Evolve 70 Manual

70mm, 100mm and 140mm

Chromatography Columns

DELTA PRECISION LTD

Chromatography Column

Operating Manual and Installation Guide

70mm, 100mm and 140mm Columns

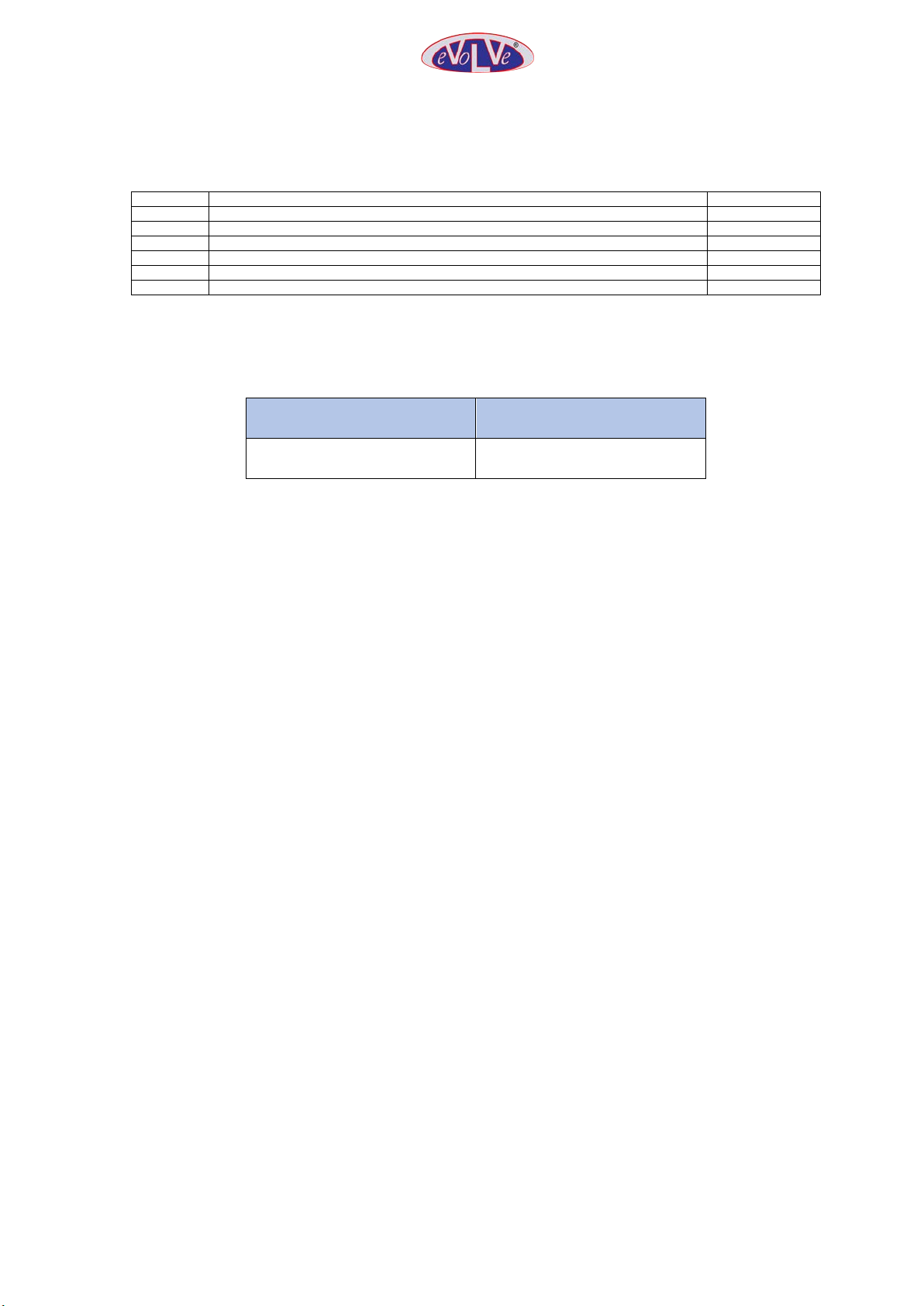

Revision History

Revision

Comments

Date

A

Initial release

21/11/2014

B

Photos updated

25/02/2015

C

Address Updated

21/06/2018

D

Pressure Equipment Directive updated

06/04/2021

E

Technical specification updated caster not available on 70-140mm columns

22/04/2021

F

Updated to reflect Evolve® Trademark status

12/07/2021

Evolve® is a registered trademark of Delta Precision Ltd. Evolve® is a registered trademark in the

EU, UK and US.

Manual Revision

Date

F

July 2021

Table of Contents

Column Hardware .......................................................................................................... 1

Mechanical Description ........................................................................................................................... 1

Technical Data. ...................................................................................................................................... 3

Weights and Dimensions ........................................................................................................................ 3

Pressure Drop ........................................................................................................................................ 4

Material Conformity ............................................................................................................................... 6

Chemical Compatibility .......................................................................................................................... 7

Safety Guidelines ............................................................................................................ 9

Pressure Equipment Directive (PED). ................................................................................................... 9

Over-pressurization ................................................................................................................................. 9

Handling ................................................................................................................................................ 9

Chemical compatibility .......................................................................................................................... 10

Installation and Column Set-up ................................................................................... 11

Installation. .......................................................................................................................................... 11

Column Operation ........................................................................................................ 15

Hydrostatic Leak Test ......................................................................................................................... 15

Media Preparation ............................................................................................................................... 16

Column Packing (Constant Flowrate Method) ...................................................................................... 16

Unpacking ........................................................................................................................................... 18

Cleaning and Storage ............................................................................................................................ 18

Maintenance ................................................................................................................. 20

Routine Maintenance Procedures-General guidelines .............................................................................. 20

Disassembly of 70mm, 100mm and 140mm Columns ......................................................................... 21

Reassembly of 70mm, 100mm and 140 column. ................................................................................... 24

Troubleshooting ........................................................................................................... 27

Leakage from adjuster seal .................................................................................................................... 27

Leakage from fixed bed support seal ..................................................................................................... 27

Leakage from inlet or outlet .................................................................................................................. 27

Excessive column back pressure ............................................................................................................ 28

Media Leakage .................................................................................................................................... 28

Kits, Spare parts and Accessories ................................................................................. 29

Spare parts and kits ............................................................................................................................. 31

Spare Parts and kits Cont. ................................................................................................................... 32

Accessories ............................................................................................................................................ 34

Contact Us .................................................................................................................... 35

Appendix 1 Chromatography Performance .................................................................. 36

Performance Measurement and Column Efficiency ................................................................................. 36

Performance Results From Evolve®Columns ........................................................................................ 38

Table of Figures

Figure 1.1 Evolve®Column Range 70mm, 100mm, 140mm, 200mm and 250mm columns .................... 2

Figure 1.2. Pressure Drop Evolve®70mm column ..................................................................................... 4

Figure 1.3 Pressure Drop Evolve®100mm column ................................................................................... 4

Figure 1.4 Pressure Drop Evolve®140mm column ................................................................................... 5

Figure 3.1 Diagram showing the location of the fixed bed support ............................................................. 11

Figure 3.2 Photograph showing the installation of the fixed bed support .................................................... 12

Figure 3.3 Diagram showing the location of the adjuster bed support ........................................................ 13

Figure 3.4 Photograph showing the location of the adjuster bed support ..................................................... 13

Figure 4.1 Schematic of the column with part identification ....................................................................... 17

Figure 5.1 Adjuster Assembly Evolve® 100 column .............................................................................. 22

Figure 5.2 Fixed Assembly Evolve® 100 column ................................................................................... 23

Figure 5.3 Diagram showing the location of the fixed bed support ............................................................. 24

Figure 5.4 Photograph showing the installation of the fixed bed support .................................................... 24

Figure 5.4 Photograph showing the location of the adjuster bed support ..................................................... 25

Figure 5.5 Diagram showing the location of the adjuster bed support ........................................................ 25

Figure 5.6 Photograph showing the final location of the adjuster bed support ............................................. 26

Figure 5.7 Photograph showing the alignment of marking on flowtube and adaptor to ensure component is

correctly tightened ....................................................................................................................... 26

Figure A1 Description of Column Efficiency Calculations ........................................................................ 37

Figure A2 Example of typical chromatogram. Evolve®250mm column. 2% Acetone sample, flowrate

100cm/hr, bed height 19.5cm. ................................................................................................... 38

This manual suits for next models

9

Table of contents

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual