Evoqua IONPURE IP-LXM04 Manual

IONPURE®

LX CEDI

Modules

Operation

&

Maintenance

Manual

IP-MAN-LX-1220-EN

Rev 3

December 2020

This manual covers

model numbers:

·IP-LXM - - EU-4

·IP-LXM - - HI-3

·IP-LXM - - X-4

·IP-LXM - - Z-5

Evoqua Water Technologies, LLC

558 Clark Road

Tewksbury, Massachusetts 01876, USA

ionpure@evoqua.com (email)

www.ionpure.com (web)

Visit web site to find local Ionpure contact

IONPURE ®LX CEDI Modules

Page 2 IP-MAN-LX-1220-EN.pdf

TABLE OF CONTENTS

DISCLAIMER STATEMENT 5

PROPRIETARY RIGHTS STATEMENT 5

MANUAL USER'S GUIDE 5

OPERATING MANUAL REVISION HISTORY 6

1. INTRODUCTION 7

1.1. LX Product Family Overview 7

1.2. Using This Manual 8

1.3. Installation Precautions 8

1.4. Operating Precautions 9

1.5. Shutdown Precautions 9

2. PRE-INSTALLATION: PREPARATION & REQUIREMENTS 10

2.1. Tools Required 10

2.2. Unpacking and Moving LX Modules 10

2.3. Electrical and Plumbing Connection Requirements 11

2.4. Operating Requirements 11

2.4.1. Operating Environment 12

2.4.2. Space Requirements 12

2.4.3. Module Orientation 12

2.4.4. DC Electrical Requirements 12

2.4.5. Feed Water Requirements 12

2.4.6. Drain Requirements 13

2.5. Flow Rates and Pressure Drops 13

3. LX MODULE INSTALLATION 14

3.1. Preparation 14

IONPURE ®LX CEDI Modules

Page 3 IP-MAN-LX-1220-EN.pdf

3.2. Checking Tie Bar Torque 15

3.2.1. Tightening End Plate Tie-bar Nuts 15

3.3. Water Connection Configuration and Fittings 16

3.3.1. LX Piping Adapter Sealing Mechanism – EU, X, Z Modules (BSP Male) 16

3.3.2. LX Piping Adapter Sealing Mechanism – HI Modules (BSP Female) 17

3.4. Electrical Connections 18

3.4.1. Electrical Precautions 18

3.5. RO/CEDI System Design Considerations 19

4. PREPARATION FOR STARTUP 20

4.1. Verify Feed Water Meets LX Quality Requirements 20

4.2. Estimate DC Current Required 20

5. START-UP PROCEDURE 21

5.1. Test Interlocks 21

5.2. Startup of LX Modules 21

5.3. Minimum Reject Flow Rate 21

5.4. Water Recovery 21

5.4.1. Example calculation of recovery 22

5.4.2. Example calculation of reject flow 22

6. MAINTENANCE AND TROUBLESHOOTING 23

6.1. General Maintenance Guidelines 23

6.1.1 Operating Data Log Sheet 23

6.1.2 Periodic Maintenance 23

6.2. Approved Cleaning Procedures 23

6.3. Cleaning and Sanitization Prompts 24

IONPURE ®LX CEDI Modules

Page 4 IP-MAN-LX-1220-EN.pdf

6.4. Clean-In-Place (CIP) System Construction 24

6.5. Chemical Cleaning and Sanitization Precautions 26

6.6. Typical Procedure for Cleaning or Sanitization 26

6.6.1 Preparation 26

6.6.2 Cleaning 26

6.6.3 Return to service 27

6.7. Cleaning Solution Recipes 28

6.8. Recommended Grades for Cleaning Chemicals 30

6.9. Hot Water Sanitization (HWS) 31

6.8.1 HWS Phase 1 – Hot Water Introduction 31

6.8.2 HWS Phase 2 – Temperature Hold 31

6.8.3 HWS Phase 3 – Return to service 32

7. TROUBLESHOOTING 33

8. SHUTDOWN AND STORAGE 40

8.1. System Shutdown 40

8.2. Startup After Shutdown 40

8.3. Rebuild or Repair 40

8.4. Disposal 40

APPENDIX A: LX MODULE SPECIFICATIONS 41

APPENDIX B1: LX LAYOUT & ELEVATION DRAWING (EU, X, Z) 43

APPENDIX B2: LX LAYOUT & ELEVATION DRAWING (HI) 44

APPENDIX B3: LX JUNCTION BOX DRAWING (ALL MODELS & SIZES) 45

APPENDIX C: LX ADAPTER LIST 46

APPENDIX D: LX MATERIALS OF CONSTRUCTION & APPROVALS 47

IONPURE ®LX CEDI Modules

Page 5 IP-MAN-LX-1220-EN.pdf

DISCLAIMER STATEMENT

The operation and maintenance manual should provide complete and accurate

information to meet your operating and/or service requirements based on the information

available at the time of publication. The information in this manual may not cover all

operating details or variations or provide for all conditions in connection with installation,

operation and maintenance. Should questions arise which are not answered specifically

in this manual, contact your water system supplier.

IONPURE reserves the right to make engineering refinements that may not be reflected

in these manuals. The material in these manuals is for informational purposes and is

subject to change without notice.

PROPRIETARY RIGHTS STATEMENT

This manual discloses information in which IONPURE has proprietary rights. Neither

receipt nor possession of this manual confers or transfers any right to the client, and by

its retention hereof, the client acknowledges that it will not reproduce or cause to be

reproduced, in whole or in part, any such information except by written permission from

IONPURE. The client shall have the right to use and disclose to its employees the

information contained herein for the purpose of operating and maintaining the IONPURE

equipment, and for no other purpose.

In the event the content of this manual is altered or section/items are omitted during a

reproduction, in whole or in part, and instructions or definitions within the reproduction

result in personal injury to those who follow the altered instructions, the burden of

responsibility for personal injury falls solely on the party who effects the reproduction.

MANUAL USER'S GUIDE

This manual describes the procedures necessary to install, operate, and maintain your

IONPURE Continuous Electrodeionization modules. Please read this manual carefully

before installing and operating your modules. The module warranty may be voided if

installation or operation instructions are not followed correctly.

Notes, Warnings, Cautions are used to attract attention to essential or critical information

in a manual. Warnings and Cautions will appear before the text associated with them,

and notes can appear either before or after the associated text.

NOTE: Notes are used to add information, state exceptions, and point out areas

that may be of greater interest or importance.

IONPURE ®LX CEDI Modules

Page 6 IP-MAN-LX-1220-EN.pdf

Cautions indicate a situation that may cause damage or

destruction of equipment or may pose a long-term health hazard.

Warnings indicate condition, practices, or procedures which

must be observed to avoid personal injury or fatalities.

IONPURE continually strives to provide safe, efficient, trouble-free equipment using the

optimum technology for your application. If problems should develop, IONPURE's

worldwide network of technical support will be available to provide assistance. For

service, sales, parts, or additional manual copies, please visit the website:

www.ionpure.com.

OPERATING MANUAL REVISION HISTORY

Event Date Description

First publication 05-2018 LX Family Operation & Maintenance Manual.

Rev 1 09-2018 Corrections on Table 6-1 (LX-4).

Added cleaning chemical grade suggestions (6.8).

Rev 2 10-2019 2.3 Added metric wire sizes.

3.4 Added terminal strip torque specification and

corrected junction box connection hole size.

Rev 3 12-2020 Updated LX-Z to reflect change from -4 to -5.

Removed obsolete parts from LX adapter list.

Updated L&E drawing in Appendix B1.

IONPURE ®LX CEDI Modules

Page 7 IP-MAN-LX-1220-EN.pdf

1. INTRODUCTION

1.1.LX Product Family Overview

Ionpure LX modules are medium flow rate CEDI devices. Their compact state-of-the-art

design assures ease of installation, maintenance, and service. LX modules are available

in the following sizes:

Size Nominal Flow Description

IP-LXM04 2.0 gpm (0.45 m3/h) 4-cell

IP-LXM10 5.0 gpm (1.14 m3/h) 10-cell

IP-LXM18 9.0 gpm (2.05 m3/h) 18-cell

IP-LXM24 12.5 gpm (2.84 m3/h) 24-cell

IP-LXM30 15.0 gpm (3.4 m3/h) 30-cell

IP-LXM45 22.5 gpm (5.1 m3/h) 45-cell

For more information on the LX module specifications and flow rates, see Section 2.4 and

Appendix A of this Manual.

There are four different types of LX modules (see Appendix D), each of which is available

in the six sizes listed above:

EU-4 For European Pharmacopeia (EP) applications

HI-3 For U.S. Pharmacopeia (USP) applications, hot water sanitizable (HWS)

X-4 For USP, NSF (drinking water) and general use (worldwide) applications

Z-5 For General Industry, with improved Cl2tolerance

Figure 1-1: LX Module (Cathode/Plumbing Side Shown)

HI type (BSP Female) EU / X / Z type (BSP Male)

IONPURE ®LX CEDI Modules

Page 8 IP-MAN-LX-1220-EN.pdf

1.2.Using This Manual

Service technicians should review this manual prior to going to the installation site. It lists

tools and materials needed to install the modules. It also outlines the site information

required to prepare for installation.

NOTE: The warranty may be void if installation or operation instructions contained in this

manual are not followed exactly.

This manual describes the installation, operation, and routine maintenance of the LX

modules. It also contains information on basic troubleshooting (See Section 7).

IONPURE strongly recommends all users read the entire contents of the manual. If the

LX module is not operating properly after going through the basic troubleshooting

exercises, contact your Local Service Provider.

1.3.Installation Precautions

·During operation, the electrode wiring inside the module junction

boxes are at high voltage and present a shock hazard.

THEREFORE, BEFORE TOUCHING THE INSIDE OF THE

JUNCTION BOX, CONFIRM THAT AC POWER TO THE DC

POWER SUPPLY HAS FIRST BEEN DISCONNECTED AND

LOCKED OUT ACCORDING TO STANDARD LOCKOUT/

TAGOUT PROCEDURES.

·To minimize the possibility of electric shock, confirm that all ground

wires are properly connected.

·Do not open the LX module. Opening the module will void the

warranty and cause irreversible damage.

·The module must be operated according to the design

specifications for temperature and humidity.

·Metal piping should never be connected directly to the module.

Non-metallic piping adapters are required at the module inlets and

outlets. It is then allowable to transition to metallic piping.

·Pipe sections prepared for installation must be inspected, and be

free of debris from storage or cutting tool particles. This must be

done before installation.

·Because LX modules have narrow flow distribution channels,

plugging by particles can cause permanent damage. Always

install pressure gauges, sampling ports, sensors, etc. in tee

fittings. Do not drill or tap into piping.

IONPURE ®LX CEDI Modules

Page 9 IP-MAN-LX-1220-EN.pdf

·Always flush out the piping to remove any debris before operating

the LX module.

·Installation of the LX module must be completed in accordance

with the procedures outlined in this manual. If deviations from the

prescribed procedures are deemed necessary to achieve the

desired performance, consult your local Service Provider.

1.4.Operating Precautions

·DO NOT APPLY POWER TO THE LX MODULE UNTIL PROPER

FLOW AND PRESSURE HAVE FIRST BEEN CHECKED AND

VERIFIED.

·Never block off (dead-head) the LX outlets. Dead-heading the

outlets can result in over-pressurization, leading to permanent

damage.

·Do not operate the module under conditions other than those

stated in the module manual. The prescribed feed water

requirements, electrical requirements, and flow configurations,

must be followed at all times. If the feed water quality or the

product water requirements change, contact the IONPURE

Technical Support Department for assistance.

·Once every six months:

oMake sure all wiring connections are tight.

oTest safety interlocks such as flow switches or connections to upstream

equipment.

oCheck torque on tie bar nuts and tighten as required.

1.5.Shutdown Precautions

·Confirm that the pressure in the unit is relieved until all pressures inside the unit are

atmospheric (i.e., all pressure gauges should read zero).

·Drain standing water and valve off or plug all inlets and outlets. This is to minimize

bacteria growth and prevent drying of ion exchange resins during shutdown.

IONPURE ®LX CEDI Modules

Page 10 IP-MAN-LX-1220-EN.pdf

2. PRE-INSTALLATION: PREPARATION & REQUIREMENTS

2.1.Tools Required

·Dolly or forklift to move the module into place

·Cords, cables or straps to secure module to dolly or forklift

·Slip joint pliers, for tightening of plumbing connectors

·Wire cutters/strippers, for wiring connections inside junction box

·Screwdrivers (flat blade and Phillips head) to connect wires at terminal strip

·Adjustable torque wrench with 10-50 ft-lb (14-68 N-m) range, 3/8” (10 mm) drive

·19 mm extra deep socket (Ionpure part number W2T210908)

·19 mm open end wrench

2.2.Unpacking and Moving LX Modules

·After uncrating the module, inspect it for any signs of damage. If damage is apparent,

immediately notify the carrier and your CEDI System Provider.

·The LX modules can weigh 70-330 lbs. (32-150 kg) dry, depending on size, and may

require mechanical assistance for lifting and moving into position. Both LX endplates

have two ¾-10 tapped holes for installation of lifting eyebolts, if desired.

·Ensure that lifting apparatus has appropriate load rating.

Figure 1-2: LX Module Lifting Points (Cathode/Plumbing Side Shown)

¾”-10

tapped hole

¾”-10

tapped hole Eyebolt or handle

(not provided)

IONPURE ®LX CEDI Modules

Page 11 IP-MAN-LX-1220-EN.pdf

2.3.Electrical and Plumbing Connection Requirements

·Two electrical junction boxes are included with all LX modules, one on each of the LX

endplates. A single conduit connection is required through a 1/2” NPT hole on the

bottom of either junction box to provide power to the CEDI module.

·Connection of the DC power supply to the LX module should be made with 12 or 10

AWG (4.0 or 6.0 mm2) wire. All wiring should be done in accordance with local

electrical codes.

·Terminal strip screws should be tightened to 7.0 in-lbf(0.8 N-m).

·Ionpure LX modules have four (4) connection points, identified in Table 2-1, below.

The hot water sanitizable (HI) modules have female connections while the non-hot

water sanitizable (EU, X, Z) modules have male connections. This is done to prevent

accidental installation of a non-HWS module into an HWS system.

·The LX modules require special plumbing adapters, which are not included with the

modules. A list of various adapters is given in Appendix C. Adapter drawings are

available upon request.

·To avoid the risk of electrical shock, some form of grounding must be used on any

stream where the plumbing is stainless steel or if there are samples points or

instrumentation near the module.

oFor sanitary applications, a grounding cap can be used, Ionpure part number

W3T83436, which is actually a ¾” TC cap with a welded stud to be wired to

ground.

oFor non-sanitary applications, a ¼” SS threaded grounding rod can be used,

Ionpure part number W2T211647.

Table 2-1. LX Module Plumbing Connections

Connection EU, X, Z modules HI modules

Dilute in 1-1/4” BSP Male 1-1/4” BSP Female

Dilute out (product) 1-1/4” BSP Male 1-1/4” BSP Female

Concentrate in 3/4” BSP Male 3/4” BSP Female

Concentrate out (reject) 3/4” BSP Male 3/4” BSP Female

2.4.Operating Requirements

In order to operate to specification, the LX module must have the following conditions

present. If any of these conditions are unmet, do not attempt to install the LX module

without specific instructions from your Local Service Provider’s Technical Support.

IONPURE ®LX CEDI Modules

Page 12 IP-MAN-LX-1220-EN.pdf

2.4.1. Operating Environment

The LX module requires indoor installation out of direct sunlight. The maximum ambient

temperature should not exceed 113 °F (45° C). The module can tolerate humidity of up

to 90%, as long as condensation does not occur.

2.4.2. Space Requirements

The physical dimensions of the LX modules are given in appendix A.1. In addition to the

size of the module itself, the arrangement of the piping and the electrical connections will

determine the amount of space the module needs to operate. This arrangement varies

from site to site. Space should be allowed for module servicing/replacement.

2.4.3. Module Orientation

The LX modules must be installed vertically and fastened to the system frame by the L-

shaped feet on the bottom of the module.

2.4.4. DC Electrical Requirements

The LX module DC power requirements are listed in Table 2-2. In all cases the cathode

must be at ground potential. Connections are shown in section 3.4 and Appendix B3.

Table 2-2. DC Power Requirements for the LX Modules

LX Model ►EU, X, Z HI

LX Size ▼Max DC Volts DC Amps Max DC Volts DC Amps

IP-LXM04 27 1-6 50 1-10

IP-LXM10 67 1-6 125 1-10

IP-LXM18 120 1-6 225 1-10

IP-LXM24 160 1-6 300 1-10

IP-LXM30 200 1-6 375 1-10

IP-LXM45 300 1-6 565 1-10

NOTE: The DC3 power supply (maximum 600 VDC) can beused with all LXmodels. The

DCR power supply can also be used but requires correct sizing of isolation transformer.

2.4.5. Feed Water Requirements

Feed water for the LX module must always meet the specifications outlined in Table 2-3.

In most cases, pre-treating LX module feed water with reverse osmosis (RO) will bring it

IONPURE ®LX CEDI Modules

Page 13 IP-MAN-LX-1220-EN.pdf

within these specifications. Depending on the conditions, however, some sites may

require additional pretreatment. To determine if additional pretreatment is required,

compare the LX feed water on site with the feed water requirements listed below.

NOTE: Recycling the LX reject to the RO feed will cause the CO2load on the LX to

increase, and may have an impact on the LX product water quality. Please refer to

Ionpure.com for additional reject stream system design guidance including the following

paper: “Process and System Design for Reliable Operation of RO/CEDI Systems”,

Jonathan Wood and Joe Gifford, International Water Conference, 2004 (Paper 47).

Table 2-3. CEDI Feed Water (RO Permeate) Requirements - Also See Appendix A.2

Parameter EU, X ZHI

FCE* (µS/cm) ≤40 µS/cm ≤40 µS/cm ≤40 µS/cm

Total hardness (as

CaCO3)≤1.0 ppm ≤1.0 ppm ≤1.0 ppm

Total chlorine (as Cl2)≤0.02 ppm ≤0.05 ppm ≤0.02 ppm

Silica (ppm as SiO2)≤1.0 ppm ≤1.0 ppm ≤1.0 ppm

Iron, manganese, sulfide ≤0.01 ppm ≤0.01 ppm ≤0.01 ppm

TOC (ppm as C) ≤0.5 ppm ≤0.5 ppm ≤0.5 ppm

Operating pH range 4 – 11 4 – 11 4 – 11

Feed water temperature 41 - 113 °F

(5 – 45 °C) 41 - 113 °F

(5 – 45 °C) 41 - 140 °F

(5 – 60 °C)

Inlet pressure ≤100 psig

(6.9 bar)

≤100 psig

(6.9 bar)

≤100 psig

(6.9 bar)

*FCE stands for feed (water) conductivity equivalent)

FCE = measured µS/cm + (ppm CO2)(2.79) + (ppm SiO2)(2.04)

2.4.6. Drain Requirements

Place the LX module near a drain that can accommodate 100% of the total feed flow.

2.5.Flow Rates and Pressure Drops

See Appendix A, Table A.2.

IONPURE ®LX CEDI Modules

Page 14 IP-MAN-LX-1220-EN.pdf

3. LX MODULE INSTALLATION

3.1.Preparation

Confirm that the pre-installation requirements outlined in Section 2 are met and the

system is ready for LX Module installation.

·Remove any packaging materials and move the module to its

operating location. Use safe lifting practices when moving the module

(see Section 2.2).

·To avoid corrosion, the piping adapters must be non-metallic.

·LX modules are shipped without connection adapters and with dust plugs installed.

·Plumbing adapters available from Ionpure are listed in Appendix C. Some adapter

drawings are available from Ionpure if you choose to make your own adapters.

·Remove all four red dust plugs that seal the inlet and outlet ports on

each LX module (Figure 3-1 below shows the bottom dust plugs for

both type LX endblocks). Failure to remove red dust plugs can cause

permanent damage to the modules.

Figure 3-1a LX HI modules (BSPF) with red shipping plugs

Figure 3-1b LX-EU, LX-X, LX-Z modules (BSPM) with red shipping plugs

Remove these red

dust plugs (LX-HI)

Remove these red dust

plugs (LX-EU, LX-X, LX-Z)

IONPURE ®LX CEDI Modules

Page 15 IP-MAN-LX-1220-EN.pdf

3.2.Checking Tie Bar Torque

The nuts on the threaded tie bars can loosen during shipment, and if

not retightened the pressure from the incoming water can cause

permanent damage. Therefore, the tie bar nut torque must be

checked and the module tightened as required after any

transport and before flowing water into the module. Refer to Figure 3-1 and re-torque

as required. Not all modules will require retightening but all should be checked.

Always drain water from the LX module before tightening the endplate tie bar nuts. This

relieves pressure in the module. Failure to do so can result in irreversible damage.

Do not open the LX Module. Opening the module will void the warranty and do irreversible

damage.

3.2.1. Tightening End Plate Tie-bar Nuts

Figure 3-2 shows the sequence in which to re-

torque the tie bars. Start the torqueing process

with #1, and finish with #14. Use the following

procedure:

·Use a 19 mm open ended wrench to hold the

acorn nuts on the plumbing (cathode) end of

the module.

·Set the torque wrench to 15 ft-lbs (20 N-m).

Using a 19 mm extra deep socket (such as

IONPURE part number W2T210908 ▼) on the

torque wrench, turn all 14 tie-bar

brass hex nuts (anode end) to 15

ft-lbs (20 N-m) following the

sequence in Figure 3-2.

·Reset the torque wrench to 25 ft-lbs (34 N-m)

and repeat the sequence as required until all tie

bars are at 25 ft-lbs (34 N-m). Use caution to

avoid over tightening. Do not exceed 25 ft-lbs

(34 N-m) of torque without consulting Ionpure

Technical Support. Figure 3-2

LX Tightening Sequence

IONPURE ®LX CEDI Modules

Page 16 IP-MAN-LX-1220-EN.pdf

3.3.Water Connection Configuration and Fittings

Make sure all upstream pretreatment equipment and piping have been

thoroughly flushed with particle-free water before connecting them to

the LX Module. Flushing removes any particles left in the piping from

cutting and assembly. If particles remain, they could plug the passages inside the LX

Module.

NOTE: Failure to properly flush the pretreatment water system of installation

debris to drain prior to flowing water to the CEDI can result in particulate fouling

that may be irreversible.

Ionpure LX modules have a cast aluminum endplate with through-holes to allow access

to the endblock piping connectionsdescribed in Table 2-1. There are four (4) connection

points:

·Product (Dilute) Inlet – top left

·Product (Dilute) Outlet – bottom right

·Reject (Concentrate) Inlet – top right

·Reject (Concentrate) Outlet – bottom left

The above connection descriptions are for co-current, downflow (top-to-bottom)

operation, whichhasbeen thepreferredmode of LXmoduleoperation for nearly20 years.

LXHI-3 and LXZ-5 modules must be operated downflow for optimum performance.

LXEU-4 and LXX-4 modules can also be operated upflow, which may be convenient due

to piping constraints in certain situations. Please check with your local Ionpure Technical

Support if you are considering upflow operation.

Detailed dimensions of the LX module port locations are given in the layout and elevation

drawings in Appendix B, Drawings B1 (EU, X, Z) and B2 (HI).

3.3.1. LX Piping Adapter Sealing Mechanism – EU, X, Z Modules (BSP Male)

The endblocks used in LX models EU, X and Z are made of thermoplastic elastomer,

(TPE) which is molded through (4) hard plastic fittings with Male BSP parallel threads.

The TPE covers the face of the threaded fittings, making a flat surface for sealing of the

external piping adapters. The end block threads are NOT TAPERED pipe threads and

the threads DO NOT CREATE the seal, they allow the sealing surfaces to move towards

each other and they hold the piping adapters in place. The seal comes from the TPE

through-port gasket that isolates the endplate and creates a sealing surface directly to

the internal LX spacer. See Figure 3-3, below.

IONPURE ®LX CEDI Modules

Page 17 IP-MAN-LX-1220-EN.pdf

Figure 3-3 LX Piping Adapter Sealing Mechanism: Non-HWS Modules

3.3.2. LX Piping Adapter Sealing Mechanism – HI Modules (BSP Female)

The female threads in the LX HI module endblock are BSP parallel threads. They are

NOT TAPERED pipe threads and the threads DO NOT CREATE the seal, they allow the

sealing surfaces to move towards each other and they hold the piping adapter in place.

The seal comes from a separate flat silicone gasket inserted in the endblock. See Figure

3-4, below.

Figure 3-4 LX Piping Adapter Sealing Mechanism: HWS Modules

NOTE: Do NOT use Teflon®tape or any other pipe sealant (such as pipe dope) on the

BSP thread adapters, whether male or female. The use of these products on the BSP

threads will prevent proper sealing of the adapters.

IONPURE ®LX CEDI Modules

Page 18 IP-MAN-LX-1220-EN.pdf

3.4.Electrical Connections

All LX modules have two electrical junction boxes (one on each endplate) to allow

convenient connection of the module to the DC power supply that provides the driving

force for the electrodeionization process. Only one electrical connection is required per

module, and either junction box can be used. Power connections to the terminal strip

inside the module junction box (see Figure 3-5 and Appendix B3) should be made with

12 or 10 AWG (4.0 or 6.0 mm2) wire and conduit or cord connections should be supplied

via the 1/2” NPT hole on the bottom of the junction box.

The DC wire color conventions used on the LX modules are as follows:

·Red/White (+) to DC positive terminal of power controller

·Black/White (–) to DC negative terminal of power controller

·Green/Yellow to earth ground

Terminal strip screws should be tightened to 7.0 in-lbf(0.8 N-m). Wire stripping length is

7.0 mm (0.276”).

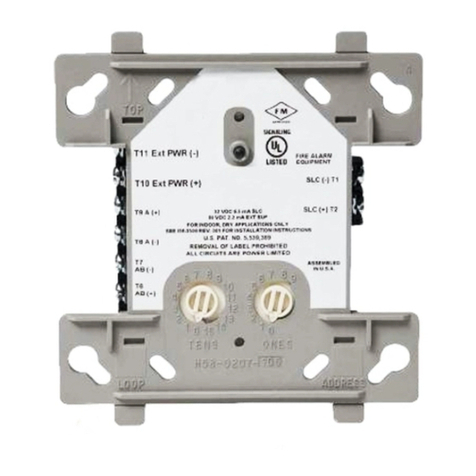

Figure 3-5 Inside the LX Junction Box

3.4.1. Electrical Precautions

·Disconnect power before opening any enclosure and follow

accepted Lockout/Tagout procedures when working on the

system.

·Do not run AC and DC wiring within the same conduit. This may

cause interference and lead to malfunctions.

IONPURE ®LX CEDI Modules

Page 19 IP-MAN-LX-1220-EN.pdf

·Ensure that polarity of DC connections is correct before applying

DC power. Operation with polarity reversed will permanently

damage the cathode. It is critical that the red and black wires are

correctly oriented on the positive (+) and negative (-) terminal

blocks.

·The ground in the junction box must be connected to earth ground.

·All wiring done in the field must conform to local electrical codes. Consult your Local

Service Provider if there is a conflict between the instructions in this manual and the

local codes.

·Power connections for the modules must be connected to a suitable DC power supply

capable of meeting the DC power requirements of the module (see Table 2-2).

3.5.RO/CEDI System Design Considerations

·Direct feed of an RO system to the CEDI system requires use of a pressure relief valve

or rupture disk between the RO and CEDI to prevent accidental overpressure of the

CEDI.

·If the CEDI system is fed from a tank instead of directly from an RO system, there are

two requirements:

oThe CEDI feed pump must be sized so that its dead-head pressure does not

exceed the 100 psig (6.9 bar) pressure limit of the CEDI modules.

oThere must be prefiltration directly upstream of the CEDI system (5 micron

suggested) as experience has shown tanks and repumping to be a common

source of particulate contamination.

·The CEDI DC power supply must be interlocked with the RO feed pump or the CEDI

feed pump (whichever is appropriate) to ensure that the power supply can’t be

energized if the pump is not running.

·In addition, the EDI system must have low flow protection for both the product and

reject.

·Piping to the CEDI modules should be designed to minimize mechanical stress on the

CEDI piping connectors.

·Start/stop systems should have provisions to automatically divert

RO permeate to drain upon startup from standby condition. This

is necessary because the initial RO permeate is usually worse

quality than the RO feed water! It is better to flush for a set time (3-5 minutes) rather

than to a conductivity endpoint.

·Systems that reclaim CEDI reject and send it back to the RO inlet should have

provisions for venting the electrode gases.

·Automatic valves downstream of the CEDI should be designed to close slowly (>3

seconds) and must avoid momentary dead-heading of the CEDI module.

IONPURE ®LX CEDI Modules

Page 20 IP-MAN-LX-1220-EN.pdf

4. PREPARATION FOR STARTUP

4.1.Verify Feed Water Meets LX Quality Requirements

Check the LX feed water quality by running the RO system to drain and testing to make

sure the feed water quality meets all the feed water requirements given in Table 2-3.

Below are some of the test kits or devices that may be useful:

Table 4-1 Useful Equipment for Feed Water Testing

Analyte Model Minimum Increment

Conductivity Myron L Ultrameter II 4P 0.1 µS/cm

CO2Hach CA-23 (#143601) 1.25 mg/l

Cl2Hach CN-70 (#1454200) 0.02 mg/l

Hardness Hach HA-71A (#145201) 1.0 mg/l

Silica Hach SI-7 (#2255000) 0.05 ppm

4.2.Estimate DC Current Required

An important part of the startup process for the LX module is setting the operating current

correctly for each application.

The amount of DC current required depends on the following site-specific conditions:

·Flow rate per module

·CEDI feed water conductivity equivalent (FCE)

·Measured feed water conductivity (may require a portable conductivity meter)

·Feed water carbon dioxide concentration (requires test kit such as above)

·Feed water silica concentration (usually low enough to be neglected)

·Product water quality required

The best way to determine the amount of DC current required is to use the Ionpure

projection tool, IP-PRO: https://ippro.evoqua.com/

Alternatively, it can be estimated using the equation below (based on Faraday’s Law).

NOTE: Contact local Ionpure Technical support for assistance.

DC amps = (1.31)(product flow, L/min/cell)(FCE, µS/cm)/current efficiency, %

Where FCE = measured µS/cm + (ppm CO2)(2.79) + (ppm SiO2)(2.04)

This manual suits for next models

5

Table of contents

Other Evoqua Control Unit manuals

Popular Control Unit manuals by other brands

Georg Fischer Piping Systems

Georg Fischer Piping Systems CONTAIN-IT Plus instruction manual

Nakanishi

Nakanishi E800Z Operation manual

Emerson

Emerson Fisher ED instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 14 instruction manual

BIFFI

BIFFI ICON3000 Series Installation, operation and maintenance manual

Honeywell

Honeywell Notifier FCM-1 Installation and maintenance instructions