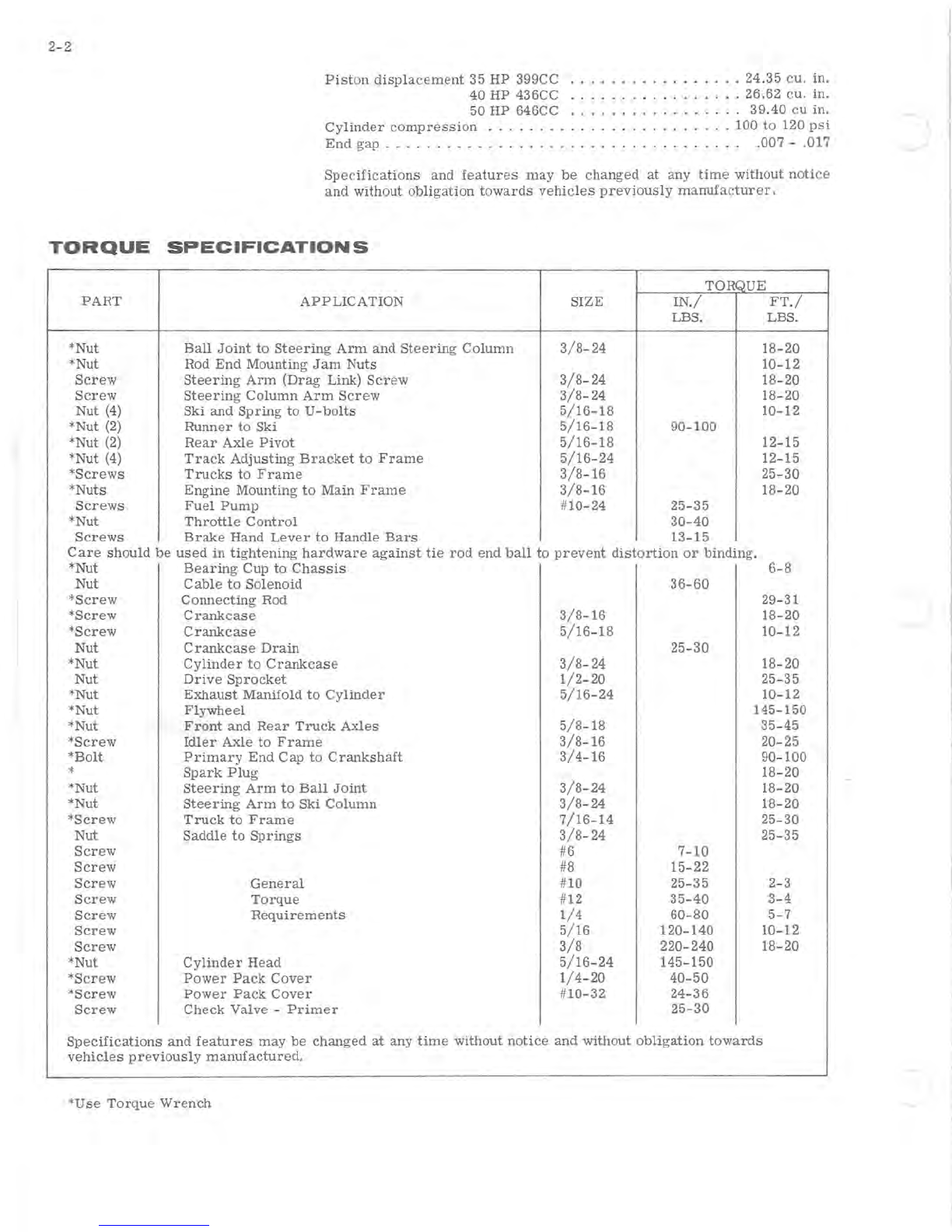

TORQUE

SPECIFICATIONS

TORQUE

PART

APPLICATION

SIZE

IN./

FT./

LBS. LBS.

*Nut

Ball

Joint

to

Steering

Arm

and

Steering

Column

3/8-24

18-20

*Nut Rod

End

Mounting

Jam

Nuts

10-12

Screw

Steering

Arm

(Drag

Link)

Screw

3/8-24

18-20

Screw

Steering

Column

Arm

Screw

3/8-24

18-20

Nut (4)

Ski

and

Spring

to

U-

bolts

5/16-18

10-12

*Nut (2)

Runner

to

Ski

5/16-18

90-100

*Nut

(2)

Rear

Axle

Pivot

5/16-18

12-15

*Nut

(4)

Track

Adjusting

Bracket

to

Frame

5/16-24

12-15

*Screws

Trucks

to

Frame

3/8-16

25-30

*

Nuts

Engine

Mounting

to

Main

Frame

3/8-16

18-20

Screws

Fuel

Pump

#

10-24

25-35

*Nut

Throttle

Control

30-40

Screws

Brake

Hand

Lever

to

Handle

Bars

13-15

Care

should

be

used

in

tightening

hardware

against

tie

rod

end

ball

to

prevent

distortion

or

binding.

*Nut

Bearing

Cup

to

Chassis

6":'8

Nut

Cable

to

Solenoid

36-60

*Screw

Connecting

Rod

29-31

*Screw

Crankcase

3/8-16

18-20

*Screw

Crankcase

5/16-18

10-12

Nut

Crankcase

Drain

25-30

*

Nut

Cylinder

to

Crankcase

3/8-24

18-20

Nut

Drive

Sprocket

1/2-20

25-35

*Nut

Exhaust

Manifold

to

Cylinder

5/16-24

10-12

*Nut

Flywheel

145-150

*Nut

Front

and

Rear

Truck

Axles

5/8-18

35-45

*Screw

Idler

Axle

to

Frame

3/8-16

20-25

*Bolt

Primary

End

Cap

to

Crankshaft

3/4-16

90-100

*

Spark

Plug

18-20

*Nut

Steering

Arm

to

Ball

Joint

3/8-24

18-20

*Nut

Steering

Arm

to

Ski

Column

3/8-24

18-20

*Screw

Truck

to

Frame

7/16-14

25-30

Nut

Saddle

to

Springs

3/8-24

25-35

Screw

#6

7-10

Screw

#8

15-22

Screw

General

#10

25-35

2-3

Screw

Torque

#12

35-40

3-4

Screw

Requirements

1/4

60-80

5-7

Screw

5/16

120-140

10-12

Screw

3/8

220-240

18-20

*Nut

Cylinder

Head

5/16-24

145-150

*Screw

Power

Pack

Cover

1/4-20

40-50

*Screw

Power

Pack

Cover

#

10-32

24-36

Screw

Check

Valve

-

Primer

25-30

Specifications

and

features

may

be

changed

at

any

time

without

notice

and

without

obligation

towards

vehicles

previously

manufactured.

*Use

Torque

Wrench

2-3

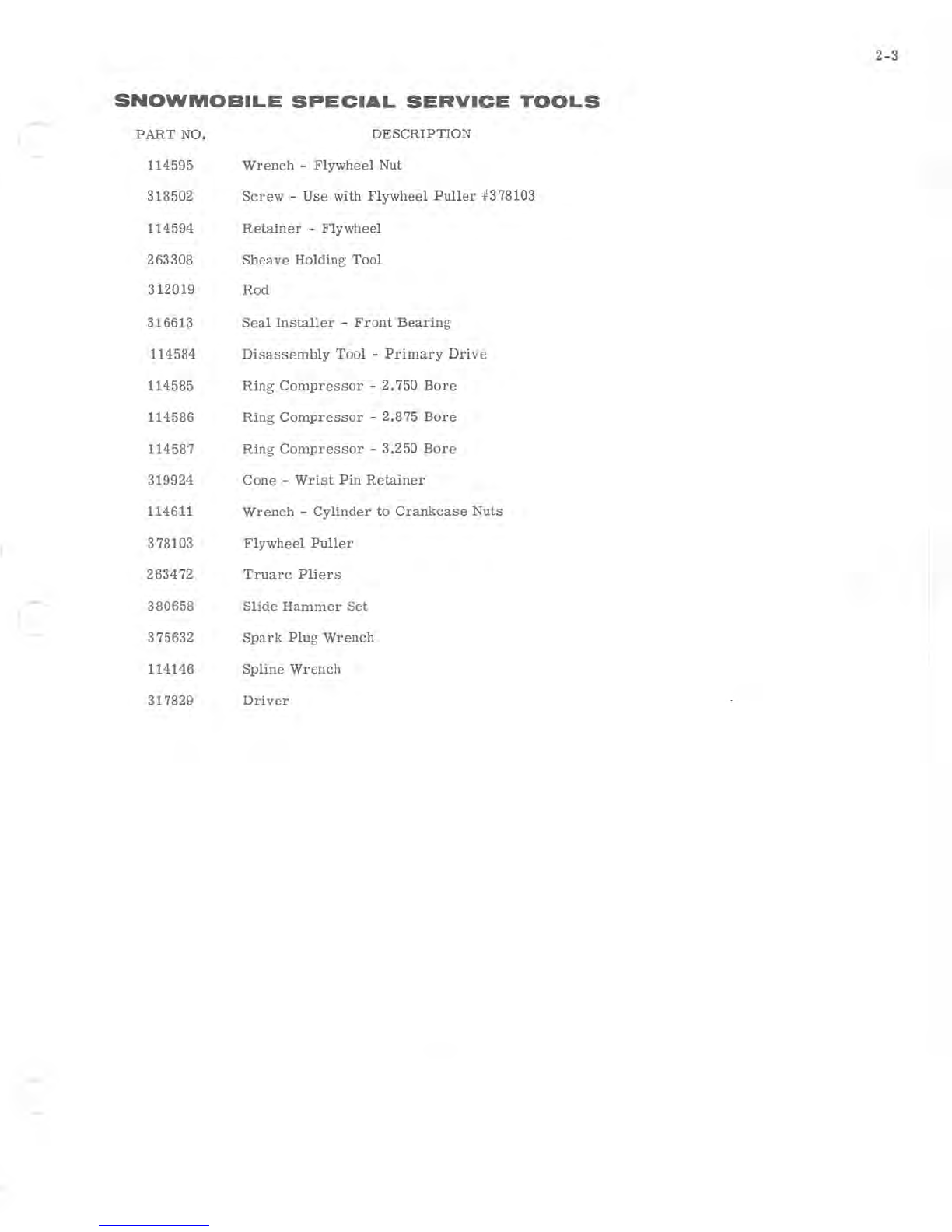

SNOWMOBILE

SPECIAL

SERVICE

TOOLS

-

PART

NO. DESCRIPTION

114595

Wrench

-

Flywheel

Nut

318502

Screw

-

Use

with

Flywheel

Puller

#378103

114594

Retainer

-

Flywheel

263308

Sheave

Holding

Tool

312019

Rod

316613

Seal

Installer

-

Front

Bearing

114584

Disassembly

Tool

-

Primary

Drive

114585

Ring

Compressor

-2.750

Bore

114586

Ring

Compressor

-2.875

Bore

114587

Ring

Compressor

-

3.250

Bore

319924

Cone

-

Wrist

Pin

Retainer

114611

Wrench

-

Cylinder

to

Crankcase

Nuts

378103

Flywheel

Puller

263472

Truarc

Pliers

380658

Slide

Hammer

Set

375632

Spark

Plug

Wrench

114146

Spline

Wrench

317829

Driver

)

-

3-1

SECTION

3

GENERAL

SNOWMOBILE

INFORMATION

TWO-STROKE

CYCLE

ENGINE

THEORY

As

the

piston

leaves

bottom

dead

center

(BDC),

it

creates

a

depres-

sion

in

the

crankcase

causing

air

to

flow

in

thru

the

carburetor.

Fuel

is

added

to

this

air

in

the

proper

proportion

for

combustion

and

the

air-

fuel

mixture

(charge)

then

passes

thru

the

reed

spring

inlet

valve

to

the

crankcase

.

The

next

time

the

piston

moves

toward

BDC

it

compresses

the

charge

in

the

crankcase

and

as

the

top edge of

the

piston

uncovers

the

transfer

port

the

pressurized

charge

is

forced

into

the

cylinder

on

the

combustion

chamber

side

of

the

piston.

The

piston

then

reverses

direction

and

in

moving

toward

TDC

it

closes

the

transfer

port

and

the

exhaust

port

respectively.

The

secondary

compression

of

the

charge

takes

place

at

this

time.

As

the

piston

nears

the

top

of

the

stroke

this

charge

is

ignited

by

means

of

an

electric

spark.

The

pressure

formed

by

the

burning

gases

forces

the

piston

back

toward

BDC. When

the

top

edge

of

the

piston

uncovers

the

exhaust

port,

the

burned

gases

begin

to

leave

the

cylinder.

A

little

more

travel

of

the

piston

opens

the

trans-

fer

port

and

the

incoming

charge

forces

the

remaining

burned

gases

out

while

the

piston

moves

past

BDC.

As

it

moves

back

toward

TDC

closing

the

transfer

port

and

subsequently

the

exhaust

port

it

begins

the

secondary

compression

mentioned

earlier.

This

cycle

repeats

itself

once

each

engine

revolution

which

consists

of

two

strokes

of

the

piston,

one

from

BDC

to

TDC

and

one

from

TDC

to

BDC.

Consequently

the

engine

utilizing

this

basic

principle

is

called

a

two-stroke

cycle

engine.

It

can

be

seen

then

that

the

two-stroke

cycle

engine

achieves

basically

the

same

operation

as

the

more

commonly

understood

four-stroke

cycle

engine.

The

intake,

compression,

power

and

exhaust

strokes

of

the

four-stroke

cycle

engine

become

the

induction,

primary

compression,

transfer,

secondary

compression,

power

and

exhaust

all

taking

place

during

two

strokes

of

the

piston.

CARBURETION

GaSOline,

in

its

liquid

state,

burns

relatively

Slowly

with

an

even

flame.

However,

when gaSOline

is

combined

with

air

to

form

a

vapor,

the

mixture

becomes

highly

inflammable

and

burns

with

an

explosive

effect.

To

obtain

best

results,

the

fuel

and

air

must

be

correctly

pro-

portioned

and

thoroughly

mixed.

It

is

the

function of

the

carburetor

to

accomplish

this.

Gasoline

vapor

will

burn

when

mixed

with

air

in

a

proportion

from

12:1

to

18:1 by

weight.

Mixtures

of

different

proportions

are

required

for

different

purposes.

Idling

requires

a

relatively

rich

mixture;

a

leaner

mixture

is

desirable

for

maximum

economy

under

normal

load

conditions;

avoid

lean

mixtures

for

high

speed

operation.

The

carbure-

tor

is

designed

to

deliver

the

correct

proportion

of

fuel

and

air

to

the

engine

for

these

various

conditions.

The

carburetor

is

essentially

a

simple

metering

device.

A

diaphragm

and

valve

system

allows

a

constant

fuel

supply

to

be

maintained

in

the

INDUCED

LOW

VENTURI

PRESSURE

L

-~~

______

~·~*~n

---+

I=======~==~===

FUEL FORCED UPWARDS

BY ATMOSPHERIC PRESSURE

Figure

3-1

1713

6

3-2

/'

/'

'ij'

)

REED PLATE AND BASE ASSEM.

170

88

Figure

3-2

metering

chamber

at

just

slightly

below

atmospheric

pressure.

Needle

valves

permit

a

precise

amount

of

fuel

to flow

from

the

metering

chamber

to

the

carburetor

throat.

The

upstroke

of

the

piston

creates

a

suction

which

draws

air

through

the

leaf

valves

and the

carburetor

throat

. At a

particular

point

the

throat

is

restricted

by a

venturi

(see

Figure

3-1). The

venturi

has

the

effect

of

reducing

air

pressure

in

the

air

stream,

creating

a

partial

vacuum

which

draws

fuel

from

the

dis

-

charge

port.

As

it

is

rushed

along to

the

firing

chamber,

the

fuel

is

swirled

about

in

the

air

stream

and

vaporized.

A

throttle

or

butterfly

valve

in

the

throat

regulates

the

amount

of

air

drawn

through

the

carburetor.

To

vary

the

speed

of

the

engine,

the

throttle

opens

or

closes,

regulating

the

amount

of

fuel-air

mixture

drawn

into

the

engine.

A

richer

fuel

mixture

is

required

for

starting

a

cold

engine.

A

sec-

ond

shutter,

called

a choke,

is

placed

into

the

throat

forward

of

the

jets,

to

restrict

the

flow

of

air.

When

the

choke

shutter

is

closed,

more

gas-

oline

and

less

air

is

allowed

into

the

air

stream

resulting

in

a

richer

fuel-

air

mixture.

When

normal

operating

temperature

is

reached,

the

choke

is

opened

and

the

standard

ratio

of

gasoline

and

air

allowed

to

flow

from

the

carburetor.

The

system

which

controls

the

intake

of

the

fuel-air

mixture

in

the

two

cycle

engine

consists

of a

set

of

valves

which

serve

the

same

pur-

pose

as

the

intake

valves

on a

four

cycle

engine.

The

reed

valves

are

thin,

flexible

metal

strips

mounted

between

the

carburetor

intake

mani-

fold and

crankcase.

When

the

piston

is

on

the

up-stroke,

it

creates

a

partial

vacuum

in

the

crankcase.

Atmospheric

pressure

forces

the

reeds

away

from

the

body

(see

Figure

3-2),

opening

the

passage

between

the

carburetor

and

crankcase.

When

the

piston

is

on

the

down-stroke,

it

compresses

the

crankcase

charge,

forcing

the

reeds

against

the

passage

opening, and

sealing

off

the

crankcase

from

the

carburetor.

8ince

the

opening

and

closing

may

occur

in

excess

of

seven

thousand

times

per

minute,

the

reeds

must

be

thin

and

flexible.

IGNITION

Two

charge

COils,

are

mounted on

the

alternator

stator,

located

under

the

flywheel.

The

same

flywheel

magnets

which

induce

current

in

the

alternator

stator

also

generate

about 300

volts

A.C.

in

the

charge

coils

as

the

flywheel

rotates.

No

external

voltage

source

is

required.

The

300

volts

A.C.

is

converted

to D.C.

in

the

Power

Pack

28,

and

is

stored

in

the

Power

Pack

28

capacitor.

One gap

between

the

sensor

magnets,

part

of

the

flywheel hub,

passes

the

sensor

coil,

also

under

the

flywheel.

h

lw,lm

UNOTE

One thing

to

note

in

this

system

is

that

there

are

two

sensor

coils.

Below

the

idle

RPM

range

and

up to

apprOximately

900

RPM,

the

retard

sensor

turns

on

the

electronic

switch

in

the

Power

Pack

28. At

RPMs

over

900

the

advance

sensor

coil

generates

enough

voltage

to

turn

on

the

electronic

switch

in

the

Power

Pack

28

before

the

retard

sensor

does.

80, we

have

an

automatic

electronic

advance

built

into

the

system.

The

small

voltage

generated

in

the

sensor

coil

activates

one

of

two

electronic

switches

in

the

POWER PACK 28.

This

switch

discharges

the

300

volts

stored

in

the

capacitor

into

one of

the

ignition

coils.

The

ignition

coil

steps

the

voltage

up

to

30,000

volts,

which

is

fed

to

the

spark

plug. When

the

capaCitor

is

discharged,

the

electronic

switch

opens

and

allows

the

charge

coils

to

again

charge

the

capacitor.

The

second

sensor

magnet

gap,

opposite

in

polarity

from

the

first,

generates

a

reverse

polarity

voltage

in

the

sensor

coil.

This

activates

the

second

electronic

switch

in

the

POWER PACK 28, and

discharges

the

capacitor

into

the

other

ignition

coil.

I

-

LIGHTING

SYSTEM

The

alternator

coils

produce

alternating

current

which

changes

in

frequency

at

approximately

constant

voltage

in

proportion

to

the

engine

speed.

The

alternator

A.C.

output

is

used

to

operate

lamps.

POWER

FLOW

The

transmission

assembly

transmits

power

from

the

engine

to

the

front

axle

which

propels

the

vehicle

along

the

track.

The

primary

sheave

assembly

is

attached

directly

to

the

crankshaft.

The

secondary

sheave

assembly

has

its

own

mounting

pedestal

and

is

larger

in

diam-

eter

than

the

primary

sheave

assembly.

The

two

are

connected

by

a

transmission

belt.

PRIMARY DRIVE

The

primary

sheave

is

centrifugally

operated

and

engages

the

trans

-

mission

belt

when

the

engine

speed

reaches

3000 -3600

RPM.

When

the

engine

is

rotating

at

idle

speed

or

below

3000 -3600

RPM,

the

transmission

belt

rides

on a

ball

bearing

between

the

halves

of

the

primary

sheave

assembly

(see

Figure

3-3) .

The

primary

sheave

as-

sembly

halves

are

separated

by a

compression

spring

in

the

hub

of

the

movable

sheave

half.

E

B G

0

N

M

L

TRANSMISSION

LOCKED

IN

NEUTRAL

Figure

3-3

As

the

engine

speed

increases,

centrifugal

effect

forces

a

garter

spring

in

the

end

cap

outward

against

the

contour

of

the

end

cap

and

axially

against

the

movable

sheave

half.

As

the

sheaves

are

brought

together,

the

transmission

belt

is

forced

outward

to

ride

on a

larger

diameter

of

the

primary

sheave

assembly,

increasing

belt

speed

(see

Figure

3-4).

Since

the

belt

length

remains

constant,

the

secondary

sheave

halves

spread

apart,

allowing

the

belt

to

ride

on a

smaller

diam

-

eter.

In

this

way,

the

engine

transmits

power

through

a

variable

ratio,

presenting

the

engine

with a

mechanical

advantage

most

favorable

for

the

speed

at

which

it

is

operating.

3-3

A.

Flywheel

Nut

B.

Emergency

Starting

Sheave

C.

Garter

(Activating)

Spring

D.

End

Cap

E.

Movable

Half

of

Sheave

F.

Transmission

Belt

G.

Fixed

Sheave

/

Flywheel

H.

Ball

Bearin

g

I.

Spring

Cup

J.

Compression

Spring

K.

Neutral

Lockout

Balls

L.

Splined

Shaft

(crankshaft)

M.

Bolt,

End

Cap

to

Splined

Shaft

N.

Spring

o.

Neutral

Lockout

Rod

P.

Spacer

37

1

38

3-4

TRANSMISSION HIGH

SPEED

POSITION -

BELT

ENGAGED

Figure

3-4

NEUTRAL

CONTROL

A neutral control mechanism

is

used

to

prevent the drive from engag-

ing

during

starting,

warm-up

period,

and

idle.

When

the

neutral

lockout

plunger

is

actuated,

a

cone

on

the

end

of

the

plunger

raises

two

balls

through

the

splines

of

the

primary

sheave

assembly

and

into

the

path

of

the

movable

sheave

half,

preventing

it

from

engaging

the

belt.

The

neutral

control

is

spring

actuated

and

will

engage

only

when

the

engine

is

below

approximately

2000

RPM.

371

39

NEUTRAL

CONTROL NOT

FUNCTIONING BECAUSE

RPM

TOO HIGH

Figure

3-5

37140

When

the

engine

is

running

above

approximately

2000

RPM

the

garter

spring

will

expand

by

centrifugal

effect.

See

Figure

3-5.

The

garter

spring

will

then

ride

up

the

ramp

of

the

end

cap

and

push

the

movable

sheave

toward

the

fixed

sheave.

In

dOing

this,

the

movable

sheave

has

covered

the

holes

in

the

splined

shaft

and

the

neutral

lockout

balls

can

not

be

pushed

into

the

locked

position.

If

the

engine

speed

is

now

reduced

to

below

2000

RPM,

the

garter

spring

will

close

and

allow

the

movable

half

of

the

sheave

to

move

away

from

the

fixed

sheave.

SECONDARY DRIVE

The

secondary

drive

mechanism

incorporates

a

torque

sensing

device

that

detects

the

need

for

more

power

for

steep

inclines

or

deep

snow.

The

mechanism

immediately

forces

the

secondary

sheaves

closer

to-

gether

to

lower

the

transmission

ratio

and

provide

a

higher

torque

to

the

drive

chain

and

track.

The

drive

ratio

varies

from

3

to

1

in

low

to

1

to

.68

in

high

which

yields

an

overall

drive

range

of

approximately

4.4

to

1.

Power

is

trans

-

mitted

from

the

secondary

sheave

assembly

through

a

drive

chain

to

the

front

axle.

The

ratio

between

the

secondary

sheave

assembly

and

the

front

axle

is

17:39

or

19:39.

)

4-1

SECTION

4

TROUBLE

SHOOTING

DESCRIPTION

This

section

provides

trouble

shooting

procedures

for

the

snow

ma-

chine.

Steps

to

be

followed

in

determining

causes

of

unsatisfactory

per-

formance

are

outlined.

Being

able

to

locate

the

cause

of

trouble

in

an

improperly

operating

snow

machine

is

as

important

as

being

able

to

correct

the

trouble.

A

systematic

approach

to

trouble

shooting

is

important

if

the

trouble

is

to

be

located

and

identified

in

minimum

time.

Any

service

operation

oan

be

broken

down

into

three

steps:

1.

Identifying

the

problem

2.

Determining

the

cause

of

the

problem,

and

3.

Correcting

the

problem.

Familiarity

with

the

factors

which

affect

two-cycle

engine

perform-

ance

is

important

in

making

a

correct

service

diagnosis.

Factors

which

affect

engine

performance

include

the

quality

of

the

fuel

and

fuel

mixtures,

compression,

ignition,

and

proper

drive

system

adjustment.

Engine

theory,

compression,

carburetion,

ignition

and

power

flow

are

discussed

in

Section

3.

Correct

fuel

mixture

for

this

snowmobile

is

outlined

on

page

iv,

and

fuel

blending

is

discussed

in

Section

12.

Familiarity

with

factors

which

contribute

to

abnormal

performance

of

an

engine

are

similiarly

helpful.

The

skilled

mechanic's

experience

is

a

great

asset

here.

4-2

TROUBLE

SHOOTING

PROCEDURES

Trouble

shooting

to

determine

the

cause

of

any

operating

problem

may

be

broken

down

into

the

fol-

lowing

steps:

a.

Obtaining

an

accurate

description

of

the

trouble.

b.

Preliminary

inspection.

c.

Use

of

Trouble

Check