EVOLUTION MEASUREMENT EvoScann CANDI ELE-CANDI-CANDI01 Specification sheet

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 1

Evolution Measurement Ltd

Product User Guide

EvoScann® CANDI

CANbus to USB Converter

(P# ELE-CANDI-CANDI01)

Revision History:

Issue: 1 Revision: 0

First issued –August 2020

Issue: 1 Revision: 1

Updated Logging Information / GUI Info

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 2

Content:

Section: Page:

1 Introduction………………………………………………………….……………………..3

1.1 Scope & Definitions

1.2 Description

2Technical Data……………………………………………………………..………..4

2.1 Specification

2.2 Dimensions

3Installation & Use…………………………………………………….……………..6

3.1 Unpack and Inspect

3.2 Drivers and GUI Installation

3.3 Electrical Connection

4Operation……………………..………………………………………………….…..8

5 Maintenance……………………………………………..…………………………..8

5.1 General Information

5.2 Safety Information

5.3 Fault finding

5.4 Repair and Recalibration

6 Storage and Disposal…………………..……………………………………..……9

6.1 Storage

6.2 Disposal

7 GUI - Graphical User Interface Use………………………………………………10

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 3

1. Introduction

1.1 Scope & Definitions

This manual provides installation, operation and maintenance instructions for the EvoScann® CANDI

CANbus to USB Converter

1.2 Description

EvoScann® CANDI is designed for use with our range of P-Series Pressure Scanners and allows for

integration of a single scanner with a personal computer running our Graphical User Interface (GUI).

The CANDI is powered over a USB port on your personal computer and operation is enabled by

installation of the required drivers and software provided on the USB Drive.

The CANDI and GUI allow for set-up and configuration of an individual EvoScann® P-Series Pressure

Scanner, where access to a CANbus enabled system is not possible, and provides for simple scanning

and logging, or to allow troubleshooting and fault identification.

Electrical connection can be made to the EvoScann® P-Series Pressure Scanner either via the green

4-way terminal block or fixed ASX Circular Connector. Note, only one scanner should be attached at a

time, using only one connection method.

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 4

2. EvoScann® CANDI CANbus to USB Converter Technical data

2.1 Specification

Standard Supply: Peli 1040 Micro Case

EvoScann® CANDI Converter

1 m USB Lead

ASX Mating Connector

USB Drive with Files

P-Series Inputs: CANDI - ASX Connector –ASX002-05SB-HE-R (Socket)

P-Series –ASX Connector –ASX602-05PB-HE-R (Plug)

CANDI –Screw Terminal –MKDS ¼-3,5

USB Connection: CANDI –Micro USB Type B Female, USB 2.0

PC –USB A Female

(Supplied Lead Male USB A to Male USB Micro B –1 m)

Power Requirement: USB 5 V ± 5%

Note: CANDI has an internal 12V DC Voltage Converter

Construction materials: Aluminium / Plastic / Stainless Steel

Operating Temperature: +10°C to +60°C

Communication: CANbus over USB

Operating System: Windows®10, 8.1 (32/64-bit)

Driver Requirement: PEAK-System Installation Package (Supplied)

National Instruments™ Runtime Engine (Supplied)

Software: Evolution Measurement Node Tool (P-Series Specific)

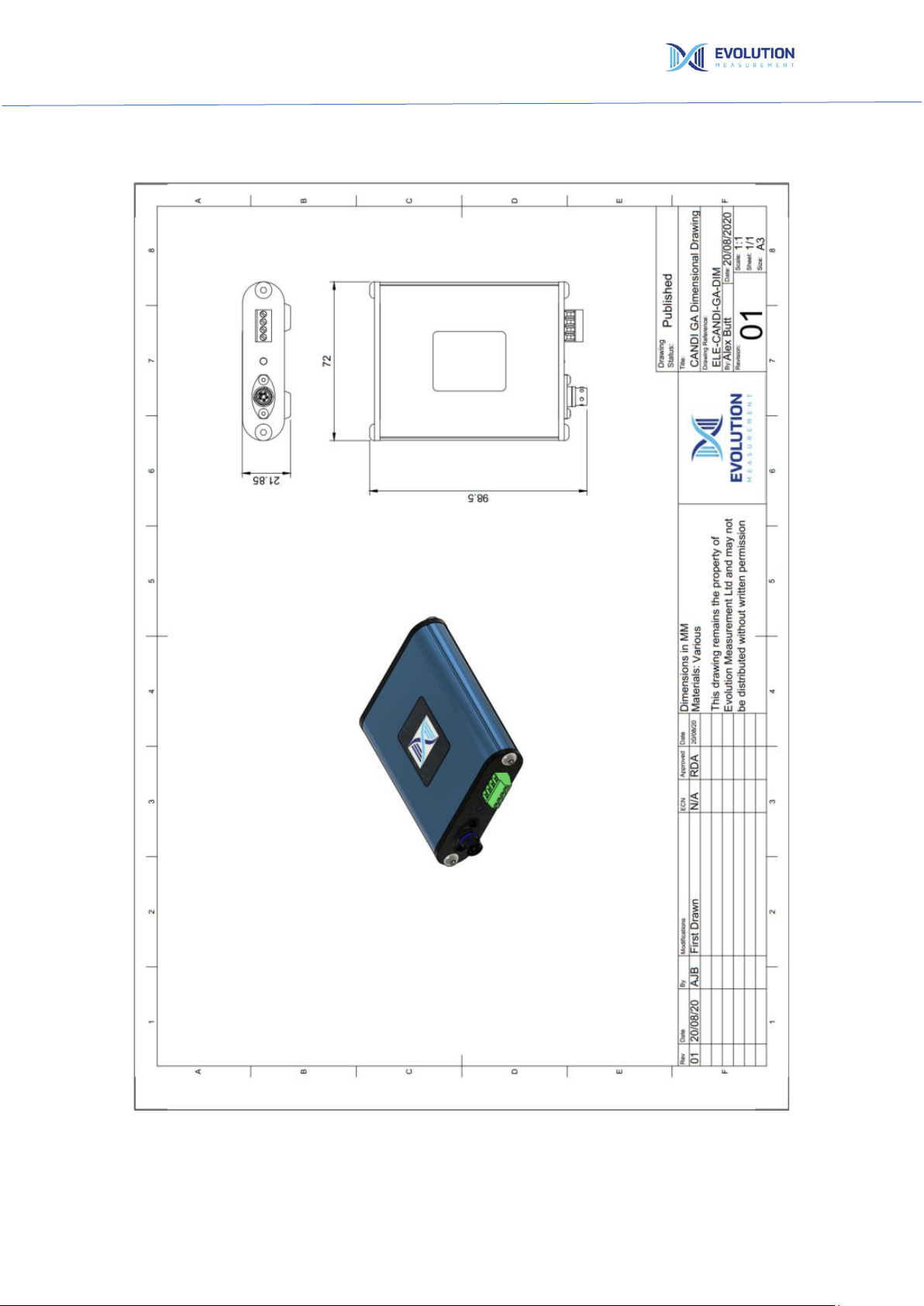

Dimensions:

Outer case: 85 x 75 x 20 mm

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 5

2.2 Product Outline Dimensions EvoScann® CANDI CANbus to USB Converter

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 6

3. Installation & Use

EvoScann® CANDI is ideal for use as a desktop tool, or as part of a remote measurement package.

Consideration of mounting position and use will ensure optimal performance and instrument longevity.

The EvoScann® CANDI is designed to be robust but should be handled and installed with all reasonable

and usual precautions necessary for a measurement instrument.

3.1 Unpack and Inspect

Remove all packaging materials from the unit and check for any damage.

If the unit has been damaged, notify the supplier and carrier in writing within three days of delivery,

stating the item number, serial number and order number.

Retain all package materials for further inspection. Do not use the unit if it has been damaged.

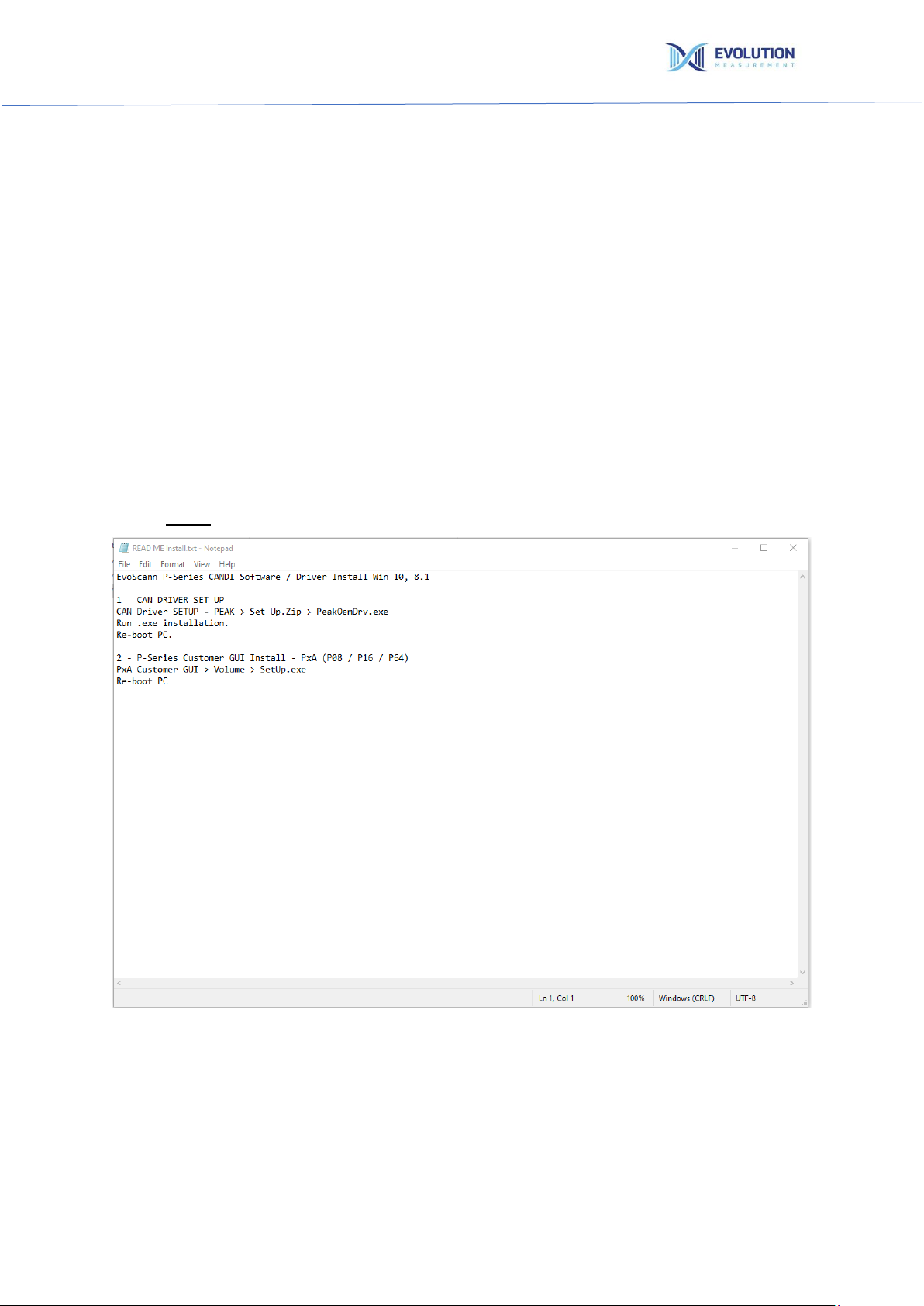

3.2 Drivers and GUI Installation

Refer to the supplied USB Drive for files and Readme.txt regarding installation of the Drivers and GUI

version before any connection to the EvoScann® P-Series Pressure Scanner is attempted.

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 7

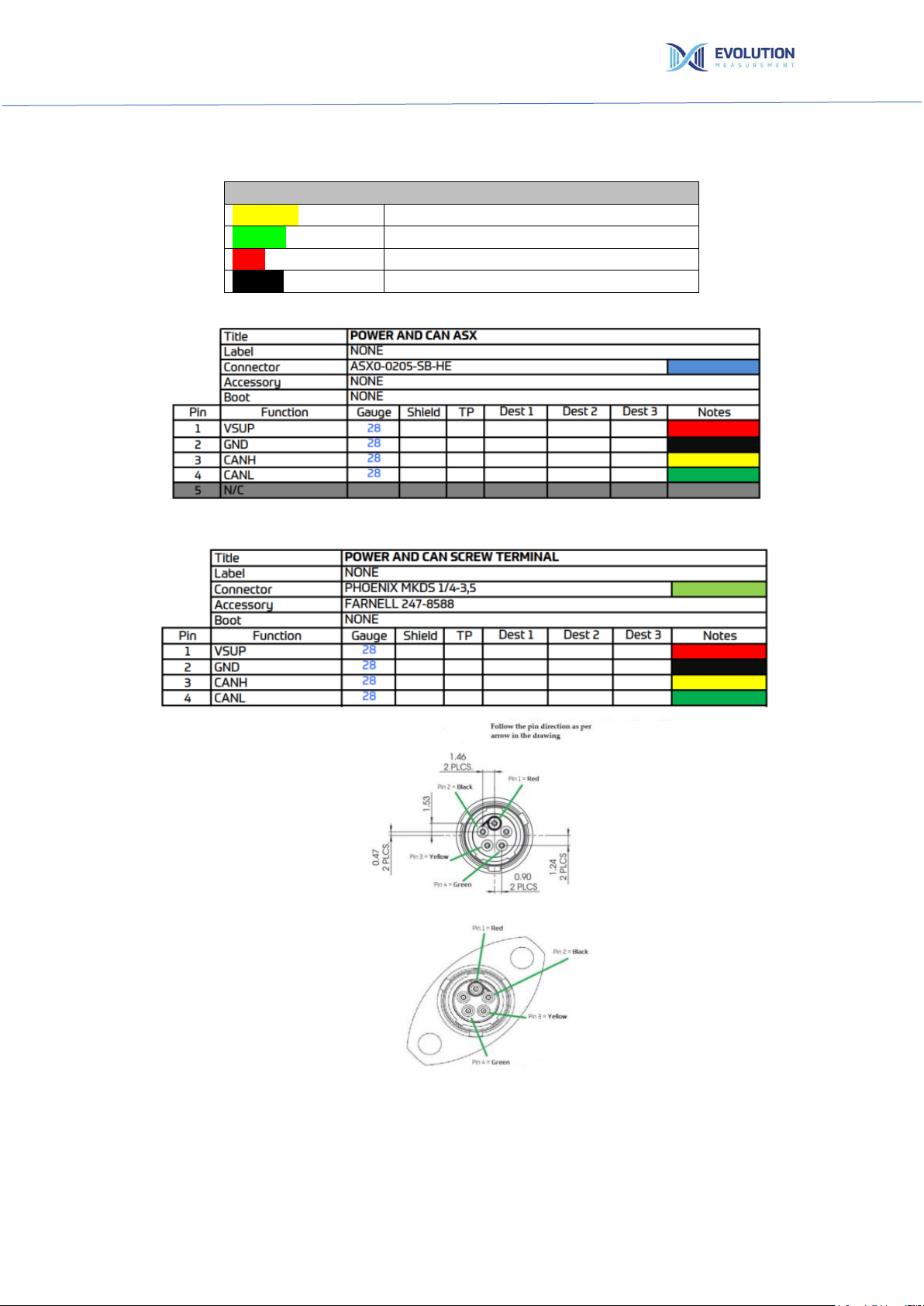

3.3 Electrical Connection

Electrical Cable Identification

Cable Identification

YELLOW

CANH

GREEN

CANL

RED

SUPPLY (VSUP)

BLACK

GND

(Note: Check direction indication marked on the one fitted to your CANDI)

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 8

4. Operation

Operation of the EvoScann® CANDI is simple and straightforward. With the GUI running and the P-Series

electrically connected the scanner will immediately start to scan.

Below is a screenshot of a typical display from the EvoScann® GUI, with EvoScann®

(P-Series P8-A for information). Refer to Section 7 for use.

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 9

5. Maintenance

5.1 General Information

EvoScann® CANDI is designed to require no user intervention other than checking electrical

connections are sound for the connected equipment

5.2 Safety Information

Observe all appropriate safety precautions when operating any electrical equipment. Always ensure

wiring is done by competent persons in strict accordance with the electrical connection details in this

document.

Do not use abrasive or solvent substances to clean the unit.

Do not attempt to open the EvoScann® CANDI. The unit is factory sealed and opening the unit will result

in removal of any and all warranty.

5.3 Fault finding

Symptom:

Check likely cause:

Scanner not functioning

Ensure Drivers are fully installed and operational.

Ensure correct wiring connections are made.

Ensure USB is connected to a functional Port

Scanner reading incorrect pressures

Check correct range is selected

Scanner reading intermittently

Check correct version of GUI is being used for P-

Series connected

5.4 Repair & Recalibration

Field repair is not possible with EvoScann® CANDI. All repairs must be carried out by Evolution

Measurement Ltd.

To ensure optimum service and performance, return to Evolution Measurement Ltd.

See contact us page.

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 10

6. Storage and Disposal

6.1 Storage

EvoScann® CANDI should be placed in its supplied case when not in use and store in a clean, dry, dust

and moisture-free area, avoiding temperature extremes. Avoid the risk of droppage, vibration or other

unnecessary impact.

6.2 Disposal

At end of life, dispose of EvoScann® CANDI in full accordance with all local procedures and practices, or

return the unit to Evolution Measurement Ltd for disposal. Do not incinerate as the product may emit

noxious fumes.

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 11

7. GUI –Graphical User Interface Use

Sensors Tab

Main Screen - Shows display of channels selected from channel list available 1…..>.

Sensor No. –Serial Number

Firmware –P-Series Firmware Revision

Period –Set Period of P-Series

CAN ID –Set CAN ID of P-Series (Hex)

CAN ID SR –Set CAN ID of the Slow Row data when in 7-Byte mode. [Auto] sets CAN ID +1 (Hex)

Temperature display - shows sensor temperature for internal compensations.

Length –8 Byte / 7 Byte (8 Byte Default)

Range –Selected Range

Pressures –Shows live channel pressures in selected pressure range mode

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 12

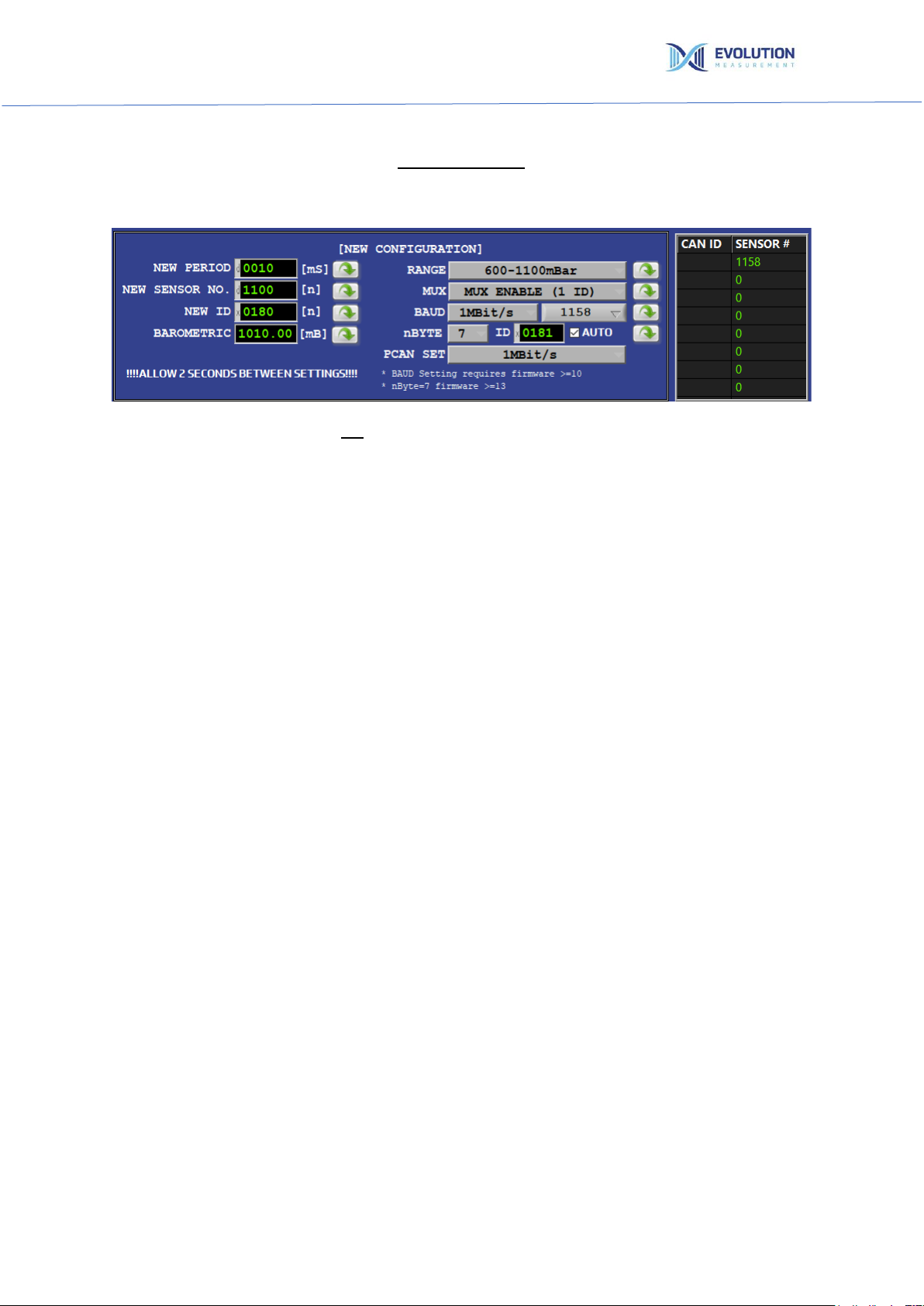

New Configuration

Changing data and pressing the green download button saves the entry into the connected P-Series.

Care should be taken as there is no ‘restore to factory’ function.

Note: Screen shows generic data not ‘As Set’ data

New Period –Limits 0002 (2 m/s) to 00100 (100 m/s)

New Sensor No. - Changes Serial Number (Not Recommended)

New ID –Changes Can ID

Barometric –Allows user to enter barometric pressure read from a transfer standard, or similar, to

enable correction of output (Absolute Units Only).

Range –Allows user to change from selectable ranges depending on GUI version.

Mux –Allows the user to change from Multiplexer Enabled (1 ID) or Multiplexer Off (3 ID). Refer to your

EvoScann® P-Series Manual for further details

BAUD –Allows rate to be set –Sensor ID Number (>=Ver 10 Firmware Required)

nBYTE –8 Byte / 7 Byte (8 Byte Default)

ID –User configurable (Hexadecimal)

PCAN –Period Setting Options

EvoScann® CANDI

©Evolution Measurement Ltd 2021. All rights reserved Doc.No: M-90223 Iss.1 Rev 1

Page | 13

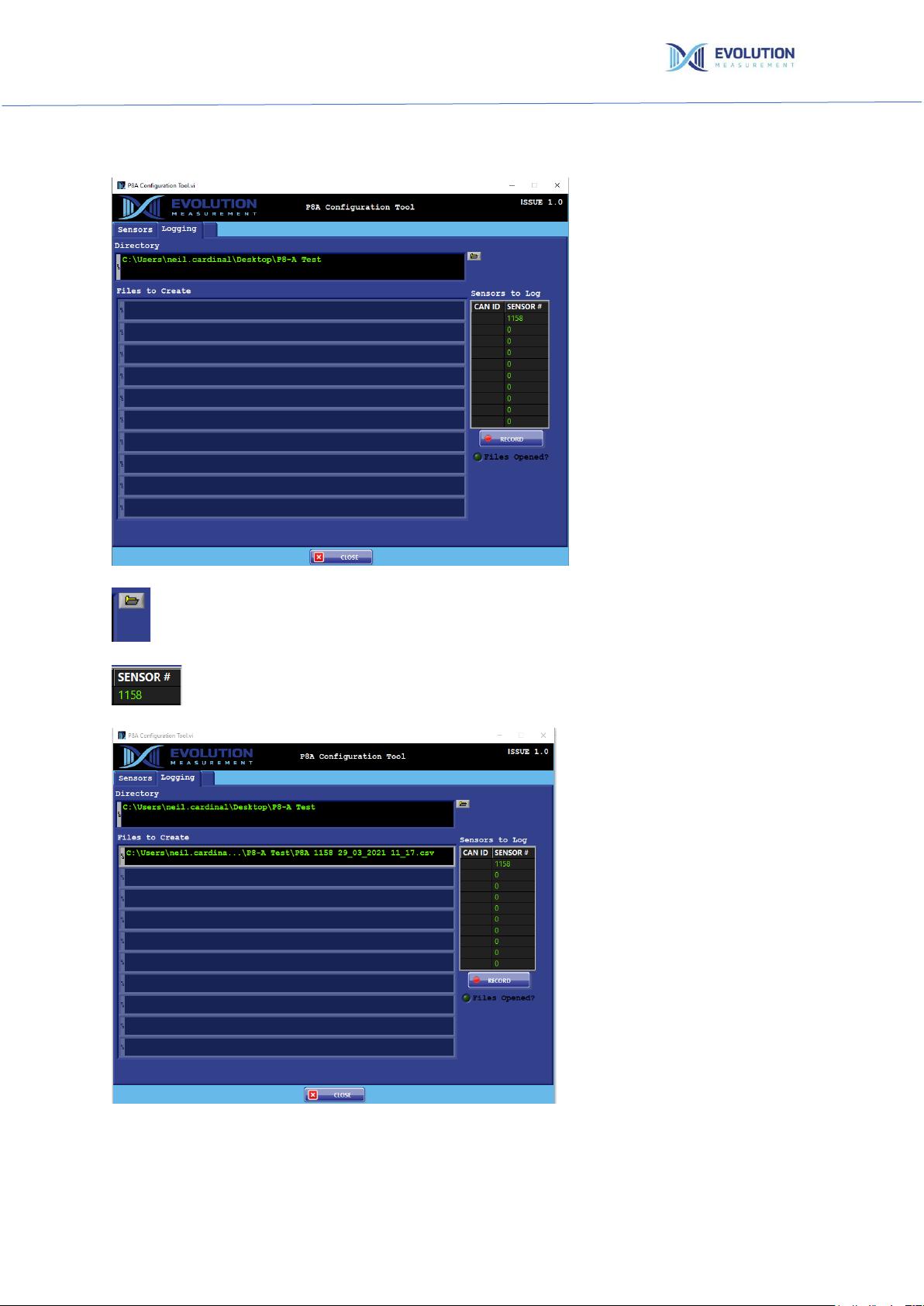

Logging Tab

Press the file icon, the route path can now be set for the log file.

Click Sensor Number to create individual log file…

Record –Starts the current log file / Logging - Stops the current log file.

Table of contents